Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dist-010H Pressure Swing

Caricato da

NicandroGonzalesDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dist-010H Pressure Swing

Caricato da

NicandroGonzalesCopyright:

Formati disponibili

Dist-010H

Revised: Nov 20, 2012

Pressure Swing to Overcome Azeotropes with Aspen HYSYS V8.0

Separation of Ethanol and Benzene

1. Lesson Objectives

Learn how to use pressure swing to separate a binary mixture that forms an azeotrope into two pure components

2. Prerequisites

Aspen HYSYS V8.0 Introduction to azeotropic mixtures Introduction to distillation

3. Background

Ethanol and benzene form an azeotrope and the azeotropic composition is sensitive to pressure. Therefore, it is possible to use pressure swing to separate this binary mixture into pure components. The examples presented are solely intended to illustrate specific concepts and principles. They may not reflect an industrial application or real situation.

4. Problem Statement and Aspen HYSYS Solution

Problem Statement

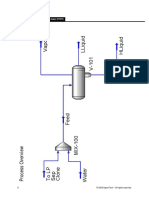

The first column operates under a pressure of 3 bars and the second one at 0.1 bar. A compressor is used to pressurize the recycle stream from 0.1 bar to 3 bars before it is recycled back to the first column. Since the relative volatility is large except for the azeotrope point, there is no need to add a third component (as a solvent).

Aspen HYSYS Solution

4.01. 4.02. Start a new simulation in Aspen HYSYS V8.0. Create a component list. In the Component Lists folder select Add. Add Ethanol and Benzene to the component list.

Dist-010H

Revised: Nov 20, 2012

4.03.

Define property package. In the Fluid Packages folder select Add. Select PRSV as the property package.

4.04.

Go to the simulation environment by clicking the Simulation button in the bottom left of the screen.

4.05.

We will first add two Material Streams to the flowsheet. Name one of the streams Feed and the other Recycle .

Dist-010H 4.06.

Revised: Nov 20, 2012

Double click on the Feed stream. This will be the ethanol-benzene feed to the process. In the Worksheet tab enter a Vapour Fraction of 0.5, a Pressure of 3 bar, and a Molar Flow of 100 kgmole/h. In the Composition form enter Mole Fractions of 0.5 for both ethanol and benzene .

4.07.

We will now define the stream Recycle . This stream will consist of ethanol and benzene vapors that come off the top of the second column, which we will recycle so we dont throw away any product. Double click on the Recycle stream. In the Worksheet tab enter a Vapour Fraction of 1, a Pressure of 3 bar, and a Molar Flow of 200 kgmole/h. In the Composition tab enter Mole Fractions of 0.5 for both ethanol and benzene . These values are initial estimates. They will eventually be replaced by the actual recycled product.

Dist-010H

Revised: Nov 20, 2012

4.08.

We are now ready to add a Distillation Column Sub-Flowsheet to the flowsheet from the Model Palette .

Dist-010H 4.09.

Revised: Nov 20, 2012

Double click the distillation column ( T-100). This will launch the Distillation Column Input Expert. On Page 1 specify the following information. Change the # Stages to 30 and select streams Feed and Recycle to enter on stage 10. Select Full Reflux for Condenser, create an Ovhd Vapour Outlet stream called Vap, a Bottoms Liquid Outlet called Benzene , and a Condenser Energy Stream called Q-Cond1. When complete click Next.

4.10.

On Page 2 of the Distillation Column Input Expert select a Once-through, Regular Hysys reboiler. Click Next. On Page 3 of the Distillation Column Input Expert enter Condenser and Reboiler Pressures of 3 bar. For this simulation we will assume no pressure drop through the column. In real life this wouldnt be the case. Click Next.

4.11.

Dist-010H

Revised: Nov 20, 2012

4.12.

Page 4 asks for Temperature estimates. These are optional values that will help the column solver converge. For this column we will leave all estimates blank. Click Next.

4.13.

On the final page of the expert enter a Reflux Ratio of 3. Click Done .

Dist-010H

Revised: Nov 20, 2012

4.14.

The Column: T-100 window will now appear. We must define the design specifications for the column. We have already specified the reflux ratio, but we still need to specify the mole fraction of benzene in the bottoms stream. First go to the Specs Summary form and make sure that only the Reflux Ratio specification is checked as active.

Dist-010H 4.15.

