Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Development of High Performance Concrete

Caricato da

Yathish143Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Development of High Performance Concrete

Caricato da

Yathish143Copyright:

Formati disponibili

Development of High Performance Concrete of grade M-60 for containment dome for Kaiga Project

The containment dome of the Kaiga Project, by virtue of its specific geometry, the sheer dimensions, and structural congestion of the reinforcement, posed a unique construction challenge. For the first time in India, the use of High Performance oncrete !HP " of #$%& grade 'as made on such a large scale. #eticulous planning, e(tensive testing and fla'less e(ecution yielded the desired results. #r. #ittal elaborates.

)uclear Po'er orporation has pioneered the use of High Performance oncrete !HP " in India. This concrete has been specially developed to cater to the design requirements of high compressive and tensile stresses coupled 'ith durability and impermeability. Inner containment dome of *eactor +uilding$ll of the Kaiga Project is constructed using HP of grade #$%& 'ith microsilica and high range superplasticisers. The dome structure 'as a highly congested one, 'ith reinforcement and prestressing cables, and placement of concrete at a height of ,& meters using concrete pumps and Placers$$ this required a concrete mi( of flo'able consistency. number of trials 'ere carried out at the oncrete Testing .aboratory ! T." of Kaiga Project to achieve the optimum mi( proportions of the concrete. .ater, a fe' full scale moc/ ups 'ere also conducted at the plant site to demonstrate the proper placement and compaction of the concrete under field conditions. 0alient features of mi( design are given belo'. SELECT !" !# C!"C$ETE "%$ED E"TS& #or ma'ing high performance concrete( it i) e))ential to )elect proper ingredient)( eval*ate their propertie) and have the 'no+-ho+ of the interaction of different material) for optim*m *)age, Cement& t i) the mo)t important ingredient of HPC( +hich determine) the )trength and propertie) of fre)h and hardened concrete -.-grade cement +a) )elected(con)idering it) compre))ive )trength at vario*) age)( finene))( heat of h/dration( al'ali content( and compati0ilit/ +ith admi1t*re),

Te)t for determination of 2ir content of the fre)hl/ mi1ed concrete,

2ggregate& 2ggregate occ*pie) 60 to 304 of the concrete vol*me and pla/) a )ignificant role in achieving the propertie) of concrete, Coar)e 2ggregate&

50 mm do+n cr*)hed granite )tone) +ere *)ed a) coar)e aggregate), Some important propertie) li'e cr*)hing )trength( d*ra0ilit/( gradation( fla'ine)) and elongation indice) +ere given )pecial con)ideration +hile )electing the aggregate for HPC, 2) the ten)ile )trength of concrete +a) of prime importance( it +a) nece))ar/ to red*ce the fla'/ and elongated particle) to red*ce the +ea'er 6one) in the concrete, Thi) +a) achieved 0/ )creening the aggregate thro*gh )peciall/ de)igned )ieve),

Sl*mp te)t for determination of +or'a0ilit/ of concrete,

#ine 2ggregate& $iver )and +a) *)ed a) fine aggregate, t +a) properl/ graded and +a)hed at )ite to remove deleterio*) material) and chloride contamination, Micro)ilica& Micro)ilica +a) *)ed to achieve high compre))ive and ten)ile )trength( d*ra0ilit/( lo+ permea0ilit/ and improved propertie) of fre)h concrete, t ma/ 0e noted that micro)ilica +a) *)ed for the fir)t time in ndia, Micro)ilica - a mineral compo)ed of *ltra fine )olid( amorpho*) gla))/ )phere) of )ilicon dio1ide Si!5- i) prod*ced d*ring the man*fact*ring of )ilicon and ferro-)ilicon, t contain) 78-984 amorpho*) Si!5in the form of micro)copic )pherical particle), The average particle )i6e of micro)ilica i) 0,: to 0,5 micron( +hich i) )imilar to to0acco )mo'e and nearl/ :00 time) )maller than that of a cement grain, Specific )*rface of micro)ilica i) :8.0 );,m<gm, Large )*rface area and high content of amorpho*) )ilicon dio1ide give) micro)ilica )*per po66olanic propertie), Micro)ilica improve) the )trength of concrete 0/ t+o mechani)m)( vi6,( 2) a )*per po66olana, 2) a filler,

