Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chart

Caricato da

Sherif AbdelhameedDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chart

Caricato da

Sherif AbdelhameedCopyright:

Formati disponibili

Corrosion prevention is an essential factor in the economic utilisation of steel.

Provision of the appropriate protective coating can bring initial savings plus substantial economies in service, due to reduction or elimination of maintenance and lost service time, and by deferring the replacement date of structures and equipment. In suitable applications hot dip galvanizing provides ideal corrosion protection for steel no other coating matches galvanizings unique combination of low rst cost, ease of inspection for coating quality, durability, predictable performance, low maintenance, and resistance to abrasion and mechanical damage.

INTRODUCTION

When designing a structure which is to be hot dip galvanized, it must be borne in mind that articles are immersed into and withdrawn from a bath of molten zinc heated to a temperature of about 450C. Design and fabrication is required to conform to acceptable standards which apply, regardless of whether a galvanized or a painted coating is to be applied. In the case of galvanizing, some additional requirements which aid access and drainage of molten zinc, will improve the quality of the coating and also reduce costs. With certain fabrications, holes which are present for other purposes may fulfil the requirements of venting of air and draining of zinc; in other cases it may be necessary to provide extra holes for this purpose. For complete protection, molten zinc must be able to flow freely to all parts of the surfaces of a fabrication. With hollow sections or where there are internal compartments, the galvanizing of the internal surfaces eliminates any danger of hidden corrosion occurring in service. Some general principles for guidance are: Holes both for venting and draining should be as large as possible. The absolute minimum hole sizes are given in table 2. Holes for venting and draining should be diagonally opposite one another at the high point and low point of the fabrication as it is suspended for galvanizing (figure 10). With hollow sections sealed at the ends, holes should be provided, again diagonally opposite one another, as near as possible to the ends of the hollow member (figure 8). In some cases it may be more economical to provide V or U shaped notches (figure 9) in the ends of the tubes, or to grind corners off rectangular hollow sections. These procedures will provide ideal means for venting and draining. Where holes are provided in end plates or capping pieces, they should be placed diagonally opposite to one another, off centre and as near as possible to the wall of the member to which the end plate is connected (figure 7). Internal and external stiffeners, baffles, diaphragms, gussets etc., should have the corners generously cropped with centre holes (particularly for "Road Sign Gantry" type of configurations) to aid the flow of molten zinc and to prevent air entrapment (figures 2, 11 and 24 and detail X). Bolted joints are best made after hot dip galvanizing. SIZE Facilities exist to galvanize articles of virtually any size and shape (see list of members with kettle sizes - available from the Hot Dip Galvanizers Association).When an article is too big for single immersion in the largest bath available it may be possible to galvanize it by double-end dipping (table 1), depending on the handling facilities and layout of the galvanizing plant (check with the galvanizer). Large cylindrical objects can often be galvanized by progressive dipping (figure 1). MODULAR DESIGN Large structures are also hot dip galvanized by designing in modules for later assembly by bolting or welding. Modular design techniques often produce economics in manufacture and assembly through simplified handling and transport (see also Masking). STEEL GRADE It is possible to hot dip galvanize all structural steels and the ultimate coating thickness achieved is determined by steel analysis, immersion time and to a lesser degree, zinc temperature. In modern steel making practice, either aluminium or silicon is added to molten steel as de-oxidising agents. Aluminium adEdges Because a hot dip galvanized coating is formed by metallurgical reaction between molten zinc and steel, the coating thickness on edges and corners is equal to, or thicker than that on flat surfaces. Thus the rounding of sharp edges, as required for paint coatings, is not necessary. If subsequent painting is required, sharp edges should be rounded during fabrication to a radius of 3mm or 50% of steel thickness. Welding Welds should be continuous and free from excessive pin-holing and porosity. Weld slag, normally associated with stick welding, is not readily removed by acid cleaning and such slag must be removed by mechanical means prior to hot dip galvanizing. Shielded arc welding is preferred since this method does not result in the presence of tightly adhering slag. Weld Spatter Weld spatter does not reduce the protective properties of a hot dip galvanized coating to the same extent as a paint coating, but it is recommended practice to remove spatter prior to hot dip galvanizing. Punching Full size punching of holes is permitted when (amongst other requirements such as distortion free, burr free, not subject to fatigue), according to Clause 4.3.6.3.c of SANS 2001-CS1, the thickness of the material is not greater than the hole diameter plus 3mm; nor greater than 12mm. Clause 4.3.6.4 Punching and reaming reads: Punching is permitted without the conditions of 4.3.6.3 provided the holes are punched at least 2mm less in diameter than the required size and the hole is subsequently reamed to the full diameter. Material of any thickness may be punched at least 3mm undersize and then reamed, or be drilled. Good shop practice in relation to ratios of punched hole diameter to plate thickness, and punch/die diametral clearance to plate thickness should be observed. For static loading, holes may be punched full size in material up to mm thick where Fy is Fy material yield stress up to 360MPa. Shearing and Flame Cutting Edges of steel sections greater than 16mm thick subject to tensile loads should be machined or machine flame cut. Edges of sections up to 16mm thick may be cut by shearing. Sheared edges to be bent during fabrication should have stress raising features such as burrs and flame gouges removed to a depth of at least 1.5mm. Temperatures associated with flame cutting alter the surface properties of steel and if such surfaces are not thoroughly ground, a thinner galvanized coating will be formed (usually below the minimum specified). Before bending, edges should be radiused over the full arc of the bend. Bending Steels that are susceptible to embrittlement and fatigue failure should be bent over a smooth mandrel with a minimum radius 2 to 3 times material thickness. Where possible hot work at red heat. Cold bending is unlikely to affect steels less than 3mm thick. COATING REPAIR PROCEDURES By the Galvanizer In terms of SANS 121:2011 (ISO 1461:2009) a galvanizer may repair a coating by either zinc metal spraying or zinc rich epoxy.The latter method must conform to certain requirements in the specification. The preferred method of repair is by zinc metal spraying. Repair will only be necessary if bare spots are present, usually caused by inadequate cleaning, air entrapment or if mechanical damage has occurred. No single uncoated area shall exceed 10cm2 and the total uncoated areas for renovation by the galvanizer or on site shall not exceed 0,5% of the total area of the component. Zinc Metal Sprayed Coatings Method The damaged area is to be lightly blasted using preferably a pencil blasting nozzle or the surrounding coating should be masked in order to limit damage.

