Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Perception of IBS in Malaysian Construction Market

Caricato da

Amirah AqilahDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Perception of IBS in Malaysian Construction Market

Caricato da

Amirah AqilahCopyright:

Formati disponibili

ICCBT2008

Perception of Industrialized Building System (IBS) Within the Malaysian Market

A. Idrus*, Universiti Teknologi Petronas, MALAYSIA N. F. K. Hui, Universiti Teknologi Petronas, MALAYSIA C. Utomo, Universiti Teknologi Petronas, MALAYSIA

ABSTRACT The Industrialized Building Systems (IBS) has the known theoretical advantages of speed, safety and quality. However, in Malaysia, wet construction method is still widely accepted as a convention and safe option despite incurring higher cost and slow production rate. The objective of this research is to investigate the underlying reasons for the cold reception and hence for the small market share for industrialized construction in Malaysia (Perak, Penang & Kedah). IBS only accounts for approximately 15% of the market share due to several reasons despite a series of promotion campaign by Construction Industry Development Board (CIDB). Survey research method (SRM) is being implemented in this project. SRM is done through questionnaire and personal interview method. Fabrication of questionnaire consists of close-ended questions and open-ended questions. Systematic random sampling is being selected as this technique spread the sample more evenly over the population and it is easier to conduct than simple random sample. Questionnaire is distributed through snail mail and follow up is done subsequently to maintain a consistent number of feedbacks by the respondents. Feedback is analyzed by implementing descriptive method and then analytical method. It can be observed from the feedback that the major reasons of the cold reception of IBS in Malaysia are failure in the transfer of technology, resistance of industry players to change, conventional system is more open and flexible and IBS generally is more costly than conventional system . Keywords: Perception, IBS, Questionnaire Survey.

*Correspondence Author: Assoc. Prof. Dr. Arazi B Idrus, Universiti Teknologi Petronas, Malaysia. e-mail: arazi_idrus@petronas.com.my

ICCBT 2008 - B - (07) pp75-92

Perception of Industrialized Building System (IBS) Within the Malaysian Market

1.

INTRODUCTION

The government has put plenty of efforts to enhance the current conventional, labor-intensive activities to a more technologically advanced method of construction such as the Industrialised Building Systems (IBS). This is being done so that Malaysia is capable of producing fast and high quality products, and able to compete with the global market. Industrialised Building Systems (IBS) is a construction process that utilizes techniques, products, components, or building systems which involve prefabricated components and onsite installation [1]. IBS promises several advantages over conventional in-situ systems such as reduction of unskilled workers, less wastage of materials which means cost savings, less building materials required, faster and better quality control of construction and increased site cleanliness and safety. With its current levels of quality, productivity and safety, and excessive reliance on unskilled foreign workers, the state of the local construction industry is not in line with future developments planned for Malaysia. Early efforts by the government to promote the usage of IBS as an alternative to the conventional method had not made a headway. Therefore the government, through its agency, the Construction Industry Development Board (CIDB) had redesigned its strategies and, with the guidance from CIDBs IBS Steering Committee had, in 2003, formulated a roadmap based on a 5-M strategy (Manpower, Materials-ComponentsMachines, Management-Processes-Methods, Monetary and Marketing). Its objective is to have an industrialized construction industry for Malaysia and achieving Open Building by the year 2010. Road Map 2003-2010, as it is called [2], evolved on the policy of phased reduction of dependency on foreign labour and encouragement policy on the investment in technologies, techniques and the methodology of construction. According to the Road Map, foreign workers in the construction industry will be decreased to 55% by year 2005, 25% by year 2007 and 15% by year 2010. As an initial pace towards achieving these targets, the CIDB aggressively holds campaigns nationwide to promote the utilization of IBS components and off-site construction. Besides these campaigns, and to further enhance the implementation of IBS utilization, the Government had also formulated a policy requiring a certain minimum percentage of IBS utilization to be satisfied in government building projects. In addition, a 50% minimum implementation of IBS utilization in a project would entitle CIDB levy exemptions. Despite the above campaigns and incentives from the Government, the market share for IBS in 2003 stood only at 15%, and this figure has not changed much since then. The traditional in-situ or the so called Dirty, Difficult and Dangerous method of construction seems to be the preferred choice for most people until today. IBS Survey 2003, and even the more recent IBS Survey 2005 [3], did not specifically address the underlying reasons for the low market share of IBS in this country. This paper aims to investigate the perceptions and subsequently the underlying reasons for the poor reception of Industrialised Building Systems within the Malaysian construction industry.

76

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

2.

