Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Neutral Bio Polish

Caricato da

Kushagradhi DebnathCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Neutral Bio Polish

Caricato da

Kushagradhi DebnathCopyright:

Formati disponibili

Neutral Bio-polishing gives even better fabric quality

By: Novozymes

Neutral bio-polishing gives even better fabric quality

By: Novozymes

Cellusoft CR, Novozymes latest product, helps textile manufacturers to boost the quality and finish of their fabrics. Most fabrics containing natural cotton fibres have tiny, loose or protruding yarns dotted over their surface, giving them a fuzzy texture. With repeated wearing and washing, these yarns break and their ends become tangled, resulting in pilling, which can make fairly new garments look old and worn. Bio-Polishing removes projecting fibres to improve the texture and appearance of fabrics. This not only creates a smoother fabric with resistance to pilling, but also improves softness, luster and drape. In short, Bio-Polished fabrics look better and last longer. Bio-Polishing uses a group of enzymes called cellulases. These enzymes have the ability to degrade cellulose, the basic structural building block of plants and the major constituent of other cellulosic fibres. When the enzymes are applied to the fabric, they partially digest excess and protruding yarns, loosening them from the fabric. The resulting fuzz is then removed by high-speed mechanical agitation of the fabric, for example in a jet dyer. Sensitive cellulases However, this process has been hampered by the sensitivity of conventional Bio-Polishing enzymes to pH. Most cellulases will only operate effectively across a very narrow, acidic pH range. Even very small differences in pH can alter the performance and effect of the enzymes. All this means that manufacturers must take great care to ensure that the solution is at the correct pH for the enzyme to work properly and that the pH is uniform throughout the solution. The processes taking place before Bio-Polishing, for example bleaching and dyeing, require a high, alkaline pH. Operators must therefore carefully adjust the pH of the solution by adding acid prior to Bio-Polishing. The time taken to adjust the pH and wait for even circulation can significantly draw out the Bio-Polishing process. Seemingly trivial differences in pH between batches can lead to variability in the finish of the end product. Worse still, the acidic pH needed for optimum enzyme performance can reduce the dye retention of the fabric, resulting in color fading. A new generation of Bio-Polishing Novozymes latest product, Cellusoft CR, is an easy-to-use, fast-acting cellulase specially developed to improve Bio-Polishing in the textile industry. But what sets Cellusoft CR apart from the conventional cellulases used in Bio- Polishing? Han Kuilderd, mill industry manager at Novozymes, explains: Cellusoft CR is unique in that it allows Bio-Polishing under neutral conditions. The key advantage of Cellusoft CR is that it operates across a much wider pH range than the conventional cellulases used in Bio-Polishing. This eliminates the need to adjust the pH of the solution after dyeing or bleaching, reducing the total time needed for the Bio-Polishing process. Furthermore, because the enzyme can operate optimally over a wider pH range, small differences in pH do not affect the finish of the final product. In other words, Cellusoft CR ensures consistency of the end product with each and every batch. There are other advantages too. Cellusoft CR has excellent color retention properties when used on dyed fabrics. It minimizes fabric weight loss in Bio-Polishing. And it produces a visibly smoother fabric with lower lint formation and higher tensile strength. Cost-effective quality in no time Bio-Polishing has the potential to give textile manufacturers a clear edge over their competitors. But up to now many have avoided Bio-Polishing altogether because of poor repeatability and the time needed to complete the process. Others only consider using Bio-Polishing as a remedial measure for fabrics in which pilling is identified as a problem.

With Cellusoft CR, Novozymes offers textile manufacturers a reliable, cost-effective Bio-Polishing solution. With its broad pH range (pH 5-8), Cellusoft CR can be easily incorporated into standard protocols to improve the quality of a multitude of fabrics. Cellusoft CR is ideal for all textile manufacturers, whether they are currently using Bio-Polishing or not, says Han Kuilderd. Besides the readily visible effects on fabric quality, the broad pH profile of Cellusoft CR will help manufacturers to reduce acid consumption, processing times and batch failures. And this ultimately adds up to cost-savings.

