Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Instruction Book FXe1-5 en

Caricato da

visaguyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Instruction Book FXe1-5 en

Caricato da

visaguyCopyright:

Formati disponibili

Atlas Copco Refrigerant compressed air dryers

FXe 1, FXe 2, FXe 3, FXe 4, FXe 5

Instruction book

Atlas Copco Refrigerant compressed air dryers

FXe 1, FXe 2, FXe 3, FXe 4, FXe 5

From following serial No. onwards: CNO 164 293

Instruction book

Original instructions

Copyright notice

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers and drawings. This instruction book is valid for CE as well as non-CE labelled machines. It meets the requirements for instructions specified by the applicable European directives as identified in the Declaration of Conformity.

2011 - 08 No. 2920 7100 00

www.atlascopco.com

Instruction book

Table of contents

1

1.1 1.2 1.3 1.4 1.5

Safety precautions..........................................................................................................4

SAFETY ICONS...................................................................................................................................4 SAFETY PRECAUTIONS, GENERAL...........................................................................................................4 SAFETY PRECAUTIONS DURING INSTALLATION...........................................................................................5 SAFETY PRECAUTIONS DURING OPERATION..............................................................................................6 SAFETY PRECAUTIONS DURING MAINTENANCE OR REPAIR...........................................................................7

2

2.1 2.2 2.3 2.4

General description........................................................................................................9

INTRODUCTION...................................................................................................................................9 AIR SYSTEM....................................................................................................................................10 REFRIGERATION SYSTEM....................................................................................................................11 AUTOMATIC REGULATION SYSTEM........................................................................................................12

3

3.1 3.2 3.3

Installation.....................................................................................................................13

DIMENSION DRAWINGS.......................................................................................................................13 INSTALLATION PROPOSAL...................................................................................................................14 PICTOGRAPHS.................................................................................................................................15

4

4.1 4.2 4.3 4.4 4.5 4.6

Operating instructions.................................................................................................16

WARNINGS......................................................................................................................................16 CONTROL PANEL..............................................................................................................................16 STARTING.......................................................................................................................................16 DURING OPERATION..........................................................................................................................17 STOPPING.......................................................................................................................................18 CONDENSATE DRAIN SYSTEM..............................................................................................................18

5 6

Maintenance instructions............................................................................................20 Device settings.............................................................................................................21

2920 7100 00

Instruction book

7 8

8.1 8.2

Problem solving............................................................................................................22 Technical data...............................................................................................................25

REFERENCE CONDITIONS AND LIMITATIONS............................................................................................25 AIR DRYER DATA..............................................................................................................................25

Pressure equipment directives...................................................................................27

2920 7100 00

Instruction book

1 1.1

Safety precautions Safety icons

Explanation

Danger for life Warning Important note

1.2

Safety precautions, general

General precautions

All responsibility for any damage or injury resulting from neglecting these precautions, or non-observance of the normal caution and care required for installation, operation, maintenance and repair, even if not expressly stated, will be disclaimed by the manufacturer.

1. The dryers are designed for normal indoor use. 2. The operator must employ safe working practices and observe all related work safety requirements and regulations. 3. If any of the following statements does not comply with the applicable legislation, the stricter of the two shall apply. 4. Installation, operation, maintenance and repair work must only be performed by authorized, trained, specialized personnel. 5. The dryer is not considered capable of producing air of breathing quality. To obtain air of breathing quality, the compressed air must be adequately purified according to the applicable legislation and standards. 6. Before any maintenance, repair work, adjustment or any other non-routine checks, stop the dryer, press the emergency stop button, switch off the voltage and depressurize the dryer. In addition, the power isolating switch must be opened and locked. 7. Never play with compressed air. Do not apply the air to your skin or direct an air stream at people. Never use the air to clean dirt from your clothes. When using the air to clean equipment, do so with extreme caution and wear eye protection. 8. The owner is responsible for maintaining the dryer in safe operating condition. Parts and accessories shall be replaced if unsuitable for safe operation. 9. It is not allowed to walk or stand on the dryer or its components.

