Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab 6

Caricato da

Bhupender SharmaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lab 6

Caricato da

Bhupender SharmaCopyright:

Formati disponibili

MECE3320

MeasurementsandInstrumentationLab

Lab-6:DynamicResponseofTemperature

MeasuringDevices

1. Introduction

Thermocouples

When a pair of electrical conductors (metals) are joined together, a thermal emf is

generated when the junctions are at different temperatures. This phenomenon is known

as the Seebeck effect. Such a device is called a thermocouple. The resultant emf

developed by the thermocouple is in the millivolt range when the temperature difference

between the junctions is ~ 100

0

C. To determine

Figure 1 - Measuring the EMF of a Thermocouple

the emf of a thermocouple as a function of the temperature, one junction is maintained at

some constant reference temperature, such as ice-water mixture at a temperature of 0

0

C. The thermal emf, which can be measured by a digital voltmeter as shown in Figure

1, is proportional to the temperature difference between the two junctions. To calibrate

such thermocouple the temperature of the second junction can be varied using a

constant temperature bath and the emf recorded as a function of the temperature

difference between the two nodes.

The output voltage, E, of such a simple thermocouple circuit is usually written in the

form,

3 2

3

1

2

1

CT BT AT E + + = (1)

where T is the temperature in

0

C, and E is based on a reference junction temperature of

0

0

C. The constants A, B and C are dependent on the thermocouple material.

Providing a fixed reference temperature for the reference junction using an ice bath can

make the use of a thermocouple cumbersome. Hence, commercially available

thermocouples usually consist of two leads terminating in a single junction. The leads

are connected to a thermocouple signal conditioning box containing an electrical circuit

which provides a reference voltage equal to that produce by a reference junction placed

at 0

0

C, a process called ice point compensation. These thermocouple signal

conditioners or power supplies usually display the temperature directly and or provide a

voltage output that is proportional to the thermocouple temperature. A similar

thermocouple signal conditioner with a digital temperature display and an analog voltage

output is used in the present experiment.

Thermistors

The thermistor, a thermally sensitive resistor, is a solid semiconducting material. Unlike

metals, thermistors respond inversely to temperature, i.e., their resistance decreases as

the temperature increases. The thermistors are usually composed of oxides of

manganese, nickel, cobalt, copper and several other nonmetals. The resistance is

generally an exponential function of the temperature, as shown in Equation 2:

|

|

.

|

\

|

=

|

|

.

|

\

|

0 0

1 1

ln

T T R

R

| (2)

where R

0

is the resistance at a reference temperature, T

0

, while | is a constant,

characteristic of the material. T

0

, the reference temperature, is generally taken as 298 K

(25

0

C). Since all measurements made with thermistors can be reduced to detecting the

resistance changes, the thermistor must be placed in a circuit and the resistance

changes recorded in terms of the corresponding voltage or current changes. The

formula relating the voltage (or current) changes to the resistance changes for a given

circuit has to be determined theoretically or empirically, or by a combination of both.

In the design of thermistor circuits, one must take the precaution that within the range of

the operating conditions; the circuit remains stable at all times. Thermistor resistance

varies inversely with temperature. The voltage applied directly across a thermistor

causes its temperature to rise, and its resistance to decrease. Sufficiently high voltage

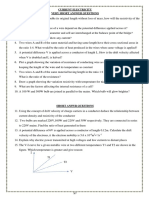

may cause thermal "runaway" (curve A in Figure 2), in which condition, higher currents

and temperatures are induced until the thermistor

Figure 2 - Thermistor Behavior and Thermal Runaway

fails, or the power is reduced. A series resistor, introduced to limit current, ensures

stability (curve B). Thermal "runaway" will, in all probability, permanently damage the

thermistor, or change its characteristic properties.

To increase the precision of the measurement, one should add a voltage divider to the

circuit shown in Figure 3(a). This will convert it to a Wheatstone bridge circuit, as shown

in Figure 3(b). The out-of-balance voltage, AV, can then be measured and related to the

resistance of the thermistor. A correct choice of resistors R

2

and R

3

will remove the

mean DC value of AV. Note that although the bridge circuit can increase the precision of

the readings, the sensitivity is still the same as for the simple voltage divider circuit

shown in Figure 3(a). The simple DC bridge circuit of Figure 3(b) is generally

satisfactory for most applications.