METHODOLOGY

2.1 Population and Sample The survey research methodology has been used for this research. The target population consists of contractors, architects, engineers and developers in the Malaysian construction industry. Due to financial and time constraints, a target population of 180 respondents was set, consisting of 90 contractors, 30 developers, 30 architects and 30 engineers. For the same reasons too, the study population was further confined to only the northern states of Peninsular Malaysia, namely, Perak, Penang and Kedah. However, considering the objectives of the research, these states would represent regions away from the influence of the promotional activities of the CIDB central office and also away from the much-concentrated existence of IBS manufacturers in the Klang Valley. This would in fact provide a better picture of the perceptions and the underlying reasons for the cold reception of IBS in Malaysia. . The contractors, architects, engineers and developers were respectively selected from the Contractors Directory in the CIDB website, Architects Directory in the Pertubuhan Arkitek Malaysia (PAM) website, 2006/2007 Consulting Engineers Directory of the Association of Consulting Engineers Malaysia (ACEM) and the Members Directory in the Real Estate and Housing Developers Association (REHDA) website. The number of respondents for each category is evenly distributed according to the respective three states of Perak, Kedah and Penang (each): 30 contractors, 10 architects, 10 engineers and 10 developers. The systematic random sampling technique was used in selecting the samples. Contractors formed the highest percentage in the distribution because they were thought to be the key players in the industry who handle first hand experience with IBS components. To obtain a consistent result of the feedback, a minimum of 30 replies was set for statistical analysis [4]. 2.2 Questionnaire Outline The structured questionnaire format was designed to be simple and which would require minimal filling-in time. A three-point Semantic Differential Scale [5] was used to rate respondents opinions. The questionnaire form consisted of five Sections A, B, C, D and E. The information gathered was as follows: Section A - Company Profile - Position of respondent in the company. - Company address and contact number for reference. - CIDB Registration grade of the company. - Survey on Completed Projects - Number of completed projects by the company concerned. - Number of completed projects utilizing IBS Section B, C & D - Opinion Survey - The perceived benefits of using IBS.

ICCBT 2008 - B - (07) pp75-92

77

Perception of Industrialized Building System (IBS) Within the Malaysian Market

- IBS knowledge of architects, engineers, clients and government (approving) authorities. - Acceptance towards IBS usage by architects, engineers, clients and contractors. - Using IBS in future construction projects. - Making compulsory IBS usage in construction. - Respondents comments on the usage of IBS in construction projects. Section E - Comments and Suggestions -Suggestions for enhancement. 2.3 Facto-face interviews A total of five face-to-face interviews were conducted to selected samples obtained by the systematic random sampling process. Out of these, three were contractors and two engineers. The interviews were meant to complement the results from questionnaire survey. Although basically the interview format was the same as the questionnaire, it also contained additional questions to probe further information regarding the topic, in particular, the underlying reasons for the responses. 2.4 Method of Analysis All data obtained will be analyzed by descriptive and analytical methods. Analytical method will be conducted if the feedback received is high in quantity. Descriptive statistical analysis presents data that have been retrieved into tabular and figure form. Data will be analyzed using the Index Average Method [6] as follows:

Index Average = ( a i xi )

(Eqn. 1)

Where: ai = constant xi = variables representing respondents frequency

3.

RESULTS

3.1 Response Rate (Figure 1) The respondents were given the option of returning the questionnaire forms by mail or fax. A total 35 respondents out of 180 returned the questionnaire. Though only 19.4% of the respondents replied, this low percentage had been expected for a mailed and questionnairebased survey research.

78

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

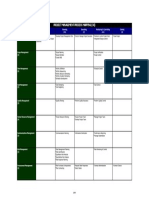

Figure 1. Response Rate 3.2 Respondents Category (Table 1, Figure 2) Of the 35 completed forms, contractors form the highest number of respondents at 15 companies (42.8%), followed by architect firms 10 (28.6%), engineering consultants (consultant) 5 (14.3%) and developers, also 5 (14.3%).

Table 1. Respondents Category

Figure 2. Respondents category 3.3 Contractor Registration Grade (Table 2) From the 15 contractors, 5 contractors are CIDB G7-registered contractors, 2 contractors in CIDB G6-registered category and both 1 contractor in CIDB G3 and G6-registered category respectively. Remaining 6 contractors did not state their CIDB registration grade. With regard to Pusat Khidmat Kontraktor (PKK) classes, 5 contractors were categorized as PKK Class A, 2 contractors in Class C while the remaining did not state their PKK grade at all.

Table 2. Contractor Registration Grade

ICCBT 2008 - B - (07) pp75-92

79

Perception of Industrialized Building System (IBS) Within the Malaysian Market

3.4 Respondent Designation (Table 3, Figure 3) Most (28%) of the respondents came from the top management level, which is good for an opinion-based survey analysis. Consultant architect (2 8%) and project engineer (20%) has the highest percentage among other designations. This is good for an opinion survey analysis as the respondents are more likely to portray the actually company direction as they are directly involved with design and construction of IBS.

Table 3. Respondents Designation

Figure 3. Respondents Designation

3.5 Respondents Experience in Building Construction Industry Most of respondents have good experience in IBS at (69%) whereby they have been in the construction industry ranging from 10 years to 20 years. This is followed by respondents who have more than 20 years experience in construction industry at 16%. This is a good statistical result as respondents whose working experience is at least 10 years have had sufficient knowledge concerning conventional system which has been practiced and they are able to compare the advantages and flaws of both systems. This is good for the opinion based survey.

Table 4. Respondents Experience in Building Construction Industry

Figure 4. Respondents Experience

80

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

3.6 Respondents Knowledge in IBS (Table 5, Figure 5) Most of the respondents (56%) have good knowledge of IBS while 25% of them were reported to be having poor knowledge in IBS. Some 19% of the respondents have excellent knowledge in IBS. A few respondents did not state anything about their IBS knowledge, which could reflect on their unfamiliarity with IBS. With more than 50% of respondents who have at least good knowledge in IBS, we can expect that the results of the feedback or views received would be sufficiently reliable.

