Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

7 Pyrotek Crossfeeder

Caricato da

Muhamad Hafidz RyansyahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

7 Pyrotek Crossfeeder

Caricato da

Muhamad Hafidz RyansyahCopyright:

Formati disponibili

New Cross-Feeder Refractory

Technology

Alan Sale, Pyrotek

The Ideal Cross-Feeder

Strong and Hard

Low thermal expansion

Low thermal conductivity

High resistance to molten aluminium attack

Current Materials

Thermal conductivity vs. Material life

Current Materials

Dense material = longer life, less

insulating

Lighter material = less life, more

insulating

25,000 MT

25,000 MT

The Ideal Cross-Feeder

Introducing TITANTM Refractory

Strong and Hard

Low thermal expansion

Low thermal conductivity

High resistance to molten aluminium attack

TITANTM Cross-feeder

Function

1. Reduce molten metal heat loss at cast start and

run

2. Reduce heat transfer into the steel table

3. Reduce maintenance between drops and in the

mold room

Reduce metal temperature loss

Reduce heat transfer

Reduce Maintenance

TITANTM Crossfeeder

WHY IS TITAN UNIQUE?

It is a true composite refractory

featuring a hard hot face backed with

a unique insulating body

TitanTM Cross-Feeder

PyroformHP vs. TITANTM

Properties Pyroform

HP

TITAN

Heat sink, C

P

, BTU/lb F 19.5 17.0

Thermal conductivity,

BTU-in/ft

2

/hr/ F

1.55 1.46

Thermal expansion,

in/in/ F x 10 E

-6

1.60 1.30

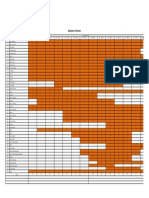

Cross-Feeder Insulation Comparison

Wagstaff cross-feeder temperature comparison

0

100

200

300

400

500

600

0 12 24 36 48 52 58 64 70 76

Insural 140 Pyroform PC Titan

T

e

m

p

e

r

a

t

u

r

e

,

F

Casting time, minutes

End of Cast

Thermocouple Placement

Benefits of TitanTM Cross-Feeders

Better insulating

Lower maintenance

Greater energy savings

Design advantages

Benefits of TitanTM Cross-Feeders

Better insulating

Reduce cast start defects due to

temperature loss

Uniform temperature distribution

across the table

Less refractory and mold table

maintenance

Better Insulating

Average 1% gain in pit yield due to

reduction of cast start defects

Benefits of TitanTM Cross-Feeders

Lower Maintenance

Between drop maintenance

Refractory maintenance between

casting campaigns

Refractory life

Benefits of TitanTM Cross-Feeders

Greater energy savings

Possible to reduce furnace temperature

Energy Savings with TitanTM

Titan Crossfeeder

Holding furnace - Gas cost savings

Furnace size, thousand lb 125000

Natural gas cost, $/thousand cubic feet $10

Temperature decrease in F using FS RFM/ WolliteX-feeder 15

Calculated energy to reach 1337 F

(1)

58540625

Calculated energy to reach the lower casting temperature 58118750

Calculated energy difference =Delta Q/furnace load 421875

Number of cast/year based 6 cast/day and 325 working days 1950

Total energy difference in BTU 822656250

Natural gas energy in BTU/ cf 1080

Calculated natural gas volume @ 50% efficiency inmcf 1522

Calculated annual cost saving/furnace $15,000

(1) Q=Cp

Al

x furnace weight x temperature +latent heat of fusion

Benefits of TitanTM Cross-Feeders

Design advantages

All geometry shapes and designs

Possible to eliminate joints

Multiple hot face materials available

Summary

TITAN

TM

Refractory

COST EFFECTIVE ADDS VALUE

Reduce temperature cast start defects

Reduce between drop maintenance

Reduce refractory maintenance

Longer refractory life

Unlimited geometric designs

Multiple mold position modules

Potrebbero piacerti anche

- Continuous casting The Ultimate Step-By-Step GuideDa EverandContinuous casting The Ultimate Step-By-Step GuideNessuna valutazione finora

- Pyrotek PromagDocumento2 paginePyrotek PromaggpucellaNessuna valutazione finora

- Cif Purge Plug Systems en 3Documento3 pagineCif Purge Plug Systems en 3abdeljalil elbadrNessuna valutazione finora

- Achenbach ExtractDocumento56 pagineAchenbach ExtractCatanescu Alexandru-LaurentiuNessuna valutazione finora