Figure 3 - Thermistor Circuit

Considering this circuit, we now derive the relation between T and AV. In general,

|

|

.

|

\

|

+

+

= A

T

T

R R

R

R R

R

E V

1 3 2

2

(3)

Assume R

1

=R

3

. Then,

|

|

.

|

\

|

+

+

= A

T

T

R R

R

R R

R

E V

1 2 1

2

(4)

Rearranging for R

T

,

( )

( )

|

|

.

|

\

|

+ A +

+ A

=

2 1 1

2 1 2

1

R R V ER

R R V ER

R R

T

(5)

The relation between T and R

T

is given by,

|

|

.

|

\

|

(

=

0

0

1 1

exp

T T

R R

T

| (6)

or,

|

|

.

|

\

|

+ =

0 0

ln

1 1 1

R

R

T T

T

|

(7)

Substituting for R

T

from Equation 5, we have

( )

( )

(

|

|

.

|

\

|

+ A +

+ A

+ =

2 1 1

2 1 2

0

1

0

ln

1 1 1

R R V ER

R R V ER

R

R

T T |

(8)

If we further assume R

1

=R

2

=R

3

=R

b

, we have,

(

|

|

.

|

\

|

A +

A

+ =

V E

V E

R

R

T T

b

2

2

ln

1 1 1

0 0

|

(9)

T is not a linear function of V, and so any linear analog recorder will be in error when

linear interpolation is used between calibration points (for small ranges in temperatures,

the error may be negligible). If we measure E along with our scans of the AVs, then the

only unknowns in Equation 9 are R

0

and |. These unknowns are determined by static

calibration experiment. You will perform a 3 or 4 point static calibration of both the

thermocouple and the thermistor.

Dynamic Response of Thermal Systems

When temperature measurements of a transient process are made, it is

important to verify that the dynamic response of the measuring device is fast enough to

accurately track the time varying temperature. In the second part of this experiment, we

will study the influence of different parameters on the transient response characteristics

of a thermal system. In this experiment, we will measure the response of thermocouple

(or a modified thermocouple). The thermocouple is modeled as a spherical ball, as

shown in Figure 4. The thermocouple temperature is, T, mass m and specific

Figure 4 Thermocouple bead modeled as a simple thermal system

heat capacity c. If the sphere is suddenly exposed to an environment at temperature T

,

then, after making the appropriate assumptions, the energy balance for this transient

process is given by:

t d

dT

mc T T hA =

) (

The solution for the above first order equation is the well known exponential decay given

as:

t ) / (

0

mc ha

e

T T

T T

=

where the time constant t =mc/hA. In this experiment, we will examine the influence of

properties such as mass, surface area and specific heat capacity of the bead on its

dynamic response.

2. Procedure:

1. Time response measurement.

Procedure:

a. Open the LabView program for temperature measurement (You should have

already downloaded the program before coming to the lab). Place the

thermocouple in the water bath (room temerature).

b. Start the labview program (dont forget to give an appropriate filename).

c. Wait for 10 seconds while the program is running.

d. Now, remove the thermocouple from the water bath and immediately transfer

it to the ice bath.

e. wait for about 20 seconds.

m, T

q

convection

T

f. Stop the labview program.

g. Open the file you saved and check if the data is saved correctly.The first

column is the time. The second column is the temperature.

a. From the data file you saved, determine the time constant of the

thermocouple using the following two methods.

i. Using the time history plot (time vs. temp.)

ii. Using the semi-log plot (refer to the handout/website for

details).

Potrebbero piacerti anche

- Objectives: Temperature Measuring DevicesDocumento8 pagineObjectives: Temperature Measuring DevicesSai Swaroop MandalNessuna valutazione finora

- Experiment DescriptionDocumento9 pagineExperiment DescriptionPutu Diah Prajna ParamitaNessuna valutazione finora

- Experiment 4 Dynamic Response of Temperature Measuring Devices (Transient Heat Transfer)Documento6 pagineExperiment 4 Dynamic Response of Temperature Measuring Devices (Transient Heat Transfer)praful2604Nessuna valutazione finora

- Temperature Sensor - The ThermistorDocumento5 pagineTemperature Sensor - The ThermistorAndrei MunteanNessuna valutazione finora

- Experiment No 6 IAS-GTU-6th Sem CivilDocumento5 pagineExperiment No 6 IAS-GTU-6th Sem CivilJATINKUMAR CHAUDHARINessuna valutazione finora