Table 5. Respondents Knowledge of IBS

Figure 5. Respondents IBS Knowledge

3.7 Perception of IBS 3.7.1 Advantages of IBS (Table 6, Figure 6) As seen in Figure 6, most of the respondents agreed that IBS enhanced the quality of the finished work of construction (71%). For example, by using the conventional system whereby timber and nails are involved, the probability of the timber bulging is high, causing uneven surface. Also, IBS was perceived to be able to provide cleaner, neater, and safer construction (63%). Less formwork and falsework are used in IBS construction so the method is less hazardous to the workers. IBS proved to be neater as it uses a systematic method, and can be reused for repeated type of construction. Also, 57% of respondents disagreed that IBS is comparatively cheaper than conventional system. This might have occurred due to the low scale of economy often associated with IBS projects. Thus, at the current situation, the cost for IBS construction may he higher than conventional system, causing most industry players to choose conventional method for their projects. 57 % respondents at least agreed that IBS would lead to labour reduction. However, 43% of them felt that by using IBS, labour force still cannot be reduced. This implied that IBS-knowledgeable labour are still very much needed for design, fabrication and installation works. Further, 40% of respondents felt that IBS is not easy to install, indicating insufficient knowledge in IBS design and installation among workers.

ICCBT 2008 - B - (07) pp75-92

81

Perception of Industrialized Building System (IBS) Within the Malaysian Market Table 6. Advantages of IBS

Figure 6. Advantages of IBS

82

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

3.7.2 Problems of IBS in Construction Industry (Table 7, Figure 7) 66% of the respondents, especially from contractors, clarified that they are strongly reluctant and 23% reluctant of using IBS as they resist changing from their conventional system. They have practiced conventional system since at least 10 years ago and IBS is totally new to them. Most of the contractors labourers too, are also unfamiliar with IBS. Malaysian foreign construction labors, especially from Indonesia are generally used to conventional construction system and IBS is also seldom used in these foreign countries. In addition, 63% of respondents strongly agreed and 29% agreed that there is a failure in IBS technology transfer in Malaysia. This may happen due to two reasons; insufficient guidelines and unclear standards. This will be discussed in more detail later. However, 49% of respondents denied that there are insufficient IBS knowledgeable personnel in Malaysian industry; simply means that there are Malaysian construction industry players with IBS knowledge but due to other reasons, IBS is not being widely used. Also, 54% of respondents at least agreed that there are insufficient manufacturers in Malaysia. This complements the fact that there are only 3 IBS manufacturers in Northern Malaysia.

Table 7. Problems of IBS in Construction Industry

ICCBT 2008 - B - (07) pp75-92

83

Perception of Industrialized Building System (IBS) Within the Malaysian Market

Figure 7. Problems of IBS in Construction Industry

3.7.3 Perception of Conventional Construction (Table 7, Figure 8) Generally, 57% of the respondents agreed that for the current situation of construction industry in Malaysia, using the conventional system is comparatively cheap compared to IBS system. This might be because of the low scale of economy often associated with IBS as mentioned earlier. The number of projects in Malaysia utilizing IBS is generally low and therefore, the market demand for IBS manufacturers and IBS usage is low as well, thus giving rise to the high cost. In addition, 44% strongly agreed that they preferred conventional system than IBS because they found that conventional system is more open and flexible. An open or flexible system would be easier to implement since mostly timber, steel bar and nails only are required for construction. These items does not need to be custom-fabricated and can be fabricated on site. However, majority (89%) of respondents, especially from the contractors, strongly disagreed that conventional method is cleaner, safer and neater. In fact, 74% of respondents did not think that conventional systems will decrease labor, compared with 43% in the case of IBS (Figure 6).

84

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

Table 8. Perception on Conventional Construction

Figure 8. Perception on Conventional Construction

ICCBT 2008 - B - (07) pp75-92

85

Perception of Industrialized Building System (IBS) Within the Malaysian Market

3.8 Acceptance Towards IBS (Table 9, Table 10) Most respondents were of the opinion that the general acceptance towards IBS usage in Malaysia is currently good, despite the fact that IBS only holds about 15% share of the construction market. They also felt that the current available IBS technology in Malaysia is generally good.

Table 9. Acceptance Towards IBS Usage in

Table 10. Current Available IBS Technology in Malaysia

3.9 CIDB Promotion and Involvement (Table 11, Figure 9, Table 12) 55% of the respondents clarified that the promotional campaign and seminars done by CIDB is ineffective. According to some of the reasons given, seminars carried out by CIDB annually are also insufficient in numbers. 45% of them, however, thought that the campaign is good. Perhaps these companies are situated at a more urban area whereby the effectiveness of the campaign is higher. Table 11. CIDB Promotion

Figure 9. CIDB Promotion

Majority (61%) of respondents thought that the incentive provided by the government, especially through the CIDB, is poor. Incentive in the sense of monetary, machineries, man power, promotion and material provided by the government have not reached up to the expectation of the Malaysian construction industry players to implement IBS.

