Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Document

Caricato da

ice_PL0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

37 visualizzazioni12 paginesdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentosdf

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

37 visualizzazioni12 pagineDocument

Caricato da

ice_PLsdf

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 12

Todd Gooding

Business Development Manager

The Well Commander

Mitigate drilling hazards with the industrys most versatile

drilling valve

A COMPLETE redesign of the ball-activated Centurion

Circulating Valve (CCV): greatly improved reliability and

increased applicability

A drilling specialists ideal tool for mitigating drilling hazards

It is a drilling valve for use in operations that may encounter lost circulation, wellbore

instability or hole-cleaning challenges.

- 5-in., 7-in., 8 -in. and limited 9 -in. OD sizes to cover every hole size

- Short one-piece body with no internal threads (no bucking machine needed)

- Features an oil-filled chamber with a floating piston that isolates the tool-

activation mechanism from drilling fluids and debris

WELL COMMANDER

A drilling valve that is activated via steel ball, offering a

variety of options to the operator:

Reduced pressure drop allows greatly increased pump rates to aid cuttings-beds

removal with higher fluid-flow velocities

Coarse lost-circulation or wellbore-strengthening materials can bypass sensitive

downhole drilling tools and be easily placed in the loss zone

Kill-weight fluid can be pumped in underbalanced or managed-pressure drilling

applications before initiating a trip

Excellent for hole cleaning during underreaming, hole-opening, or coring operations

The tool can condition fluid at high flow rates in any drilling or displacement string

Helps fill or drain the drillstring during trips to control surge and swab pressures and to

enhance tripping operations by minimizing fluid discharge

Often referred to as a Drilling By-Pass Sub Valve or

Circulating Valve

WELL COMMANDER

WELL COMMANDER Primary Applications & Rig Time Savers

Other Applications

Displacements and cleanouts

Conditioning fluids

Specialized coring techniques

Spotting LCM

Eliminate trips for redress or open ended drillpipe

Medium- and coarse-LCM compatible

Boosting Annular Velocity

Cuttings and debris removal for enhanced hole

cleaning, especially in ERD wells

Higher flow rates above BHA restrictions

Underreaming / milling operations

Riser/BOP Washing

Through-bore maintained >

Tandem run options >

Free-point access >

Tripping Dry Pipe

The automatic locking mechanism gives

enhanced options for improved pipe drainage or

filling, especially with small pipe or restrictive

BHAs

WELL COMMANDER - Improved Technical Limits

See animation

WELL COMMANDER - Open and close sequence

Main body

Proprietary

upper ball seat

WELL COMMANDER Utilizing Shut off Ball

Main body

Lower ball seat

Bypass Ball Catcher

All Well Commander balls are collected in the ball catcher

Through-bore maintained

Access below the tool for smaller-ball-activated tools

Option to activate tools independently

Select wireline access below Well Commander

Note: accessibility may depend on wireline tool

dimensions and number of balls in the ball catcher

Ball Catcher Technology

WELL COMMANDER ByPass Ball Catcher

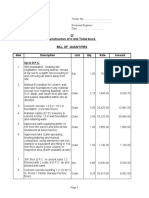

WELL COMMANDER Technical Data

WELL COMMANDER (size in.) 9 8 7 5

Material AISI 4145 AISI 4145 AISI 4145 AISI 4145

OD (in.) 9.50 8.25 7.00 5.00

Min ID Lower ball seat 2,40 2.40 1.985 1.610

Length (ft) 18.2 18.1

13.7

(incl. catcher)

11.8

(incl. catcher)

Number of circulating ports (in. x in.) 5 5 5 (1.35 x 0.65) 5 (1.10 x 0.50)

Total circulating area through ports (TFA) 6.43 sq. in. 6.43 sq. in. 3.93 sq. in 2.48 sq. in.

Max circ rates (closed/open)

1344/1680

gpm

1344/1680

gpm

840/1050

gpm

672/840

gpm

Opening/closing pressure

(Operating and shut-off balls)

1,600psi (+/-20%)

And 800 max

1,600psi

(+/-20%)

And 800 max

2,000psi (+/-20%)

And 650 max

2,000psi

(+/-20%) and

430 max

Cycles (ball capacity of catcher)

7 (14) 7 (14) 7 (14) 7 (14)

O.D. Opening / Closing Ball (in.) 2.500 2.500 2.125 (2 1/8) 1.760

O.D. BHA Shut-off Ball (in.) 2.430 2.430 2.063

1.698 (shot

blasted)

