Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fire Hydrant Specs

Caricato da

MajuraDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fire Hydrant Specs

Caricato da

MajuraCopyright:

Formati disponibili

Section D – Contents 1

Fire Hydrants

D 1.1 Fire Hydrant – Breakaway 6/02

D 1.2 Repair Kit – Fire Hydrant Traffic 9/01

D 1.3 Extension Kit – Fire Hydrant – 6” & 12” 9/01

D 1.4 Extension Kit – Fire Hydrant – 12” 9/01

Exhibit HH Fire Hydrants 9/01

Material Specifications D 1.1

Fire Hydrant – Breakaway

AKA

General:

Fire hydrants shall conform to ANSI/AWWA

C502-94 and the latest revisions thereto.

Traffic section, lower barrel, and shoe interior

must be epoxy coated.

Design:

Breakaway, dry barrel type, with drain holes

plugged. Operating nut and hose nozzle cap

nuts must be 1 ½” pentagon shape.

Connections:

Inlet: Mechanical joint

Outlets: (2) 2 ½” hose nozzles and (1) 4 ½”

pumper nozzle.

Special Features:

Traffic coupling must be made of Bronze,

Cast Iron, or Stainless Steel. No substitutes.

Hydrant stems, stem threads, and bearings shall

be protected by an oil or grease self-lubricating

system. Accessory kits have been removed

from specification as of March 5, 2001.

See Exhibit HH (Annual Bid)

Size/Details OUC Item ID Manufacturer Catalog Number

6” x 30” 095-01230 American Flow Control B-84-B

6” x 36” 095-01236 Clow Valve Medallion

6” x 42” 095-01242 Kennedy Valve K-81D

6” x 48” 095-01248 M&H Valve #929

6” x 54” 095-01254 Mueller A-423

6” x 60” 095-01260 U.S. Pipe & Fdry. Metropolitan M-94

American AVK Series 2780

Revision Date: 6/20/02 (RNK) Material Specifications

Water Business Unit

9/05/01 (RNK) ORLANDO UTILITIES

3/05/01 (RNK) COMMISSION

8/31/98 (DSW)

Material Specifications D 1.2

Repair Kit – Fire Hydrant Traffic

AKA Safety Flange Repair Kit, Collision Repair Kit

General:

All components of the traffic repair kit shall be

designed for and properly fit the specific make

and model fire hydrant for which they are

intended. Neither the traffic kits nor any

component of the kits shall diminish the

operating efficiency or service life of the fire

hydrant to which they are attached. All

components shall conform, when applicable, to

ANSI/AWWA C502-94 and the latest

revisions thereto.

Special Features:

Traffic coupling must be made of Bronze,

Cast Iron, or Stainless Steel. No substitutes.

Traffic repair kits shall include the appropriate

amount of stem couplings, pins, flange and

bonnet o-rings or gaskets, safety flange(s),

lubricant, bolts, and nuts as required.

Size/Details OUC Item ID Manufacturer Catalog Number

1] 5 ¼” AFC B84B 095-01302 1] American Flow

Control (AFC) AFCB84BTRK

or Hydrant Repair Parts HRPI-473/584

2] 5 ¼” Clow Medallion 095-01304 2] Clow Valve Co. R1620653

or Hydrant Repair Parts HRPI-653

3] 5 ¼” Clow 2500 095-01305 3] Clow Valve Co. R1620545

or Hydrant Repair Parts HRPI-2500

4] 5 ¼” Kennedy K81D 095-01306 4] Kennedy Valve K8149

Guardian or Hydrant Repair Parts HRPI-5-8149

5] 5 ¼” Mueller 095-01308 5] Mueller A 301

Centurion or Hydrant Repair Parts HRPI-301

or Hydraflo 2074

6] 5 ¼” M&H 929 095-01310 6] M&H 442929-5 ¼

or Hydrant Repair Parts 929-5 ¼

or Hydraflo 1507

7] 5¼” US PIPE M-94 095-01312 7] US PIPE V658665

Revision Date: 9/05/01 (RNK) Material Specifications

Water Business Unit

8/26/99 (RNK) ORLANDO UTILITIES

10/16/98 (DSW) COMMISSION

Material Specifications D 1.3

Extension Kit – Fire Hydrant – 6”

AKA

General:

All components of the fire hydrant

extension kit shall be designed for and

properly fit the specific make and model

fire hydrant for which they are intended.