Micro)ilica had to 0e imported from "or+a/ a) it i) not availa0le in ndia, Micro)ilica i) an *ltra fine material of lo+ 0*l' den)it/( +hich ma'e) it diffic*lt to handle( )tore and tran)port, Therefore( it i) proce))ed and )*pplied in den)ified form, Thi) agglomeration of micro)ilica formed 0/ den)ification 0rea') do+n d*ring mi1ing,

2dmi1t*re& S*cce)) of High performance concrete lie) in the proper *)e of high range +ater-red*cing admi1t*re) commonl/ 'no+n a) )*perpla)tici)er), High )trength concrete ha) lo+ +ater to 0inder ratio( and *ltra fine particle) in the form of micro)ilica, Hence( effective di)per)ion of cement and micro)ilica i) nece))ar/ to achieve proper +or'a0ilit/ of the concrete +itho*t increa)ing the *nit +ater content and cement content of mi1, Thi) i) achieved 0/ *)ing )*perpla)tici)er, The optim*m do)e of admi1t*re +a) eval*ated 0/ con)i)tenc/ te)t, 2t thi) do)e it red*ced +ater content of the mi1 0/ .84 and prod*ced a concrete of the de)ired flo+a0le con)i)tenc/, $etarder +a) al)o added to increa)e the )etting time of the concrete and improve the )l*mp retention propertie) to avoid cold joint) d*ring con)tr*ction, =ater& Pota0le +ater +a) fo*nd )*ita0le for ma'ing HPC, The thermal )tre))e) +ere red*ced 0/ re)tricting the placement temperat*re of concrete 0elo+ 5.>C, Thi) +a) achieved 0/ replacing part of +ater +ith thin fla'e) of ice, Mi1 De)ign& Mi1 de)ign involve) the proportioning of different ingredient) of concrete in the optim*m ;*antitie) 0a)ed on their propertie) to achieve the concrete of )pecified )trength( +or'a0ilit/ and d*ra0ilit/, Target )trength of the concrete i) fi1ed 0a)ed on )tandard deviation,

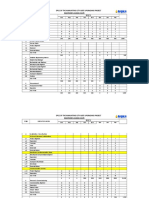

Con)idering e1tremel/ good degree of ?*alit/ control( the )tandard deviation for compre))ive )trength i) a))*med a) 8,8 MPa and that for )plit ten)ile )trength a) 0,. MPa, @Corre)ponding to appro1imatel/ 34 coefficient of variationA Target )trength for compre))ive )trength B 60C:,68D8,8 B 69 MPa Target )trength for )plit ten)ile )trength B .,73C:,68D0,. B -,.3 MPa Selection of =<E $atio& $elation)hip 0et+een compre))ive )trength and +ater to 0inder ratio @=<EA +a) e)ta0li)hed thro*gh vario*) trial) *)ing )ame ingredient), Thi) i) given in #ig*re-:, t can 0e )een from the fig*re that for compre))ive )trength re;*irement of 69 MPa( a =<E ratio of 0,.8 i) )*fficient, E*t 0a)ed on the data availa0le on )plit ten)ile )trength( it +a) o0)erved that thi) compre))ive )trength level +o*ld not 0e )*fficient to prod*ce a concrete of the de)ired )plit ten)ile )trength, Hence =<EB0,.5 +a) )elected con)idering the re;*ired high val*e of )plit ten)ile )trength and lo+ permea0ilit/ of the concrete, Calc*lation !f Mi1 Proportion)& 2ir content for concrete mi1 +ith 50 mm do+n aggregate +a) a))*med a) :4, 20)ol*te vol*me method +a) *)ed to determine the ;*antitie) of different ingredient), Preliminar/ trial) +ere carried o*t to determine e1actl/ the *nit +ater content( air content( )and percentage and +or'a0ilit/ of the concrete, #ig*re-5 )ho+) the final mi1 proportion), #*rther trial) +ere carried o*t to determine )tati)tical parameter) of compre))ive )trength of c*0e) and c/linder)( )plit ten)ile )trength( and other propertie) of fre)h and hardened concrete, Propertie) of #re)h Concrete& Te)t re)*lt) of fre)h concrete are given in Ta0le-:,