Connection, Up standard tool (in.) 7-5/8 REG Box 6-5/8 REG Box

4 IF Box

(XT57 also)

3 IF Box

(NC38)

Connection, Down (in.) 7-5/8 REG Pin 6-5/8 REG Pin

4 IF Pin

(XT57 also)

3 IF Pin

(NC38)

Well Commander enhancements over other multi-activation

circulating tools and bypass systems

Shorter one-piece body with no internal threads

Activation sleeve housed in protected oil-filled chamber as a barrier against debris in

solids-laden fluids

Floating piston fitted to compensate hydrostatic pressures experienced downhole

Improved exit-port design reduces erosion potential on the main body of the tool

Rotational motion of the activation sleeve reduces friction and allows smoother

operation

Can be fitted with jets to enhance washing

WELL COMMANDER Enhancements

Questions?

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- (Ulf Langefors) The Modern Technique of Rock Blast (B-Ok - CC) PDFDocumento440 pagine(Ulf Langefors) The Modern Technique of Rock Blast (B-Ok - CC) PDFkike100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- PPC Product SheetDocumento18 paginePPC Product SheetSantanu LayekNessuna valutazione finora

- MINE5008 Responsible Mining Semester 1 2023 Kalgoorlie CampusDocumento13 pagineMINE5008 Responsible Mining Semester 1 2023 Kalgoorlie Campusice_PLNessuna valutazione finora

- Stuck Pipe PreventionDocumento64 pagineStuck Pipe PreventionmmbatainehNessuna valutazione finora

- ASME Paper by Sparks - The Influence of Tension, Pressure & WeightDocumento9 pagineASME Paper by Sparks - The Influence of Tension, Pressure & Weightice_PLNessuna valutazione finora

- Mathcad FunctionsDocumento3 pagineMathcad FunctionsAzwan MahmudNessuna valutazione finora

- MINE5009 Mining Methods and Processes Semester 1 2023 Kalgoorlie Campus FODocumento14 pagineMINE5009 Mining Methods and Processes Semester 1 2023 Kalgoorlie Campus FOice_PLNessuna valutazione finora

- SM SeriesDocumento36 pagineSM SeriesGiorgiana RosuNessuna valutazione finora

- Holliday Steam Well DesignDocumento8 pagineHolliday Steam Well Designice_PLNessuna valutazione finora

- Doris: Dropped Objects Register of Incidents & StatisticsDocumento15 pagineDoris: Dropped Objects Register of Incidents & Statisticsice_PLNessuna valutazione finora

- Introduction Rev1Documento22 pagineIntroduction Rev1ice_PLNessuna valutazione finora

- Deformation of Drill Pipe Held in Rotary SlipsDocumento20 pagineDeformation of Drill Pipe Held in Rotary Slipsice_PL100% (1)

- Halliburton Packer Information PDFDocumento76 pagineHalliburton Packer Information PDFrlk2806100% (4)

- History of OCTGDocumento7 pagineHistory of OCTGice_PLNessuna valutazione finora

- Well Commanddfsder HollandDocumento2 pagineWell Commanddfsder Hollandice_PLNessuna valutazione finora

- Arc VISIONDocumento4 pagineArc VISIONBASNessuna valutazione finora

- IntroductionDocumento10 pagineIntroductionice_PLNessuna valutazione finora

- ImpulseDocumento2 pagineImpulseice_PLNessuna valutazione finora

- Hydra Jar ProceduresDocumento3 pagineHydra Jar Proceduresice_PLNessuna valutazione finora

- Hole Cleaning Pipe RotationDocumento8 pagineHole Cleaning Pipe Rotationice_PLNessuna valutazione finora

- Well CommanderDocumento8 pagineWell Commanderice_PLNessuna valutazione finora

- Hydra Jar Accelerator AP CsDocumento1 paginaHydra Jar Accelerator AP Csice_PLNessuna valutazione finora

- Powerdrive x6Documento7 paginePowerdrive x6ice_PLNessuna valutazione finora

- Hydra JarDocumento4 pagineHydra Jarice_PLNessuna valutazione finora

- Powerpak HandbookDocumento0 paginePowerpak HandbookPehr HedströmNessuna valutazione finora

- Schlumberger Log Interpretation ChartsDocumento287 pagineSchlumberger Log Interpretation Chartsice_PL100% (10)

- Powerpak HandbookDocumento0 paginePowerpak HandbookPehr HedströmNessuna valutazione finora

