Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ta Ha - Presentation - HRW

Caricato da

hoabien82Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ta Ha - Presentation - HRW

Caricato da

hoabien82Copyright:

Formati disponibili

GII PHP X L M CHUYN NGHIP H THNG TIT KIM NNG LUNG HIU QU

Distributed by

Global Network

Distributed by

HEAD OFFICE & PLANT # 1

PLANT # 2

PLANT # 3

3108-3 Aoyagi, Koga City, Fukuoka, 811-3134 JAPAN

3172-15 Aoyagi, Koga City, Fukuoka, 811-3134 JAPAN

3172-11 Aoyagi, Koga City, Fukuoka, 811-3134 JAPAN

The Subsidiary Companies

SEIBU GIKEN DST AB SEIBU GIKEN AMERICA, , Inc. SEIBU GIKEN (Changshu) Co., Ltd.

Avestagatan 33 /163-53, Spnga, SWEDEN

2929 Park Drive West,Owatonna, MN 55060, U.S.A.

8th Jin Lin Road, Changshu Southeast Development Zone, Jiahgsu 21500, P.R CHINA

Distributed by

I. Function of HI PANEX ION

The separator divides the rotor into the exhaust (RA-EA) and the supply (OA-SA) zones. Almost all the total heat passing through the exhaust zone is absorbed into the rotor element Th t the That th function f ti of f this thi heat h t exchanger h is i to t supply l the th fresh f h air i after ft bringing b i i it close to the room air condition when there is a difference in temperature and/or humidity, and thus save energy.

Distributed by

II. ION POWER TOTAL HEAT EXCHANGER

2.1. Structual Model of Ion Exchange Resin (IER)

Distributed by

2.2. Excellent Effect in Odor Transfer Prevention As adsorbent for latent heat (moisture) exchange, ion exchange resin, which adsorbs little odor, has been adopted for the first time in the world. Odor transfer and accumulation is extremely little compared with a former type using silica gel gel.

Distributed by

IER, unlike silica gel or molecular sieves, does not have pores and yet has internal storage capacity. This resin is similar to materials that have been used in reverse osmosis water treatment plants for years. Water vapor is selectively attracted to and held to the resin surface by ionic bonds at multiple sites of either +/- or-/+ orientation. Ion exchange resin has no micropore in the dried condition, and gaps filled with water grow when the resin adsorbs humidity, but these is no space capable of adsorbing compounds other than water vapor Osmotic pressure (similar to partial vapor pressure differential) draws the water t molecule l l th through h th the membrane b lik like surface f of f the th IER. IER Other Oth molecules of a larger kinetic diameter are blocked and not internally adsorbed.

Distributed by

2.3. Odor Transfer Comparision Graph

2.4. Comparision With Various Desiccant

Distributed by

III. ADVANTAGES AND SPECIAL FEATURES

1. New HI-PANEX has achieved thorough improvement of IAQ (inner air quality) by using ion power and anti-germ / mold-proof agent together 2 Best solution for cross contamination 2. contamination. 3. No air leakage 4. Excellent energy saving effect especially for long summer/winter season areas 5 More 5. M value-added l dd d f features t 6. Easy retrofits and replacements due to our rotor construction 7. Certified by Eurovent and AHRI*

Distributed by

IV. Characteristics & Application of HI-PANEX-ION

4.1 Characteristics 1. High efficiency & big energy conservation (Sensible & Latent heat) 2. The total manfacturing process from corrugating g g materials to assembling g the unit is made at our factory (Japan - G7) 3. Smooth rotor surface finished by our original polishing machines. 4. Meet any requirements from customers with many options of basic materials & rotor size 5 Excellent corrosion resistance 5. 6. Washable rotor, simple & easy maintenance 7. Easy connection & assembling even for the large type cassette. cassette 8. Prevention of ammonia gas transfer

10

Distributed by

4.2 Application 1. Production and preservation for Pharmaceuticals, Foods, Chemical industries. 2. Quality control, production improvement for Pharmaceuticals, Chemical fertilizers and Food processing industries using hygroscopic materials. 3. Anti-bacteria, Dehumidification and p prevention of condensation for the p power stations, Chemical plants, ships and Precision industries. 4. Maintenance for Thermal power stations, Water power stations and Large turbines in Chemical plants. 5. Anti-corrosion for the storage in the ship. Dehumidification for Warehouses and Vessels. 6 Air conditioning 6. conditioning, humidity control for Clean room room, Environmental test room room, 7. Museum and Gallery. 8. Anti- corrosion, prevention of condensation and preservation at low humidity area for Space defensive apparatus apparatus, Tank Tank, Aircraft, Aircraft Missile and control equipment for Rocket. 9. Prevention of condensation & mold by Comfortable air conditioning (RH 50% or less), ) reduction of f maintenance cost and improvement of f IAQ Q (in-door ( air quality for in-door pool and lobby in the Hotel.

11

Distributed by

Thank you for your attention!