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com To promote your company, product and services via promotional article, follow this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- UNIQEMA HypermerPolymericSurfactantsDocumento2 pagineUNIQEMA HypermerPolymericSurfactantsKushagradhi DebnathNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Catalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationDocumento21 pagineCatalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationKushagradhi DebnathNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Barco Projection SystemDocumento7 pagineBarco Projection SystemKushagradhi DebnathNessuna valutazione finora

- The Impact of 'Zero' Coming Into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurDocumento23 pagineThe Impact of 'Zero' Coming Into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurKushagradhi DebnathNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Hydrosulfite Types: Technical InformationDocumento8 pagineHydrosulfite Types: Technical InformationKushagradhi DebnathNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- British BS 5867 Part 2 Type B and C PDFDocumento1 paginaBritish BS 5867 Part 2 Type B and C PDFKushagradhi Debnath100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Reactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design ApproachDocumento10 pagineReactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design ApproachKushagradhi DebnathNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Taiwan K.K. Corp: Technical Data SheetDocumento2 pagineTaiwan K.K. Corp: Technical Data SheetKushagradhi DebnathNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Chemours Capstone For Textiles K25183-1Documento1 paginaChemours Capstone For Textiles K25183-1Kushagradhi DebnathNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Documento1 paginaThe+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Kushagradhi DebnathNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- No Vo GADocumento2 pagineNo Vo GAlongthNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Synthesis and Application of Cationic SoDocumento5 pagineSynthesis and Application of Cationic SoKushagradhi DebnathNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterDocumento1 paginaISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterKushagradhi DebnathNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Basosoft N-Ap: Technical InformationDocumento7 pagineBasosoft N-Ap: Technical InformationKushagradhi DebnathNessuna valutazione finora

- GOTS 3.0-4.0 Positive List 1Documento8 pagineGOTS 3.0-4.0 Positive List 1Kushagradhi DebnathNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

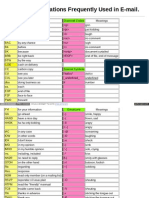

- A List of Abbreviations Frequently Used in E-Mail.: ItalicsDocumento3 pagineA List of Abbreviations Frequently Used in E-Mail.: ItalicsKushagradhi DebnathNessuna valutazione finora

- Process Chemicals ViswaatDocumento6 pagineProcess Chemicals ViswaatKushagradhi DebnathNessuna valutazione finora

- Evaluation of DetergentsDocumento14 pagineEvaluation of DetergentsKushagradhi DebnathNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Calculation of Dyeing Recipe Calculation For Dyeing LabDocumento3 pagineCalculation of Dyeing Recipe Calculation For Dyeing LabKushagradhi DebnathNessuna valutazione finora

- Problems and Aspects of Natural DyesDocumento8 pagineProblems and Aspects of Natural DyesKushagradhi Debnath100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Dwarkesh Enterprise: Properties of GREEN, VIOLET & BLUE PigmentsDocumento1 paginaDwarkesh Enterprise: Properties of GREEN, VIOLET & BLUE PigmentsKushagradhi DebnathNessuna valutazione finora

- HeiQ Product Range 2014-03-25Documento37 pagineHeiQ Product Range 2014-03-25Kushagradhi Debnath100% (1)

- Phosphate EstersDocumento4 paginePhosphate EstersKushagradhi DebnathNessuna valutazione finora

- Singeing: ND THDocumento45 pagineSingeing: ND THSubham PalNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Study of The Effects of Time On Biopolishing of Cotton Knit FabricsDocumento54 pagineStudy of The Effects of Time On Biopolishing of Cotton Knit Fabricskhansha ComputersNessuna valutazione finora

- Ans Majeed 16-NTU-1336: Presented byDocumento11 pagineAns Majeed 16-NTU-1336: Presented byBasit KhanNessuna valutazione finora

- Bangabandhu Textile Engineering College: Project WorkDocumento5 pagineBangabandhu Textile Engineering College: Project WorkGolam Samdanee TaneemNessuna valutazione finora

- Presentation1 PROJECTDocumento39 paginePresentation1 PROJECTSagar ShriNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- BOMT22005060 Report Number:: Intertek India Private LimitedDocumento7 pagineBOMT22005060 Report Number:: Intertek India Private LimitedasopaNessuna valutazione finora

- Home ScienceDocumento13 pagineHome ScienceJhilik DeyNessuna valutazione finora

- 021 Standard Quality Level PDFDocumento42 pagine021 Standard Quality Level PDFhasan mehedi pialNessuna valutazione finora