- UsingDocumento16 pagineUsingガンディー サガールNessuna valutazione finora

- SLB PosterDocumento3 pagineSLB Posterice_PL100% (2)

- BBCVDocumento6 pagineBBCVSanthosh PgNessuna valutazione finora

- R 18 Model B Installation of TC Auxiliary Lights and WingletsDocumento29 pagineR 18 Model B Installation of TC Auxiliary Lights and WingletsAlejandro RodríguezNessuna valutazione finora

- Cencon Atm Security Lock Installation InstructionsDocumento24 pagineCencon Atm Security Lock Installation InstructionsbiggusxNessuna valutazione finora

- WVU's Response Letter To Campbell Regarding HugginsDocumento4 pagineWVU's Response Letter To Campbell Regarding HugginsJosh JarnaginNessuna valutazione finora

- S200 For Sumber RezekiDocumento2 pagineS200 For Sumber RezekiIfan JayusdianNessuna valutazione finora

- Change Language DynamicallyDocumento3 pagineChange Language DynamicallySinan YıldızNessuna valutazione finora

- Chapter 1 Hospital and Clinical Pharmacy Choplete PDF Notes D.Pharma 2nd Notes PDF NoteskartsDocumento7 pagineChapter 1 Hospital and Clinical Pharmacy Choplete PDF Notes D.Pharma 2nd Notes PDF NoteskartsDrx Brajendra LodhiNessuna valutazione finora

- Faculty of Business and Law Assignment Brief Mode E and R RegulationsDocumento4 pagineFaculty of Business and Law Assignment Brief Mode E and R RegulationsSyeda Sana Batool RizviNessuna valutazione finora

- Oasis 360 Overview 0710Documento21 pagineOasis 360 Overview 0710mychar600% (1)

- Rhino HammerDocumento4 pagineRhino HammerMichael BNessuna valutazione finora

- Company Law Handout 3Documento10 pagineCompany Law Handout 3nicoleclleeNessuna valutazione finora

- 14 CE Chapter 14 - Developing Pricing StrategiesDocumento34 pagine14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalNessuna valutazione finora

- To Syed Ubed - For UpdationDocumento1 paginaTo Syed Ubed - For Updationshrikanth5singhNessuna valutazione finora

- Usha Unit 1 GuideDocumento2 pagineUsha Unit 1 Guideapi-348847924Nessuna valutazione finora

- Marketing Management - Pgpmi - Class 12Documento44 pagineMarketing Management - Pgpmi - Class 12Sivapriya KrishnanNessuna valutazione finora

- Safety Inspection Checklist Project: Location: Inspector: DateDocumento2 pagineSafety Inspection Checklist Project: Location: Inspector: Dateyono DaryonoNessuna valutazione finora

- Theories of Economic Growth ReportDocumento5 pagineTheories of Economic Growth ReportAubry BautistaNessuna valutazione finora

- Journalism Cover Letter TemplateDocumento6 pagineJournalism Cover Letter Templateafaydebwo100% (2)

- bz4x EbrochureDocumento21 paginebz4x EbrochureoswaldcameronNessuna valutazione finora

- Emco - Unimat 3 - Unimat 4 LathesDocumento23 pagineEmco - Unimat 3 - Unimat 4 LathesEnrique LueraNessuna valutazione finora

- Admission Notice: Weekend Masters Program (WMES)Documento4 pagineAdmission Notice: Weekend Masters Program (WMES)masud100% (1)

- Tech Mahindra Sample Verbal Ability Placement Paper Level1Documento11 pagineTech Mahindra Sample Verbal Ability Placement Paper Level1Madhav MaddyNessuna valutazione finora

- Mutual Fund Insight Nov 2022Documento214 pagineMutual Fund Insight Nov 2022Sonic LabelsNessuna valutazione finora

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Documento6 pagineType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNessuna valutazione finora

- Triplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionDocumento2 pagineTriplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionMaz Ariez EkaNessuna valutazione finora

- DevelopersDocumento88 pagineDevelopersdiegoesNessuna valutazione finora

- Chapter03 - How To Retrieve Data From A Single TableDocumento35 pagineChapter03 - How To Retrieve Data From A Single TableGML KillNessuna valutazione finora

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Documento3 pagineEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandNessuna valutazione finora

- Musings On A Rodin CoilDocumento2 pagineMusings On A Rodin CoilWFSCAO100% (1)

- Best Practices in Developing High PotentialsDocumento9 pagineBest Practices in Developing High PotentialsSuresh ShetyeNessuna valutazione finora