Neither the extension kit nor any

component of the kit shall diminish the

operating efficiency or service life of the

fire hydrant to which they are attached. All

components shall conform, when

applicable, to ANSI/AWWA C502-94 and

the latest revisions thereto.

Special Features:

Extension coupling must be made of Bronze,

Cast Iron, or Stainless Steel. No substitutes.

Fire hydrant extension kits shall include

the appropriate quantity of barrels, flanges,

couplings, stems or rods, gaskets, lubricant,

and hardware to properly complete the

installation.

Size/Details OUC Item ID Manufacturer Catalog Number

1] 5 ¼” Mueller 095-01004 1] Mueller A 320-6

Centurion – 6” ext. or Hydrant Repair Parts HRPI-375-6”

or Hydraflo 1341 – 6”

2] 5 ¼” Clow 095-01008 2] Clow R1620664

Medallion – 6” ext. or Hydrant Repair Parts HRPI-475-6”

3] 5¼” US PIPE M-94 095-01010 3] US PIPE V664509

- 6” ext.

4] 5¼” US PIPE M-250 095-01012 4] US PIPE V658249

- 6” ext.

Revision Date: 9/05/01 (RNK) Material Specifications

Water Business Unit

8/26/99 (RNK) ORLANDO UTILITIES

3/10/97 (DSW) COMMISSION

Material Specifications D 1.4

Extension Kit – Fire Hydrant – 12”

AKA

General:

All components of the fire hydrant

extension kit shall be designed for and

properly fit the specific make and model

fire hydrant for which they are intended.

Neither the extension kit nor any

component of the kit shall diminish the

operating efficiency or service life of the

fire hydrant to which they are attached. All

components shall conform, when

applicable, to ANSI/AWWA C502-94 and

the latest revisions thereto.

Special Features:

Extension coupling must be made of Bronze,

Cast Iron, or Stainless Steel. No substitutes.

Fire hydrant extension kits shall include

the appropriate quantity of barrels, flanges,

couplings, stems or rods, gaskets, lubricant,

and hardware to properly complete the

installation.

Size/Details OUC Item ID Manufacturer Catalog Number

1] 5 ¼” Mueller 1] Mueller A320-12

Centurion – 12” ext. 095-01104 or Hydrant Repair Parts HRPI-375-12”

or Hydraflo 1341 – 12”

2] 5 ¼”Clow Medallion 095-01108 2] Clow R1620665

– 12” ext. or Hydrant Repair Parts HRPI-475-12”

3] 5¼” US PIPE M-94 095-01109 3] US PIPE V664519

- 12” ext.

4] 5¼” US PIPE M-250 095-01110 4] US PIPE V658259

- 12” ext.

Revision Date: 9/05/01 (RNK) Material Specifications

Water Business Unit

8/26/99 (RNK) ORLANDO UTILITIES

3/10/97 (DSW) COMMISSION

Exhibit HH 1

Fire Hydrants

Specifications

Fire hydrants provided under this specification shall be post type, dry-barrel, Class A fire hydrants

conforming to ANSI/AWWA C502-94 and the latest revisions thereto. The hydrants shall further

comply with all requirements of Associates Factory Mutual Fire Insurance Companies and shall be

listed with Underwriter’s Laboratories. The flow capacity shall be 1250 gpm with a maximum

permissible head loss of 6.0 psi, the rated water working pressure shall be 150 psi, and the test pressure

shall be 300 psi. All hydrants meeting this specification shall be the traffic “breakaway” type.

The inlet connection shall be mechanical joint conforming to ANSI Specification A21.10 for

connection to pipe 6 inches in diameter. Bolt holes at either side of the exterior flange shall be slotted

to the outer face of the flange to accommodate tie rods, or the fire hydrant shall be equipped with

strapping lugs. Accessories for the mechanical joint ends shall include rubber gaskets with glands and

COR-TEN bolts and nuts. Drain holes in the shoe or seat shall be deleted at the factory or they shall be

plugged with brass plugs.