NOTE:This chart is purely indicative and similar charts can be prepared for baths of different dimensions. The maximum sizes which a particular galvanizer can process should always be checked at the design stage. Holes 12mm diameter or larger

VENTING, FILLING AND DRAINAGE

WELDING, HANDLING, MASKING, IDENTIFICATION, MINIMIZING DISTORTION AND CLEARANCE FOR MOVING PARTS

MASKING Masking materials have been developed, which if applied prior to hot dip galvanizing, will prevent the formation of the galvanized coating on surfaces where it is not desired. Contact the Association for further information. COMBINATIONS OF FERROUS SURFACES Fabrications containing a combination of castings and steels, or rusted and mill scaled surfaces must be abrasive blast cleaned before galvanizing. WELD SLAG In circumstances where seal welding is not practical, a degree of temporary surface staining at crevices may be apparent after hot dip galvanizing and quenching. This is often incorrectly described as acid staining. Clean with a bristle brush and mild detergent if necessary. Crevices of this nature can be sealed after hot dip galvanizing with an appropriate sealant. LARGER OVERLAPPING SURFACES Figure 17 If contacting surfaces cannot be avoided, one diameter 10mm hole is to be provided in one of the members for every 100cm2 of overlap area and the perimeter of the contacting area should be continuously welded (figure 23). A vent hole in one member will ensure the safety of galvanizing personnel and prevent damage to the article. Figure 21 Figure 22 OVERLAPPING SURFACES A minimum gap of at least 2mm between plates, overlapping surfaces and back-toback angles and channels, must be provided (figure 21). When small overlaps are unavoidable, seal edges by welding.

Figure 20

Angle bracings should, if possible, be stopped short of the main boom flange

Figure 2

Figure 3

Figure 10

Weld slag must be removed by abrasive blast cleaning, de-scaling, chipping, grinding, ame cleaning or a pneumatic needle gun. PROVISION FOR HANDLING

External stiffeners, welded gussets and webs on columns and beams and gussets in channel sections should have their corners cropped. The gaps created should be as large as possible (detail X is preferable) without compromising structural strength. If welding is required around the edge created, a radiused corner is desirable to facilitate continuity of the weld around the cut end to the other side. Circular holes are less effective: if used, they should be as close to corners and edges as practicable. Where more convenient, the cropped corners or holes may be in the main beam. Consultation with the galvanizer, regarding the appropriate vent and drainage hole sizes is recommended. WELDED PIPE SECTIONS Closed sections must never be incorporated in a fabrication. Sections should be interconnected using open mitred joints as illustrated in figure 4, or interconnecting holes should be drilled before fabrication as in figure 5.

Open mitred joints

TANKS AND CLOSED VESSELS When both internal and external surfaces are to be hot dip galvanized at least one lling and draining hole must be provided, with a vent hole diagonally opposite to allow the exit of air during immersion. For each 0,5 cubic metres of volume, provide one ll/drain hole of minimum size 60mm and vent hole of minimum size 40mm. Internal bafes should be cropped as illustrated or as per detail X above, especially for structures such as "Road Sign Gantries" which also require considerably larger centre holes in bafe plates and base plates. Manholes or pipes should nish ush inside to prevent trapping excess zinc. Lifting lugs should be provided opposite the biggest and most accessible filling / draining hole and adjacent to the vent hole on the opposite end (see figure 10). The lugs must be designed to accommodate the excess mass of molten zinc within the cylinder / pipe on withdrawal. Large vessels require an appropriate size manhole in the baffle.

Work not suitable for handling with chains, baskets, hooks or jigs must be provided with suspension holes or lifting lugs (see figure 10). If in doubt check with the galvanizer. In case of double-sided fillet welds, the weld must be continued around the ends of the sheet to prevent the penetration of acid into any conceivable crevice. MATERIALS SUITABLE FOR HOT DIP GALVANIZING All ferrous materials are suitable, including sound stress-free castings. Brazed assemblies may be hot dip galvanized but check first with galvanizer. Assemblies soft soldered or aluminium rivetted cannot be hot dip galvanized. DISTORTION Distortion can be minimised by: Use of symmetrical designs. Use of sections of a similar thickness (figure 16). Use of stiffened unsupported steel sections, particularly when steel is less than 3 - 4mm thick. Use of preformed members with the correct minimum bend radius to minimise stress. Use of balanced or staggered welding techniques to minimise stresses. Large open fabrications, thin walled trough sections and tanks may require temporary cross stays to prevent distortion during hot dip galvanizing. Maximising ll, drain and vent hole sizes and optimising their positions. Figure 15 Use of symmetrical sections minimises distortion during hot dip galvanizing. Avoid combinations of thick and thin materials. Bolt together after individually hot dip galvanizing. Figure 18