- Chap 08Documento34 pagineChap 08marihomenonNessuna valutazione finora

- Ne6 Determination of Temperature Coefficient of Resistance: DT R DRDocumento2 pagineNe6 Determination of Temperature Coefficient of Resistance: DT R DRmedoomanNessuna valutazione finora

- Semiconductor Sensors of Temperature: The Measurement ObjectiveDocumento6 pagineSemiconductor Sensors of Temperature: The Measurement ObjectiveTaufik Hidayat SoiNessuna valutazione finora

- API NTC Engineering NotesDocumento4 pagineAPI NTC Engineering NotesPanagiotis PlatisNessuna valutazione finora

- Jntuk R13 Physics Lab Manual PDFDocumento62 pagineJntuk R13 Physics Lab Manual PDFgaruda198250% (2)

- (I) Platinum Resistance Thermometers Thermocouples Thermistors Optical PyrometersDocumento10 pagine(I) Platinum Resistance Thermometers Thermocouples Thermistors Optical Pyrometersamritsaikias4Nessuna valutazione finora

- Experiment 4: Temperature Measurements: Concepts Emphasized: Resistor Temperature Detector, Thermistor, and ThermocoupleDocumento9 pagineExperiment 4: Temperature Measurements: Concepts Emphasized: Resistor Temperature Detector, Thermistor, and ThermocoupleKalyani KattaNessuna valutazione finora

- Thermodynamic System Properties and Gas Laws TutorialDocumento6 pagineThermodynamic System Properties and Gas Laws TutorialDivij SoodNessuna valutazione finora

- Experiment A - Linear and Radial Heat ConductionDocumento17 pagineExperiment A - Linear and Radial Heat Conductionjulissa barreraNessuna valutazione finora

- Instrumentation and Process Control (IPC)Documento31 pagineInstrumentation and Process Control (IPC)M Arslan AshrafNessuna valutazione finora

- 66 - 15575 - Ec410 - 2014 - 1 - 2 - 1 - Lecture 12Documento31 pagine66 - 15575 - Ec410 - 2014 - 1 - 2 - 1 - Lecture 12sijal2005Nessuna valutazione finora

- AN569/D Transient Thermal Resistance - General Data and Its UseDocumento16 pagineAN569/D Transient Thermal Resistance - General Data and Its UseMarcelo GalasNessuna valutazione finora

- 1 Introduction and Temperature SensorsDocumento27 pagine1 Introduction and Temperature SensorsAimi Syamimi Ab GhafarNessuna valutazione finora

- A Controlled-Temperature Hot-Wire Anemometer With Voltage Feedback LinearizationDocumento6 pagineA Controlled-Temperature Hot-Wire Anemometer With Voltage Feedback LinearizationdanilodspNessuna valutazione finora

- Temperature Measurement Version 1Documento25 pagineTemperature Measurement Version 1Didi AdilahNessuna valutazione finora

- Energy Gap of SemiconductorDocumento7 pagineEnergy Gap of SemiconductorVyshu MaminiduNessuna valutazione finora

- Apho2018 Theory Q3 Thermoelectricity QuestionDocumento7 pagineApho2018 Theory Q3 Thermoelectricity Questionmpecth100% (1)

- Basic Control System Equipments: Transducers ResearchDocumento21 pagineBasic Control System Equipments: Transducers ResearchBurak OğuzNessuna valutazione finora

- Temp TransducerDocumento32 pagineTemp TransducerGunjan VarshneyNessuna valutazione finora

- PTCDocumento4 paginePTCHellena LaNessuna valutazione finora

- H2 - Radial Heat ConductionDocumento4 pagineH2 - Radial Heat Conductionmege1105Nessuna valutazione finora

- Into Electrical Form Which Can Be Further Used For Electronic Devices. A SensorDocumento11 pagineInto Electrical Form Which Can Be Further Used For Electronic Devices. A SensorGaurav SharmaNessuna valutazione finora

- Therm Is TorDocumento4 pagineTherm Is TorJashim UddinNessuna valutazione finora

- Simple Experiment On NTCDocumento12 pagineSimple Experiment On NTCOihane GomezNessuna valutazione finora

- Apt 0406Documento6 pagineApt 0406skgaddeNessuna valutazione finora

- Experiment Title: Measurement of Temperature Using Different Thermal Sensors/transducersDocumento14 pagineExperiment Title: Measurement of Temperature Using Different Thermal Sensors/transducersZobaeir Akanda RatulNessuna valutazione finora