86

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al. Table 12. CIDB Involvement

Figure 10. CIDB Involvement 3.10 Suggestions and Comments on the Usage of IBS in Malaysia (Table 13, Figure 11)

From the survey, 28 respondents (80%) strongly agreed and 7 respondents (20%) agreed that more workers should be trained with IBS knowledge. The rationale behind this opinion might be based on the fact that despite the IBS technology having been around in Malaysia a long time ago, there is still an acute shortage of personnel and workers trained in IBS as such it is difficult to implemented the technology well. In addition, 26 (74%) respondents strongly suggested and 9 respondents (24%) suggested that government bodies should promote the setting up of more new IBS factories through technology transfer. This will not only ensure capacity of the industry to provide consistent supply of IBS products but also indirectly avoid monopoly by existing IBS manufacturers in Malaysia, which currently have only a very small population. Monopoly of IBS business is one of the factors responsible for the high cost of IBS products in Malaysia. The results also show that 25 respondents (71%) firmly suggested and 10 (29%) agreed that CIDB with collaboration with the Board of Architects Malaysia (BAM) and Board of Engineer Malaysia (BEM) to encourage designers to design using IBS. However, more than half of total respondents, at 27 respondents (77%) strongly opposed that IBS should be made compulsory in Malaysia. None agreed that to make IBS compulsory in Malaysian construction project. Obviously, all construction parties disagree to make IBS compulsory so as they might be able to have a variety of choice to decide, on which will be more economical and beneficial for respective project. In addition, almost half (17 or 49%) of respondents strongly disagreed on making compulsory for architects to design in accordance with modular coordination. Most of the respondents, particularly architects, personally thought that architectural designs are not the prime solution to solve low reception of IBS in Malaysia; other major reasons should be considered instead. Also, the respondents called for more effective seminars and promotional campaigns to be carried out. They also wanted more incentives from the government through relevant bodies. Generally, the respondents also agreed that more Research and Development (R&D) centre should be formed specifically to enhance IBS technology in Malaysia so that standardization of IBS components can be effectively carried out. Proof of cost and time savings by using IBS should be researched and published publicly so that more parties will get to know the benefits of IBS better.

ICCBT 2008 - B - (07) pp75-92

87

Perception of Industrialized Building System (IBS) Within the Malaysian Market

Table 13. Suggestion and Comments on the Usage of IBS in Malaysia

88

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

Figure 11. Suggestion and Comments on the Usage of IBS in Malaysia

3.11

IBS Prospect in Future Projects (Table 14, Figure 12)

Referring to Figure 12, sadly more than half of the respondents (18 or 51%) suggested that they will not recommend their respective companies to implement IBS in their next project. Only a minority (8 or 23%) supported the usage of IBS in their next project. Only this group of people believed that IBS has the potential to be a trustable system at least for short term. Whereby 9 respondents (26%) had no opinion at all on whether they will suggest their companies to implement IBS. This might happen as they were still unsure of the usage of IBS in their projects.

Table 14. IBS Prospect in the Future Project

Figure 12. Willingness to recommend the implementation of IBS for next project

ICCBT 2008 - B - (07) pp75-92

89

Perception of Industrialized Building System (IBS) Within the Malaysian Market

4.

DISCUSSION AND LIMITATIONS OF RESEARCH

4.1 Discussion During the interviews, the author has gathered beneficial information concerning the IBS and also general overview of the current situation in Malaysia. The number of IBS manufacturers in Malaysia are comparatively low, recording only 50 companies registered in Malaysia, with only three companies operating in the northern states of Malaysia at present, all three situated in Perak. According to some respondents, not more than 50 high-rise housing projects throughout Malaysia have implemented IBS. Perhaps IBS has not fully recovered from the stigma of low- cost and leaking image often associated with the system in the past but the main reason that consultants, contractors, developers and especially clients still prefer conventional construction is because of the relatively cheap and abundant supply of foreign labour from neighbouring Indonesia, Myanmar, Vietnam and the sub-coentinent. The rate of labour in Malaysia is cheap compared with, for example, Finland in which the rate of labour is ten time higher [7]. Besides, implementing IBS at this stage where there is no scale of economy would be very expensive for contractors, especially those from the lower classes, as they do not have sufficient capital funding to afford IBS. Besides, due to failures of the closed system in the past, they do not want to risk their respective companies by implementing a comparatively new system especially when they are still unfamiliar with the systems. Furthermore, the failure of technology transfer also results in the low reception of IBS in the Malaysian Market. For instance, before the proper guidelines laid down by CIDB, there was no standards for contractors or consultants to follow and abide. Also, contributing to this scenario is poor industry practice which includes poor planning and manufacturer driven. As one assistant director of Jabatan Kerja Raya (JKR) Perak commented, IBS is not favorable for the current industry because of the new technology implied. Contractors inclusive of engineers and technical personnel do not possess adequate knowledge of the technology, especially at the critical jointing area between precast units where leakages often occur if not installed with the right method, such as in the bathroom area whereby the joint must be properly sealed and waterproof. Most contractors are still practicing conventional construction because they have been used to the system before the introduction of IBS. They resist IBS and cannot adapt themselves to the new technology as they do not possess the required knowledge. CIDB has sponsored and conducted several seminars concerning IBS throughout the year. However, the seminar has not received positive feedback from consultants, contractors and engineer. Besides, CIDB only organizes IBS seminar about once a year which, to many respondents, is inadequate. Although ideally, a survey covering the whole of Malaysia including Sabah and Sarawak, due to time and financial constraints, the study had to be based on a survey population covering the northern states of Perak, Kedah and Penang only. Nevertheless, considering the objectives of the research, this region would represent regions away (but not too far away) from the influence of the promotional activities of the CIDB central office and also away from the more-concentrated existence of IBS manufacturers in the Klang Valley. As a blessing in

