Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Choosing A Turbo - For Turbojet

Caricato da

avinashmenonDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Choosing A Turbo - For Turbojet

Caricato da

avinashmenonCopyright:

Formati disponibili

Choosing a turbo

Find a turbo your budget can easily cope with, as you'll be spending a fair bit more on ancillaries. Try not to use too small a turbo as their turbine efficiencies can be so low as to make the engine a poor performer at best or a non-starter at the worst. Small turbo's can also have miss-matched compressor turbine flow characteristics for our use, but which are !" for a turbo.

Anatomy Of a Turbocharger

The shaft assembly should spin freely with no a#ial play $good thrust bearing%, but there will be radial wobble if you grab the end of the shaft at either compressor or turbine, as long as neither compressor or turbine scrape against the housings without oil in the &brass bush& bearings, they should be fine when there is oil pressure to them. Check for bent or damaged blades, re'ect the turbo if there are any signs of damage, as you will be running it harder than on any engines it might have come from.

Compressor/Turbine Shaft Assembly

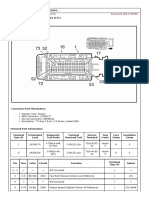

Try using a turbo from at least a ( litre engine or bigger which has a compressor wheel inlet $)nducer, see diagram above% diameter of *.+,--..//& or larger. )f possible find one designed for high pressure &boost&, something off a large generator or industrial stationary engine that's setup for continuous heavy boost. )f you can view the entire compressor wheel with its housing removed, a compressor wheel that has its inducer diameter of around . (rds of the overall diameter $0#ducer, see diagram above% is a good possibility, e.g. (& inducer and 1.,& e#ducer diameter. 2odern ones will probably have a bit better efficiency and hopefully a little more safety built into it. The relative si3es of the compressor wheel inducer and the turbine wheel e#ducer, also needs to be considered. Try and find a turbo whose turbine e#ducer area is around ./4-.,4 larger than the compressors inducer area. The table below lists a few e#amples in terms of diameters rather than area which is easier to gauge5

Compressor Inducer Diameter (inches) 2 2.5 3 3.5 4 Turbine Exducer Diameter (inches) 2.3 2.8 3.4 3.9 4.5

6ear in mind that your turbo does not have to match these numbers e#actly they are 'ust a guide. 7 turbo whose compressor inducer is .- and turbine e#ducer is ...- or ..1- for e#ample, may actually perform better than another turbo that also has a compressor inducer of .- and turbine e#ducer of ..(- as the table suggests. This is due to the many other variables such as relative hub blade ratios and blade angles that can affect final performance.

The turbine housing should be of the &open& variety with no centre divide where the hot gases go in $see picture below%, the divide causes a loss in efficiency because of all that e#tra friction, and you'll end up with less thrust from your engine if you use a divided housing.

Divided Turbine Housing

7dditionally, some turbine housings have internal waste-gates $see picture below% found on smaller automotive vehicles, particularly diesels. )nternal waste-gates are built into the turbine housing and consist of a 8flapper- valve, crank arm, rod end, and pneumatic actuator and provide a means to control the compressor boost pressure of the engine. For our purposes, waste gates are not a good thing, the hole in the turbine housing will need to be sealed and they are a general indication that there may be a mismatch of compressor turbine, i.e. the turbine housing may be too small compared to the compressor. Some automotive turbochargers do not use a waste-gate at all as do many used in large commercial diesel applications. Turbochargers without a waste-gate are referred to as 9free-floating:.

Internal Waste gate

To find ma# ;<2 of your chosen turbo, that corresponds to the groups accepted ma#imum compressor tip speed of *1,/ feet per second, it can be worked out by measuring the outlet diameter $e#ducer% of the compressor in inches, multiply by &<)&$(.*1.% to get circumference in inches, divide that by *. to get the circumference in feet, divide that into *1,/, to get ;<2 sec then multiply by =/ for ;<2, e.g. our compressor is 1., inches overall so 1.,& > (.*1. ? *1.*(& div by *. ? *.*++, ft circumference *1,/ ft sec div by *.*++, ? *.(*.1 rps > =/ ?+(,@@1 ;<2 ma#.

