Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Transmission Construction Standard: Saudi Electricitycompany

Caricato da

Tori SmallTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Transmission Construction Standard: Saudi Electricitycompany

Caricato da

Tori SmallCopyright:

Formati disponibili

-. ~~ ~~.,...,.

tl ~~I

Saudi ElectricityCompany

RI-.-112.11

18"'10110.0

GENERAL PURPOSE FENCING

PROPRIETARYINFORMATION

This document contains proprietary information developed by and for exclusive use of Saudi Electricity

Company. Your acceptance of the document is an acknowledgement that it must be used for the identified

purpose/application and during the period indicated. It cannot be used or copied for any other purposes nor

released to others without prior written authorization of Saudi Electricity Company. Saudi Electricity Company

will not be responsible for misuse and/or misapplication, and any harm resulting therefrom. Saudi Electricity

Company also reserves the right to take any necessary actions to protect its interest against unauthorized use.

ORIGINATED BY c APPROVED BY

Engr. Khalaf M.AI-Ma'ashi

Division Manager,

Engineering Support

ngr. Abdullah M. AI-Garni

Department Manager,

Transmission Standards &

Specifications

Date of Approval:

Engr. Saleh N. AI-Sohaibani

Executive Director,

Engineering & Projects

,

TRANSMISSION CONSTRUCTION STANDARD

J

TCSM11201 RO/JOA

PAGE NO. 1 OF 12

0

Q..

a..

w

(,)

0

C>

0:

0

Cl)

z

0

Ci5

:>

w

0::

Z

0

i=

a..

0:

(,)

Cl)

w

0

Q)

1ii

0

ci

.... C\I

Z

(")

December 03, 2008

PAGE NO. 2 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

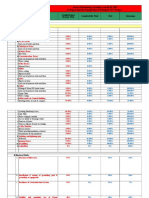

TABLE OF CONTENT

1.0 SCOPE

2.0 GENERAL REQUIREMENTS

3.0 FENCING SYSTEM COMPONENTS

4.0 CONSTRUCTION

4.1 Grading

4.2 Excavation

4.3 Post

4.4 Bracing in the Plane o f Fence

4.5 Gates

4.6 Barbed Wire

4.7 Top Rail

4.8 Tension Wire

4.9 Chain Link Fence Fabric

4.10 Stretcher Bars and Bands

4.11 Fence Anchor

4.12 Bolts

4.13 Concrete

4.14 Miscellaneous

5.0 STORAGE OF MATERIAL

6.0 CLEAN UP

7.0 REFERENCES

PAGE NO. 3 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

1.0 SCOPE

1.1 This Standard covers the construction of General Purpose and Perimeter Fencing for

non-vital or non-sensitive facilities.

1.2 The types of fencing that this standard will apply are listed below. However, the type

of fence shall be determined by the proponent organization as to operational, safety

and security requirement not covered by HCIS (SSD).

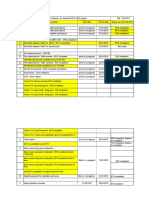

The following Table lists the different types of fencing:

Barbed Wire Fencing

Type

Height of

Fencing

Fabric mm

Top

Rail

Brace

Post (l) No. of

supporting

Arms

No. of

Strands

Continues

Concrete

Anchor

I 2440 YES YES 2 6 YES

II 2440 YES YES 2 6 NO

III 2440 NO NO 2 6 NO

IV 2135 NO NO 1 3 NO

V 2135 NO NO 0 0 NO

PAGE NO. 4 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

2.0 GENERAL REQUIREMENTS

2.1 Fencing shall be built in strict accordance with the referenced Engineering Standard

Drawings and specification in a workman like manner.

2.2 The type of fencing required is dependent upon operational, safety and security

requirements as determined by the Proponent Organization.

2.3 Type I fence shall be used for all facilities where security is of concern and the

bottom of the chain link fence fabric tied to a continuous concrete anchor.

2.4 All fencing components except concrete and asphalt felt shall be hot-dip galvanized

in accordance with the relevant ASTM specifications. (Vinyl -clad fabric, wires and

gate in filling may be substituted for use at severely corrosive locations when

specified).