90

ICCBT 2008 - B - (07) pp75-92

A.Idrus et. al.

disguise, this region would in fact do provide an averaged or moderated picture of the perceptions of IBS for the whole of Malaysia. Out of the 180 questionnaires sent, 35 were returned representing a response rate of about 19 %. This is considered very good bearing in mind the typically response rate by the Malaysian construction industry is only between 5-15% (compare for example IBS Survey 2003 = 4.4%, IBS Survey 2005 = 6.6%). After the survey programme, a check on the causes of nonresponses revealed that this was caused by one of the following reasons: change of correspondent address, lack of resources, lack of interest, and policy of company not to participate in surveys. Non-response such as this would, however, not hamper the outcome of the survey. Rather, it does imply that those responses received and analysed are of intrinsic interest, coming from a cross-section of willing participants.

5.

CONCLUSION

A research survey has been conducted to investigate the perceptions of Industrialized Building Systems (IBS) and the underlying reasons for the current poor reception of the system in the Malaysian construction industry. Based on the survey conducted, the following conclusions can be made: 1) Industrialised Building System (IBS) in Malaysia is perceived to be a system of construction which can offer benefits of speed, quality and safety to construction projects. IBS in Malaysia is also perceived to have a good technology. IBS, however, is not perceived to be a system which can provide cost reduction compared with traditional in-situ construction. In fact, IBS project proposals are often rejected solely on the basi s of cost. There is a strong indication that many in the industry are reluctant to switch to the IBS method of construction. Consequently, many will not recommend the use of IBS in their future projects. The underlying reasons for the cold reception of IBS are as follows: (a) The perception of the high cost of IBS as in (2) above. The high cost is believed to be due to lack of economy of scale in IBS projects and business monopoly by the small number of IBS producers in Malaysia (b) The perception of a state of failure in IBS technology transfer. A large faction of the industry feels that the technology transfer in IBS is a failure. They claim that there are insufficient IBS guidelines and unclear standards for IBS. (c) Resistance to change It is human nature to resist change from the more familiar to the less familiar (IBS) method of working. (d) Conventional in-situ system is still attractive. Industry professionals are still confident with the conventional in-situ system, which has been proven to be a relatively cheap, open, flexible and reliable method of construction.

ICCBT 2008 - B - (07) pp75-92 91

2)

3)

4)

Perception of Industrialized Building System (IBS) Within the Malaysian Market

5)

More people in the industry are of the opinion that the present promotional campaigns and seminars organized by the CIDB are ineffective or poor. A large faction of the industry feels that the present incentives given by the government to promote IBS are inadequate. There are strong suggestions by the industry to call for more and more effective seminars; more and more effective training programmes for IBS workers, IBS supervisors and IBS designers; more numbers of IBS manufacturers and more incentives from the government for using IBS.

6)

7)

7.

ACKNOWLEDGMENTS

The authors wish to thank the Management of Universiti Teknologi Petronas for the support given to this research.

8. [1] [2] [3] [4] [5] [6] [7]

REFERENCES CIDB Malaysia, IBS Roadmap 2003-2010. CIDB Malaysia, IBS Survey 2003: Survey on the Usage of IBS in Malaysian Construction Industry. CIDB Malaysia, IBS Survey 2005: Survey on Malaysian Architects. Saunders et al, 1997. Research Methods for Business Students. Pitman Publishing, London. Fowler, Jr., F.J. 1988. Survey Research Methods, Sage Publication, London. Hammad et al, 1996. Gardiner and Theobald, 2006. International Construction Cost Survey. Gardiner & Theobald, London

92

ICCBT 2008 - B - (07) pp75-92

Potrebbero piacerti anche

- Industrialized Building System in Malaysia Challenges and The Way ForwardDocumento15 pagineIndustrialized Building System in Malaysia Challenges and The Way ForwardMohd Huzairi SalgimanNessuna valutazione finora

- IbsDocumento4 pagineIbsMohd Fazli LajakNessuna valutazione finora

- Drivers and Barriers of IBS Adoption in MalaysiaDocumento8 pagineDrivers and Barriers of IBS Adoption in MalaysiaFollyla LauraNessuna valutazione finora

- Ops-06 1 PDFDocumento13 pagineOps-06 1 PDFHadii BaigNessuna valutazione finora

- Articulo Cientifico 2Documento14 pagineArticulo Cientifico 2humberto bordaNessuna valutazione finora

- IBSDocumento13 pagineIBSMohd Isa Aziz JaafarNessuna valutazione finora

- Building Information Modelling in Malaysian IndustDocumento12 pagineBuilding Information Modelling in Malaysian IndustPigmy LeeNessuna valutazione finora

- Insight IBS Bumi 2016Documento6 pagineInsight IBS Bumi 2016najlanizamNessuna valutazione finora

- The Potential Application of IBS Modular System in TheDocumento8 pagineThe Potential Application of IBS Modular System in TheJudy TanNessuna valutazione finora

- Construction Cost Index A Case Study in MalaysiaDocumento12 pagineConstruction Cost Index A Case Study in MalaysiaEsther KihoroNessuna valutazione finora