Potrebbero piacerti anche

- Constructing A Turbocharger Turbojet EngineDocumento52 pagineConstructing A Turbocharger Turbojet Enginerocketman19911Nessuna valutazione finora

- Ramjets & Pulse JetsDocumento10 pagineRamjets & Pulse JetsInterogator5Nessuna valutazione finora

- Development in The Performance of Valve Less Pulsejet EngineDocumento3 pagineDevelopment in The Performance of Valve Less Pulsejet EngineInternational Journal of Science and Engineering InvestigationsNessuna valutazione finora

- A Review of Free-Piston Engine History and Applications.Documento16 pagineA Review of Free-Piston Engine History and Applications.Thulasi RamNessuna valutazione finora

- A Review of Free-Piston Engine History and ApplicationsDocumento17 pagineA Review of Free-Piston Engine History and ApplicationsĐạt Võ100% (1)

- Free Piston Engine Working PDFDocumento2 pagineFree Piston Engine Working PDFAmyNessuna valutazione finora

- Instructions For Making The Inflatable KiteDocumento15 pagineInstructions For Making The Inflatable KiteLuka NikitovicNessuna valutazione finora

- Nano Ic EngineDocumento12 pagineNano Ic EngineVinod JadavNessuna valutazione finora

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationDa EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNessuna valutazione finora

- Design and Testing of An Autorotative Payload Delivery SystemDocumento11 pagineDesign and Testing of An Autorotative Payload Delivery SystemvictorNessuna valutazione finora

- Externally Fired Microturbine FlyerDocumento1 paginaExternally Fired Microturbine FlyerPaulFerry100% (1)

- Gluehareff Pressure Jet Engine: Past. Present and FutureDocumento9 pagineGluehareff Pressure Jet Engine: Past. Present and FuturesnizzNessuna valutazione finora

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocumento37 pagineProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew Skillinpinchi877012Nessuna valutazione finora

- Hydrofoil Seaplane DesignDocumento139 pagineHydrofoil Seaplane DesignVăn Tuấn NguyễnNessuna valutazione finora

- Jet - The story of jet propulsion: The inventors The aircraft The companiesDa EverandJet - The story of jet propulsion: The inventors The aircraft The companiesNessuna valutazione finora

- Improved Aeronca Engine: For Advanced Military TrainingDocumento1 paginaImproved Aeronca Engine: For Advanced Military Trainingseafire47Nessuna valutazione finora

- Drilling and Milling Table: CompoundDocumento4 pagineDrilling and Milling Table: CompoundmountaineerjpNessuna valutazione finora

- Theoretical and Experimental Evaluation of Pulse Jet EngineDocumento59 pagineTheoretical and Experimental Evaluation of Pulse Jet EngineJonas KnollNessuna valutazione finora

- Weight - BalanceDocumento4 pagineWeight - BalanceAEROWORKERNessuna valutazione finora

- 2895-Different Types of PumpsDocumento1 pagina2895-Different Types of PumpsDinkalai WaronfireNessuna valutazione finora

- Center Punch Grinding JigDocumento2 pagineCenter Punch Grinding JigmododanNessuna valutazione finora

- Pulse Detonation EngineDocumento29 paginePulse Detonation Enginev2brother100% (6)

- Dynajet Pulsejet EngineDocumento4 pagineDynajet Pulsejet Enginedaks4uNessuna valutazione finora

- Pulse JetDocumento65 paginePulse Jetarjun kumarNessuna valutazione finora

- Pulse Detonation Engine: Nitish Kumar Regd No:-0701223318Documento16 paginePulse Detonation Engine: Nitish Kumar Regd No:-0701223318Vishal KumarNessuna valutazione finora

- Turbo Jet EngineDocumento15 pagineTurbo Jet EngineMuhammad Bin RiazNessuna valutazione finora

- High Power Rocket Motor Basics: Adapted From Rocket Chronicles Inc.'s Web SiteDocumento5 pagineHigh Power Rocket Motor Basics: Adapted From Rocket Chronicles Inc.'s Web Sitepamos1111Nessuna valutazione finora