- Fiberseal Felts and Blankets - HIGH-TEMPERATURE INSULATING MATERIALSDocumento2 pagineFiberseal Felts and Blankets - HIGH-TEMPERATURE INSULATING MATERIALSEzequiel BonaniNessuna valutazione finora

- Lecture 15: Application of Refractory MaterialsDocumento7 pagineLecture 15: Application of Refractory MaterialsMiguel Kühnert FrichenbruderNessuna valutazione finora

- PEP Session Industrial RefractoriesDocumento64 paginePEP Session Industrial RefractoriesNowsherwan MazariNessuna valutazione finora

- Slide Gate System DevelopmentDocumento14 pagineSlide Gate System DevelopmentA.S.M. Mosayeb RafiNessuna valutazione finora

- Vibradamp DC30 122IPMDocumento3 pagineVibradamp DC30 122IPMtrublu260112Nessuna valutazione finora

- Https WWW - Elkem.com Global ESM Support Technical-Papers Refractories 37-The Use of Microsilica in Refractory CastablesDocumento28 pagineHttps WWW - Elkem.com Global ESM Support Technical-Papers Refractories 37-The Use of Microsilica in Refractory CastablesSachin SahooNessuna valutazione finora

- Materials in Industrial Furnace ConstructionDocumento28 pagineMaterials in Industrial Furnace ConstructionAlexander TabaresNessuna valutazione finora

- Combo Bag 1379 RFM Skim Dam E4Documento1 paginaCombo Bag 1379 RFM Skim Dam E4MeteusNessuna valutazione finora

- Alcoa AP BrochureDocumento8 pagineAlcoa AP BrochureGanesh AshokanNessuna valutazione finora

- Almatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionDocumento15 pagineAlmatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionSaptarshi SenguptaNessuna valutazione finora

- Refractory For EAF-GuideDocumento4 pagineRefractory For EAF-GuideJayasimha TammineniNessuna valutazione finora

- Pyrotek - SIVEX - Ceramic FoamDocumento2 paginePyrotek - SIVEX - Ceramic FoamajoilhamNessuna valutazione finora

- INITEK Process: Coatings Filtration Feeding Systems Melt Shop Refractories Binders CruciblesDocumento8 pagineINITEK Process: Coatings Filtration Feeding Systems Melt Shop Refractories Binders CruciblesMatheusM.FerreiraNessuna valutazione finora

- 678 TF Combo Bag E4Documento2 pagine678 TF Combo Bag E4MeteusNessuna valutazione finora

- Advantage and Disadvantage of Raw MaDocumento19 pagineAdvantage and Disadvantage of Raw MaNaelNessuna valutazione finora

- Furnaces and Refractories: 6. WorksheetsDocumento36 pagineFurnaces and Refractories: 6. WorksheetsDHSanjNessuna valutazione finora

- Refractory Lining For Induction Furnace PDFDocumento3 pagineRefractory Lining For Induction Furnace PDFmeNessuna valutazione finora

- FIRE Compendium Series: Refractory Castable EngineeringDocumento2 pagineFIRE Compendium Series: Refractory Castable EngineeringKhaled BOUALINessuna valutazione finora

- Refractories For Induction Furnaces For DisplayDocumento9 pagineRefractories For Induction Furnaces For Displayabdul rochimNessuna valutazione finora

- REFractories FOR GLASS-TRL PDFDocumento24 pagineREFractories FOR GLASS-TRL PDFram cNessuna valutazione finora

- Introduction To Fused Cast RefractoryDocumento7 pagineIntroduction To Fused Cast RefractorypetemberNessuna valutazione finora

- Stainless Steel AOD Operation and Slag Optimisation PDFDocumento41 pagineStainless Steel AOD Operation and Slag Optimisation PDFPrakash MishraNessuna valutazione finora

- MonolithicRefractory PDFDocumento2 pagineMonolithicRefractory PDFmevaNessuna valutazione finora

- 228-04 KALTEK SG Iron French FoundryDocumento4 pagine228-04 KALTEK SG Iron French FoundryMar CarreonNessuna valutazione finora

- High Temperature Furnaces: General CatalogueDocumento27 pagineHigh Temperature Furnaces: General Catalogueedwcaran100% (1)

- Float Glass RefractoryDocumento4 pagineFloat Glass RefractorySans SenNessuna valutazione finora