Revised: Nov 20, 2012

Now we will create a specification for the mole fraction of benzene in the bottoms stream. Go to the Specs form under the Design tab. Click Add and select Column Component Fraction. Select Stream for Target Type , Benzene for Draw, enter 0.999 for Spec Value , and select Benzene for Component.

4.16.

The Degrees of Freedom for the column should now be 0. Click the Run button to begin calculations. The column should quickly converge.

Dist-010H

Revised: Nov 20, 2012

4.17.

We will now insert a second Distillation Column Sub-Flowsheet.

4.18.

Double click on the second column ( T-101) to open the Distillation Column Input Expert. On the first page change the # Stages to 30 and select the stream Vap to enter on stage 10. Select Full Reflux for the Condenser, create an Ovhd Vapour Outlet called Rec, a Bottoms Liquid Outlet called Ethanol, and a Condenser Energy Stream called Q-Cond2. Click Next when complete.

Dist-010H

Revised: Nov 20, 2012

4.19.

On Page 2 of the Distillation Column Input Expert leave the default selections for a Once-through, Regular Hysys reboiler. Click Next.

10

Dist-010H 4.20.

Revised: Nov 20, 2012

On Page 3 of the Distillation Column Input Expert enter Condenser and Reboiler Pressures of 0.1 bar. Click Next when complete.

4.21.

On Page 4 of the Distillation Column Input Expert leave all fields for temperature estimates blank. Click Next.

11

Dist-010H 4.22.

Revised: Nov 20, 2012

On the final page of the Distillation Column Input Expert enter a Reflux Ratio of 1. Click Done when complete to configure the column.

4.23.

Go to the Specs Summary form under the Design tab. We wish to specify the reflux ratio and the mole fraction of ethanol in the bottoms stream. We have already specified the reflux ratio, but we still need to create a specification for the mole fraction of ethanol in the bottoms. First, make sure that the only current active specification is the Reflux Ratio.

4.24.

Now we will create a specification for the mole fraction of ethanol in the bottoms stream. Go to the Specs form under the Design tab. Click Add and select Column Component Fraction. Select Stream for Target Type , Ethanol for Draw, enter 0.999 for Spec Value , and select Ethanol for Component. 12

Dist-010H

Revised: Nov 20, 2012

4.25.

The Degrees of Freedom for the column should now be 0. Click the Run button to begin calculations. The column should converge.

13

Dist-010H

Revised: Nov 20, 2012

4.26.

Before we connect the recycle loop we must first add a compressor to raise the pressure of stream Rec. Add a Compressor to the flowsheet from the Model Palette .

14

Dist-010H 4.27.

Revised: Nov 20, 2012

Double click on the compressor ( K-100). Select stream Rec as the Inlet. Create an Outlet called RecHighP and an Energy stream called Q-Comp.

4.28.

In the Worksheet tab enter an outlet Pressure of 3 bar. The compressor should solve.

15

Dist-010H

Revised: Nov 20, 2012

4.29.

We are now ready to connect the recycle loop. Add a Recycle block to the flowsheet from the Model Palette .

4.30.

Double click on the recycle block ( RCY-1). Select stream Rec-HighP as the Inlet and select stream Recycle as the Outlet. The flowsheet should solve after a few moments.

16

Dist-010H

Revised: Nov 20, 2012

4.31.

The flowsheet is now complete. Check results. Double click on stream Benzene and stream Ethanol. You will find that the flowrate of each stream is roughly 50 kgmole/h with a mole fraction of 0.999 of each respective product.

17

Dist-010H

Revised: Nov 20, 2012

5. Conclusions

Pressure swing distillation can be a good method for separating a binary mixture that forms an azeotrope when: The azeotropic composition is sensitive to a pressure change The relative volatility of the two components is large except at the azeotropic point

6. Copyright

Copyright 2012 by Aspen Technology, Inc. (AspenTech). All rights re served. This work may not be reproduced or distributed in any form or by any means without the prior written consent of AspenTech. ASPENTECH MAKES NO WARRANTY OR REPRESENTATION, EITHER EXPRESSED OR IMPLIED, WITH RESPECT TO THIS WORK and assumes no liability for any errors or omissions. In no event will AspenTech be liable to you for damages, including any loss of profits, lost savings, or other incidental or consequential damages arising out of the use of the information contained in, or the digital file s supplied with or for use with, this work. This work and its contents are provided for educational purposes only.