2920 7100 00

Instruction book

1.3

Safety precautions during installation

1. The dryer must only be lifted using suitable equipment and in accordance with the applicable safety regulations. Loose or pivoting parts must be securely fastened before lifting. It is strictly forbidden to dwell or stay in the risk zone under a lifted load. Lifting acceleration and deceleration must be kept within safe limits. Wear a safety helmet when working in the area of overhead or lifting equipment. 2. Place the dryer where the ambient air is as cool and clean as possible. If necessary, install a suction duct. Never obstruct the air inlet. Care must be taken to minimize the entry of moisture at the inlet air. 3. Any blanking flanges, plugs, caps or desiccant bags must be removed before connecting the pipes. 4. Air hoses must be of correct size and suitable for the working pressure. Never use frayed, damaged or worn hoses. Distribution pipes and connections must be of the correct size and suitable for the working pressure. 5. The aspirated air must be free of flammable fumes, vapours and particles, e.g. paint solvents, that can lead to internal fire or explosion. 6. Arrange the air intake so that loose clothing worn by people cannot be sucked in. 7. Ensure that all piping is free to expand under heat and that it is not in contact with or close to flammable materials. 8. No external force may be exerted on the air outlet valve. The connected pipe must be free of strain. 9. If remote control is installed, the machine must bear a clear sign stating "Danger: This machine is remotely controlled and may start without warning". The operator has to make sure that the machine is stopped and that the isolating switch is open and locked before any maintenance or repair. As a further safeguard, persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the starting equipment. 10. Air-cooled machines must be installed in such a way that an adequate flow of cooling air is available and that the exhausted cooling air does not recirculate to the inlet. 11. The electrical connections must correspond to the applicable codes. The machines must be earthed and protected against short circuits by fuses in all phases. A lockable power isolating switch must be installed near the equipment. 12. On machines with automatic start-stop system or if the automatic restart function after voltage failure is activated, a sign stating "This machine may start without warning" must be affixed near the instrument panel. 13. Never remove or tamper with the safety devices, guards or insulation fitted on the machine. Every pressure vessel or auxiliary installed outside the machine to contain air above atmospheric pressure must be protected by a pressure-relieving device or devices as required. 14. Piping or other parts with a temperature in excess of 80C (176F) and which may be accidentally touched by personnel during normal operation must be guarded or insulated. Other high-temperature piping must be clearly marked. 15. For water-cooled machines, the cooling water system installed outside the machine has to be protected by a safety device with set pressure according to the maximum cooling water inlet pressure. 16. If no safety valve is present in the air net close to the desiccant dryer (e.g. safety valve of compressor), full flow safety valves must be installed on the dryer vessels. 17. If the maximum pressure of the compressor is higher than the design pressure of the dryer, a full flow safety valve must be installed between the compressor and the dryer in order to blow off the excessive pressure in case the safety valve of the dryer should be out of order or blocked.

Precautions during installation

2920 7100 00

Instruction book

Also consult following safety precautions: Safety precautions during operation and Safety precautions during maintenance or repair. These precautions apply to machinery processing or consuming air or inert gas. Processing of any other gas requires additional safety precautions typical to the application which are not included herein. Some precautions are general and cover several machine types and equipment; hence some statements may not apply to your machine.

1.4

Safety precautions during operation

1. Always be careful when touching any piping or components of the dryer during operation. On dryers using heat to regenerate the desiccant, some parts will become very hot. 2. Use only the correct type and size of hose end fittings and connections. When blowing through a hose or air line, ensure that the open end is held securely. A free end will whip and may cause injury. Make sure that a hose is fully depressurized before disconnecting it. 3. Persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the remote start equipment. 4. Never operate the machine when there is a possibility of taking in flammable or toxic fumes, vapours or particles. 5. Never operate the machine below or in excess of its limit ratings. 6. Keep all bodywork closed during operation. Bodywork should be opened for short periods only, e.g. to carry out routine checks. Wear ear protectors when removing a panel. 7. People staying in environments or rooms where the sound pressure level reaches or exceeds 90 dB(A) shall wear ear protectors. 8. Periodically check that: All guards are in place and securely fastened All hoses and/or pipes inside the machine are in good condition, secure and not rubbing There are no leaks All fasteners are tight All electrical leads are secure and in good order Safety valves and other pressure-relief devices are not obstructed by dirt or paint Air outlet valve and air net, i.e. pipes, couplings, manifolds, valves, hoses, etc. are in good condition, free of wear or abuse 9. If warm cooling air from dryers is used in air heating systems, e.g. to warm up a working area, take precautions against air pollution and possible contamination of the breathing air. 10. Do not remove any of, or tamper with, the sound-damping material. 11. Never remove or tamper with the safety devices, guards or insulations fitted on the machine. Every pressure vessel or auxiliary installed outside the machine to contain air above atmospheric pressure shall be protected by a pressure-relieving device or devices as required.