STRENGTHENING GUSSETS AND WEBS Welded strengthening gussets and webs on columns and beams, and strengthening gussets in members fabricated from channel or I-beam sections should have corners cropped or holed (figures 2 & 24) to prevent the entrapment of air in pockets and corners allowing complete access of pickle acids and molten zinc to the entire surface of the work, and Figure 23 to facilitate drainage during withdrawal from degreaser, acid solutions, rinsewater, ux and molten zinc. CLEARANCE FOR MOVING PARTS Drop handles, hinges, shackles, shafts and spindles require a minimum radial clearance, to allow for the thickness of the hot dip galvanized coating (see below). Shaft or spindle size Up to 30mm diameter Over 30mm diameter Minimum radial clearance 2,0mm 2,0 - 2,5mm Figure 25 Figure 24

4500

Figure 4

Holes 20mm diameter or larger

Alternatively external holes may be positioned as in figure 6, a method which is often preferred by the galvanizer, since quick visual inspection shows that the work is safe to galvanize. Pipe ends can be left open, or provided with removable plugs (see unwanted vent holes). SMALL TUBULAR FABRICATIONS Small tubular fabrications must be vented, preferably with holes not less than 10mm diameter (see table 2). UNWANTED VENT HOLES These may be closed by hammering in lead plugs after galvanizing and filing off flush with surrounding surfaces.

OVERSIZE TAPPING ALLOWANCE FOR HOT DIP GALVANIZED NUTS The zinc coating on external threads shall be free from lumps and shall not have been subjected to a cutting, rolling or finishing operation that could damage the zinc coating. The zinc coating of an external standard metric thread that has not been undercut shall be such as to enable the threaded part to fit an oversized tapped nut in accordance with the allowances given in the table below (See also NOTE 1 in Specifying Hot Dip Galvanizing) Nominal size of thread (mm) M8 to M12 M16 to M24 Allowance

Figure 5

TUBULAR FABRICATIONS/HOLLOW STRUCTURALS Drain/vent hole sizes should be preferably 25% of internal diameter or diagonal dimension for sections yielding a maximum cross sectional area of 180cm2. This percentage can be dependent on the shape of the fabrication, therefore consultation with the galvanizer at the design stage is recommended. FOR MUCH IMPROVED COATING QUALITY, REDUCED COATING GROWTH, PROVIDING AN IMPROVED AESTHETICALLY PLEASING APPEARANCE, APPROPRIATELY SIZED AND POSITIONED FILL, DRAIN AND VENT HOLES CAN MAKE A HUGE CONTRIBUTION. Figure 11 When vessels and heat exchangers etc., are not to be galvanized inside, snorkel tubes or extended vent pipes must be fitted after discussion with the galvanizer, to allow air to exit above the level of molten zinc in the galvanizing bath. Figure 13 Figure 12

Figure 1

Complete and rapid immersion of the item in the galvanizing bath, i.e no double end dipping. Air cooling after hot dip galvanizing in preference to water quenching.

Figure 6

Table 1

ditions (as in aluminium-killed steel - Si less than 0.04%) has no effect on the structure and coating thickness. Silicon-killed steel with silicon (Si) ranging between 0.15 to 0.25% is ideal for heavy duty coatings. On either side of this range, excessively thick and brittle coatings can develop if extended immersion times in molten zinc cannot be avoided. The immersion cycle is determined by the configuration of the structure and thickness of the section. (The thicker the steel, the longer the immersion time). The impact of phosphorous (P) in steel can be severe regardless of the Si present. At levels below 0.015% P has little influence on coating growth. Above 0.02% the effect is extremely severe even when Aluminium-killed steel is galvanized. It is for this reason that hot dip galvanizing specifications provide for minimum coating thickness and no maximum limit is set. The specification does not stipulate a maximum upper coating thickness. (See NOTE 1 in Specifying Hot Dip Galvanizing). BENDING AND FORMING AFTER HOT DIP GALVANIZING Components which have been hot dip galvanized should not be bent or formed by applying heat above the melting temperature of zinc as this can cause embrittlement due to intergranular liquid zinc penetration between steel crystal boundaries. FABRICATION DEFECTS Burrs Unlike a paint coating, burrs will be overcoated by hot dip galvanizing but the removal of a burr after galvanizing may result in the presence of a small uncoated surface and for this reason, burrs must be removed prior to galvanizing.

A zinc metal sprayed coating is then applied to the abrasive blasted surface to a 100m thickness or equal to the surrounding coating thickness, if a duplex coating is to be applied. The repaired area is then wire brushed, (preferably stainless steel) to remove loosely adhering over sprayed zinc.Wire brushing provides the added benefit of sealing the pores that may be present in the sprayed coating. Zinc Rich Epoxy or Zinc Rich Paint Method The defective area shall be blasted as above or abraded with abrasive paper (roughness 80 grit). All dust and debris must be completely removed. In the event of moisture being present, all surfaces are to be properly dried. A zinc rich paint or epoxy containing greater than 80% zinc in the dry film, should be applied to a DFT of 100m (overlapping the bare spot by 5mm) or equal to the surrounding coating thickness, if a duplex coating is to be applied. The preferred product is a two component zinc rich epoxy. Coating Repair Products Approved products for repair were only available in large containers. Due to the large quantities involved and short pot life when mixed, the products proved to be expensive and wasteful. Products are now available in a two component, solvent free form, packed for convenience in handy, easy to use squish packs. One of these products is available from the Association and all of its members. The galvanizer acts as a sub-contractor to a steel fabricator and as such, his contractual relationship is normally with the fabricator, not with the ultimate user or specifier. It is important, therefore, that the users' or specifiers requirements for hot dip galvanizing are made clear to the fabricator and that all instructions are channelled (in writing) via the fabricator to the galvanizer. Alternatively, the selected galvanizer should be invited to participate in the initial project team meetings, when surface finishes as in duplex coatings or Architectural Hot Dip Galvanizing, are crucial.