- Thermocouple Experiment Explores Transient ResponseDocumento4 pagineThermocouple Experiment Explores Transient ResponseSarfaras Ali KNessuna valutazione finora

- IR SensorsDocumento17 pagineIR SensorsShahana sayyedNessuna valutazione finora

- ME3122-1 Temperature Measurement Lab ManualDocumento17 pagineME3122-1 Temperature Measurement Lab ManualKevin100% (1)

- Engg Physics - II Record 1st March 2013Documento37 pagineEngg Physics - II Record 1st March 2013garuda1982Nessuna valutazione finora

- Transducers Measuring Temperature and Pressure: Presented by Group-12 of C.S./I.T. BATCH OF 2008-2009Documento44 pagineTransducers Measuring Temperature and Pressure: Presented by Group-12 of C.S./I.T. BATCH OF 2008-2009api-19822723Nessuna valutazione finora

- Exp 6 Process Measurements TemperatureDocumento17 pagineExp 6 Process Measurements TemperatureHardik AgravattNessuna valutazione finora

- THERMISTORDocumento17 pagineTHERMISTORJaymar Abapo LumasagNessuna valutazione finora

- BTMR1313 Assignment: Department of Electrical &electronic Engineering Faculty of Engineering and TechnologyDocumento9 pagineBTMR1313 Assignment: Department of Electrical &electronic Engineering Faculty of Engineering and TechnologyKAI ZHI LIMNessuna valutazione finora

- Thermistors in Homebrew ProjectsDocumento5 pagineThermistors in Homebrew ProjectsSorin Mihai VassNessuna valutazione finora

- Testing of Thermocouples PDFDocumento6 pagineTesting of Thermocouples PDFbasdownloadNessuna valutazione finora

- Me 335 Exp 2Documento8 pagineMe 335 Exp 2Brian AliasgharNessuna valutazione finora

- Experiment-2 Sensitivity of Error Detector: Exp - No: 2 (A) DateDocumento11 pagineExperiment-2 Sensitivity of Error Detector: Exp - No: 2 (A) DateVenkata Siva ReddyNessuna valutazione finora

- Experimental 1 Thermoelectricity ProblemDocumento9 pagineExperimental 1 Thermoelectricity Problemjas dwanNessuna valutazione finora

- Electrolytic Capacitor Thermal Model and Life Study For Forklift Motor Drive ApplicationDocumento6 pagineElectrolytic Capacitor Thermal Model and Life Study For Forklift Motor Drive ApplicationpanoskakNessuna valutazione finora

- MEC 2600 Lab Manual 1 (Thermo)Documento43 pagineMEC 2600 Lab Manual 1 (Thermo)AbdurrahmanNessuna valutazione finora

- Parametric sensitivity and runaway criteria for fixed bed catalytic reactorsDocumento14 pagineParametric sensitivity and runaway criteria for fixed bed catalytic reactorsbrenobsaNessuna valutazione finora

- Infineon Thermal Equivalent Circuit Models ApplicationNotes v01 01 enDocumento13 pagineInfineon Thermal Equivalent Circuit Models ApplicationNotes v01 01 enjbranthooverNessuna valutazione finora

- General Technical InformationDocumento12 pagineGeneral Technical InformationNguyen TheanhNessuna valutazione finora

- Thermocouple LectureDocumento13 pagineThermocouple LectureBilal RafiqNessuna valutazione finora

- Exp #3: Temperature Transducers: Objectives: To Understand The Operation of Thermistors and Realization of A TemperatureDocumento15 pagineExp #3: Temperature Transducers: Objectives: To Understand The Operation of Thermistors and Realization of A TemperatureKhawar RiazNessuna valutazione finora

- Teknik Akuisisi Data Temperature MeasurementDocumento20 pagineTeknik Akuisisi Data Temperature MeasurementIrma Septiana LubisNessuna valutazione finora

- Unit 1: DC Circuits: Summary and Learning OutcomesDocumento12 pagineUnit 1: DC Circuits: Summary and Learning OutcomesKevin CheeNessuna valutazione finora

- Peltier CoolingDocumento13 paginePeltier Coolingapi-243810683Nessuna valutazione finora

- MKL 3 ReportDocumento9 pagineMKL 3 ReportMatthew NelsonNessuna valutazione finora

- Shell Energy BalancesDocumento26 pagineShell Energy BalancesSaiful Bahri100% (1)