Also consult following safety precautions: Safety precautions during installation and Safety precautions during maintenance or repair. These precautions apply to machinery processing or consuming air or inert gas. Processing of any other gas requires additional safety precautions typical to the application which are not included herein. Some precautions are general and cover several machine types and equipment; hence some statements may not apply to your machine.

Precautions during operation

2920 7100 00

Instruction book

1.5

Safety precautions during maintenance or repair

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Always use the correct safety equipment (such as safety glasses, gloves, safety shoes, etc.). Use only the correct tools for maintenance and repair work. Use only genuine spare parts. All maintenance work shall only be undertaken when the machine has cooled down. A warning sign bearing a legend such as "Work in progress - do not start" shall be attached to the starting equipment. Persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one checking or working on the machine. To this end, a suitable notice shall be affixed to the remote starting equipment. Close the dryer air outlet valve before connecting or disconnecting a pipe. Before removing any pressurized component, effectively isolate the machine from all sources of pressure and relieve the entire system of pressure. Never use flammable solvents or carbon tetrachloride for cleaning parts. Take safety precautions against toxic vapours of cleaning liquids. Scrupulously observe cleanliness during maintenance and repair. Keep dirt away by covering the parts and exposed openings with a clean cloth, paper or tape. Never weld on, or in any way modify, pressure vessels. Whenever there is an indication or any suspicion that an internal part of a machine is overheated, the machine shall be stopped but no inspection covers shall be opened before sufficient cooling time has elapsed; this to avoid the risk of spontaneous ignition of the oil vapor when air is admitted. Never use a light source with open flame for inspecting the interior of a machine, pressure vessel, etc. Make sure that no tools, loose parts or rags are left in or on the machine. All regulating and safety devices shall be maintained with due care to ensure that they function properly. They may not be put out of action. Before clearing the machine for use after maintenance or overhaul, check that operating pressures, temperatures and time settings are correct. Check that all control and shut-down devices are fitted and that they function correctly. Protect the motor, electrical and regulating components, etc. to prevent moisture from entering them, e.g. when steam-cleaning. Make sure that all sound-damping material and vibration dampers, e.g. damping material on the bodywork, is in good condition. If damaged, replace it by genuine material from the manufacturer to prevent the sound pressure level from increasing. Never use caustic solvents which can damage materials of the air net, e.g. polycarbonate bowls. The following safety precautions are stressed when handling refrigerant: Never inhale refrigerant vapours. Check that the working area is adequately ventilated; if required, use breathing protection. Always wear special gloves. In case of refrigerant contact with the skin, rinse the skin with water. If liquid refrigerant contacts the skin through clothing, never tear off or remove the latter; flush abundantly with fresh water over the clothing until all refrigerant is flushed away; then seek medical first aid. The following safety precautions are stressed when handling desiccant: Take precautions not to inhale desiccant dust. Check that the working area is adequately ventilated; if required, use breathing protection. Do not overfill the dryer when replacing desiccant.

Precautions during maintenance or repair

21.

2920 7100 00

Instruction book

Also consult following safety precautions: Safety precautions during installation and Safety precautions during operation. These precautions apply to machinery processing or consuming air or inert gas. Processing of any other gas requires additional safety precautions typical to the application which are not included herein. Some precautions are general and cover several machine types and equipment; hence some statements may not apply to your machine.

2920 7100 00

Instruction book

2 2.1

General description Introduction

General views

FXe 1 up to FXe 5

Introduction The FXe air dryers remove moisture from compressed air by cooling the air to near freezing point. This causes water to condense. The condensate is automatically drained. The air is warmed up before leaving the dryer.

2920 7100 00

Instruction book

2.2

Air system

Air flow diagram

FXe 1 up to FXe 5

Reference A B Dm 1 2 3 9 13

Name Air inlet Air outlet Ball valve Air/air heat exchanger Air refrigerant heat exchanger/evaporator Condensate separator Automatic condensate drain Dewpoint indicator

Description Compressed air enters (A) the heat exchanger (1) and is cooled by the outgoing (B), cold, dried air. Water in the incoming air starts to condense. The air then flows through heat exchanger/evaporator (2) where the refrigerant evaporates causing the air to be cooled further to close to the evaporating temperature of the refrigerant. More water in the air condenses. The cold air then flows through separator (3) where all the condensate is separated from the air. The condensate is drained by the automatic drain (9). The cold, dried air flows through heat exchanger (1) where it is warmed up by the incoming air to approx. 10C (18F) below the incoming air temperature. Condensation in the air net cannot occur unless the air is cooled to below the pressure dewpoint indicated by the dewpoint indicator (13) on the control panel.