AspenTech, aspenONE, and the Aspen leaf logo, are trademarks of Aspen Technology, Inc.. Brands and product names mentioned in this documentation are trademarks or service marks of their respective companies.

18

Potrebbero piacerti anche

- Automotive Sensor Testing and Waveform AnalysisDa EverandAutomotive Sensor Testing and Waveform AnalysisValutazione: 4.5 su 5 stelle4.5/5 (13)

- Diesel Common Rail Injection Electronic Components ExplainedDa EverandDiesel Common Rail Injection Electronic Components ExplainedValutazione: 3.5 su 5 stelle3.5/5 (7)

- Con Men ScamsDocumento14 pagineCon Men ScamsTee R TaylorNessuna valutazione finora

- Introduction to the simulation of power plants for EBSILON®Professional Version 15Da EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Nessuna valutazione finora

- 1.6.-How To Teach Reported Speech - Review - Practice & Lesson PlanDocumento8 pagine1.6.-How To Teach Reported Speech - Review - Practice & Lesson Planspatel1972100% (2)

- Hysys 8.8 - ManualDocumento606 pagineHysys 8.8 - ManualCarlos Vaz88% (8)

- Compressor and Pump CurvesDocumento14 pagineCompressor and Pump CurvesSyed Muzamil AhmedNessuna valutazione finora

- 6710 NotesDocumento45 pagine6710 NotesAndrés SuquilloNessuna valutazione finora

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingDa EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingValutazione: 5 su 5 stelle5/5 (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Column SizingDocumento16 pagineColumn SizingSyed Muzamil Ahmed100% (9)

- Ablutophobia Fear of Bathing and HomoeopathyDocumento8 pagineAblutophobia Fear of Bathing and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- DC-DC Converter Reliability Design and TestingDocumento16 pagineDC-DC Converter Reliability Design and TestinggirisanaNessuna valutazione finora

- EHY904.088.01 Student Virtual PDFDocumento64 pagineEHY904.088.01 Student Virtual PDFNicandroGonzales100% (1)

- Distillation CalculationDocumento76 pagineDistillation CalculationNicandroGonzalesNessuna valutazione finora

- TUTORIAL DE COMPRESI Ôn - HYSYS PDFDocumento18 pagineTUTORIAL DE COMPRESI Ôn - HYSYS PDFShirley Hernandez JimenezNessuna valutazione finora

- Air Cooler Design With Aspen EDR PDFDocumento26 pagineAir Cooler Design With Aspen EDR PDFNicandroGonzales0% (1)

- 12.10 Reactive Distillation PDFDocumento9 pagine12.10 Reactive Distillation PDFAries RiyantoNessuna valutazione finora

- 01 Getting StartedDocumento32 pagine01 Getting StartedSufyan KhanNessuna valutazione finora

- Ammonia Simulation - HYSYS V 8.0Documento33 pagineAmmonia Simulation - HYSYS V 8.0niral100% (1)

- Petroleum Refinery Engineering (CHL 794) Department of Chemical Engineering, Iitd Tutorial Sheet - 4Documento15 paginePetroleum Refinery Engineering (CHL 794) Department of Chemical Engineering, Iitd Tutorial Sheet - 4'Tuan Syafiq'Nessuna valutazione finora

- HYSYS Distillation Column Simulation TutorialDocumento7 pagineHYSYS Distillation Column Simulation Tutorialcmlim100% (2)

- Design 002H AmmoniaSynthesis ClosedLoopDocumento15 pagineDesign 002H AmmoniaSynthesis ClosedLoopNicandroGonzalesNessuna valutazione finora

- Wamit V6.4: Diffraction-Radiation ComputationDocumento66 pagineWamit V6.4: Diffraction-Radiation ComputationAnonymous JEe6LWPNessuna valutazione finora

- Dynamic Analysis of Cyclohexane Production With Aspen HYSYS® V8.0Documento0 pagineDynamic Analysis of Cyclohexane Production With Aspen HYSYS® V8.0udokasNessuna valutazione finora

- Process Engineering: Facts, Fiction and FablesDa EverandProcess Engineering: Facts, Fiction and FablesValutazione: 3 su 5 stelle3/5 (2)

- Stoichiometric Reactors ASPENDocumento9 pagineStoichiometric Reactors ASPENRafique Ahmed AbroNessuna valutazione finora

- Aspen Plus Tutorial 2 Absorption Column SimulationDocumento12 pagineAspen Plus Tutorial 2 Absorption Column Simulation82ghost82Nessuna valutazione finora