- A Flying Ejection Seat, Foldable Jet Powerd AutogyroDocumento12 pagineA Flying Ejection Seat, Foldable Jet Powerd AutogyroAlan Anthony Leaton100% (1)

- RamjetDocumento8 pagineRamjetBala MuruganNessuna valutazione finora

- Hydrogen Peroxide-Optimal For Turbo Machinery and Power ApplicationsDocumento17 pagineHydrogen Peroxide-Optimal For Turbo Machinery and Power ApplicationsVeljko Korvin KokovićNessuna valutazione finora

- Mandrel Design For Rocket MotorsDocumento4 pagineMandrel Design For Rocket Motorsobx4ever100% (1)

- The Gyroplane Breguet, Louis - (1937)Documento36 pagineThe Gyroplane Breguet, Louis - (1937)Mariela Tissera100% (1)

- CNC Touch Probe DrawingsDocumento13 pagineCNC Touch Probe DrawingsmikcomiNessuna valutazione finora

- Vortex Tube ManufacturingDocumento3 pagineVortex Tube ManufacturingSameer JainNessuna valutazione finora

- Construction and Manufacture of AutomobilesDa EverandConstruction and Manufacture of AutomobilesValutazione: 5 su 5 stelle5/5 (1)

- Model TurbinesDocumento104 pagineModel TurbinesKhalid Saif100% (2)

- Project Pulse Jet EngineDocumento18 pagineProject Pulse Jet EngineJoel Kevin SaldanhaNessuna valutazione finora

- Fuel Alcohol ProductionDocumento51 pagineFuel Alcohol ProductionplutocowNessuna valutazione finora

- T Project ReportDocumento63 pagineT Project ReportArif AhmadNessuna valutazione finora

- Pulse JetDocumento7 paginePulse JetMuhammad FikriNessuna valutazione finora

- Wren 44i Gold Thrust Instructions - 2016Documento27 pagineWren 44i Gold Thrust Instructions - 2016AurangzebNessuna valutazione finora

- Peter M. BowersDocumento9 paginePeter M. Bowersretread1100% (2)

- 55 Watt Gas CO2 Laser TubeDocumento66 pagine55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Complete Puls Engine UitlegDocumento35 pagineComplete Puls Engine UitlegadsjhgNessuna valutazione finora

- Portable Arc FurnaceDocumento4 paginePortable Arc Furnaceputra38Nessuna valutazione finora

- The Best Tutorial For Making An RC PlaneDocumento8 pagineThe Best Tutorial For Making An RC PlaneJosephRomeraloNessuna valutazione finora

- Project Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinDocumento37 pagineProject Pulse-Jet Group 4: Jeffrey Dennen Justin Marriott Brian Melo Matthew SkillinultimatesrNessuna valutazione finora

- Celta Precourse Task ShruthiDocumento13 pagineCelta Precourse Task ShruthiavinashmenonNessuna valutazione finora

- Automotive Human Factors: - Passenger Car Distance ControlDocumento14 pagineAutomotive Human Factors: - Passenger Car Distance ControlavinashmenonNessuna valutazione finora

- Hella Headlight Adjustment PDFDocumento24 pagineHella Headlight Adjustment PDFavinashmenonNessuna valutazione finora

- Lighting Systems From Light To Advanced Vision Technologies Technical Handbook Valeoscope en 998542 WebDocumento100 pagineLighting Systems From Light To Advanced Vision Technologies Technical Handbook Valeoscope en 998542 WebavinashmenonNessuna valutazione finora

- Amarnath Menon Kaipencheri: Racing SummaryDocumento2 pagineAmarnath Menon Kaipencheri: Racing SummaryavinashmenonNessuna valutazione finora

- D2876 LE405 - CatalogueDocumento192 pagineD2876 LE405 - CatalogueЮрий80% (5)

- No Aria 85.2140?) : M L WMQQM U?m?m? PC 1 .L 5,5,5, 5Documento12 pagineNo Aria 85.2140?) : M L WMQQM U?m?m? PC 1 .L 5,5,5, 5Qwerty UiopNessuna valutazione finora

- Instrumentation Bently NevadaDocumento1 paginaInstrumentation Bently Nevadaابزار دقیقNessuna valutazione finora