- Implementation of Just-In-Time Approach in Construction Project (A Review Paper)Documento5 pagineImplementation of Just-In-Time Approach in Construction Project (A Review Paper)IJRASETPublicationsNessuna valutazione finora

- Nicmar - Sode: Proposed Synopsis OnDocumento10 pagineNicmar - Sode: Proposed Synopsis OnBijay Kumar GuptaNessuna valutazione finora

- A Cost Control System Development - A Collaborative Approach For Small and Medium-Sized ContractorsDocumento8 pagineA Cost Control System Development - A Collaborative Approach For Small and Medium-Sized Contractorsntl9630Nessuna valutazione finora

- Assessment of BIM Implementation Among M PDFDocumento9 pagineAssessment of BIM Implementation Among M PDFShafira & GeaNessuna valutazione finora

- A Proposed Model For Studying Information Technology Governance, Management, and Services of An Enterprise - An Integrated Framework of COBIT 5, ITIL®V3, and BSCDocumento5 pagineA Proposed Model For Studying Information Technology Governance, Management, and Services of An Enterprise - An Integrated Framework of COBIT 5, ITIL®V3, and BSCgugupmNessuna valutazione finora

- Full Text 01Documento11 pagineFull Text 01PJP ServicesNessuna valutazione finora

- Comparison Between Conventional System and Industrialized Building System (Ibs)Documento10 pagineComparison Between Conventional System and Industrialized Building System (Ibs)Nur EffarihaNessuna valutazione finora

- Conference Paper 1Documento9 pagineConference Paper 1reenaNessuna valutazione finora

- Construction Cost Comparison Between Conventional and Formwork SystemsDocumento7 pagineConstruction Cost Comparison Between Conventional and Formwork SystemsmrlobboNessuna valutazione finora

- With Cover Page v2Documento7 pagineWith Cover Page v2cemil uruçNessuna valutazione finora

- 1 Examining Factors Affecting Budget Overrun of Construction Projects UndertakenDocumento9 pagine1 Examining Factors Affecting Budget Overrun of Construction Projects Undertaken敬贤Nessuna valutazione finora

- Muhammad Nur Helmi Bin Mohd Mislim 2020845232 BCT563 Assignment2 PDFDocumento6 pagineMuhammad Nur Helmi Bin Mohd Mislim 2020845232 BCT563 Assignment2 PDFMAXSWELL MANGGIE ZAMRYNessuna valutazione finora

- Productivity Improvement in Construction Site. Modification To ProposalDocumento8 pagineProductivity Improvement in Construction Site. Modification To ProposalAbdallaNessuna valutazione finora

- IBS RoadmapDocumento24 pagineIBS RoadmapmisswanyNessuna valutazione finora

- Ijert Ijert: A Review of IBS Malaysian Current and Future StudyDocumento6 pagineIjert Ijert: A Review of IBS Malaysian Current and Future StudyJudy TanNessuna valutazione finora

- 10 18400-Tekderg 977849-1905248Documento28 pagine10 18400-Tekderg 977849-1905248sushil.tripathiNessuna valutazione finora

- Benchmarking For Quality Management & Technology: Article InformationDocumento11 pagineBenchmarking For Quality Management & Technology: Article InformationasyrafmuhddNessuna valutazione finora

- AaaaaaaaaaaaaaaaaaaaaaaaaaaaaDocumento2 pagineAaaaaaaaaaaaaaaaaaaaaaaaaaaaaAnna Jane CagangNessuna valutazione finora

- Shardy Abdullah PDFDocumento15 pagineShardy Abdullah PDFreenaNessuna valutazione finora

- Literature Review Construction Industry in MalaysiaDocumento6 pagineLiterature Review Construction Industry in MalaysiaxmniibvkgNessuna valutazione finora

- Identifying Control Factors For Business Process Improvement in Telecom Sector Using Taguchi ApproachDocumento10 pagineIdentifying Control Factors For Business Process Improvement in Telecom Sector Using Taguchi ApproachDavid OrellanaNessuna valutazione finora

- IT Balanced Scorecard (IT BSC) Based Strategic Framework For Assessing The Impacts of Business Strategic-IT AlignmentDocumento9 pagineIT Balanced Scorecard (IT BSC) Based Strategic Framework For Assessing The Impacts of Business Strategic-IT AlignmentEddy SNessuna valutazione finora

- In Construction: Case Analysis of UK Construction Sector: Module Code: EG7302 Module Name: Engineering Management ProjectDocumento14 pagineIn Construction: Case Analysis of UK Construction Sector: Module Code: EG7302 Module Name: Engineering Management ProjectRaghav GoyalNessuna valutazione finora

- A Case Study On Product Lifecycle ManagementDocumento10 pagineA Case Study On Product Lifecycle ManagementAruna MNessuna valutazione finora

- Implementation of Prefabrication and Modular Offsite Construction Using BIM and Lean Construction TechniquesDocumento8 pagineImplementation of Prefabrication and Modular Offsite Construction Using BIM and Lean Construction Techniquessagasfn94Nessuna valutazione finora

- IBS in SarawakDocumento5 pagineIBS in SarawakHani HusainiNessuna valutazione finora

- Changing Technology Its Impact To Employee PerformanceDocumento7 pagineChanging Technology Its Impact To Employee PerformanceTugonon M Leo RoswaldNessuna valutazione finora