10

2920 7100 00

Instruction book

2.3

Refrigeration system

Refrigerant flow diagram

FXe 1 up to FXe 5

Reference 2 4 6 7 8 9 10

Name Air refrigerant heat exchanger/evaporator Refrigerant compressor Condenser Refrigerant filter Expansion capillary tube Automatic condensate drain Liquid separator

Description Compressor (4) delivers hot, high-pressure refrigerant gas which flows through condenser (6) where most of the refrigerant condenses. The liquid flows through liquid refrigerant dryer/filter (7) to capillary tube (8). The refrigerant leaves the capillary tube at evaporating pressure. The refrigerant enters evaporator (2) where it withdraws heat from the compressed air by further evaporation at constant pressure. The heated refrigerant leaves the evaporator and is sucked in by the compressor (4) through the liquid separator (10).

2920 7100 00

11

Instruction book

2.4

Automatic regulation system

Air and refrigerant flow diagram

FXe 1 up to FXe 5

Reference 5 11 12

Name Hot gas by-pass valve Motor and fan Fan control switch

Description The condenser pressure must be kept as constant as possible to obtain stable operation. Fan control switch (12) (not on FXe 1 and FXe 2) therefore stops and starts the cooling fan (11). If, under partial or no load, the evaporator pressure drops below a certain level, the hot gas by-pass valve (5) opens and hot, high-pressure gas is fed to the evaporator circuit to prevent the evaporator pressure from dropping any further.

12

2920 7100 00

Instruction book

3 3.1

Installation Dimension drawings

FXe 1 up to FXe 5

FXe 1 up to FXe 5

Reference (1) (2) (3) (4)

Name Air inlet Air outlet Electrical cable connection Condensate drain outlet, internal pipe diameter 10 mm / 0.39 in

2920 7100 00

13

Instruction book

3.2

Moving

Installation proposal

To move the dryer use a fork lift truck. Do not use metal cables for lifting. Move the dryer gently.

Example of compressor room For FXe 1 up to FXe 5:

Installation proposal for FXe 1 up to FXe 5

Reference -

Description The refrigerant air dryer should be installed on a level floor suitable for its weight. Install the dryer where the ambient air is as clean as possible and where the temperature of the air will never exceed the limits. See Reference conditions and limitations Keep the ventilation gratings of the dryer free. The recommended minimum distance between the top of the unit and the ceiling is 1.5 m (58.5 in). The minimum distance between the wall and the back of the compressor must be 1.5 m (58.5 in). Lay out the condensate drain hose via a funnel towards a drain collector to allow visual inspection. The hose must slope downwards. If the condensate drain has been fitted outside the compressor room where it may be exposed to freezing temperatures, it must be insulated. The power cable must be connected by a qualified electrician. Connect the dryer to the correct voltage; if necessary, check the unit data plate. Check that the electrical installation corresponds to local codes. The dryer must be earthed and protected against short circuits using an automatic cut-out device with a differential device. An isolating switch must be installed near the dryer.

14

2920 7100 00

Instruction book

Reference -

Description Connect the compressed air lines to the marked inlet and outlet pipes of the dryer (see Dimension drawings). Provide an air inlet valve and outlet valve. If a by-pass pipe and valve are installed, the dryer can be serviced while it is by-passed. Location of isolating switch and fuses. Minimum distance 1.5 m (58.5 in).

1 2

3.3

Pictographs

Pictographs

Reference 1 2 3 4 5 6

Name Warning, under tension Warning, air not fit for breathing Warning, high pressure Warning, rotating fan Warning, hot surface Switch off the voltage and depressurize the dryer before maintenance or repair

2920 7100 00

15

Instruction book

4 4.1

Operating instructions Warnings

The operator must apply all relevant safety precautions, including those mentioned in this manual.

Safety precautions

Altitude operation Consult Atlas Copco if operating above 3000 m (9843 ft).