- Simulatiing Porosity in Ductile Iron - Etip17Documento2 pagineSimulatiing Porosity in Ductile Iron - Etip17yeokbinNessuna valutazione finora

- Chemical Interactions in Calcium Aluminate Cement Cac Based Castables Containing MagnesiaDocumento8 pagineChemical Interactions in Calcium Aluminate Cement Cac Based Castables Containing MagnesiaDick ManNessuna valutazione finora

- IM Fused Alumina Article - Dec 20071 PDFDocumento5 pagineIM Fused Alumina Article - Dec 20071 PDFMrutunjay Patra100% (1)

- Ladle Refractories Web 2017 PDFDocumento12 pagineLadle Refractories Web 2017 PDFrivrsideNessuna valutazione finora

- Raw Materials For Manufacturing of Superior Quality Mgo-C BricksDocumento8 pagineRaw Materials For Manufacturing of Superior Quality Mgo-C Bricksjom erfNessuna valutazione finora

- Extraction of Aluminum From DrossDocumento5 pagineExtraction of Aluminum From DrossPrashant ParshivnikarNessuna valutazione finora

- 2011-RHI Bulletin 1Documento9 pagine2011-RHI Bulletin 1Bagas Prasetyawan Adi NugrohoNessuna valutazione finora

- FP 266 enDocumento28 pagineFP 266 enAritonang SuryaNessuna valutazione finora

- Refractor I NessDocumento12 pagineRefractor I NesskazamNessuna valutazione finora

- MCM AllDocumento7 pagineMCM AllPalanisamy RajaNessuna valutazione finora

- Mathios Refractories Catalog Web EditionDocumento92 pagineMathios Refractories Catalog Web EditionNick Limperios100% (1)

- Fused and Sintered AluminaDocumento7 pagineFused and Sintered AluminaSaragadam DilsriNessuna valutazione finora

- Refractory Lining Project Corrected (Chapter 1)Documento7 pagineRefractory Lining Project Corrected (Chapter 1)Don Rayburn PilanNessuna valutazione finora

- Cast Alloys in Aluminium 2013Documento16 pagineCast Alloys in Aluminium 2013Fernando Martinez ContrerasNessuna valutazione finora

- Molding Training PresentationDocumento30 pagineMolding Training PresentationVinesh RJNessuna valutazione finora

- Refractory Castable DewateringDocumento6 pagineRefractory Castable DewateringJarek PlaszczycaNessuna valutazione finora

- Electric Arc Furnace: SteelDocumento37 pagineElectric Arc Furnace: SteelAristeudesQuintinoNessuna valutazione finora

- Reference-List Seven Blast Furnace RepairsDocumento6 pagineReference-List Seven Blast Furnace RepairsNishant BandaruNessuna valutazione finora

- Vesuvius ResearchDocumento9 pagineVesuvius ResearchRohit ThapliyalNessuna valutazione finora

- Lecture - Magnesium Alloys - Hue'sDocumento29 pagineLecture - Magnesium Alloys - Hue'sMurali ManuNessuna valutazione finora

- Gouda Refractories Brochure WEbDocumento16 pagineGouda Refractories Brochure WEbjsszep jNessuna valutazione finora

- 4.13.9 Typical Refractories in Industrial UseDocumento8 pagine4.13.9 Typical Refractories in Industrial UsePalash SwarnakarNessuna valutazione finora

- Specification HGRM-30 GRADEDocumento1 paginaSpecification HGRM-30 GRADESanjayNessuna valutazione finora

- Casting MetallurgyDocumento53 pagineCasting MetallurgyShanmugam BalasubramaniamNessuna valutazione finora

- Use of Silicon Carbide in The Induction FurnaceDocumento2 pagineUse of Silicon Carbide in The Induction FurnaceXantos YulianNessuna valutazione finora

- Hot Green Sand ProblemsDocumento5 pagineHot Green Sand ProblemsbvphimanshuNessuna valutazione finora

- FHS Ladle Installation Manual Incld OPI - 10.5.2018Documento28 pagineFHS Ladle Installation Manual Incld OPI - 10.5.2018Nguyễn ChungNessuna valutazione finora

- Properties of TiB2Documento12 pagineProperties of TiB2DnayneshwarNessuna valutazione finora

- BF Cast House Product & DesignDocumento50 pagineBF Cast House Product & DesignHara Prasad MurtyNessuna valutazione finora

- A Review Influence of Refractories On Steel Quality PDFDocumento20 pagineA Review Influence of Refractories On Steel Quality PDFBagas Prasetyawan Adi NugrohoNessuna valutazione finora