- Research 3Documento10 pagineResearch 3Danial IlyasaNessuna valutazione finora

- The Implementation of Lean Construction and Six Sigma Concepts in Light Brick Installation: A Case Study in Cordova Apartment ProjectDocumento10 pagineThe Implementation of Lean Construction and Six Sigma Concepts in Light Brick Installation: A Case Study in Cordova Apartment Projecthumberto bordaNessuna valutazione finora

- Six Sigma Application For Library ServicesDocumento6 pagineSix Sigma Application For Library ServicesdrustagiNessuna valutazione finora

- AnnisaS2 MDY OptimizingCommissioningSchedulingEPCCIndustryProjectsbyDocumento9 pagineAnnisaS2 MDY OptimizingCommissioningSchedulingEPCCIndustryProjectsbyAniketsingh MundlothNessuna valutazione finora

- Analysis of Construction Project Cost Overrun by Statistical MethodDocumento10 pagineAnalysis of Construction Project Cost Overrun by Statistical MethodIJRASETPublicationsNessuna valutazione finora

- Ijret - The Construction Labour Shortage in Johor Bahru, MalaysiaDocumento5 pagineIjret - The Construction Labour Shortage in Johor Bahru, MalaysiaInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- IJRTI1807004Documento5 pagineIJRTI1807004Atul JaiswalNessuna valutazione finora

- Green Construction and Sustainable IBSDocumento7 pagineGreen Construction and Sustainable IBSAdi Fikri Sidi100% (1)

- 1 s2.0 S1877042812046605 MainDocumento8 pagine1 s2.0 S1877042812046605 MainJanithaNessuna valutazione finora

- Study On The Use of Industrialised Building System (IBS) in Malaysian Private Construction ProjectsDocumento8 pagineStudy On The Use of Industrialised Building System (IBS) in Malaysian Private Construction ProjectsAsyraf JagungNessuna valutazione finora

- BIM, Lack of Importance For Construction Projects in IndiaDocumento7 pagineBIM, Lack of Importance For Construction Projects in IndiaIJRASETPublicationsNessuna valutazione finora

- Jasdeep SynopsisDocumento8 pagineJasdeep SynopsisNageshwar SinghNessuna valutazione finora

- Synopsis ON "A Detailed Study On Just in Time Production To Reduce Inventory Level in Cipla Limitd"Documento8 pagineSynopsis ON "A Detailed Study On Just in Time Production To Reduce Inventory Level in Cipla Limitd"Nageshwar SinghNessuna valutazione finora

- A Study of Precast Concrete in Malaysia: Setting UpDocumento3 pagineA Study of Precast Concrete in Malaysia: Setting UpnuafzanNessuna valutazione finora

- Ce168p-2 Seu # 3Documento6 pagineCe168p-2 Seu # 3Charmie LlenarezNessuna valutazione finora

- Industrialised Building System Ibs in SaDocumento6 pagineIndustrialised Building System Ibs in SanajlanizamNessuna valutazione finora

- Quality Analysis in Construction Projects Using Six Sigma ConceptDocumento8 pagineQuality Analysis in Construction Projects Using Six Sigma Conceptのれ はぼぇんNessuna valutazione finora

- A Study of the Supply Chain and Financial Parameters of a Small BusinessDa EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNessuna valutazione finora

- Project Control Methods and Best Practices: Achieving Project SuccessDa EverandProject Control Methods and Best Practices: Achieving Project SuccessNessuna valutazione finora

- Leveraging on India: Best Practices Related to Manufacturing, Engineering, and ItDa EverandLeveraging on India: Best Practices Related to Manufacturing, Engineering, and ItNessuna valutazione finora

- Incentivizing Collaborative BIM-Enabled Projects: A Synthesis of Agency and Behavioral ApproachesDa EverandIncentivizing Collaborative BIM-Enabled Projects: A Synthesis of Agency and Behavioral ApproachesNessuna valutazione finora

- Challenges and Best Practices of Managing Government Projects and ProgramsDa EverandChallenges and Best Practices of Managing Government Projects and ProgramsNessuna valutazione finora

- Use of Preservation Chemicals Following Hydrostatic Testing of PipelinesDocumento3 pagineUse of Preservation Chemicals Following Hydrostatic Testing of PipelinesAmirah AqilahNessuna valutazione finora

- 694aa 2Documento28 pagine694aa 2hatakerobotNessuna valutazione finora

- SENSONICDocumento8 pagineSENSONICAmirah AqilahNessuna valutazione finora

- Thesis& Dissertation-UserManual-Student-v2 - 0 PDFDocumento15 pagineThesis& Dissertation-UserManual-Student-v2 - 0 PDFSusan CookNessuna valutazione finora

- Zeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaDocumento4 pagineZeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaAmirah AqilahNessuna valutazione finora

- BSD-Steel Guide 2011 2Documento112 pagineBSD-Steel Guide 2011 2Kiran Kumar K T0% (1)

- The Impacts of Tourism Industry On Host CommunityDocumento10 pagineThe Impacts of Tourism Industry On Host Communitycris409009Nessuna valutazione finora

- Eot PDFDocumento12 pagineEot PDFAmirah AqilahNessuna valutazione finora

- Novelty in Theme ParksDocumento24 pagineNovelty in Theme ParksAmirah AqilahNessuna valutazione finora