- HYSYS Tutorial 5 ExamplesDocumento8 pagineHYSYS Tutorial 5 ExamplesFauzi Mahmud100% (2)

- Synthesis of Methanol using Steam Reforming of Natural GasDocumento56 pagineSynthesis of Methanol using Steam Reforming of Natural GasNicandroGonzalesNessuna valutazione finora

- Working Guide to Reservoir Rock Properties and Fluid FlowDa EverandWorking Guide to Reservoir Rock Properties and Fluid FlowValutazione: 3 su 5 stelle3/5 (1)

- Chemical Engineering 422 Simulation With Hysys: NotesDocumento9 pagineChemical Engineering 422 Simulation With Hysys: NotesNoor Ul HaqNessuna valutazione finora

- Azeotropic DistillationDocumento26 pagineAzeotropic DistillationNaveen KamatNessuna valutazione finora

- Examples 4Documento71 pagineExamples 4Khaled AthmaniNessuna valutazione finora

- Matbal 001 Flowsheet CycloHexaneDocumento23 pagineMatbal 001 Flowsheet CycloHexanesoniyalavangareNessuna valutazione finora

- Pressure Swing To Overcome Azeotropes With Aspen Plus® V8.0Documento16 paginePressure Swing To Overcome Azeotropes With Aspen Plus® V8.0JúpiterNessuna valutazione finora

- Hysys Class 5Documento5 pagineHysys Class 5Salim ChohanNessuna valutazione finora

- Chlorobenzene Plant TutorialDocumento21 pagineChlorobenzene Plant Tutorialdjona lokimaNessuna valutazione finora

- 2.1. Flash Equilibrium (Isothermal)Documento12 pagine2.1. Flash Equilibrium (Isothermal)Hien Ngo ThiNessuna valutazione finora

- Thermo 020 DecanterDocumento9 pagineThermo 020 DecanterNouman AliNessuna valutazione finora

- Dist-020H CO2 AbsorberDocumento9 pagineDist-020H CO2 AbsorberudokasNessuna valutazione finora

- CH 07Documento37 pagineCH 07kentalNessuna valutazione finora

- Manual (Simulation)Documento17 pagineManual (Simulation)Asad RazaNessuna valutazione finora

- Rx-004 CSTR Series CistotransDocumento19 pagineRx-004 CSTR Series CistotransMuhammad Hamza EjazNessuna valutazione finora

- HHH HHHHDocumento12 pagineHHH HHHHhichamNessuna valutazione finora

- Jordan University of Science & Technology: Chemical Engineering DepartmentDocumento15 pagineJordan University of Science & Technology: Chemical Engineering DepartmentLa Casa JordanNessuna valutazione finora

- Distillation of Close Boiling Components With Aspen HYSYS® V8.0Documento12 pagineDistillation of Close Boiling Components With Aspen HYSYS® V8.0Trúc LinhNessuna valutazione finora

- Repor of Application ComputerDocumento13 pagineRepor of Application ComputerHussein Al HabebNessuna valutazione finora

- Simulador de Amoniaco Guia HysysDocumento18 pagineSimulador de Amoniaco Guia HysysJuan Guerrero MartinezNessuna valutazione finora

- Aspen Plus - Plug Flow ReactorDocumento8 pagineAspen Plus - Plug Flow ReactorGyan PrameswaraNessuna valutazione finora

- 1Documento18 pagine1Konul AlizadehNessuna valutazione finora

- Week 3Documento10 pagineWeek 3Soumya RocxNessuna valutazione finora

- Complete Simulation of Hydrogen from Switchgrass ConversionDocumento28 pagineComplete Simulation of Hydrogen from Switchgrass Conversionbasura12345Nessuna valutazione finora

- Reactor (CSTR)Documento12 pagineReactor (CSTR)fatiehah93100% (1)

- Lab # 15Documento13 pagineLab # 15Kashaf TehreemNessuna valutazione finora

- ChemSepTutorial SimpleDistillationDocumento27 pagineChemSepTutorial SimpleDistillationEvangelista LindaNessuna valutazione finora

- Coco Startup 1Documento12 pagineCoco Startup 1Fabio Alejandro MeloNessuna valutazione finora

- Thermo 020H DecanterDocumento7 pagineThermo 020H DecanterAshrafMostafaNessuna valutazione finora