1escription of Test 0lump mm

)o. of 0amples 3, 3, 3 3 3, 3, 3 3

-verage 2alue 45, 43& 4&, 9& 786, &.9, 6?7& 8.43

#imimum #a(imum 2alue 2alue 46& 44& 4&& 5, 78,8 &.5& 7&& 46& 44& 9, 78=4 4.4

& min. 3& min. 8, min. 6& min.

:nit ;eight !Kg<cum" -ir content !>" 0etting time !hr?min" +leeding !>"

Ta0le - :& Propertie) of #re)h Concrete Concrete mi1 +a) *niform( cohe)ive and of flo+a0le con)i)tenc/, t +a) )*ita0le for p*mping, The *)e of micro)ilica )ignifica0ntl/ red*ced )egregation and 0leeding of concrete, Concrete )etting time of 6 hr), +a) o0)erved( +hich +a) fo*nd )*ita0le for placement condition), Propertie) of Hardened Concrete& Te)t) +ere carried o*t to )t*d/ different propertie) of hardened concrete, The te)t re)*lt) are given in Ta0le-5, C*0e Compre))ive Strength& #rom the re)*lt)( itF can 0e )een that the average c*0e compre))ive )trength achieved i) 36 Mpa, The val*e of compre))ive )trength ranged from 69,6 MPa to 7-,5 MPa +ith a )tandard deviation of .,76 MPa( +hich i) le)) than the a))*med val*e of 8,8 MPa, #rom the )tati)tical anal/)i) the characteri)tic )trength +or') o*t to 69,8 MPa, Thi) i) d*e to the )election of lo+er =<E ratio @0,.5A to meet the re;*irement) of high )plit ten)ile )trength,

Compressive testing of concrete sample in progress.

Split Ten)ile Strength&

The average )plit ten)ile )trength achieved i) -,.6 Mpa( ranging from .,93 MPa to -,9MPa, The characteri)tic )plit ten)ile )trength +or') o*t to .,9- MPa( +hich i) higher than the de)igned val*e of .,73 MPa, Permea0ilit/& Te)t) for +ater permea0ilit/ +ere carried o*t a) per the te)t proced*re given in D " :0-7, n all the )ample) +ater penetration +a) fo*nd to 0e nil, Thi) confirm) that the *)e of micro)ilica( and lo+ +ater to 0inder ratio ha) re)*lted in the impermea0le concrete, #rench Code $CC-%& The dome )tr*ct*re i) de)igned *)ing #rench code), The concrete mi1 +a) al)o te)ted in accordance +ith the #rench )pecification) $CC-% to ;*alif/ the mi1, oefficient of variation alculated haracteristic 0trength

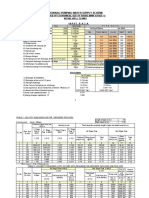

1escription of )o. of Test 0amples ube ompressive 0trength !#Pa" 0plit tensile 0trength !#Pa" ylinder comp.0trength !#Pa" Fle(ural 0trength !#Pa" #odulus of @lasticity !#Pa" Premeability

-verage 2alue

#a(. #in. 0tandard 2alue 2alue 1eviation

3,

=,.9

58.7

69.6

3.56

,.&5

69.,

3,

8.36

8.98

3.9=

&.76

,.56

3.98

3,

64.7

=4.=

,,.7

3.68

,.98

,,.7

,.53

8.8&= ( 4&

8

;ater Penetration $)I.$ Ta0le - 5 & Te)t $e)*lt)