2.5 Brace posts shall be installed to all type I and Type II 1ine posts. Pull posts, with a

minimum outside diameter of 73mm, shall be installed as line posts for Types III, IV

and V fencing at l00 m centers of uninterrupted fencing runs.

2.6 Fence posts shall be grounded and gate frame including plunger rod shall be bonded

in accordance with TES-P-119.10 unless otherwise specified in the project

specifications.

2.7 Concrete for footings and fence anchor shall have a minimum compressive strength

at 28 days in accordance with exposure requirement of concrete as per 70-TMSS-03.

2.8 The post/foundation interface shall be treated as indicated in Footing Details given in

70-TMSS-02.

2.9 Footings for all posts shall extend 100 mm below the end of the post.

2.10 If precast fence post footings are used, backfill shall be compacted to meet or exceed

the existing soil density.

2.11 Excavation for fence posts shall not be started prior to completion of final grading.

2.12 Warning signs "Danger High Voltage with Bone and Skull" and "Danger High

Voltage Keep Away" shall be installed on each side of the fence and at the gates as

per requirement of TES-P-119.13.

PAGE NO. 5 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

3.0 FENCING SYSTEM COMPONENTS

3.1 All fencing components including all necessary fittings and Accessories shall meet

or exceed the requirements of 70-TMSS-02.

3.2 The fencing system posts shall be Schedule 40, ASTM A53 galvanized steel pipe of

the following sizes:

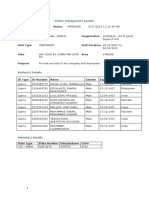

CLASSIFICATION OF POSTS

NOMINAL

DIAMETER

mm

ACTUAL

O.D.

mm

Brace (post and rail) 31.75 42.2

Line 50.8 60.3

End 63.5 73

Corner 63.5 73

Gates as follows:

Single gate up t o 1.8 m wide 63.5 73

Double gate up t o 3.7 m wide 63.5 73

Single gate over 1.8 m t o 4.0 m wide 88.9 101.6

Double gate over 3.7 m t o 8.0 m wide 88.9 101.6

3.3 Post heights from finished grade to top of post (without extension arm) shall be as

indicated in the table below:

FENCE TYPE

I

II

III

IV

V

Post :

HEIGHT IN MM.

Walk Gate

2465 2465 2700 2455 2165

End & Drive

2760 2760 2700 2455 2165

Line

2400 2400 2400 2100 2165

Corner

2465 2465 2465 2100 2165

PAGE NO. 6 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

3.4 Concrete for foundation shall be ready mixed concrete conforming to 70-TMSS-03

per exposure requirement.

3.5 Field mixed concrete, if unavoidable, shall also meet the requirements of TCS-Q-

113.03 and 70-TMSS-03 in all respect including the following:

3.5.1 Concrete field mix design, trial mix test results, test results of aggregates

including mixing water shall be submitted to SEC for review and approval.

3.5.2 All materials tested for a field mix concrete shall be insured as a

representative sample of materials delivered on site.

3.5.3 Batching of concrete ingredients shall be by weight. Volume batching shall

not be permitted.

3.5.4 Water dispensing equipment shall be provided with calibrated water gauge.

3.5.5 Field mixing shall be by the use of mechanical mixer. Manual mixing shall

not be permitted.

3.6 Reclaimed material shall be used only on the written approval by the SEC

Representative.

PAGE NO. 7 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

4.0 CONSTRUCTION

4.1 Grading

4.1.1 Fence shall be installed to conform to the alignment and finished grade as

indicated on the drawings. Where necessary, the fence grade shall be adjusted

to fit the ground contour by slipping the fence fabric links. On steep grades,

the posts may be set normal to the slope, provided transition sections are

constructed.

4.1.2 Ground surface irregularities shall be machine graded by the Contractor as

required to eliminate frequent changes in vertical alignment and to provide a

smooth profile for the fence. Clearance below the bottom of the fence shall

not exceed 25 mm.

4.1.3 The plan and profile of each reach of fence between corner posts or between

corner posts and gate posts shall be straight. The Contractor shall grade

ground surfaces as required to achieve the straight profiles before each reach

of fence is installed.