- Day 4 Hands-On - Distillation Column Design PDFDocumento9 pagineDay 4 Hands-On - Distillation Column Design PDFRavi Tejasvi BajpaiNessuna valutazione finora

- Tutorial 5Documento6 pagineTutorial 5Hafiz Mudaser AhmadNessuna valutazione finora

- Lab 2 Hysys Distillation ColumnDocumento8 pagineLab 2 Hysys Distillation ColumnAl FatahNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- 3f73 PDFDocumento10 pagine3f73 PDFRick HughesNessuna valutazione finora

- 1 Optimal Design of Plate and Frame Heat Exchangers For Efficient Heat Recovery in Process IndustriesDocumento11 pagine1 Optimal Design of Plate and Frame Heat Exchangers For Efficient Heat Recovery in Process Industriess111_sunilNessuna valutazione finora

- Plate Heat Exchanger ExperimentDocumento7 paginePlate Heat Exchanger ExperimentDhrumil GandhiNessuna valutazione finora

- Phe RefDocumento77 paginePhe RefNicandroGonzalesNessuna valutazione finora

- Design and Cost Optimization of Plate Heat ExchangerDocumento6 pagineDesign and Cost Optimization of Plate Heat ExchangerinventyNessuna valutazione finora

- Heat ExchangersDocumento48 pagineHeat ExchangersRiccat Shio'TangNessuna valutazione finora

- Unisim® Plate Heat Exchanger Modeler: (Referred To As Unisim® Phe)Documento21 pagineUnisim® Plate Heat Exchanger Modeler: (Referred To As Unisim® Phe)Ian MesianoNessuna valutazione finora

- Models - Mph.transport and Adsorption PDFDocumento16 pagineModels - Mph.transport and Adsorption PDFNicandroGonzalesNessuna valutazione finora

- The Effect of The Corrugation Inclination Angle On The Thermohydraulic Performance of Plate Heat ExchangersDocumento11 pagineThe Effect of The Corrugation Inclination Angle On The Thermohydraulic Performance of Plate Heat ExchangersNicandroGonzalesNessuna valutazione finora

- AspenCOMThermoV9 Ref PDFDocumento360 pagineAspenCOMThermoV9 Ref PDFNicandroGonzalesNessuna valutazione finora

- Heat-Transfer, Pressure-Drop and Performance Relationships For In-Line, Staggered, and Continuous Plate Heat ExchangersDocumento13 pagineHeat-Transfer, Pressure-Drop and Performance Relationships For In-Line, Staggered, and Continuous Plate Heat ExchangersNicandroGonzalesNessuna valutazione finora

- Measurement of The Heat Transfer Coefficient in Plate Heat Exchangers Using A Temperature Oscillation TechniqueDocumento7 pagineMeasurement of The Heat Transfer Coefficient in Plate Heat Exchangers Using A Temperature Oscillation TechniqueNicandroGonzalesNessuna valutazione finora

- 3f73 PDFDocumento10 pagine3f73 PDFRick HughesNessuna valutazione finora

- 8 PDFDocumento8 pagine8 PDFNicandroGonzalesNessuna valutazione finora

- CFD Studies On Flow Through Compact HeatDocumento71 pagineCFD Studies On Flow Through Compact HeatRushikesh KekareNessuna valutazione finora

- Paper24 PDFDocumento4 paginePaper24 PDFhamidrezaee008Nessuna valutazione finora

- Simulacion Aero Enfriador PDFDocumento40 pagineSimulacion Aero Enfriador PDFNicandroGonzalesNessuna valutazione finora

- Self-Guided Demo Aspen Air Cooled ExchangerDocumento26 pagineSelf-Guided Demo Aspen Air Cooled ExchangerAnonymous LLLK3pqNessuna valutazione finora

- CH3080 SeparationsDocumento42 pagineCH3080 SeparationsNicandroGonzalesNessuna valutazione finora

- Contactor Vol 8 No 8 Quench Towers PDFDocumento2 pagineContactor Vol 8 No 8 Quench Towers PDFNicandroGonzalesNessuna valutazione finora

- Creating A Column Internals Configuration PDFDocumento6 pagineCreating A Column Internals Configuration PDFNicandroGonzalesNessuna valutazione finora

- DISPERSIONDocumento26 pagineDISPERSIONNicandroGonzalesNessuna valutazione finora

- Workshop 12Documento111 pagineWorkshop 12Manash MudoiNessuna valutazione finora