Moc' *p St*die)& 2fter de)igning the concrete mi1 and e)ta0li)hing vario*) parameter) of fre)h and hardened concrete in the la0orator/ 0/ trial )t*die)( a fe+ f*ll )cale field moc'*p) +ere done to demon)trate that concrete co*ld 0e properl/ placed and compacted *nder field condition), #or the)e moc'*p )t*die)( a portion of ring 0eam and a portion of dome near )team generator opening) +a) )elected( the latter 0eing the mo)t diffic*lt portion for concreting in the +hole )tr*ct*re, The)e moc'*p) +ere )im*lated to act*al )ite condition)

@i,e, reinforcement( pre)tre))ing ca0le)( em0edment) etc,A and +ere carried o*t *)ing the act*al con)tr*ction e;*ipment) +hich +ere propo)ed to 0e *)ed, Concrete core) +ere drilled o*t at )everal location) to verif/ proper placement and compaction of concrete even in the conge)ted area),

#ail*re pattern of concrete )pecimen) *)ed for determination of compre))ive and )plit ten)ile )trength of concrete,

The concrete +a) p*mped to a height of 80 m to chec' it) p*mpa0ilit/ characteri)tic), =et )ieve anal/)i) of concrete )ample) 0efore and after p*mping en)*red identical proportion), Concrete )ample) +ere al)o ta'en after p*mping to the dome height and c*red *nder field condition) to determine it) in situ )trength, The 2verage in situ compre))ive and ten)ile )trength +a) 3- MPa and -,.- MPa re)pectivel/( +hich i) compara0le to la0orator/ val*e) a) given in ta0le - 5, The)e moc'*p) +ere nece))ar/ to gain confidence( fore)ee the diffic*ltie)( and fine-t*ne the concrete mi1, The act*al concrete +or' of $E- nner Containment dome commenced on Gan*ar/ 6( :997 and +a) )*cce))f*ll/ completed on March :7( :997,

#r. -mit #ittal is a graduate from +IT0 Pilani !495=". He joined Kaiga Project in 4955. He is 'or/ing as In$charge of oncrete Testing .aboratory at Kaiga Project. He 'on 4st priAe for e(cellence in oncrete consecutively thrice for the year 4993, 4998, 499, conducted by -merican oncrete Institute.

Potrebbero piacerti anche

- Manpower HistogramDocumento15 pagineManpower HistogramZaem Afifi100% (3)

- Study On Partial Replacement of Cement by Saw Dust Ash in ConcreteDocumento6 pagineStudy On Partial Replacement of Cement by Saw Dust Ash in ConcreteYonas D. Ebren100% (1)

- QC TEST 125 QuestionsDocumento12 pagineQC TEST 125 QuestionsShazab Nawaz100% (1)

- Gen TT Install InstructionsDocumento25 pagineGen TT Install Instructionsspsperformance1Nessuna valutazione finora

- STAAD Pro Basic CommandsDocumento2 pagineSTAAD Pro Basic CommandsRajesh Kumar R K91% (11)

- Assessment of Predictability of Fiber Reinforced Cemented Soils Unconfined Compressive and Tensile StrengthDocumento8 pagineAssessment of Predictability of Fiber Reinforced Cemented Soils Unconfined Compressive and Tensile StrengthRoberta Bomfim BoszczowskiNessuna valutazione finora

- Modified Review IDocumento17 pagineModified Review IShaik Asif AliNessuna valutazione finora

- Mechanical Properties of Modified Reactive Powder Concrete: January 1997Documento17 pagineMechanical Properties of Modified Reactive Powder Concrete: January 1997Ahmed EsamNessuna valutazione finora

- Study On The Effect of Partial Replacement of Fly Ash and Rice Husk On Concrete PavementDocumento11 pagineStudy On The Effect of Partial Replacement of Fly Ash and Rice Husk On Concrete PavementIJRASETPublicationsNessuna valutazione finora