- ThermocoupleDocumento12 pagineThermocoupleKarim ZianniNessuna valutazione finora

- Temperature Background Spring 2016Documento4 pagineTemperature Background Spring 2016tegalNessuna valutazione finora

- Utility TurbinesDocumento67 pagineUtility TurbinesBapu612345Nessuna valutazione finora

- Design and Analysis of Micro Steam Turbine Using Catia and AnsysDocumento4 pagineDesign and Analysis of Micro Steam Turbine Using Catia and AnsysInternational Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Holcomb Pres PDFDocumento47 pagineHolcomb Pres PDFBhupender SharmaNessuna valutazione finora

- Steam Turbine BladesDocumento1 paginaSteam Turbine BladesBhupender SharmaNessuna valutazione finora

- Draft WO For Refractory Dry Out-Heat Up Combusion in WHRB 8 Boiler RAS - PPDocumento5 pagineDraft WO For Refractory Dry Out-Heat Up Combusion in WHRB 8 Boiler RAS - PPBhupender SharmaNessuna valutazione finora

- Control Protection PDFDocumento81 pagineControl Protection PDFBhupender SharmaNessuna valutazione finora

- M.TECH THESIS GUIDELINESDocumento9 pagineM.TECH THESIS GUIDELINESabhi_engg06Nessuna valutazione finora

- STEAM TURBINE 3 Design and MaterialsDocumento19 pagineSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- Sedlov 2017 J. Phys.: Conf. Ser. 891 012206Documento7 pagineSedlov 2017 J. Phys.: Conf. Ser. 891 012206Bhupender SharmaNessuna valutazione finora

- Theoretical Analysis of The Performance of Pressure CondonserDocumento10 pagineTheoretical Analysis of The Performance of Pressure CondonsersivaNessuna valutazione finora

- Turbine Protection SystemDocumento11 pagineTurbine Protection Systemadam jordan100% (1)

- Ejectors: Wide Uses & Selection GuideDocumento6 pagineEjectors: Wide Uses & Selection Guidehappale2002Nessuna valutazione finora

- Part01 Energy Introduction 2013 v8Documento33 paginePart01 Energy Introduction 2013 v8Bhupender SharmaNessuna valutazione finora

- AuditDocumento31 pagineAuditBhupender SharmaNessuna valutazione finora

- Steam Turbines PDFDocumento46 pagineSteam Turbines PDFasp992450% (2)

- Vector Analysis by Schaum's OutlineDocumento234 pagineVector Analysis by Schaum's OutlineKayerzzzNessuna valutazione finora

- Hot Wire Anemometer: SyllabusDocumento10 pagineHot Wire Anemometer: SyllabusBhupender SharmaNessuna valutazione finora

- New Microsoft Office Word DocumentDocumento40 pagineNew Microsoft Office Word DocumentBhupender SharmaNessuna valutazione finora

- Unit 3-32Documento23 pagineUnit 3-32Ahmad Fahmi HidayatullahNessuna valutazione finora

- Solar EnginDocumento1 paginaSolar EnginBhupender SharmaNessuna valutazione finora

- Case studies on preventing boiler tube erosionDocumento13 pagineCase studies on preventing boiler tube erosionpankajbtc007100% (1)

- Solar EnginDocumento1 paginaSolar EnginBhupender SharmaNessuna valutazione finora

- Derived Physical Quantity Formula Dimensiona L Formula S.I Unit of Physical QuantityDocumento2 pagineDerived Physical Quantity Formula Dimensiona L Formula S.I Unit of Physical QuantityBhupender SharmaNessuna valutazione finora

- Boiler CalculationsDocumento16 pagineBoiler CalculationsBilly Moerdani100% (1)

- New Microsoft Office Word DocumentDocumento40 pagineNew Microsoft Office Word DocumentBhupender SharmaNessuna valutazione finora

- Shivamogh KavachDocumento7 pagineShivamogh KavachVijay SharmaNessuna valutazione finora

- Notes On Solar Engg.Documento8 pagineNotes On Solar Engg.Bhupender SharmaNessuna valutazione finora

- Part01 Energy Introduction 2013 v8Documento33 paginePart01 Energy Introduction 2013 v8Bhupender SharmaNessuna valutazione finora

- Management 2011 12Documento174 pagineManagement 2011 12abhishekpaneriNessuna valutazione finora