- 05 - DYNSIM Modelling Equipment and Streams PDFDocumento17 pagine05 - DYNSIM Modelling Equipment and Streams PDFNicandroGonzalesNessuna valutazione finora

- Assessment: Direction: Read The Story of "Silence - A Fable" by Edgar Allan Poe. Interpret and Analyze The StoryDocumento4 pagineAssessment: Direction: Read The Story of "Silence - A Fable" by Edgar Allan Poe. Interpret and Analyze The StoryElsa BorrinagaNessuna valutazione finora

- DIWADocumento64 pagineDIWADyanWahyu NMibhye SygSmuaNessuna valutazione finora

- Development Through The Lifespan Test 1Documento3 pagineDevelopment Through The Lifespan Test 1Alexandra CastroNessuna valutazione finora

- 03.KUNCI KODING 11 IPA-IPS SMT 2 K13 REVISI - TP 23-24 - B.InggrisDocumento2 pagine03.KUNCI KODING 11 IPA-IPS SMT 2 K13 REVISI - TP 23-24 - B.InggrisfencenbolonNessuna valutazione finora

- Solución: R T β T R (T) = 1000 Ω ΩDocumento6 pagineSolución: R T β T R (T) = 1000 Ω ΩDuvan BayonaNessuna valutazione finora

- Memorial On Behalf of PetitionerDocumento35 pagineMemorial On Behalf of PetitionerAjitabhGoel67% (3)

- Reporter Matt Rudd Goes On An Extraordinary Plane RideDocumento2 pagineReporter Matt Rudd Goes On An Extraordinary Plane RideHAnhh TrầnnNessuna valutazione finora

- Arp ReflectionDocumento3 pagineArp Reflectionapi-317806307Nessuna valutazione finora

- LESSON 1 Definition and Functions of ManagementDocumento2 pagineLESSON 1 Definition and Functions of ManagementJia SorianoNessuna valutazione finora

- Endocrine System Multiple Choice QuestionsDocumento42 pagineEndocrine System Multiple Choice QuestionswanderagroNessuna valutazione finora

- Technical and Cost Model For Slipway DevelopmentDocumento36 pagineTechnical and Cost Model For Slipway DevelopmentshahjadaNessuna valutazione finora

- Report Anomalies and Normalization SummaryDocumento5 pagineReport Anomalies and Normalization SummaryThomas_GodricNessuna valutazione finora

- Angles and ProtractorsDocumento5 pagineAngles and Protractorsapi-340307917Nessuna valutazione finora

- Community-Acquired Pneumoniaandhospital-Acquiredpneumonia: Charles W. Lanks,, Ali I. Musani,, David W. HsiaDocumento15 pagineCommunity-Acquired Pneumoniaandhospital-Acquiredpneumonia: Charles W. Lanks,, Ali I. Musani,, David W. HsiaMajo EscobarNessuna valutazione finora

- Pan AfricanismDocumento12 paginePan AfricanismOscar MasindeNessuna valutazione finora

- LIC Jeevan Labh Plan (836) DetailsDocumento12 pagineLIC Jeevan Labh Plan (836) DetailsMuthukrishnan SankaranNessuna valutazione finora

- Mythical Origins of The Hungarian Medieval LegislationDocumento8 pagineMythical Origins of The Hungarian Medieval LegislationLucas LixaNessuna valutazione finora

- Francis Asbury Revival Study PDFDocumento10 pagineFrancis Asbury Revival Study PDFLauRa Segura VerasteguiNessuna valutazione finora

- Topic 5 English Sound SystemDocumento7 pagineTopic 5 English Sound SystemAnonymous G91XTp9Nessuna valutazione finora

- PGW Spring SuitDocumento14 paginePGW Spring Suitapi-3700386Nessuna valutazione finora

- MKTG10001Documento38 pagineMKTG10001Jessica KokNessuna valutazione finora

- Copyright Protection for TV Show FormatsDocumento11 pagineCopyright Protection for TV Show FormatsJoy Navaja DominguezNessuna valutazione finora

- Guide Number 5 My City: You Will Learn To: Describe A Place Tell Where You in The CityDocumento7 pagineGuide Number 5 My City: You Will Learn To: Describe A Place Tell Where You in The CityLUIS CUELLARNessuna valutazione finora

- FortiEDR Product Overview TrainingDocumento16 pagineFortiEDR Product Overview TrainingRafael Steven Soto del CampoNessuna valutazione finora