- Understanding Coman Building DefectDocumento6 pagineUnderstanding Coman Building DefectAmirah AqilahNessuna valutazione finora

- Study of Heritage Building Via Lime Plaster in MalaysiaDocumento100 pagineStudy of Heritage Building Via Lime Plaster in MalaysiaAmirah Aqilah100% (1)

- Preliminary Evaluation of ProblemDocumento9 paginePreliminary Evaluation of ProblemAmirah AqilahNessuna valutazione finora

- RAG 132 Lecture IntentionDocumento17 pagineRAG 132 Lecture IntentionAmirah AqilahNessuna valutazione finora

- Building Plans Submission and Approval ProcessDocumento41 pagineBuilding Plans Submission and Approval ProcessAmirah Aqilah56% (18)

- Act 625Documento7 pagineAct 625Amirah AqilahNessuna valutazione finora

- File Backup Using PCINDocumento3 pagineFile Backup Using PCINnestor gonzalez de leonNessuna valutazione finora

- Online Doctor Appointment App Streamlines Healthcare AccessDocumento4 pagineOnline Doctor Appointment App Streamlines Healthcare AccessFassy ur RehmanNessuna valutazione finora

- Corporate Strategy - Tencent AnalysisDocumento9 pagineCorporate Strategy - Tencent AnalysisJosh Forbes100% (2)

- Zip CrackerDocumento12 pagineZip CrackerabhishekNessuna valutazione finora

- Service and Maintenance D9Documento84 pagineService and Maintenance D9abduallah muhammadNessuna valutazione finora

- Pneumatic Tire Roller HP 240 Specs & FeaturesDocumento2 paginePneumatic Tire Roller HP 240 Specs & FeaturesHamdi JemmaliNessuna valutazione finora

- Rubina ResumeDocumento1 paginaRubina ResumeDisha ModNessuna valutazione finora

- Network Management CourseDocumento4 pagineNetwork Management CourseRichard CoronelNessuna valutazione finora

- RFP ErpDocumento358 pagineRFP Erpanand kumarNessuna valutazione finora

- PublicPaper Dorn PDFDocumento32 paginePublicPaper Dorn PDFAnonymous 07vOE7U31LNessuna valutazione finora

- Bitumen Sand LayerDocumento4 pagineBitumen Sand LayerChristian Camilo Pira RoaNessuna valutazione finora

- Generative AI-v4Documento17 pagineGenerative AI-v4James Siva Kumar100% (1)

- Grashoff's Law and Four Bar InversionsDocumento41 pagineGrashoff's Law and Four Bar Inversionsmani88kctNessuna valutazione finora

- 6.2 - CAPEX and OPEX Selection and Prioritization Engl v5Documento21 pagine6.2 - CAPEX and OPEX Selection and Prioritization Engl v5Bharath0% (1)

- Maurice Fuller Resume - 10.11.1.ITDocumento3 pagineMaurice Fuller Resume - 10.11.1.ITmfuller11Nessuna valutazione finora

- Philippine Currency Security FeaturesDocumento16 paginePhilippine Currency Security FeaturesMid AcidNessuna valutazione finora

- Asset Management SystemDocumento112 pagineAsset Management Systemdeepak chandruNessuna valutazione finora

- Switching - Data CommunicationsDocumento37 pagineSwitching - Data CommunicationsPNessuna valutazione finora

- SWE30UB Operator's ManualDocumento115 pagineSWE30UB Operator's ManualIisakkiNessuna valutazione finora

- TI-Nspire CAS Vs TI-89Documento2 pagineTI-Nspire CAS Vs TI-89trmpereiraNessuna valutazione finora

- Ipc Standards - : Everything You Need From Start To FinishDocumento1 paginaIpc Standards - : Everything You Need From Start To FinishChobits PhamNessuna valutazione finora

- Service Chatbots FinalDocumento33 pagineService Chatbots FinalRamanjot KaurNessuna valutazione finora

- MFI-9 Specification SheetDocumento3 pagineMFI-9 Specification SheetAkhilesh KumarNessuna valutazione finora

- Amal J RajDocumento2 pagineAmal J Rajamal j rajtNessuna valutazione finora

- The Specifications of 151821-2010: Details PDFDocumento1 paginaThe Specifications of 151821-2010: Details PDFSaul UribeNessuna valutazione finora

- China Rise On AIDocumento54 pagineChina Rise On AIalekkos alexandroupolusNessuna valutazione finora

- Keywords: INSC 20263 (BIS) Terry Gray 1 October 4, 2020Documento19 pagineKeywords: INSC 20263 (BIS) Terry Gray 1 October 4, 2020ngkimngann27Nessuna valutazione finora

- Project Management Process Mapping OverviewDocumento1 paginaProject Management Process Mapping Overviewprerna93Nessuna valutazione finora

- CIGRE US National Committee 2019 Grid of The Future SymposiumDocumento9 pagineCIGRE US National Committee 2019 Grid of The Future SymposiumbenlahnecheNessuna valutazione finora

- Concrete Quality: Software For Concrete QA/QC & Mix DesignDocumento11 pagineConcrete Quality: Software For Concrete QA/QC & Mix Design16bagaspratamaNessuna valutazione finora