Holes or notches placed at locations agreed with the galvanizer - ideally on both sides of members, or diagonally opposite each other.

Figure 26

IDENTIFICATION MARKINGS For permanent identification use heavily embossed, punched or welded lettering. For temporary identification use heavily embossed metal tags wired to the work, water soluble paint or the correct marking pen. Do not use enamel/oil paints, adhesive labels or any other coating that cannot be readily removed by degreasing or pickling. If present, these coatings require to be removed by paint stripper, grinder or abrasive blasting prior to pickling and hot dip galvanizing. An appropriate marking pen which is easily removable in the cleaning process is available (contact the Association).

0,33 0,38

V or U notches can be cut into ends or end corners of members before welding.

Figure 7

Figure 8

Figure 9

Figure 14

Figure 16

Figure 19

On bolts greater than M24, undercutting of bolt threads is frequently preferred to oversizing of nut threads. The allowance should be increased to 0,4mm.

SPECIFYING HOT DIP GALVANIZING

SANS14713 (ISO14713:2009): Protection against corrosion of iron and steel in structures - Zinc and aluminium coatings - Guidelines. SANS4998 (ISO4998:2005): SANS3575 (ISO3575:2005): Continuous hot dip zinc coated carbon steel sheet of structural quality. Continuous hot dip zinc coated carbon steel sheet of commercial, lock forming and drawing grades. Fasteners Hot dip galvanized coatings. Applicable for all fasteners exceeding a tensile strength of 1000Mpa.

Profiles Steel > 6mm Steel > 3mm to 6mm Steel 1.5mm to 3mm Steel < 1.5mm

MINIMUM COATING THICKNESS ON ARTICLES THAT ARE NOT CENRIFUGED SANS 121:2011 (ISO 1461:2009)

Local coating thickness min. m* 70 55 45 35 Local coating mass (minimum) 505 395 325 250 Mean coating thickness, min. m* 85 70 55 45 Mean coating mass (minimum) 610 505 395 325

INSPECTION OF WORK BEFORE DESPATCH TO THE GALVANIZER

Fabricated assemblies, castings and other components for hot dip galvanizing should be inspected and any significant surfaces identified, before despatch to the galvanizer to ensure that the following points conform to design requirements. This may avoid costly rectification and delays at the galvanizing plant. SIZE AND SHAPE Check that work is suitably sized and dimensioned for the handling and galvanizing facilities of the selected galvanizer. It may be too late to make changes to the design but it is costly to despatch work which the galvanizer cannot process. STRUCTURAL STEEL Check that punching, shearing and bending have been carried out in conformity with the recommendations above. SATISFACTORY HOT DIP GALVANIZING Observance of the points listed above will ensure optimum hot dip galvanized product quality and minimise extra costs or delays. Check that closed vessels and tubular fabrications are vented with appropriate size holes, for safety and satisfactory hot dip galvanizing. Check that welding slag and spatter have been completely removed (anti-spatter agents are highly recommended). Check that assemblies comprising castings and steels of widely differing surface conditions have been abrasive blast cleaned. This will minimise differences in the coating. Check that castings are abrasive blast cleaned before despatch unless otherwise arranged. Check that large grey iron castings have been normalised. Check that all temporary fabrication markings are easily removed by the galvanizing process and that permanent identification markings (if necessary) have been provided. Check that an appropriate marking pen which is easily removed, has been used. Contact the Association.

THE HOT DIP GALVANIZERS ASSOCIATION OF SOUTHERN AFRICA

Introduction The Hot Dip Galvanizers Association of Southern Africa was founded in 1965 and its membership represents the majority of the available hot dip galvanizing capacity of Southern Africa. The Vision To position the Hot Dip Galvanizers Association of Southern Africa, comprising all its Members and other interested parties, as a professional organization serving the interests of all parties dependant upon the hot dip galvanizing industry. Charter Statement The primary role of the Hot Dip Galvanizers Association of Southern Africa is to promote a higher level of acceptance of, and confidence in, hot dip galvanized products and offerings on a national basis. The Association is the vehicle that provides all of its members with technical know-how and marketing support in order to grow the quality and acceptability of hot dip galvanizing in the marketplace. The Hot Dip Galvanizers Association of Southern Africa is an advisory body and independent authority, representing the end-users, consumers and specifiers of hot dip galvanized steel products, ensuring quality standards and customer satisfaction with the corrosion prevention system supplied by hot dip galvanizers of southern Africa. Delivery Activities: Promoting the use of hot dip galvanizing for cost effective corrosion protection in applications where its use is appropriate. Providing technical assistance and advice for specifiers, fabricators and end users while also recommending alternative protective methods where appropriate. Identifying and investigating potential new applications for hot dip galvanizing. Participating in development projects on behalf of industry by providing assistance in the form of technical consulting, practical recommendations and assistance with the preparation of design specifications. Providing assistance with quality control during fabrication and hot dip galvanizing. Disseminating technical knowledge by providing a consulting and training service as well as the publication of technical literature. Providing training and education for member companies to ensure a high standard of quality and service throughout the galvanizing industry. Publications Available from the Association Association Magazine Hot Dip Galvanizing Today. (Free publication produced quarterly) Steel Protection by Hot Dip Galvanizing and Duplex Coating Systems. Practical Guidelines for the Inspection and Repair of Hot Dip Galvanized Coatings. HDGASA01-1990 Code of Practice for Surface Preparation and Application of Organic Coatings Applied to New Unweathered Hot Dip Galvanized Steel. HDGASA02-1990 Specification for the Performance Requirements of Duplex Coating Systems. HDGASA03-2006 Hot Dip Galvanizing and Duplex Coating Protection Specification. Hot Dip Galvanizing for Architectural Purposes Check List. Wall Chart - Design for Hot Dip Galvanizing. Facts About Hot Dip Galvanizing Please visit our website www.hdgasa.org.za for Information Sheets, Case Studies and other technical information.