4.2

Control panel

Description

FXe 1 up to FXe 5

Reference 1 2

Name Dewpoint indicator Dryer on/off switch

4.3

Starting

Attention

To ensure optimum operational efficiency, do not use dryer on/off switch (2) repeatedly within a short time period. Wait at least 5 minutes to start the dryer again after stopping to allow pressure equalization. To keep the compressed air net free of condensate, start the dryer before starting the compressor and stop the compressor before stopping the dryer.

16

2920 7100 00

Instruction book

Procedure

FXe 1 up to FXe 5

Step 1 2 3 4 5

Action If installed, close the dryer by-pass valve. See .Installation proposal Press dryer on/off switch. (2) Open dryer air inlet valve (customer's installation). Approx. 5 minutes later, open dryer air outlet valve (customer's installation). Approx. 10 minutes later, the nominal dewpoint will be reached.

4.4

During operation

Procedure

FXe 1 up to FXe 5

Regularly check: The pressure dewpoint indicator (1) on the control panel. The pressure dewpoint will deviate from nominal if the air inlet conditions or volume flow differ from nominal. That condensate is discharged via condensate outlet. The amount depends on the operating conditions.

2920 7100 00

17

Instruction book

4.5

Stopping

Attention

To ensure optimum operational efficiency, do not use dryer on/off switch (2) repeatedly within a short time period. Wait at least 5 minutes to start the dryer again after stopping to allow pressure equalization. To keep the compressed air net free of condensate, start the dryer before starting the compressor and stop the compressor before stopping the dryer.

Procedure

FXe 1 up to FXe 5

Step 1 2 3

Action Close the dryer inlet and outlet valve (customers installation). Press dryer on/off switch (2), the dryer stops. If provided, open the dryer by-pass valve.

4.6

Condensate drain system

The dryers are equipped with an electronic condensate drain (EWD). The condensate from the condensate trap accumulates in a collector. When the condensate reaches a certain level, it is discharged through the drain outlet (1). The condensate can also be drained by pressing the test button (2). The drain filter can be cleaned by opening by unscrewing the inspection nut (3).

Automatic drain

18

2920 7100 00

Instruction book

2920 7100 00

19

Instruction book

Maintenance instructions

Before starting any maintenance or repair work, close the air inlet and outlet valve and switch off the voltage. When removing the side panels of the dryer, be aware that internal elements such as the pipes can be hot. Therefore, wait until the dryer has cooled down before removing the side panels. Dryers of FX type contain refrigerant HFC. When handling refrigerant, all applicable safety precautions must be observed. Please be aware of the following points: Contact of refrigerant with the skin will cause freezing. Special gloves must be worn. In case of contact with the skin, the skin should be rinsed with water. On no account may clothing be removed. Fluid refrigerant will also cause freezing of the eyes; safety glasses must hence be worn. Refrigerant is hazardous. Do not inhale refrigerant vapours. Check that the working area is adequately ventilated.

Safety precautions

Local legislation Local legislation may stipulate that: Work on the refrigerant circuit of the cooling dryer or on any equipment which influences its function must be undertaken by an authorised control body. The installation is checked once a year by an authorised control body. Instructions Keep the dryer clean. Inspect and clean the filter of the automatic condensate drain monthly, in dusty environment drain weekly: Release the pressure in the dryer by pressing the TEST push button on top of the condensate drain (before switching off the supply voltage). Switch off the voltage Remove the filter from the automatic drain and clean it with an air jet, working from inside to outside Reinstall the filter Brush or blow off the finned surface of the condenser monthly. Do not use water or solvents.

20

2920 7100 00

Instruction book

Device settings

The regulating and safety devices are factory-adjusted to obtain optimum performance of the dryer. Do not alter the setting of any of the devices.

Regulating and safety devices

2920 7100 00

21

Instruction book

Problem solving

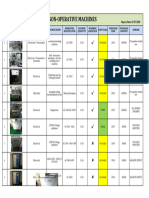

Air inlet and outlet valve (1) and condensate drain (2) on FXe 1 up to FXe 12

Attention

Use only authorised parts. Any damage or malfunction caused by the use of unauthorised parts is not covered by Warranty or Product Liability. Apply all relevant Safety precautions. Before carrying out any maintenance or repair work on the dryer: Close air inlet and outlet valve of the dryer. Press the test button on the electronic condensate drain to depressurize the air system. Move dryer on/off switch to position 0. Switch off the voltage. See section Stopping. Open the isolating switch to prevent an accidental start. The air inlet and outlet valve can be locked during maintenance or repair work as follows: Close the valve. Using a wrench, remove the screw fixing the handle. Lift the handle and turn it until the slot of the handle fits over the blocking edge on the valve body. Fit the screw.