The barrel section of the hydrant shall be made in two or more sections, with a flange located at least

two inches above the finished grade line, and provided with a break flange, flange clips or lugs at the

ground line. Undercut or frangible bolts for the break connection are not acceptable. Hydrants shall

have the capability of turning the upper barrel section 360º at any desired angle. Iron components, i.e.

barrel, lower barrel, and shoe, shall be all cast iron or ductile iron. The traffic section, lower barrel,

and shoe interior of the hydrant shall have a minimum 4 mil thickness of factory applied thermosetting

(epoxy) coating.

The main valve shall be compression type, opening against pressure and closing with pressure. The

main valve opening shall be 5 1/4 inches in size. The hydrant main valve and operating parts including

valve seat, valve seat insert, and upper valve washer shall all be bronze, meeting either ASTM B-61, B-

62, B-98, B-150, or B-763. The main valve shall be placed between the lower barrel flange and the

shoe flange thus assuring accessibility. To prevent overtravel, a travel stop shall be placed in either the

hydrant shoe or hydrant bonnet.

Hydrant stems, stem threads, and bearings shall be protected by a self-lubricating system consisting of

an oil or grease filled reservoir serviceable by external means. Oil or grease used for lubrication shall

be non-toxic and safe for use in potable water systems. Grease shall be non-hardening. Any migration

or leakage of oil or grease into the barrel or bonnet areas is unacceptable. The bonnet shall be of dry

type design.

Revision Date: 9/5/01 (RNK) Material Specifications

9/4/98 (DSW) Water Business Unit

5/8/92 (DSW) ORLANDO UTILITIES

COMMISSION

Exhibit HH 2

Fire Hydrants

Specifications (cont.)

Mechanical working areas in the hydrant bonnet shall be protected from water intrusion from both

inside and outside the hydrant by use of “O” rings. Hydrants having stem thread (upper or lower) that

is constantly exposed or immersed in water are not acceptable.

All internal stem pins or bolts and nuts shall be stainless steel. The safety stem coupling shall be of

either Cast Iron, Bronze, or Stainless Steel.

The fire hydrants shall open left (counter-clockwise). They shall have pentagon shaped operating nuts

and cap nuts measuring 1 ½” inches from point to flat.

Hydrant nozzles shall consist of two 2 ½” inch hose nozzles and one 4 ½ inch pumper nozzle, all with

NFPA No. 194 for National (American) Standard Fire Hose Coupling Screw Threads. The hose and

pumper outlets shall be on the same horizontal plane with a minimum distance of 18 inches from the

center of nozzle to ground line located not more than 3 ½ inches from the centerline of the break

flange. All nozzles shall be field replaceable. There shall also be a vertical clearance of 9 inches from

the centerline of the pumper outlet to the top of the bonnet to comply with an Orlando Fire Department

requirement related to their equipment.

The American Water Works uniform color scheme shall be utilized on all fire hydrants, with the

exception of the upper barrels, which shall be aluminum or silver. Bonnet or tops and nozzle caps shall

be blue.

Fire hydrant length, also known as the bury length, shall be as measured from the bottom of the

connecting pipe to the ground line of the hydrant in six inch increments, from 30 inches to 60 inches

inclusive. The bury length shall be clearly indicated on the upper 6 inches of the lower barrel of each

hydrant.

Manufacturers of acceptable fire hydrants shall maintain an inventory of hydrants to be furnished

within the State of Florida that may be delivered to Orlando Utilities Commission within any 48 hour

time limit. The initial purchase or release for any fire hydrant contract shall include three (3) sets of

Maintenance and Repair Tools and factory made traffic hydrant repair kits.

Revision Date: 9/5/01 (RNK) Material Specifications

9/4/98 (DSW) Water Business Unit

5/8/92 (DSW) ORLANDO UTILITIES

COMMISSION

Potrebbero piacerti anche

- Site Fire-Flow Hydrant Flow Testing RequirementsDocumento30 pagineSite Fire-Flow Hydrant Flow Testing Requirementsculosucio23Nessuna valutazione finora

- Technical SpecificationDocumento12 pagineTechnical SpecificationYousuf KamalNessuna valutazione finora

- Sprinkler System - General InformationDocumento5 pagineSprinkler System - General InformationshahidenterNessuna valutazione finora

- Hydrant Flow Test Procedure and FormDocumento2 pagineHydrant Flow Test Procedure and FormMark Alvin JimenezNessuna valutazione finora