GUIDELINES FOR MINIMUM VENT AND DRAINAGE HOLE SIZES - REQUIRED BY SECTION LENGTH Tube Dia RHS Sizes (mm) 50 50 x 30 60 x 40 50 x 50 60 x 60 Length (m) 1 2 3 4 5 6 7 8 9 10+ 10 (12) 10 (12) 10(12) 12 (2x10) 12 (2x10) 12 (2x10) 16(2x12) 16 (2x12) 16(2x12) 20 (2x16) 10 (12) 10 (12) 12 (2x10) 12 (2x10) 16 (2x12) 16 (2x12) 16 (2x12) 16 (2x12) 16 (2x12) 25 (2x16) 10 (12) 12 (2x10) 12 (2x10) 16 (2x12) 16 (2x12) 20 (2x16) 20 (2x16) 20 (2x16) 25 (2x20) 25 (2x20) 12 (2x10) 12 (2x10) 12 (2x10) 16 (2x12) 16 (2x12) 20 (2x16) 20 (2x16) 25 (2x20) 25 (2x20) 25 (2x20) 60 - 76 80 x 40 70 x 70 100 x 50 76 x 76 89 80 x 80 120 x 60 102 - 114 90 x 90 120 x 80 100 x 100 127 - 152 160 x 80 120 x 120 150 x 100 140 x 140 Hole size (mm) 16 (2x12) 16 (2x12) 16 (2x12) 16 (2x12) 25 (2x20) 25 (2x20) 25 (2x20) 25 (2x20) 2x25 (3x20) 2x25 (3x20) 20 (2x16) 20 (2x16) 20 (2x16) 25 (2x20) 25 (2x20) 25 (2x20) 25 (2x20) 2x25 (3x20) 2x25 (3x20) 2x25 (3x20) 25 (2x20) 25 (2x20) 25 (2x20) 25 (2x20) 30 (2x25) 50 (2x30) 50 (2x30) 50 (2x30) 50 (2x30) 50 (2x30) 30 (2x25) 30 (2x25) 30 (2x25) 30 (2x25) 30 (2x25) 50 (2x40) 50 (2x40) 50 (2x40) 2x50 (3x40) 2x50 (3x40) 30 (2x25) 30 (2x25) 40 (2x30) 40 (2x30) 50 (2x40) 50 (2x40) 50 (2x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 40 (2x30) 40 (2x30) 50 (2x40) 50 (2x40) 50 (2x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 40 (2x30) 50 (2x40) 50 (2x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 2x50 (3x40) 165 200 x 100 150 x 150 219 180 x 180 250 x 150 245 200 x 200 220 x 220 273 300 x 200 250 x 250 340 x 200 324 400 x 200 355 300 x 300 450 x 250

BS EN ISO 10684:2004

To ensure compliance in all aspects of the standard, specifiers and customers on enquiry should request a certificate of conformance to ISO10474 such as the SABS Mark Scheme. For technical support from the HDGASA a member of the Association, is preferred.

When hot dip galvanizing is specified, the surface of the base steel is completely covered with a relatively uniform coating of zinc and the minimum thickness specified is related to the thickness of the steel being hot dip galvanized, as shown in table 3. HOT DIP GALVANIZING SPECIFICATIONS SANS121 (ISO1461:2009): Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods. Internal and/or external protective coatings for steel tubes - Specification for hot dip galvanized coatings applied in automatic plants.

Table 3

Note 1: Hot dip galvanizing specifications state the minimum acceptable coating thickness, established by a minimum of 5 individual readings per reference area. The thickness actually achieved, varies with steel composition and this can range from the minimum up to at least 50% greater. As life expectancy predictions are normally based on the minimum coating thickness, they are usually conservative. The specification does not stipulate a maximum upper coating thickness limitation, however, excessively thick coatings on threaded articles are undesirable. In order to ensure effective tensioning an appropriately oversized nut must be screwed on to the bolt for quality assurance purposes, this applies particularly to high strength bolts. LEAD TIMES As a general guide, most articles can be hot dip galvanized and returned to the fabricator within 7 days after receipt.

MINIMUM COATING THICKNESS ON ARTICLES THAT ARE CENTRIFUGED TO SANS 121:2011 (ISO 1461:2009)

Diameter of the article > 6mm diameter 6mm Local coating thickness min, um* 40 20 Local coating mass (minimum) 285 145 Mean coating thickness min, um* 50 25 Mean coating mass (minimum) 360 180

Table 4

Variance in coating thickness: A requirement for a thicker coating (25% greater than the standard in table 3 above, can be requested for components not centrifuged, without affecting specification conformity). NOTE Where steel composition does not include moderate to high reactivity, thicker coatings are not always easily achieved.