4.2 Excavation

4.2.1 Excavation for fence posts foundation shall not be started unless final grading

is completed. Prior to excavation, the Contractor shall verify from SEC the

locations of underground utilities that exist in the area.

4.2.2 Excavate or drill holes for post footings in firm, undisturbed or compacted

soil with all necessary precautions to ensure that any underground utility in

the area will not be damaged.

4.2.3 Holes shall have a diameter of not less than 250mm for line posts and 300mm

for corner posts, end, and terminal or pull posts and gate posts. Depth of

holes shall be not less than 1000 mm.

4.2.4 All loose materials inside the excavated holes shall be removed prior to

setting of fence posts and concrete pouring.

4.2.5 Excavated materials shall be removed away from around the holes.

4.2.6 All safety precautions during excavation shall be adhered to in accordance

with the requirements of the SEC Accident Prevention Manual and

Construction Safety Manual.

PAGE NO. 8 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

4.3 Post

4.3.1 Posts shall extend 900 mm into concrete footings as measured from the

ground surface.

4.3.2 All posts shall be equipped with water excluding top caps or extension arms.

4.3.3 All line posts shall be equally spaced at intervals of not more than 3 m on

centers in the line of fence. Posts shall be plumbed with tops properly aligned

except as provided on Clause 4.1.1.

4.3.4 Terminal posts (end, corner, and pull post) shall be installed at the beginning

and end of each continuous length of fence and at abrupt changes in vertical

and horizontal alignments for all types of fence.

4.3.5 Brace posts shall be attached to all SEC Type I and Type II fencing line posts

at a point 1500 mm above ground level and extend downward toward the

inside of the fence at 45 degrees in a vertical plane which is perpendicular to

the plane of the fence. For Types III, IV, and V fencing, pull posts shall be

installed at 100 m centers of uninterrupted fencing runs.

4.3.6 Where posts are set in earth, concrete foundations 1000 mm deep shall be

provided. If sound bedrock is encountered, post excavation shall be at least

600 mm into the rock and the diameter of the hole shall be a minimum of 25

mm greater than the cross section of the post. Non-shrink grout shall be used

to fill the void.

4.4 Bracing in the Plane of Fence

4.4.1 Each brace assembly shall consist of one top and one intermediate

compression member both of 42.2 mm OD Pipe and one diagonal truss rod of

at least 10 mm diameter. For Type I and Type II fencing, the top rail is the

top compression member. Pipe used for the compression members shall be of

one piece without couplings in the bracing panel.

4.4.2 End posts shall be braced to the first line post with a complete brace

assembly.

4.4.3 Corner and pull posts shall be braced in both direction to the two nearest line

posts with one complete brace assembly to each line post.

4.4.4 Each gate post shall be braced by a horizontal pipe brace and an adjustable

truss rod extending to an adjacent line post.

4.4.5 Brace in line of fence shall be installed before tension wires on posts are

tightened. When truss rods and tension wires are subjected to proper tension,

all posts shall be plumbed except as provided on para. 4.1.1.

PAGE NO. 9 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

4.5 Gates

4.5.1 Gates shall be of welded or bolted construction, adequately braced and

provided with adjustable diagonal tension bars to prevent sagging. Gates

shall be installed so that they cannot be removed without dismantling of the

hardwares.

4.5.2 Gate hinges shall be of heavy construction and allow the gate to swing 180

degrees (90 degrees either way from closed position). All gates shall be

provided with outer gate holders and closed position plunger rod receiver.

Rod catch shall consist of a roadway plate with anchor set in concrete and

arranged to engage the plunger rod.

Holders shall consist of mechanical devices for securing and supporting the

free end of the gates when in the full open position. Holders shall be mounted

on pipe posts filled with concrete and set in concrete foundations.

4.5.3 All gates shall be completely equipped with a latch of the plunger bar type.

The latch shall be so constructed that the plunger bar may be kept in the

raised position while the gate is open. All gates shall be equipped with

attachments for padlocking. The padlock has to be readily accessible from

both sides of the gate. Padlock shall be as per SOW/TS.