- Effect of Gate and Runner Design On ElecDocumento5 pagineEffect of Gate and Runner Design On ElecMario Allesina JuniorNessuna valutazione finora

- P - 31 - Synthetic Granite Composite For Precision Equipment StructuresDocumento9 pagineP - 31 - Synthetic Granite Composite For Precision Equipment StructuresFlavia GialorencoNessuna valutazione finora

- Deformation Behavior of Cement Treated Demolition Waste WithDocumento8 pagineDeformation Behavior of Cement Treated Demolition Waste WithAngel GrimaldoNessuna valutazione finora

- Fracture Toughness of Geopolymeric Concretes Reinforced With Basalt FibersDocumento6 pagineFracture Toughness of Geopolymeric Concretes Reinforced With Basalt FibersSanjeeva YedavalliNessuna valutazione finora

- Investigation of GFRP-concrete Bond: Experimental and Numerical StudiesDocumento6 pagineInvestigation of GFRP-concrete Bond: Experimental and Numerical StudiesMongi Ben OuezdouNessuna valutazione finora

- Mechanical Properties of High Volume Fly Ash Concrete Subjected To Elevated TemperaturesDocumento29 pagineMechanical Properties of High Volume Fly Ash Concrete Subjected To Elevated TemperaturesUmer FarooqNessuna valutazione finora

- Civil Engineering Department, NITK, SurathkalDocumento6 pagineCivil Engineering Department, NITK, SurathkalPremanand ShenoyNessuna valutazione finora

- An Advanced Concrete Recycling Technology and Its Applicability Assessment Through Input-Output AnalysisDocumento15 pagineAn Advanced Concrete Recycling Technology and Its Applicability Assessment Through Input-Output AnalysisAymanAlMahfuzNessuna valutazione finora

- Engineering Properties of Normal Concrete Grade 40 Containing Rice Husk Ash at Different Grinding TimesDocumento10 pagineEngineering Properties of Normal Concrete Grade 40 Containing Rice Husk Ash at Different Grinding TimesYap Wen KhongNessuna valutazione finora

- Strength Development of High Strength Concretes With and Without Silica Fume Under The Influence of High Hydration TemperaturesDocumento12 pagineStrength Development of High Strength Concretes With and Without Silica Fume Under The Influence of High Hydration TemperaturesEdicson Gabriel García MateusNessuna valutazione finora

- Feasibility of Copper Slag-Fly Ash Mix As A Road Construction MaterialDocumento2 pagineFeasibility of Copper Slag-Fly Ash Mix As A Road Construction MaterialB VAMSI KRISHNANessuna valutazione finora

- BFC10502 Past YearDocumento12 pagineBFC10502 Past Yearaoi_chiepNessuna valutazione finora

- CEP 304 Concrete Engineering Practical Quiz Batch 1 Date: 01/11/17 Time: 40 Min Name: - Roll NoDocumento2 pagineCEP 304 Concrete Engineering Practical Quiz Batch 1 Date: 01/11/17 Time: 40 Min Name: - Roll NoKaustubh SaysardarNessuna valutazione finora

- Kamal Et Al-ICACE-2018 Full Paper-FinalDocumento6 pagineKamal Et Al-ICACE-2018 Full Paper-Finalska51Nessuna valutazione finora

- Alternate To Ghat-Ki-Guni by Construction of Tunnel in Jhalana Hills JaipurDocumento46 pagineAlternate To Ghat-Ki-Guni by Construction of Tunnel in Jhalana Hills JaipurDevendra SharmaNessuna valutazione finora

- Low Heat Development in Self-Compacting Concretes For Massive StructuresDocumento11 pagineLow Heat Development in Self-Compacting Concretes For Massive StructuresDarius StanciuNessuna valutazione finora

- Three-Dimensional Modelling of Tunnel Excavation and LiningDocumento13 pagineThree-Dimensional Modelling of Tunnel Excavation and LiningCarmine TranfaNessuna valutazione finora