You are also welcome to visit us at: www taha com vn www.taha.com.vn

CTY TNHH TA HA

HUMIDITY CONTROL SOLUTION SUPPLIER

Address Email Website

: 416 Nguyen Kiem St., Ward 3, Phu Nhuan Dist., Ho Chi Minh City, Vietnam. : info@taha.com.vn : www.taha.com.vn

12

Distributed by

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 1Documento6 pagine1Jake ArbutanteNessuna valutazione finora

- Color Matching CardsDocumento2 pagineColor Matching Cardshoabien82Nessuna valutazione finora

- Christmas Puzzles: Extra ChallengesDocumento11 pagineChristmas Puzzles: Extra Challengeshoabien82Nessuna valutazione finora

- 05-A Detailed Energy Audit For A Commercial Office BLDG in HKDocumento5 pagine05-A Detailed Energy Audit For A Commercial Office BLDG in HKhoabien82Nessuna valutazione finora

- BH6 BirthdayGuide BannerDocumento15 pagineBH6 BirthdayGuide Bannerhoabien82Nessuna valutazione finora

- PSB Good Practice GuideDocumento42 paginePSB Good Practice GuideLoter BelautNessuna valutazione finora

- Chiller CompressorsDocumento41 pagineChiller Compressorsdennrich100% (2)

- 12 Psychrometry, Evaporative Cooling and Solid DryingDocumento6 pagine12 Psychrometry, Evaporative Cooling and Solid Dryinghoabien82Nessuna valutazione finora

- Commercial GeoThermal Is Heating UpDocumento6 pagineCommercial GeoThermal Is Heating UpmajortayNessuna valutazione finora

- Cty TNHH Ta Ha - VietNamDocumento4 pagineCty TNHH Ta Ha - VietNamhoabien82Nessuna valutazione finora

- Balancing of A Water and Air SystemsDocumento114 pagineBalancing of A Water and Air SystemselconhnNessuna valutazione finora

- MLL ScienceDocumento229 pagineMLL ScienceGouri RajNessuna valutazione finora

- Polymer Chemistry: Stimuli-Responsive Polymers and Their ApplicationsDocumento17 paginePolymer Chemistry: Stimuli-Responsive Polymers and Their ApplicationsPhạm PhúNessuna valutazione finora

- Report On Review of Gas Treatment Technologies: Research and Innovation Action (RIA)Documento68 pagineReport On Review of Gas Treatment Technologies: Research and Innovation Action (RIA)Qasim ShahzadNessuna valutazione finora

- Formula RioDocumento11 pagineFormula RioMoad BouzidaNessuna valutazione finora

- Further Development of Plasma SourcesDocumento4 pagineFurther Development of Plasma SourcesMisgatesNessuna valutazione finora

- Filtro SecadorDocumento10 pagineFiltro SecadorGuilherme GomesNessuna valutazione finora

- Crystallinity Appnote T14912504Documento2 pagineCrystallinity Appnote T14912504jesrcontreras1976Nessuna valutazione finora

- 5991-5857 Agilent MS Theory enDocumento43 pagine5991-5857 Agilent MS Theory enAngel GarciaNessuna valutazione finora

- SIP-PST Go Dolor Doroteo Rubis Treno FInal PaperDocumento21 pagineSIP-PST Go Dolor Doroteo Rubis Treno FInal PaperDrew DoroteoNessuna valutazione finora

- CHEM 1405 Practice Exam 2Documento7 pagineCHEM 1405 Practice Exam 2Rebecka BarryNessuna valutazione finora

- Psychrometric ChartDocumento16 paginePsychrometric ChartKhalid ChrisNessuna valutazione finora

- Drying Problem SetDocumento1 paginaDrying Problem SetCaryl Faith GadianNessuna valutazione finora

- The Consep AcaciaDocumento7 pagineThe Consep AcaciaPrincess Ruwarashe Courteney MunyoroNessuna valutazione finora

- Glycerol Based Polyurethane: KeywordsDocumento4 pagineGlycerol Based Polyurethane: Keywordsمحمد عزتNessuna valutazione finora

- COOLING TOWER With Solved Problems PDFDocumento6 pagineCOOLING TOWER With Solved Problems PDFjay TanshiNessuna valutazione finora

- Aatcc 81 (Actualizada-2022)Documento2 pagineAatcc 81 (Actualizada-2022)DIEGONessuna valutazione finora

- CHS 3531Documento47 pagineCHS 3531N.RHILWANANessuna valutazione finora

- AITS 2122 FT VIII JEEM SolDocumento16 pagineAITS 2122 FT VIII JEEM SolSreejay BommineniNessuna valutazione finora

- A Review of Microfiber and Nanofiber Based Optical Sensors PDFDocumento26 pagineA Review of Microfiber and Nanofiber Based Optical Sensors PDFliton_kabirNessuna valutazione finora

- DOW Technical - Tablet - Coating PDFDocumento11 pagineDOW Technical - Tablet - Coating PDFethylenepluschlorineNessuna valutazione finora

- FC Questions On Magnetic Materials and Its ClassificationsDocumento13 pagineFC Questions On Magnetic Materials and Its ClassificationsDawa PenjorNessuna valutazione finora

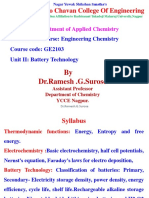

- Unit-2 Battery TechnologyDocumento47 pagineUnit-2 Battery TechnologyYash WaghmareNessuna valutazione finora

- Thermo LQ3Documento2 pagineThermo LQ3Su-ho HanNessuna valutazione finora

- LeaP Science G8 Week 3 Q3Documento4 pagineLeaP Science G8 Week 3 Q3Hydeelyn BringasNessuna valutazione finora

- Atoms Molecules and IonsDocumento3 pagineAtoms Molecules and Ionsapi-304350501Nessuna valutazione finora

- Redox Reaction - Practice SheetDocumento19 pagineRedox Reaction - Practice Sheetroopalshah73Nessuna valutazione finora

- AS (AQA 7407) Physics: Paper 1A - Particles, Waves & OpticsDocumento18 pagineAS (AQA 7407) Physics: Paper 1A - Particles, Waves & Opticsprithu shandilyaNessuna valutazione finora

- EjercicioDocumento1 paginaEjercicioRamiro PintoNessuna valutazione finora

- Flares CalculationsDocumento14 pagineFlares CalculationsAnonymous oVRvsdWzfBNessuna valutazione finora