- Deficiency Tracking LogDocumento1 paginaDeficiency Tracking Logchirese2000Nessuna valutazione finora

- Form 72-Fire Hydrant and Sprinkler System Periodic Testing and MaintenanceDocumento3 pagineForm 72-Fire Hydrant and Sprinkler System Periodic Testing and MaintenanceSatrio Budi Prakosa RachmanNessuna valutazione finora

- HSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneDocumento4 pagineHSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneTuấn PhạmNessuna valutazione finora

- MuellerCo HydrantReferenceGuide 12000 WebDocumento85 pagineMuellerCo HydrantReferenceGuide 12000 Websugiarto MarpaungNessuna valutazione finora

- BMID Hydrant Test FormDocumento2 pagineBMID Hydrant Test FormSheikh Faiz RockerNessuna valutazione finora

- Fire Hydrant Inspection Test ChecklistDocumento3 pagineFire Hydrant Inspection Test ChecklistZaky Fachrur Rozi100% (1)

- AVK HydrantDocumento16 pagineAVK HydrantNarendra Reddy BhumaNessuna valutazione finora

- Tie in MosDocumento2 pagineTie in MosAAISATNessuna valutazione finora

- Pressure Test - Hydrostatic and Pneumatic Test RequirementsDocumento6 paginePressure Test - Hydrostatic and Pneumatic Test RequirementslorenzoNessuna valutazione finora

- Section 15310 Fire Protection PipingDocumento8 pagineSection 15310 Fire Protection PipingkdpmansiNessuna valutazione finora

- FR 002 Pressure Testing Inspection ChecklistDocumento6 pagineFR 002 Pressure Testing Inspection Checklistum er100% (1)

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDocumento10 pagineSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNessuna valutazione finora

- Key Maintenance SwitchDocumento4 pagineKey Maintenance SwitchkuraimundNessuna valutazione finora

- Installation Manual OXYFLEX® MF1100 October 2014 PDFDocumento8 pagineInstallation Manual OXYFLEX® MF1100 October 2014 PDFRomuel PioquintoNessuna valutazione finora

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Documento3 pagineTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioNessuna valutazione finora

- Mueller Water Distribution Products BrochureDocumento12 pagineMueller Water Distribution Products BrochureForum PompieriiNessuna valutazione finora

- ITP - Fire Hydrant InstallationDocumento9 pagineITP - Fire Hydrant InstallationGultom Juliana LiliesNessuna valutazione finora

- 185 Spec Menara99 SoreangDocumento5 pagine185 Spec Menara99 SoreangHendra YuliantoNessuna valutazione finora

- AFSS-Commissioning & Testing..Documento4 pagineAFSS-Commissioning & Testing..sanchezdreiNessuna valutazione finora

- F03 Vendor Quarterly Compliance InspectionDocumento2 pagineF03 Vendor Quarterly Compliance Inspectionsalman ahmedNessuna valutazione finora

- 302 Hydrant TestDocumento5 pagine302 Hydrant Testsmartleo_waloNessuna valutazione finora

- Arita Katalog Building - SmallDocumento16 pagineArita Katalog Building - SmallAlamsyah PutraNessuna valutazione finora

- Temperature Controllers: Installation and MaintenanceDocumento5 pagineTemperature Controllers: Installation and MaintenanceJose Uriel Ortega LeonNessuna valutazione finora

- Technical Compliance Sheet Butterfly ValveDocumento5 pagineTechnical Compliance Sheet Butterfly Valvebiswasdipankar05Nessuna valutazione finora

- 3844-Internal Fire Hydrants and HoseDocumento22 pagine3844-Internal Fire Hydrants and HoseSOMU_61100% (1)

- Katalog ARITA 20199Documento68 pagineKatalog ARITA 20199Fresly JayaNessuna valutazione finora

- 800D SeriesDocumento3 pagine800D Seriesvkeie0206Nessuna valutazione finora

- Sa01 Genxxx SDGG PRTS 0107 V00Documento7 pagineSa01 Genxxx SDGG PRTS 0107 V00amini_mohiNessuna valutazione finora

- Pse10 0029Documento8 paginePse10 0029Daoued HaouesNessuna valutazione finora

- Check List Fire Hose Reel InstallationDocumento1 paginaCheck List Fire Hose Reel InstallationAmie GTunedNessuna valutazione finora