- M235 MTD OPERATION MANUAL 4-Head - Rev1.0Documento31 pagineM235 MTD OPERATION MANUAL 4-Head - Rev1.0ElenaNessuna valutazione finora

- 06 - 05 - 10 Characteristics of Knitted Fabrics After Enzyme TreatmentDocumento10 pagine06 - 05 - 10 Characteristics of Knitted Fabrics After Enzyme Treatmentleosun halariNessuna valutazione finora

- Pilling 1Documento16 paginePilling 1Indhu IndhhuuNessuna valutazione finora

- Knit Garment STD Reqmnt CJB PDFDocumento1 paginaKnit Garment STD Reqmnt CJB PDFmishraajitNessuna valutazione finora

- Kenmore Portable Compact Washing Machine ManuaDocumento116 pagineKenmore Portable Compact Washing Machine Manuacmoran7Nessuna valutazione finora

- OF Curriculum Vitae: Career ObjectiveDocumento3 pagineOF Curriculum Vitae: Career ObjectiveMd MasumNessuna valutazione finora

- Textile Testing and Quality Control: 1 Assignment SubmissionDocumento26 pagineTextile Testing and Quality Control: 1 Assignment Submissiontripti keshanNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Pilling Resistance TestsDocumento7 paginePilling Resistance TestsTauqeer RazaNessuna valutazione finora

- Comparison of Recycle Yarn To VirginDocumento9 pagineComparison of Recycle Yarn To VirginParvesh Khurana100% (1)

- Test ReportDocumento8 pagineTest ReportNishantNessuna valutazione finora

- Finishing FaultsDocumento4 pagineFinishing Faultsranjann349100% (1)

- Chapter 44: Fabrics and Their CareDocumento26 pagineChapter 44: Fabrics and Their CareParul PrajapatiNessuna valutazione finora

- Quality Standards Requirements PDFDocumento22 pagineQuality Standards Requirements PDFMd Matiur Rahman100% (1)

- Ekoten Textile Test Report - Lululemon - E01261Documento4 pagineEkoten Textile Test Report - Lululemon - E01261eacik7Nessuna valutazione finora

- Revolution of Biotechnology in Finishing Sector of Textile: AbstractDocumento12 pagineRevolution of Biotechnology in Finishing Sector of Textile: AbstractS BiswasNessuna valutazione finora

- Chemical Modification of PolyestersDocumento11 pagineChemical Modification of PolyestersVASANHF1Nessuna valutazione finora

- Physical Properties of Denim Fabrics After Various Denim Washing FormulasDocumento3 paginePhysical Properties of Denim Fabrics After Various Denim Washing FormulasRonak JoshiNessuna valutazione finora

- 03-ASTM - Technical - Training-081518-R1 Random Tumble Pilling TestDocumento51 pagine03-ASTM - Technical - Training-081518-R1 Random Tumble Pilling TestTahir NizamNessuna valutazione finora

- PillingDocumento8 paginePillingRafiul IslamNessuna valutazione finora

- Textile Testing and Product EvaluationDocumento64 pagineTextile Testing and Product EvaluationAnmol Jain100% (3)

- (23000929 - Autex Research Journal) Comparison of Mechanical and Thermal Comfort Properties of Tencel Blended With Regenerated Fibers and Cotton Woven FabricsDocumento6 pagine(23000929 - Autex Research Journal) Comparison of Mechanical and Thermal Comfort Properties of Tencel Blended With Regenerated Fibers and Cotton Woven FabricsAmina BenrbehNessuna valutazione finora

- Normas Iso PublicadasDocumento23 pagineNormas Iso PublicadasGIRAÚL BRITONessuna valutazione finora

- Ikigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessDa EverandIkigai: The Japanese Life Philosophy to Finding Happiness and PeacefulnessValutazione: 5 su 5 stelle5/5 (91)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffDa Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffValutazione: 5 su 5 stelle5/5 (19)

- Bare Bones: I'm Not Lonely If You're Reading This BookDa EverandBare Bones: I'm Not Lonely If You're Reading This BookValutazione: 4 su 5 stelle4/5 (11)

- Twelve Caesars: Images of Power from the Ancient World to the ModernDa EverandTwelve Caesars: Images of Power from the Ancient World to the ModernValutazione: 3.5 su 5 stelle3.5/5 (9)