4.5.4 The top rail and barbed wire for SEC Type I and Type II Fencing walk gates

shall be continuous over the gate and not swing with the gate.

4.5.5 Type III and IV walk gates and gates wider than 1.8 m for all types (except

Type V) shall be constructed with the gate frame posts extending 300 mm

above the gate frame for the attachment of 3 strands of barbed wire.

4.5.6 Barbed wire where required shall be attached to gate extended frames by

means of an eye bolt.

4.5.7 Gate for Type V fencing shall not be topped with barbed wire.

4.6 Barbed Wire

Barbed wire shall be held in the extension arm slots by means of lugs or lock wire.

Holding the barbed wire in the slots by means of tension in the wire is not permitted.

4.7 Top Rail

The top rail (42.2 mm OD pipe) in lieu of tension wire shall be used for SEC Type I

and II fencing and shall be continuous except over drive gates. One expansion

coupling shall be used for every 30 meters of rail.

PAGE NO. 10 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

4.8 Tension Wire

4.8.1 Tension wire shall be secured to beginning and end posts by means of a

winding bracket. The tension wire shall also be attached to the line posts by

tie wire wrapped around the post and secured to the tension wire by three

complete turns on each side of the post.

4.8.2 Top and bottom tension wires shall be installed before the fabric. Bottom

tension wires shall be installed approximately 50 mm above grade and shall

be attached to each post and securely anchored at terminal and gate posts.

4.9 Chain Link Fence Fabric

4.9.1 The fencing fabric for SEC Type I and Type II Fencing shall be attached to

top rails by means of tie wires spaced at intervals not exceeding 600 mm.

4.9.2 The fencing fabric shall be attached to the tension wire by means of clip or

tie wires spaced at intervals not exceeding 300 mm.

4.9.3 Attachment of fence fabric to the line posts for all type of fence shall not

exceed 355 mm on centers. Tie knots shall be made on the security side of

the fence.

4.9.4 Rolls of chain link fabric shall be joined by weaving a single strand into the

ends of the rolls to form a continuous mesh pattern.

4.9.5 Chain link fabric shall be cut and fastened independently at the terminal end,

corner or gate post by the use of stretcher bars and bands.

4.9.6 Fabric for gate shall be the same fabric used for fence, unless otherwise

specified. Install fabric with stretcher bars at vertical edges and tie at top and

bottom edges of fabric. Attach stretcher bars to gate frames with hook bolt at

not more than 355 mm on center.

4.10 Stretcher Bars and Bands

Stretcher bars shall be provided at each gate, end, corner, and pull post. Each

stretcher bar shall be threaded through the fabrics and anchored to the post at 355

mm centers by bar bands.

4.11 Fence Anchor

The fence anchor shall only be used for SEC Type I Fencing and shall be constructed

according to Standard Drawing TA-800013.

PAGE NO. 11 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

4.12 Bolts

All hardware attachment bolts shall have the threaded end peened or burred so that

removal will be difficult. Bolts shall be installed so that nuts will be at the security

side of the fence.

4.l3 Concrete

4.13.1 Concrete foundations and fence anchor shall conform to the exposure

requirement of 70-TMSS-03.

4.13.2 Each foundation shall be cured at least 72 hours before further work is done

on the post.

4.13.3 Concrete foundations shall have the same cross-section throughout the

footing depth.

4.13.4 Concrete foundations shall be circular, minimum 250 mm in diameter for line

and brace posts and with a dimension not less than the post outside diameter

plus 225 mm for end, pull, corner, and gate posts except that foundation in

bedrock shall be minimum of 25 mm larger than the OD (outside diameter)

of the post.

4.13.5 Foundations shall extend above the ground surface and shall be crowned

approximately 25 mm.

4.14 Miscellaneous.

4.14.1 When fully constructed, the barbed wire, tension wire, chain link fabric, and

truss rods shall be taut.

4.14.2 Fabric shall be stretched taut so that a pull of 70 kilograms at the middle of a

panel will not lift the bottom of the fabric more than 150 mm. from the

finished grade.