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocumento15 pagine4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriNessuna valutazione finora

- 41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFDocumento10 pagine41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFFarhan MNessuna valutazione finora

- Sample of Corrosion Mapping Using Thickness Gauge Grid FileDocumento3 pagineSample of Corrosion Mapping Using Thickness Gauge Grid FileBagus HadiwibowoNessuna valutazione finora

- QATAR Pin Braze pdfr1Documento14 pagineQATAR Pin Braze pdfr1Karunanithi NagarajanNessuna valutazione finora

- Form QT 4 (B)Documento1 paginaForm QT 4 (B)Asma FarahNessuna valutazione finora

- Automatic Fire Suppression SystemsDocumento1 paginaAutomatic Fire Suppression Systemsnvenkat.narayanNessuna valutazione finora

- MJR For 30M Maintenance Check of Check ValvesDocumento9 pagineMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Organization Chart For Pipe Line Project 01Documento1 paginaOrganization Chart For Pipe Line Project 01MaherNessuna valutazione finora

- Fluxi 2000 TZ EN-03 - 18Documento4 pagineFluxi 2000 TZ EN-03 - 18Praveen KumarNessuna valutazione finora

- ITR-B (Piping) Witness Joint1Documento1 paginaITR-B (Piping) Witness Joint1Momo ItachiNessuna valutazione finora

- Millsheet Pipa Spindo - 01Documento4 pagineMillsheet Pipa Spindo - 01Mellany SeprinaNessuna valutazione finora

- Pre-Commissioning and Commissioning For Fire Hosr Rack and Hose ReelDocumento1 paginaPre-Commissioning and Commissioning For Fire Hosr Rack and Hose Reelsoe_thumoeNessuna valutazione finora

- SWP CHECKLISTS - Welding Cutting and HeatingDocumento3 pagineSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- Request For NDT Test FormDocumento1 paginaRequest For NDT Test FormJohn OliverNessuna valutazione finora

- Technical Data: 1. DescriptionDocumento10 pagineTechnical Data: 1. DescriptionKang Kawe Waone SetiaoneNessuna valutazione finora

- Checklist For Pressure Testing Safely 2Documento2 pagineChecklist For Pressure Testing Safely 2Jonathan CambaNessuna valutazione finora

- 1 Gala Bronze Y-Strainer Fig 7654 SMDocumento1 pagina1 Gala Bronze Y-Strainer Fig 7654 SMNon Etabas GadnatamNessuna valutazione finora

- Form 70 Fire Hydrant and SprinklersDocumento2 pagineForm 70 Fire Hydrant and SprinklersmkdholkiyaNessuna valutazione finora

- P3-PTP-001 R0 Piping Pressure Test ProceduresDocumento8 pagineP3-PTP-001 R0 Piping Pressure Test ProceduresHengNessuna valutazione finora

- Compliance Sheet For Technical Spec For Fire Fighting SystemDocumento9 pagineCompliance Sheet For Technical Spec For Fire Fighting SystemAnonymous G9t3IVfL4JNessuna valutazione finora

- Why Is "Cold Cutting" Superior To Plasma Cutting?Documento9 pagineWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedNessuna valutazione finora

- Division 15 Mechanical IBS PLUMBDocumento239 pagineDivision 15 Mechanical IBS PLUMBmasahinNessuna valutazione finora

- Docslide - Us - Itp Structural WorkDocumento4 pagineDocslide - Us - Itp Structural Workomda4wadyNessuna valutazione finora

- 300 Copy Gas Cutting Daily Check ListDocumento3 pagine300 Copy Gas Cutting Daily Check ListDeepu ChandranNessuna valutazione finora

- Blackmer Tx15 To Tx4aDocumento24 pagineBlackmer Tx15 To Tx4aedwinramonNessuna valutazione finora

- M Technical ManualDocumento36 pagineM Technical ManualJuan Martin RomeroNessuna valutazione finora

- The First-Fourth Books of The HitopadésaDocumento116 pagineThe First-Fourth Books of The HitopadésaMiguel RosaNessuna valutazione finora

- Revised Research ZoomDocumento51 pagineRevised Research ZoomAubrey Unique EvangelistaNessuna valutazione finora