- Chapter 1 (Copy)Documento33 pagineChapter 1 (Copy)Andy ChoyNessuna valutazione finora

- Physics Investogatory Project 2023Documento17 paginePhysics Investogatory Project 2023revNessuna valutazione finora

- Neet Test Series 2022 Test Code: NT - 0 6: Biology Physics ChemistryDocumento22 pagineNeet Test Series 2022 Test Code: NT - 0 6: Biology Physics ChemistryEmily MaxwellNessuna valutazione finora

- Electric Field Strength and Its EffectsDocumento53 pagineElectric Field Strength and Its Effectssurya vishnu100% (1)

- Current ElectricityDocumento47 pagineCurrent Electricitysonaliraiagarwal1100% (1)

- DC Circuits and Network TheoremsDocumento74 pagineDC Circuits and Network TheoremsShailesh Bhise100% (1)

- PU12 Chemistry Question Bank – Electrochemistry QuestionsDocumento15 paginePU12 Chemistry Question Bank – Electrochemistry QuestionsAnaghesh MuruliNessuna valutazione finora

- Module03 NewDocumento230 pagineModule03 NewMiltiadis ZabelasNessuna valutazione finora

- 08.current Voltage ResistanceDocumento11 pagine08.current Voltage ResistanceretterateNessuna valutazione finora

- Assignment - Current ElectricityDocumento11 pagineAssignment - Current ElectricityPresident ObamaNessuna valutazione finora

- Self Assessment Answers 9 Asal Physics CBDocumento2 pagineSelf Assessment Answers 9 Asal Physics CBarnavpro23Nessuna valutazione finora

- AC Circuit AnalysisDocumento39 pagineAC Circuit Analysisfirdaus_n9100% (1)

- PHY1102 Electric CircuitsDocumento74 paginePHY1102 Electric CircuitsMel RSNessuna valutazione finora

- Current Electricity by AakashDocumento56 pagineCurrent Electricity by AakashNilay Lilawala56% (9)

- Chapter 4 DC MachinesDocumento80 pagineChapter 4 DC MachinesKorsa KorsaNessuna valutazione finora

- Reviewer EnerConDocumento2 pagineReviewer EnerConAldriadne Jennsica AlboniaNessuna valutazione finora

- Chapter21 PDFDocumento12 pagineChapter21 PDFMauryaNessuna valutazione finora

- Maxwell's Equations (Time Varying FieldsDocumento18 pagineMaxwell's Equations (Time Varying FieldsNurul Aqiella PolanunuNessuna valutazione finora

- Yamazaki 2002Documento5 pagineYamazaki 2002Alan100% (1)

- VedantuDocumento29 pagineVedantuDeepanshu krNessuna valutazione finora

- New Energy Technologies Issue 05Documento77 pagineNew Energy Technologies Issue 05blameitontherain9877100% (1)

- Electrochemistry and BatteriesDocumento15 pagineElectrochemistry and Batteriesvenugopal_aeroNessuna valutazione finora

- electrochemistry: TOPIC:Nernst EquationDocumento26 pagineelectrochemistry: TOPIC:Nernst EquationArtiChamoliNessuna valutazione finora

- EOCQ Ans 21Documento2 pagineEOCQ Ans 21Kamran Khan ShaikhNessuna valutazione finora

- XII Term 1 PhysicsDocumento9 pagineXII Term 1 PhysicsAbaan KhanNessuna valutazione finora

- Surendranath Centenary School - 1Documento16 pagineSurendranath Centenary School - 1priyamdattaNessuna valutazione finora

- Electrochemical SeriesDocumento9 pagineElectrochemical Seriesasim zeeshanNessuna valutazione finora

- Assignment No1 Current and ElectricityDocumento1 paginaAssignment No1 Current and ElectricityshreyaNessuna valutazione finora

- CBSE Class 12 Physics Important Questions-Current ElectricityDocumento6 pagineCBSE Class 12 Physics Important Questions-Current ElectricitypradeepNessuna valutazione finora

- PID Feedback Control Method For Linear Resonant Actuator Using An Estimated External Load From The back-EMF As A Target VoltageDocumento5 paginePID Feedback Control Method For Linear Resonant Actuator Using An Estimated External Load From The back-EMF As A Target Voltagenour el imen mouaffekNessuna valutazione finora

- Faraday Laws of Induction: ProblemsDocumento9 pagineFaraday Laws of Induction: ProblemsSyed Mustafa MunirNessuna valutazione finora