- Influence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariDocumento4 pagineInfluence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariBia MughalNessuna valutazione finora

- REVISED Concrete Technology BOOK - by Sri P. SURESHDocumento63 pagineREVISED Concrete Technology BOOK - by Sri P. SURESHV Venkata Narayana100% (1)

- The Effect of Using Granite Dust As A Component ofDocumento11 pagineThe Effect of Using Granite Dust As A Component ofr HariNessuna valutazione finora

- Determination of Shrinkage Stresses in CDocumento5 pagineDetermination of Shrinkage Stresses in CHaytham ElsayedNessuna valutazione finora

- Production and Characterization of Green Polymer Composite With Natural FillersDocumento12 pagineProduction and Characterization of Green Polymer Composite With Natural FillersGlobal Research and Development ServicesNessuna valutazione finora

- M.M. Reda (1999)Documento7 pagineM.M. Reda (1999)kashifNessuna valutazione finora

- Coefficient of Thermal Expansion For Concrete Containing Fly Ash and SlagDocumento11 pagineCoefficient of Thermal Expansion For Concrete Containing Fly Ash and SlagJHON WILMAR CARDENAS PULIDONessuna valutazione finora

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDocumento23 pagineConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNessuna valutazione finora

- Performance of Polyurethane-Coated Concrete in Sewer EnvironmentDocumento10 paginePerformance of Polyurethane-Coated Concrete in Sewer EnvironmentAndhy Arya EkaputraNessuna valutazione finora

- Processes 08 00174 v2 PDFDocumento16 pagineProcesses 08 00174 v2 PDFESTIAQ AHMEDNessuna valutazione finora

- Processes: Utilization of Pyrolytic Carbon Black Waste For The Development of Sustainable MaterialsDocumento16 pagineProcesses: Utilization of Pyrolytic Carbon Black Waste For The Development of Sustainable MaterialsЮрий КостенкоNessuna valutazione finora

- Rate Analyses For ConcreteDocumento9 pagineRate Analyses For ConcreteLOKESH PUNJNessuna valutazione finora

- CEP 304 Concrete Engineering Practical Quiz Batch 3 Date: 03/11/17 Time: 40 Min Name: - Roll NoDocumento2 pagineCEP 304 Concrete Engineering Practical Quiz Batch 3 Date: 03/11/17 Time: 40 Min Name: - Roll NoKaustubh SaysardarNessuna valutazione finora

- Aramco Standard NotesDocumento9 pagineAramco Standard NotesAmir Khan100% (1)

- Civil Engineering Interview QuestionsDocumento19 pagineCivil Engineering Interview QuestionsSrivardhanSrbNessuna valutazione finora

- Analysis and Design of Ferrocement Cut Off Trench in Earthen Dam: A Case Study of Bham DamDocumento5 pagineAnalysis and Design of Ferrocement Cut Off Trench in Earthen Dam: A Case Study of Bham DamPriyanka SoniNessuna valutazione finora

- 100 Imp PointsDocumento18 pagine100 Imp Pointsfarhan poya100% (1)

- 4N5 Ijeset0202520 PDFDocumento8 pagine4N5 Ijeset0202520 PDFBia MughalNessuna valutazione finora

- Partial Replacement of Cement With Rice Husk Ash in Cement Concrete IJERTV9IS120121Documento4 paginePartial Replacement of Cement With Rice Husk Ash in Cement Concrete IJERTV9IS120121Mohini BhartiNessuna valutazione finora

- Physical and Mechanical Properties of Quarry Dust Waste Incorporated Into Fired Clay BrickDocumento6 paginePhysical and Mechanical Properties of Quarry Dust Waste Incorporated Into Fired Clay BrickvishalNessuna valutazione finora