Faults and remedies

Condition 1 Pressure dewpoint too high Fault Air inlet temperature too high Remedy Check and correct; if necessary, install a pre-cooler.

Ambient temperature too high Check and correct; if necessary, draw cooling air via a duct from a cooler place or relocate the dryer. Air inlet pressure too low Dryer capacity exceeded Increase inlet pressure. Adjust the pressure switch. Reduce air flow.

22

2920 7100 00

Instruction book

Condition

Fault Shortage of refrigerant Refrigerant compressor does not run Evaporator pressure too high Condenser pressure too high

Remedy Have circuit checked for leaks and recharged. See 3 See 5 See 2

Condition 2 Condenser pressure too high or too low

Fault Fan or fan motor out of order

Remedy Check fan/fan motor.

Ambient temperature too high Check and correct; if necessary, draw cooling air via a duct from a cooler room or relocate the dryer. Condenser externally clogged Clean condenser.

Condition 3

Fault

Remedy Check and correct as necessary. Motor will restart when motor windings have cooled down. Wait a few minutes and restart.

Compressor stops or does not Electric power supply to start compressor is interrupted Thermal protection of refrigerant compressor motor has tripped Restart of the dryer has been too fast, not enough time for pressure balancing

Condition 4

Fault

Remedy Flush the assembly by opening the manual drain valve. Have system inspected. Clean the inlet filter of the automatic drain by opening by unscrewing the inspection nut. Check functioning of the drain by pushing the test button.

The condensate drain remains Drain system clogged inoperative

Condition 6

Fault

Remedy

Condensate trap continuously Automatic drain system out of Have system checked, if necessary order replace automatic drain.

2920 7100 00

23

Instruction book

Condition 5

Fault

Remedy Have hot gas by-pass valve adjusted. See 2 Have circuit checked for leaks and recharged.

Evaporator pressure is too high Hot gas by-pass valve or too low at unload incorrectly set or out of order Condenser pressure too high or too low Shortage of refrigerant

24

2920 7100 00

Instruction book

8 8.1

Technical data Reference conditions and limitations

Reference conditions

Unit Compressed air inlet pressure Compressed air inlet temperature Ambient temperature bar(e) C C 7 35 25

Limits

Unit Max. ambient air temperature Min. ambient air temperature Max. compressed air inlet temperature C C C 45 5 55

8.2

Air dryer data

FXe 1 up to FXe 5 - 230/1/50 Hz / 230/1/60Hz

Air dryer type Inlet capacity Outlet pressure dewpoint 7C Pressure drop Outlet pressure dewpoint 7C Power consumption /50 Hz Maximum working pressure Weight of the unit Refrigerant Total charge (approx.) Compressed air connections kg Unit l/s bar kW bar kg FXe 1 7 0.35 0.18 16 19 R134a 0.150 G 3/4 FXe 2 13 0.35 0.20 16 19 R134a 0.170 G 3/4 FXe 3 16 0.35 0.22 16 20 R134a 0.290 G 3/4 FXe 4 23 0.35 0.26 16 25 R134a 0.350 G 3/4 FXe 5 30 0.35 0.30 16 27 R134a 0.480 G 3/4

Correction factors

When the actual temperature or pressure differs from the reference figures, multiply the nominal figure with the corresponding correction factor to obtain the correct value.

2920 7100 00

25

Instruction book

Ambient temperature (C) correction factor

25 1

30 0.91

35 0.81

40 0.72

45 0.62

Inlet temperature (C) correction factor

25 1

30 1

35 1

40 0.82

45 0.69

50 0.58

55 0.45

Inlet pressure bar(e) correction factor

5 0.90

6 0.97

7 1

8 1.03

9 1.06

10 1.08

11 1.1

12 1.12

13 1.20

Outlet pressure dewpoint (C) correction factor

10 1.1

3 0.8

Filter selection

Air dryer type Inlet capacity (l/s) Filter FXe 1 7 DD/PD 9 FXe 2 13 DD/PD 17 FXe 3 16 DD/PD 17 FXe 4 23 DD/PD 32 FXe 5 30 DD/PD 44

26

2920 7100 00

Instruction book

Pressure equipment directives

All pressure-bearing components are designed according to the European Directive 97/23/EC category I or less.