- AS9100C ChecklistsDocumento79 pagineAS9100C ChecklistsManikantagupta BommisettyNessuna valutazione finora

- AITECH Accredited October 2015Documento17 pagineAITECH Accredited October 2015Jiane NavalNessuna valutazione finora

- Tower Brochure EDocumento4 pagineTower Brochure EZeeshan RiazNessuna valutazione finora

- Geomembrane Installation QADocumento23 pagineGeomembrane Installation QAMark Kevin BechaydaNessuna valutazione finora

- Cutting Performance of Glass-Vinyl Ester Composite by Abrasive Water JetDocumento34 pagineCutting Performance of Glass-Vinyl Ester Composite by Abrasive Water Jetalvian GaspolllNessuna valutazione finora

- Directional SolidificationDocumento2 pagineDirectional SolidificationTeka KamNessuna valutazione finora

- Ercan Full 47 02 PDFDocumento8 pagineErcan Full 47 02 PDFAkankshaNessuna valutazione finora

- SEDA Study - Region's Economic OpportunitiesDocumento60 pagineSEDA Study - Region's Economic Opportunitiessavannahnow.comNessuna valutazione finora

- Staineless Steel Wire Flux Cored WireDocumento6 pagineStaineless Steel Wire Flux Cored Wiregazwang478Nessuna valutazione finora

- Final Project-JohanseinDocumento79 pagineFinal Project-JohanseinJohan SeinNessuna valutazione finora

- Sheet Metal FormingDocumento4 pagineSheet Metal FormingYared AbebeNessuna valutazione finora

- Mohammed Murshid: Work ExperieanceDocumento2 pagineMohammed Murshid: Work ExperieanceMurshid MurshiNessuna valutazione finora

- Challenges Facing The Indian Manufacturing SectorDocumento9 pagineChallenges Facing The Indian Manufacturing SectorThakur KhoraNessuna valutazione finora

- Indonesia A&d IndustryDocumento19 pagineIndonesia A&d Industrymy_new_diaryNessuna valutazione finora

- Question 1 of 20 Accounting For ManagersDocumento8 pagineQuestion 1 of 20 Accounting For ManagersgghhsdNessuna valutazione finora

- EGF305 Topic 5-Intro To Failure Analysis PDFDocumento34 pagineEGF305 Topic 5-Intro To Failure Analysis PDFasdfasdNessuna valutazione finora

- Internal-Business-Process PerspectiveDocumento6 pagineInternal-Business-Process PerspectiveMUTIA ADELIA MURKINessuna valutazione finora

- ED1200Documento4 pagineED1200Mohamed TahounNessuna valutazione finora

- 3.stress ReliefDocumento2 pagine3.stress ReliefRajeevSangamNessuna valutazione finora

- Foam Core PrototypingDocumento11 pagineFoam Core PrototypingKathryn WorkmanNessuna valutazione finora

- Jenerator TWL 18.04.2020Documento2 pagineJenerator TWL 18.04.2020Rohit Om TiwariNessuna valutazione finora

- Lexicon Edition 6 - Chapter 8 Clamping SystemsDocumento67 pagineLexicon Edition 6 - Chapter 8 Clamping SystemsJelicaCvijovicNessuna valutazione finora

- Manpower & Equipment ScheduleDocumento1 paginaManpower & Equipment ScheduleColitz D. KhenNessuna valutazione finora

- Fabrication of Air Brake System Using Exhaust Gas Final Report..Documento54 pagineFabrication of Air Brake System Using Exhaust Gas Final Report..vidyadhar G64% (11)

- JM Methanol Brochure Katalco PuraspecDocumento24 pagineJM Methanol Brochure Katalco Puraspecricko4001100% (1)

- New Sms - JSW DolviDocumento2 pagineNew Sms - JSW Dolvisatyendragupta0078810Nessuna valutazione finora

- Specification For Applied Finishes For Flat RoofsDocumento6 pagineSpecification For Applied Finishes For Flat RoofsparathasiNessuna valutazione finora

- Air 5065Documento11 pagineAir 5065niky186Nessuna valutazione finora

- Gtu Teaching Scheme-BeDocumento2 pagineGtu Teaching Scheme-BeBhavesh PipaliyaNessuna valutazione finora

- Production Operation Management SCDL AssignmentDocumento26 pagineProduction Operation Management SCDL Assignmentsaurabh303100% (3)