- Ri Gao, Li-Qian Zhang, Piet Stroeven: Static Properties of Plain Reactive Powder Concrete Beams, Zhi-Min LiuDocumento8 pagineRi Gao, Li-Qian Zhang, Piet Stroeven: Static Properties of Plain Reactive Powder Concrete Beams, Zhi-Min Liupradeep kankeriNessuna valutazione finora

- Durability Characteristics OF Self Compacting Concrete: Presentation ONDocumento26 pagineDurability Characteristics OF Self Compacting Concrete: Presentation ONMonika DhaklaNessuna valutazione finora

- Jenkins McCarthy Baweja FinalDocumento7 pagineJenkins McCarthy Baweja FinalPhú Trịnh ĐìnhNessuna valutazione finora

- Material Properties of FRC With Recycled Aggregate: Jiřina TRČKOVÁ and Petr PROCHÁZKADocumento7 pagineMaterial Properties of FRC With Recycled Aggregate: Jiřina TRČKOVÁ and Petr PROCHÁZKAShruthi IyengarNessuna valutazione finora

- Predicting The Compressive Strength of Ground Granulated Blast Furnace Slag Concrete Using Artificial Neural NetworkDocumento7 paginePredicting The Compressive Strength of Ground Granulated Blast Furnace Slag Concrete Using Artificial Neural NetworkomarbossNessuna valutazione finora

- A Comparative Study On The High Strength Fibre ReinforcedDocumento7 pagineA Comparative Study On The High Strength Fibre ReinforcedDr-Rahul PanditNessuna valutazione finora

- GroundimprovementraoduttaDocumento9 pagineGroundimprovementraoduttaEr Harshvardhan IngawaleNessuna valutazione finora

- Waste Tire Rubber Particles Modified by Gamma Radiation and Their Use As Modifiers of ConcreteDocumento13 pagineWaste Tire Rubber Particles Modified by Gamma Radiation and Their Use As Modifiers of ConcretejaviergagocampusanoNessuna valutazione finora

- Ball Mill Critical SpeedDocumento8 pagineBall Mill Critical SpeedDanielito Bonito0% (1)

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Documento7 pagineInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)faumijkNessuna valutazione finora

- Sesi 2 Lampiran - BondDocumento6 pagineSesi 2 Lampiran - BondEgi rangkuNessuna valutazione finora

- Quotation For AggrementDocumento12 pagineQuotation For AggrementA.JANE GLYNNISNessuna valutazione finora

- Sustainable Medium Strength Geopolymer With Fly Ash and GGBS As Source MaterialsDocumento11 pagineSustainable Medium Strength Geopolymer With Fly Ash and GGBS As Source Materialsjyothi ramaswamyNessuna valutazione finora

- Bored Pile Design and Acceptance CriteriaDocumento2 pagineBored Pile Design and Acceptance CriterialaurenjiaNessuna valutazione finora

- S087083121730040XDocumento5 pagineS087083121730040XalfonsoNessuna valutazione finora

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDa EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNessuna valutazione finora

- Calculation of Quantity of Cement Mortar in Brickwork and PlasterDocumento2 pagineCalculation of Quantity of Cement Mortar in Brickwork and PlasterYathish1430% (1)

- Learn RA Bill-Running Account Billing SoftwareDocumento49 pagineLearn RA Bill-Running Account Billing SoftwareYathish143Nessuna valutazione finora

- Bean BallsDocumento31 pagineBean BallsYathish143Nessuna valutazione finora

- Final Survey Paper 17-9-13Documento5 pagineFinal Survey Paper 17-9-13Yathish143Nessuna valutazione finora

- Filler SlabDocumento16 pagineFiller SlabYathish143100% (5)

- Bituminous Soil StabilizationDocumento30 pagineBituminous Soil StabilizationYathish14382% (11)

- Ground Improvement Techniques by GroutingDocumento16 pagineGround Improvement Techniques by GroutingYathish143100% (1)

- CAISSON FoundationDocumento32 pagineCAISSON FoundationYathish1430% (1)