- Module 1 Inclusive Education Lecture 1 & Introduction - OnlineDocumento32 pagineModule 1 Inclusive Education Lecture 1 & Introduction - OnlineSharon ShenNessuna valutazione finora

- 3-Storeyed 31-3-2015-Schedule PDFDocumento1 pagina3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNessuna valutazione finora

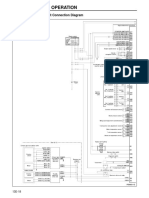

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocumento16 pagineStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarNessuna valutazione finora

- Canadian-Solar Datasheet Inverter 3ph 75-100KDocumento2 pagineCanadian-Solar Datasheet Inverter 3ph 75-100KItaloNessuna valutazione finora

- Examiners' Report Principal Examiner Feedback January 2018Documento7 pagineExaminers' Report Principal Examiner Feedback January 2018WandaNessuna valutazione finora

- 141-203 Solar 660 60 - 40 - 30 - 225 Amp Fleet Battery ChargerDocumento10 pagine141-203 Solar 660 60 - 40 - 30 - 225 Amp Fleet Battery Chargerjose alberto alvarezNessuna valutazione finora

- PC Engineering Undergr 2014Documento94 paginePC Engineering Undergr 2014Austin JamesNessuna valutazione finora

- Solved Consider Again The Demand Function For Corn in Formula 1Documento1 paginaSolved Consider Again The Demand Function For Corn in Formula 1M Bilal SaleemNessuna valutazione finora

- Silenat Berhanu SimaDocumento6 pagineSilenat Berhanu SimaSilenat BerhanuNessuna valutazione finora

- SOL-Logarithm, Surds and IndicesDocumento12 pagineSOL-Logarithm, Surds and Indicesdevli falduNessuna valutazione finora

- Empowerment TechnologyDocumento15 pagineEmpowerment Technologysxhan gwenNessuna valutazione finora

- Application Bright Ideas Education Grant Program For TeachersDocumento6 pagineApplication Bright Ideas Education Grant Program For Teachersapi-320983699Nessuna valutazione finora

- Advanced Laser Al170: Instruction ManualDocumento35 pagineAdvanced Laser Al170: Instruction ManualJuan Camilo100% (1)

- AIMMS Modeling Guide - Linear Programming TricksDocumento16 pagineAIMMS Modeling Guide - Linear Programming TricksgjorhugullNessuna valutazione finora

- Ground Vehicle Operations ICAODocumento31 pagineGround Vehicle Operations ICAOMohran HakimNessuna valutazione finora

- An Introduction To EFTDocumento24 pagineAn Introduction To EFTkunjammuNessuna valutazione finora

- pm2 5 Sensor 201605Documento6 paginepm2 5 Sensor 201605Vennela NandikondaNessuna valutazione finora

- Delonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Documento21 pagineDelonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Luis AlbertoAlmeidaSilva100% (1)

- The Extension Delivery SystemDocumento10 pagineThe Extension Delivery SystemApril Jay Abacial IINessuna valutazione finora

- PCBDocumento5 paginePCBarampandey100% (4)

- B1.10 Exchanging MaterialsDocumento4 pagineB1.10 Exchanging MaterialsYevonNessuna valutazione finora

- Xgenus X-Ray PDFDocumento61 pagineXgenus X-Ray PDFAli NuriNessuna valutazione finora

- صيانة المولدات و المحولات الكهربائيهDocumento15 pagineصيانة المولدات و المحولات الكهربائيهMostafa AllamNessuna valutazione finora

- Anatomy & Physiology MCQsDocumento26 pagineAnatomy & Physiology MCQsMuskan warisNessuna valutazione finora

- Conquering College The Most Fun You Can Have Learning The Things You Need To Know NodrmDocumento144 pagineConquering College The Most Fun You Can Have Learning The Things You Need To Know NodrmVithorNessuna valutazione finora

- DCS Ground Charts v350Documento34 pagineDCS Ground Charts v350lkjsdflkjNessuna valutazione finora

- Overleaf Keyboard ShortcutsDocumento2 pagineOverleaf Keyboard ShortcutsAlberto GiudiciNessuna valutazione finora

- Compressor-Less: Historical ApplicationsDocumento70 pagineCompressor-Less: Historical Applicationssuryakantshrotriya100% (1)