- MK - @MSITStore - C - OCSI - QuickServe 2016 OfflineDVD InstalleDocumento24 pagineMK - @MSITStore - C - OCSI - QuickServe 2016 OfflineDVD InstalleTocxoan Tocxoan100% (2)

- L175 L210 L225 L225DT L260 WSMDocumento53 pagineL175 L210 L225 L225DT L260 WSMدانيال دي اندرادي100% (1)

- Sop Zen Air CH 701 StolDocumento42 pagineSop Zen Air CH 701 Stolnazim khanNessuna valutazione finora

- K20 Engine Control Module X2 (Lt1) Document ID# 4739096Documento4 pagineK20 Engine Control Module X2 (Lt1) Document ID# 4739096Data TécnicaNessuna valutazione finora

- 03 - Eletrical Diagram - 01Documento27 pagine03 - Eletrical Diagram - 01Abas AbasariNessuna valutazione finora

- Marine Propulsion and Auxiliary Engines: Recreational ApplicationsDocumento2 pagineMarine Propulsion and Auxiliary Engines: Recreational Applicationsjorge luisNessuna valutazione finora

- Je01 Haynes Jet Engine Uk Manual Lo ResDocumento11 pagineJe01 Haynes Jet Engine Uk Manual Lo ResMauricio SantanaNessuna valutazione finora

- Dynamic Analysis of Valve Train Single Cylinder IC EngineDocumento22 pagineDynamic Analysis of Valve Train Single Cylinder IC EngineHernan SeilikovichNessuna valutazione finora

- Workshop ManualDocumento49 pagineWorkshop ManualSuministros Lago Suministros LagoNessuna valutazione finora

- MR2 Supercharger SC12/S14Documento16 pagineMR2 Supercharger SC12/S14Roland AchaiNessuna valutazione finora

- Volvo Penta D3 Workshop ManualDocumento186 pagineVolvo Penta D3 Workshop Manualm.kelleci724890% (67)

- C) There Is No Mechanical Connection With The CompressorDocumento10 pagineC) There Is No Mechanical Connection With The CompressorMc FridonNessuna valutazione finora

- ZJ Trans&XferDocumento356 pagineZJ Trans&Xferoğuzhan_tekceNessuna valutazione finora

- TATT 100Level1Manual3 15 PDFDocumento670 pagineTATT 100Level1Manual3 15 PDFFauziah67% (3)

- Mitsubishi Motor 1.5,11B 2007-2017 InglesDocumento51 pagineMitsubishi Motor 1.5,11B 2007-2017 InglesmanualNessuna valutazione finora

- MDKDP DR DV Parts ManualDocumento94 pagineMDKDP DR DV Parts ManualDave TrolianNessuna valutazione finora

- Lista Explodida LN48 Port - InglêsDocumento10 pagineLista Explodida LN48 Port - InglêsYgor Santos SCTNessuna valutazione finora

- Fact Sheet: Engine D13K500, EU6SCRDocumento3 pagineFact Sheet: Engine D13K500, EU6SCRfrank mutale100% (1)

- TM9-729 Light Tank M24Documento420 pagineTM9-729 Light Tank M24dieudecafeNessuna valutazione finora

- Axial Piston Pump 1Documento16 pagineAxial Piston Pump 1MohamedSalahNessuna valutazione finora

- Technical Specifications 2004 Audi A4 1.8T Sedan: EngineDocumento28 pagineTechnical Specifications 2004 Audi A4 1.8T Sedan: EngineEsther KoltermanNessuna valutazione finora

- DAEWOO DTCDocumento8 pagineDAEWOO DTCMinh HangNessuna valutazione finora

- Front Wheel Assy. DrumDocumento2 pagineFront Wheel Assy. DrumSoroj BiswasNessuna valutazione finora

- L-1363J - Corrected 20210420Documento77 pagineL-1363J - Corrected 20210420Juan TapiaNessuna valutazione finora

- 5 - Manual Trans Removal PDFDocumento3 pagine5 - Manual Trans Removal PDFEduardo SantosNessuna valutazione finora

- Sis 2.0Documento2 pagineSis 2.0danielNessuna valutazione finora