- Bituminous Soil StabilizationDocumento30 pagineBituminous Soil StabilizationYathish14382% (11)

- PVC Membrane RoofingDocumento20 paginePVC Membrane RoofingYathish143Nessuna valutazione finora

- A Special Tool For Peeling Wire Ends, Cutting WoodenDocumento2 pagineA Special Tool For Peeling Wire Ends, Cutting WoodenRamos LeonaNessuna valutazione finora

- Insulation CalculationDocumento10 pagineInsulation CalculationagazamiNessuna valutazione finora

- Methodology Dandeli UGDDocumento2 pagineMethodology Dandeli UGDPrathyaksh ShettyNessuna valutazione finora

- ExamDocumento18 pagineExamMark MamaradloNessuna valutazione finora

- Casement WindowsDocumento45 pagineCasement WindowsТијана Радиновић100% (1)

- Brochure Asset Doc Loc 5353646Documento1 paginaBrochure Asset Doc Loc 5353646Indra RahmadhaniNessuna valutazione finora

- 328750852089918-Working HydraulicsDocumento9 pagine328750852089918-Working HydraulicsBestway Equipment RepairingNessuna valutazione finora

- Waste Management at Construction SiteDocumento5 pagineWaste Management at Construction SiteAmbalal DhongadiNessuna valutazione finora

- T-216.02-8 Rev3 Nov2014Documento1 paginaT-216.02-8 Rev3 Nov2014Suyudi Akbari HabibiNessuna valutazione finora

- SkylightsDocumento77 pagineSkylightszameer72790% (1)

- HyperXtrude MetalDocumento2 pagineHyperXtrude MetalRanjit Kumar TANessuna valutazione finora

- Ghansali Pumping Water Supply SchemeDocumento43 pagineGhansali Pumping Water Supply SchemeProject ManagerStructuresNessuna valutazione finora

- Vbe Calculation Washington State DOT SOP732Documento18 pagineVbe Calculation Washington State DOT SOP732DigantNessuna valutazione finora

- Art 826Documento1 paginaArt 826MASOUDNessuna valutazione finora

- D7GDocumento46 pagineD7GEdwin Darquea83% (6)

- Buildingguide - Co.nz-Construction ChecklistsDocumento16 pagineBuildingguide - Co.nz-Construction ChecklistsElla CelineNessuna valutazione finora

- The Second Industrial Revolution 1850 - 1914 - 5 JULY 2022Documento41 pagineThe Second Industrial Revolution 1850 - 1914 - 5 JULY 2022Jason KDNessuna valutazione finora

- Stub - Acme - Thread - Data - Sheets Rev ADocumento4 pagineStub - Acme - Thread - Data - Sheets Rev Aakaalj qhseNessuna valutazione finora

- 2020 Speck CatalogueDocumento48 pagine2020 Speck CatalogueKunming WangNessuna valutazione finora

- A0 - ReviewedDocumento20 pagineA0 - ReviewedJODIN MAKINDA -Nessuna valutazione finora

- Abul Hassan Haveli Case StudyDocumento10 pagineAbul Hassan Haveli Case StudyAyush RawatNessuna valutazione finora

- Installation Guidelines: 1. Preparing The SubgradeDocumento3 pagineInstallation Guidelines: 1. Preparing The SubgradeElard QANessuna valutazione finora

- Aci350 3 06Documento67 pagineAci350 3 06juantovarNessuna valutazione finora

- JDE 12 - Design of ColumnsDocumento47 pagineJDE 12 - Design of Columnsyedida viswanadhNessuna valutazione finora

- Sikadur 31 CF Normal Pds enDocumento4 pagineSikadur 31 CF Normal Pds enyacovaNessuna valutazione finora

- 2014.03.27 Volume 2 Design ENDocumento134 pagine2014.03.27 Volume 2 Design ENSalman KaziNessuna valutazione finora

- Liebherr Fridge ManualDocumento18 pagineLiebherr Fridge ManualJames RavensdaleNessuna valutazione finora