Components subject to 97/23/EC Pressure Equipment Directive

2920 7100 00

27

In order to be First in MindFirst in Choice for all your quality compressed air needs, Atlas Copco delivers the products and services that help to increase your business efficiency and profitability. Atlas Copco's pursuit of innovation never ceases, driven by our need for reliability and efficiency. Always working with you, we are committed to providing you the customized quality air solution that is the driving force behind your business.

www.atlascopco.com

No. 2920 7100 00 / 2011 - 08 - Printed in Belgium

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Personal Budgeting Trend For A PersonDocumento2 paginePersonal Budgeting Trend For A PersonNufita Twandita DewiNessuna valutazione finora

- Daily Self-Evaluation - Monthly Data: P H Y S I C A LDocumento1 paginaDaily Self-Evaluation - Monthly Data: P H Y S I C A LSead ZejnilovicNessuna valutazione finora

- Process Map ExampleDocumento3 pagineProcess Map ExamplevisaguyNessuna valutazione finora

- Holiday Budget PlannerDocumento2 pagineHoliday Budget PlannervisaguyNessuna valutazione finora

- Personal Budgeting Trend For A PersonDocumento2 paginePersonal Budgeting Trend For A PersonNufita Twandita DewiNessuna valutazione finora

- Non Operative MachinesDocumento1 paginaNon Operative MachinesvisaguyNessuna valutazione finora

- Simple Gantt Chart1Documento3 pagineSimple Gantt Chart1misszomby100% (1)

- Holiday Budget PlannerDocumento2 pagineHoliday Budget PlannervisaguyNessuna valutazione finora

- Control SystemsDocumento1 paginaControl SystemsvisaguyNessuna valutazione finora

- Introduction To Programming of Embedded SystemsDocumento35 pagineIntroduction To Programming of Embedded SystemsvisaguyNessuna valutazione finora

- Personal Budgeting Trend For A PersonDocumento2 paginePersonal Budgeting Trend For A PersonNufita Twandita DewiNessuna valutazione finora

- Intelligent Security System PDFDocumento62 pagineIntelligent Security System PDFluiz augusto vieiraNessuna valutazione finora

- Simple Gantt Chart1Documento3 pagineSimple Gantt Chart1misszomby100% (1)

- Ieee 11MS09 HRDocumento6 pagineIeee 11MS09 HRvisaguyNessuna valutazione finora

- AVR194 Brushless DC Motor Control Using ATMega32M1Documento16 pagineAVR194 Brushless DC Motor Control Using ATMega32M1u776287Nessuna valutazione finora

- Automotive Embedded Systems PDFDocumento46 pagineAutomotive Embedded Systems PDFYellaturi Siva Kishore ReddyNessuna valutazione finora

- Power Electronics LectureDocumento84 paginePower Electronics LecturevisaguyNessuna valutazione finora

- Velocity of Sound On Kundts TubeDocumento7 pagineVelocity of Sound On Kundts Tubevisaguy100% (1)

- Acoustic ImpedanceDocumento4 pagineAcoustic ImpedancevisaguyNessuna valutazione finora

- ps25251 DatasheetDocumento6 pagineps25251 DatasheetvisaguyNessuna valutazione finora

- Power Spectral Density CodeDocumento4 paginePower Spectral Density CodevisaguyNessuna valutazione finora

- IBPS Clerk Vacancies Analysis byDocumento1 paginaIBPS Clerk Vacancies Analysis byvisaguyNessuna valutazione finora

- Making Sentences - EnglishDocumento10 pagineMaking Sentences - Englishrjumaat100% (2)

- Payment Instruments in India: 3.1. CurrencyDocumento5 paginePayment Instruments in India: 3.1. CurrencysciencenokiaNessuna valutazione finora

- DC MotorDocumento47 pagineDC MotorArun SaraswathyNessuna valutazione finora

- Alernate FuelsDocumento4 pagineAlernate FuelsvisaguyNessuna valutazione finora

- At CommandDocumento9 pagineAt CommandvisaguyNessuna valutazione finora

- Term Paper Bachelor IT 16s.unlockedDocumento11 pagineTerm Paper Bachelor IT 16s.unlockedvisaguyNessuna valutazione finora