4.14.3 All fence posts except alternate line post shall be connected to the grounding

grid of the fenced area in accordance with TES-P-119.10 unless otherwise

specified as not required in the SOW/TS. Also, the plunger rod shall be

bonded to the gate frame which in turn shall be bonded to the gate post.

PAGE NO. 12 OF 12 TCSM11201R0/J QA

TRANSMISSION CONSTRUCTION STANDARD

TCS-M-112.01, Rev. 0

Date of Approval: December 03, 2008

5.0 STORAGE OF MATERIAL

Materials shall be carefully handled during all phases of the work and shall be stored by

placing them on suitable blocking materials, so that no part of the item shall be in contact

with the earth.

Blocking material can be a minimum of 100xl00 mm lumber, used or damaged poles or

other similar materials which are free of protruding nails or other metal which could damage

any materials stored upon them. These items of blocking should be obtained and stored for

use as required before any materials are delivered to the storage yard.

6.0 CLEAN UP

All excess materials and other debris resulting from the fence construction shall be promptly

removed from the jobsite.

7.0 REFERENCES

7.1 Standards

7.1.1 TES-P-119.10 Substation Grounding

7.1.2 70-TMSS-02 Fence Chain Link

7.1.3 70-TMSS-03 Normal Weight Ready-Mixed Portland Cement Concrete

7.2 Drawings

TA-800013 Chain Link Boundary Fence

Potrebbero piacerti anche

- TCSP10403R0Documento30 pagineTCSP10403R0BADRI VENKATESHNessuna valutazione finora

- Coatings and Waterproofing: KhalafDocumento19 pagineCoatings and Waterproofing: KhalafmohamedNessuna valutazione finora

- 10 TMSS 01 R1Documento20 pagine10 TMSS 01 R1ateeq26_659595789Nessuna valutazione finora

- Tes P 119 07 R0Documento17 pagineTes P 119 07 R0Subhash Chekka SEC 115KV Project100% (1)

- TCS-Q-113.01 (Rev 01) -沥青混凝土路面Documento41 pagineTCS-Q-113.01 (Rev 01) -沥青混凝土路面heng liu100% (1)

- TES-P-122-07-R1-Transmission Structure SpottingDocumento18 pagineTES-P-122-07-R1-Transmission Structure SpottingMozammil AkhtarNessuna valutazione finora

- 70 TMSS 03 R0Documento38 pagine70 TMSS 03 R0Tori SmallNessuna valutazione finora

- Section Iii - Scope of Work: Saudi Electricity CompanyDocumento8 pagineSection Iii - Scope of Work: Saudi Electricity CompanyPrabhakar SvNessuna valutazione finora

- 48 TMSS 02 Rev 00Documento29 pagine48 TMSS 02 Rev 00chand saigvNessuna valutazione finora

- September 07, 2010Documento12 pagineSeptember 07, 2010Suhaib ObeidatNessuna valutazione finora

- 23 TMSS 02 R0Documento0 pagine23 TMSS 02 R0renjithas2005Nessuna valutazione finora

- Tes T 111 02R0Documento35 pagineTes T 111 02R0Mohammad Abo AliNessuna valutazione finora

- 11-TMSS-02 Rev1 PDFDocumento6 pagine11-TMSS-02 Rev1 PDFA. HassanNessuna valutazione finora

- Indices of Approved Transmission Standards and SpecificationsDocumento10 pagineIndices of Approved Transmission Standards and SpecificationsSiva KumarNessuna valutazione finora

- TES-P-119-02-R1-Basic Design AspectsDocumento25 pagineTES-P-119-02-R1-Basic Design AspectsZain-Ul- Abdeen33% (3)

- Tes P 122 181213130429Documento31 pagineTes P 122 181213130429Ahmed AboelgoodNessuna valutazione finora

- 12 Tmss 11 r0 HV Link BoxDocumento29 pagine12 Tmss 11 r0 HV Link BoxVijayan Thekke VeeduNessuna valutazione finora

- Tes P 119.25 R0Documento18 pagineTes P 119.25 R0asifaliabid100% (1)

- Tes P 122 12R0Documento15 pagineTes P 122 12R0Salman YounasNessuna valutazione finora