SANS32 (EN10240:1997):

Note: The hole sizes specified above may be substituted with a larger number of smaller holes. (minimum 10mm for vent and 12mm for fill/drain hole)

Table 2

In the case of large contracts, the galvanizer should be involved at the programming stage with the fabricator and the end user. Hot dip galvanizing is normally the final process after fabrication and prior to delivery and erection. If sufficient time for galvanizing and inspection is not provided in the overall programme, costly delays may occur at the erection stage.

RELIABILITY

The hot dip galvanized coating is formed by a metallurgical reaction between suitably cleaned steel and molten zinc. This results in the formation of a series of iron/zinc alloys which are overcoated with relatively pure zinc. The process entails total immersion of components in both pretreatment chemicals and molten zinc. This ensures uniform protection and coating reliability even on surfaces which would be inaccessible for coating by other methods.

DEPENDABILITY

Ease of inspection and dependability in service are benecial features of a hot dip galvanized coating. The cathodic protection of steel by zinc ensures that corrosion of the underlying steel cannot occur as long as zinc is present. Even at discontinuities on the coating, corrosion creep under the surrounding zinc is not possible.

PREDICTABILITY

The durability of a hot dip galvanized coating is determined by the degree of corrosion of zinc in a specic environment and the thickness of the coating. Corrosion of zinc is normally uniform, thus durability of a hot dip galvanized coating is predictable in most applications.

THE ASSOCIATION IS A TECHNICAL INFORMATION CENTRE ESTABLISHED FOR THE BENEFIT OF SPECIFIERS, CONSULTING ENGINEERS, END USERS AND ITS MEMBERS

JOHANNESBURG: Quality House, Unit U4, St. Christopher Road, St. Andrews, Bedfordview P.O. Box 2212 Edenvale 1610 Telephone: 011 456 7960 Fax: 011 454 6304 Email: hdgasa@icon.co.za CAPE TOWN: Telephone: 021 797 4735 Email: terry@hdgasa.org.za Website: www.hdgasa.org.za

Potrebbero piacerti anche

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Hot Dip Galvanizing For FastenersDocumento3 pagineHot Dip Galvanizing For FastenersIrwin CastroNessuna valutazione finora

- Ch13 Materials ApplicationsDocumento63 pagineCh13 Materials ApplicationsThefairman UnkownNessuna valutazione finora

- Stainless Steel Alloys Comparsion ChartDocumento3 pagineStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- 3coated SteelDocumento20 pagine3coated Steelalifakash1605Nessuna valutazione finora

- PART 92 Cu-Ni Welding - Part 1 Cu-Ni Material PropertiesDocumento16 paginePART 92 Cu-Ni Welding - Part 1 Cu-Ni Material Propertiesravindra_jivaniNessuna valutazione finora

- Baosteel CRGO StandardDocumento12 pagineBaosteel CRGO Standarddarkonikolic78Nessuna valutazione finora

- ASTM-A563 Fasteners MarkingDocumento1 paginaASTM-A563 Fasteners Markinga04205Nessuna valutazione finora

- Thành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateDocumento2 pagineThành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateĐình Sỹ TTPNessuna valutazione finora

- Welding TolerancesDocumento3 pagineWelding Tolerancessaeedsaeed31Nessuna valutazione finora

- Highlight HDG Inspection CoursaaaaaaaaaaaaaaaaaDocumento44 pagineHighlight HDG Inspection CoursaaaaaaaaaaaaaaaaaAyman Hamed MalahNessuna valutazione finora

- Advanced Gas Metal Arc Welding ProcDocumento20 pagineAdvanced Gas Metal Arc Welding ProcjavadmohammadiNessuna valutazione finora

- Material WeldingDocumento1 paginaMaterial WeldingDebashish ChatterjeeNessuna valutazione finora

- Aluminum 5083Documento2 pagineAluminum 5083razormebackNessuna valutazione finora

- Weight Per Meter of WeldDocumento1 paginaWeight Per Meter of Weldreza329329Nessuna valutazione finora

- CR StandardsDocumento6 pagineCR Standardsalpha_beta48Nessuna valutazione finora

- JIS G 3141 Commercial Cold Rolled SPCC SteelsDocumento6 pagineJIS G 3141 Commercial Cold Rolled SPCC SteelsAnonymous 8lxxbNcA0sNessuna valutazione finora

- ISO 9692 3 2002 Joint PreparationDocumento16 pagineISO 9692 3 2002 Joint PreparationLHYT NTUANessuna valutazione finora

- GTAW Welding of CP Titanium and Ti6Al4VDocumento1 paginaGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNessuna valutazione finora

- Ferrous Metals: General Grade Cast IronsDocumento8 pagineFerrous Metals: General Grade Cast IronskkamalakannaNessuna valutazione finora

- Projection WeldDocumento20 pagineProjection WeldCebrac ItatibaNessuna valutazione finora

- 2013 How Much Does Galvanizing CostDocumento2 pagine2013 How Much Does Galvanizing CosttassanaiNessuna valutazione finora

- Topic 1 - Mechanical Fastening 2Documento11 pagineTopic 1 - Mechanical Fastening 2nazirulhakimNessuna valutazione finora

- Welding TWIDocumento16 pagineWelding TWIEngr Arfan Ali DhamrahoNessuna valutazione finora

- Geometrical TolerancingDocumento12 pagineGeometrical TolerancingItalo Venegas100% (1)