- Finite Element Analysis of Deep DrawingDocumento4 pagineFinite Element Analysis of Deep DrawingTamer HagasNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Dynamic Shear Modulus SoilDocumento14 pagineDynamic Shear Modulus SoilMohamed A. El-BadawiNessuna valutazione finora

- Dady - Piernas LargasDocumento12 pagineDady - Piernas LargasSarha NietoNessuna valutazione finora

- Pursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyDocumento37 paginePursuit of Performance Findings From The 2014 Miller Heiman Sales Best Practices StudyLoredanaNessuna valutazione finora

- Power-Miser 12 Water Heater ManualDocumento32 paginePower-Miser 12 Water Heater ManualClaudeVanDammNessuna valutazione finora

- R67068.0002 2 HB Profibus-Schnittstelle en KueblerDocumento42 pagineR67068.0002 2 HB Profibus-Schnittstelle en KueblerSabari StunnerNessuna valutazione finora

- Cultural Practices of India Which Is Adopted by ScienceDocumento2 pagineCultural Practices of India Which Is Adopted by ScienceLevina Mary binuNessuna valutazione finora

- Power Quality Lab Manual (EE-801)Documento12 paginePower Quality Lab Manual (EE-801)ASHU KNessuna valutazione finora

- Package-Related Thermal Resistance of Leds: Application NoteDocumento9 paginePackage-Related Thermal Resistance of Leds: Application Notesalih dağdurNessuna valutazione finora

- Dimmable Bulbs SamplesDocumento11 pagineDimmable Bulbs SamplesBOSS BalaNessuna valutazione finora

- Pressure-Dependent Leak Detection Model and Its Application To A District Water SystemDocumento13 paginePressure-Dependent Leak Detection Model and Its Application To A District Water SystemManjul KothariNessuna valutazione finora

- Form No. 1 Gangtok Municipal Corporation Deorali, SikkimDocumento2 pagineForm No. 1 Gangtok Municipal Corporation Deorali, SikkimMUSKAANNessuna valutazione finora

- IA 05 Formal MethodsDocumento5 pagineIA 05 Formal MethodsAuthierlys DomingosNessuna valutazione finora

- Chapter 07Documento16 pagineChapter 07Elmarie RecorbaNessuna valutazione finora

- Introduction To The Iceberg ModelDocumento5 pagineIntroduction To The Iceberg ModelAbhay Tiwari100% (1)

- Review Rachna WasteDocumento9 pagineReview Rachna WasteSanjeet DuhanNessuna valutazione finora

- Kimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Documento6 pagineKimura K.K. (KKK) : Can This Customer Be Saved? - Group D13Mayuresh GaikarNessuna valutazione finora

- A Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Documento292 pagineA Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Jonathan MannNessuna valutazione finora

- STFC-2023 International E - conference-BITDocumento6 pagineSTFC-2023 International E - conference-BITRanilprabhu MNessuna valutazione finora

- Proposed Multimodal Terminal: Architect Rosauro H. Jamandri, M. ArchDocumento7 pagineProposed Multimodal Terminal: Architect Rosauro H. Jamandri, M. Archpepito manalotoNessuna valutazione finora

- The Invisible SunDocumento7 pagineThe Invisible SunJay Alfred100% (1)

- Sta404 07Documento71 pagineSta404 07Ibnu Iyar0% (1)

- Hayek - Planning, Science, and Freedom (1941)Documento5 pagineHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- TOA Project Presentation (GROUP 5)Documento22 pagineTOA Project Presentation (GROUP 5)Khadija ShahidNessuna valutazione finora

- Num Sheet 1Documento1 paginaNum Sheet 1Abinash MohantyNessuna valutazione finora

- ARCASIA Students Design Competition TORDocumento4 pagineARCASIA Students Design Competition TORDeena McgeeNessuna valutazione finora

- Rules and Fallacies For Categorical SyllogismsDocumento5 pagineRules and Fallacies For Categorical SyllogismsFatima Ismael PortacioNessuna valutazione finora

- Guia Instalacion APP Huawei Fusion HmeDocumento4 pagineGuia Instalacion APP Huawei Fusion Hmecalinp72Nessuna valutazione finora

- Practical Research 2.9Documento22 paginePractical Research 2.9Michael GabertanNessuna valutazione finora

- Vectors Notes (Answers)Documento24 pagineVectors Notes (Answers)ScionNessuna valutazione finora

- Motive 27Tmx: Data SheetDocumento2 pagineMotive 27Tmx: Data SheetUlisesGómezNessuna valutazione finora