- TES-P-122.08 R0 - Survey Guidelines PDFDocumento11 pagineTES-P-122.08 R0 - Survey Guidelines PDFMohamed EldinNessuna valutazione finora

- TES P 119 10 R0 1 GroundingpdfDocumento43 pagineTES P 119 10 R0 1 Groundingpdftino cardaNessuna valutazione finora

- Sceco Stanadard Fot Elec ConstDocumento28 pagineSceco Stanadard Fot Elec ConstrjshnairNessuna valutazione finora

- 20 TMSS 02 R1Documento26 pagine20 TMSS 02 R1Anonymous NrBbhHuZyiNessuna valutazione finora

- Seeds Ii 00Documento44 pagineSeeds Ii 00Tori Small83% (6)

- 12 TMSS 10Documento19 pagine12 TMSS 10Fouad AliNessuna valutazione finora

- 11 TMSS 10 R0Documento0 pagine11 TMSS 10 R0renjithas2005Nessuna valutazione finora

- Tes P 119 21 R0 PDFDocumento37 pagineTes P 119 21 R0 PDFMohammed ElmakNessuna valutazione finora

- Tes B 106.01Documento15 pagineTes B 106.01Badhur ZamanNessuna valutazione finora

- TESP12209R0 حدود الأمان Clearances1Documento39 pagineTESP12209R0 حدود الأمان Clearances1hafezasad50% (4)

- 1-) 52-TMSS-01-Rev.00Documento29 pagine1-) 52-TMSS-01-Rev.00Orcun CalayNessuna valutazione finora

- Tes P 119 10 R0 PDFDocumento43 pagineTes P 119 10 R0 PDFAbin Meetu100% (4)

- 11-TMSS-04 Revision 01Documento18 pagine11-TMSS-04 Revision 01Abu Samar100% (2)

- Sdcs 02 PDFDocumento52 pagineSdcs 02 PDFvinoth100% (6)

- 11-TMSS-03 Revision 0Documento18 pagine11-TMSS-03 Revision 0Abu SamarNessuna valutazione finora

- 53 TMSS 01 R1Documento57 pagine53 TMSS 01 R1Nauman Habib KhanNessuna valutazione finora

- Indices of Approved Transmission Standards and SpecificationsDocumento13 pagineIndices of Approved Transmission Standards and Specificationsbadhur zaman hajaNessuna valutazione finora

- Sdcs-03 Part 1 (Distribution Network Grounding) Rev01Documento107 pagineSdcs-03 Part 1 (Distribution Network Grounding) Rev01Haytham BafoNessuna valutazione finora

- 69 PDFDocumento38 pagine69 PDFproteccionesNessuna valutazione finora

- SEC Standard - TES-P-122.05PII-R1Documento28 pagineSEC Standard - TES-P-122.05PII-R1daimi143x7787Nessuna valutazione finora

- 01 TMSS 01 R0Documento0 pagine01 TMSS 01 R0hasanmnh0% (1)

- TES-H-107-02-R1 Paint Color Codes and StandardsDocumento30 pagineTES-H-107-02-R1 Paint Color Codes and StandardsNauman Habib KhanNessuna valutazione finora

- SDCS-01: Saudi Electricity CompanyDocumento30 pagineSDCS-01: Saudi Electricity Companyessam khalilNessuna valutazione finora

- 01 TMSS 01 Rev3Documento23 pagine01 TMSS 01 Rev3ahmedNessuna valutazione finora

- Tes P 122 181213125606Documento34 pagineTes P 122 181213125606Sukant BhattacharyaNessuna valutazione finora

- 31-TMSS-06 (Rev 00)Documento8 pagine31-TMSS-06 (Rev 00)GardellNessuna valutazione finora

- Tes P 104 03 R0 PDFDocumento16 pagineTes P 104 03 R0 PDFAbin MeetuNessuna valutazione finora

- 53-TMSS-01 (Rev 02)Documento57 pagine53-TMSS-01 (Rev 02)Gardell100% (2)

- Standard - 01 TMSS 01 R3Documento23 pagineStandard - 01 TMSS 01 R3arabsniper0% (2)

- Tes - P - 122.11Documento21 pagineTes - P - 122.11Enus Benjamin100% (1)