- Material ComparisonDocumento1 paginaMaterial ComparisonNoir HamannNessuna valutazione finora

- Duplex & Super Duplex InformationDocumento7 pagineDuplex & Super Duplex InformationrajeshNessuna valutazione finora

- Products GuideDocumento12 pagineProducts GuideWK SinnNessuna valutazione finora

- Carefully Evaluate Code RequirementsDocumento3 pagineCarefully Evaluate Code Requirementsmayav1Nessuna valutazione finora

- Galvanizing and Mechanical Preparation of Steel - 1Documento4 pagineGalvanizing and Mechanical Preparation of Steel - 1Saurabh SinghNessuna valutazione finora

- Defects in ForgingsDocumento13 pagineDefects in ForgingsMahander Pratap Singh100% (2)

- Tips For The Practitioner.: Flame StraighteningDocumento2 pagineTips For The Practitioner.: Flame StraighteningmikirscNessuna valutazione finora

- PreheatDocumento2 paginePreheatScott TrainorNessuna valutazione finora

- Materials Failure AnalysisDocumento53 pagineMaterials Failure Analysisulsan busanNessuna valutazione finora

- Hobart Aluminum GuideDocumento47 pagineHobart Aluminum GuideAntonioPalloneNessuna valutazione finora

- SWI Procedure PaintingDocumento6 pagineSWI Procedure PaintingRamy EidNessuna valutazione finora

- Ss Pipe WeldingDocumento3 pagineSs Pipe WeldingshridharbshenoyNessuna valutazione finora

- Design For Manufacturing, CASTINGDocumento10 pagineDesign For Manufacturing, CASTINGDarbhalaPavanKumarNessuna valutazione finora

- Alsheet: Hot-Dip Aluminum-Coated Steel SheetsDocumento12 pagineAlsheet: Hot-Dip Aluminum-Coated Steel SheetshadiNessuna valutazione finora

- FastenersDocumento11 pagineFastenersvenkat mechNessuna valutazione finora

- Final Welding of Ti Alloys and MG AlloysDocumento32 pagineFinal Welding of Ti Alloys and MG AlloysArjyajyoti GoswamiNessuna valutazione finora

- Engineering Drawing Notes BDocumento50 pagineEngineering Drawing Notes BsrchougulaNessuna valutazione finora

- Product Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'Documento2 pagineProduct Data Sheet OK Tigrod 316L: W 'Tungsten Inert Gas Arc Welding'soft4gsmNessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- Design Guidelines For PE & ROTO Lined Carbon Steel PipingDocumento8 pagineDesign Guidelines For PE & ROTO Lined Carbon Steel PipingKamatchi Nathan100% (1)

- Fastener Technical ManualDocumento70 pagineFastener Technical ManualGANESH GNessuna valutazione finora

- GMAW Facilitator GuideDocumento42 pagineGMAW Facilitator GuideEng trk100% (1)

- Alloy Guide PDFDocumento12 pagineAlloy Guide PDFArjed Ali ShaikhNessuna valutazione finora

- Maxal Guide For Aluminum WLDG 9-12Documento46 pagineMaxal Guide For Aluminum WLDG 9-12hetpinNessuna valutazione finora

- Technical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingDocumento3 pagineTechnical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingNestramiNessuna valutazione finora

- Design For Hot Dip GalvanisingDocumento9 pagineDesign For Hot Dip GalvanisingSreedhar Patnaik.MNessuna valutazione finora

- AZZ Galv Fab BookDocumento27 pagineAZZ Galv Fab BookDaren NeradNessuna valutazione finora

- SS 409M WeldingDocumento12 pagineSS 409M WeldingwentropremNessuna valutazione finora

- Hot Dip GalvanizingDocumento6 pagineHot Dip GalvanizingjpkedahNessuna valutazione finora

- 8 Fine BlankingDocumento20 pagine8 Fine BlankingNarendrareddy Ramireddy50% (6)

- Hot Dip GalvanizingDocumento24 pagineHot Dip GalvanizingKarthikeyan MuniaswamyNessuna valutazione finora

- Hot Dip Galvanizing of Sheet Metal-SpangleDocumento6 pagineHot Dip Galvanizing of Sheet Metal-SpangleAgustine SetiawanNessuna valutazione finora

- Welding DesignDocumento28 pagineWelding DesignSitaram JhaNessuna valutazione finora

- Repairing Damaged Hot-Dip Galvanized Steel With Zinc-Rich Paint, Zinc MetallDocumento4 pagineRepairing Damaged Hot-Dip Galvanized Steel With Zinc-Rich Paint, Zinc MetallMJK008100% (1)

- Hot Dip Galvanized Information Sheet No.7Documento7 pagineHot Dip Galvanized Information Sheet No.7mostafaNessuna valutazione finora

- AGA - Design Guide PDFDocumento28 pagineAGA - Design Guide PDFSherif AbdelhameedNessuna valutazione finora

- Amerlock 400GFA High Solids Glassflake Epoxy CoatingDocumento4 pagineAmerlock 400GFA High Solids Glassflake Epoxy CoatingSherif AbdelhameedNessuna valutazione finora

- PG400CDocumento4 paginePG400CSherif AbdelhameedNessuna valutazione finora

- Amercoat 253Documento4 pagineAmercoat 253Sherif AbdelhameedNessuna valutazione finora

- Amerlock 400 GFADocumento4 pagineAmerlock 400 GFASherif AbdelhameedNessuna valutazione finora

- Ceram Kote 54 SF - ARAMCO ApprovedDocumento1 paginaCeram Kote 54 SF - ARAMCO ApprovedSherif AbdelhameedNessuna valutazione finora

- Amercoat 253 FlyerDocumento1 paginaAmercoat 253 FlyerSherif AbdelhameedNessuna valutazione finora

- Eurogrit - Coal SlagDocumento2 pagineEurogrit - Coal SlagSherif AbdelhameedNessuna valutazione finora

- Tankguard ARDocumento4 pagineTankguard ARSherif Abdelhameed100% (1)

- Copon - Hycote 162 HBDocumento2 pagineCopon - Hycote 162 HBSherif AbdelhameedNessuna valutazione finora

- AGA - Design Guide PDFDocumento28 pagineAGA - Design Guide PDFSherif AbdelhameedNessuna valutazione finora

- Theoretical and Practical CoverageDocumento4 pagineTheoretical and Practical CoverageSherif AbdelhameedNessuna valutazione finora

- Norsok Standard M-501: Rev. 5, June 2004Documento24 pagineNorsok Standard M-501: Rev. 5, June 2004Nelson Matos100% (1)

- 9-09 - Guide+16 Guide To Specifying and Selecting Dust CollectorsDocumento14 pagine9-09 - Guide+16 Guide To Specifying and Selecting Dust CollectorsSherif AbdelhameedNessuna valutazione finora

- History of Psychotherapy FinalDocumento38 pagineHistory of Psychotherapy FinalMarco BonettiNessuna valutazione finora

- Matsusada DC-DC ConvertersDocumento4 pagineMatsusada DC-DC ConvertersAP SinghNessuna valutazione finora

- Handbook On National Spectrum Management 2015Documento333 pagineHandbook On National Spectrum Management 2015Marisela AlvarezNessuna valutazione finora

- Typical Cable Laying Details For Direct Buried, Low Tension CablesDocumento9 pagineTypical Cable Laying Details For Direct Buried, Low Tension CableslataNessuna valutazione finora

- NGCP - Procedures and Requirements For Energy ProjectsDocumento17 pagineNGCP - Procedures and Requirements For Energy ProjectspurplebasketNessuna valutazione finora

- Energy BodiesDocumento1 paginaEnergy BodiesannoyingsporeNessuna valutazione finora

- 1st Unseen Passage For Class 5 in EnglishDocumento7 pagine1st Unseen Passage For Class 5 in EnglishVibhav SinghNessuna valutazione finora

- Piaggio MP3 300 Ibrido LT MY 2010 (En)Documento412 paginePiaggio MP3 300 Ibrido LT MY 2010 (En)Manualles100% (3)

- Car Parking DesignDocumento6 pagineCar Parking Designcharler kinyuajNessuna valutazione finora

- GL Career Academy Data AnalyticsDocumento7 pagineGL Career Academy Data AnalyticsDeveloper GuideNessuna valutazione finora

- Research Project Presentation of Jobairul Karim ArmanDocumento17 pagineResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanNessuna valutazione finora

- College of Engineering Cagayan State UniversityDocumento16 pagineCollege of Engineering Cagayan State UniversityErika Antonio GutierrezNessuna valutazione finora

- Visual Metaphor Process BookDocumento18 pagineVisual Metaphor Process Bookmatt8859Nessuna valutazione finora

- Zener Tester: by MedhatkoDocumento6 pagineZener Tester: by Medhatkosaran gulNessuna valutazione finora

- Design of Footing R1Documento8 pagineDesign of Footing R1URVESHKUMAR PATELNessuna valutazione finora

- HCH - 15 04 004Documento5 pagineHCH - 15 04 004NarvaxisNessuna valutazione finora

- Measures of Indicator 1Documento2 pagineMeasures of Indicator 1ROMMEL BALAN CELSONessuna valutazione finora

- Philips HD 9 User ManualDocumento3 paginePhilips HD 9 User ManualNdangoh DerekNessuna valutazione finora

- E Voucher Hotel en 1241564309Documento2 pagineE Voucher Hotel en 1241564309taufksNessuna valutazione finora

- Skirmishes Graham Harman PDFDocumento383 pagineSkirmishes Graham Harman PDFparaiaNessuna valutazione finora

- TOEFL-Reading Question Type Definitions and ExplanationDocumento5 pagineTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioNessuna valutazione finora

- 448 Authors of Different Chemistry BooksDocumento17 pagine448 Authors of Different Chemistry BooksAhmad MNessuna valutazione finora

- Make Yeast StarterDocumento2 pagineMake Yeast StarterAlexandraNessuna valutazione finora

- CTRLX Automation BrochureDocumento60 pagineCTRLX Automation BrochureNinja do SofáNessuna valutazione finora

- Performance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationDocumento5 paginePerformance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationsatyanaryanakNessuna valutazione finora

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocumento4 paginePH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahNessuna valutazione finora

- THE BASIC TYPES OF SPEECHES PPTDocumento14 pagineTHE BASIC TYPES OF SPEECHES PPTKevin BanezNessuna valutazione finora

- Kat-A 4102 Rotovalve Edition3!12!02-2013 enDocumento4 pagineKat-A 4102 Rotovalve Edition3!12!02-2013 enWalter PiracocaNessuna valutazione finora

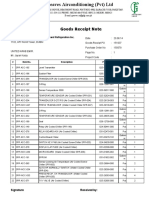

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora

- MidsemDocumento6 pagineMidsemAravind SomasundaramNessuna valutazione finora