- TESP12201R0Documento20 pagineTESP12201R0Muhammad AliNessuna valutazione finora

- VicRoads Bridge Design Technical NotesDocumento111 pagineVicRoads Bridge Design Technical NotesJunnoKaiserNessuna valutazione finora

- Section - V Technical Specifications of Contract (TSC)Documento6 pagineSection - V Technical Specifications of Contract (TSC)Praveen BandariNessuna valutazione finora

- Transmission Construction Standard: Saudi ElectricitycompanyDocumento12 pagineTransmission Construction Standard: Saudi ElectricitycompanyMohsin QureshiNessuna valutazione finora

- 3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanDocumento8 pagine3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanPhuong ThaoNessuna valutazione finora

- Civil Specification For Electrical Works - GASCODocumento29 pagineCivil Specification For Electrical Works - GASCOnpwal100% (2)

- Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocumento10 pagineReinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationKumar AtrayNessuna valutazione finora

- DO - 004 - s2016 (Corr Asphalpt Roofing) PDFDocumento5 pagineDO - 004 - s2016 (Corr Asphalpt Roofing) PDFDrew B MrtnzNessuna valutazione finora

- A-320 - Fire Proofing of Steel StructureDocumento11 pagineA-320 - Fire Proofing of Steel StructurePoorvi Bhave75% (4)

- Piping Design Plant LayoutDocumento23 paginePiping Design Plant Layoutluxvij100% (1)

- Technical Specifications of Boundary WallDocumento5 pagineTechnical Specifications of Boundary WallAndy100% (1)

- S.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsDocumento2 pagineS.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsTori SmallNessuna valutazione finora

- Assets List Against File # 23352: Alfanar ConstructionDocumento1 paginaAssets List Against File # 23352: Alfanar ConstructionTori SmallNessuna valutazione finora

- Project: JUAYMAH380/230KV BSP: SL No ADocumento4 pagineProject: JUAYMAH380/230KV BSP: SL No ATori SmallNessuna valutazione finora

- Course Book 6Documento19 pagineCourse Book 6Tori SmallNessuna valutazione finora

- I Site Progress Civil Works: A 380 KV GIS BuildingDocumento3 pagineI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallNessuna valutazione finora

- Assets List Against File # 17920: Alfanar ConstructionDocumento1 paginaAssets List Against File # 17920: Alfanar ConstructionTori SmallNessuna valutazione finora

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Documento10 pagine230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallNessuna valutazione finora

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Documento4 pagine7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallNessuna valutazione finora

- Prism Online QuestionnaireDocumento2 paginePrism Online QuestionnaireTori SmallNessuna valutazione finora

- Request# Status: Visitor Management SystemDocumento1 paginaRequest# Status: Visitor Management SystemTori SmallNessuna valutazione finora

- Acomplishment Chart 380kVDocumento8 pagineAcomplishment Chart 380kVTori Small100% (1)

- Imam Hussain Sermon at MinaDocumento15 pagineImam Hussain Sermon at MinaTori SmallNessuna valutazione finora

- Details of Company Car Expenses (01.12.15)Documento266 pagineDetails of Company Car Expenses (01.12.15)Tori SmallNessuna valutazione finora

- Main Lab: FT-A-21226 29Y Female SelfDocumento1 paginaMain Lab: FT-A-21226 29Y Female SelfTori SmallNessuna valutazione finora

- Shahrour FreedomDocumento14 pagineShahrour FreedomTori SmallNessuna valutazione finora

- Expense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterDocumento4 pagineExpense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterTori SmallNessuna valutazione finora

- CRC ChecklistDocumento1 paginaCRC ChecklistTori SmallNessuna valutazione finora

- WORK (Diwa, Angela Marie M.)Documento17 pagineWORK (Diwa, Angela Marie M.)Angela Miranda DiwaNessuna valutazione finora

- RBK-PROC-MK3 Raychem MK3Documento83 pagineRBK-PROC-MK3 Raychem MK3VictorNessuna valutazione finora

- 1979 IC MasterDocumento2.398 pagine1979 IC MasterIliuta JohnNessuna valutazione finora

- The Logic of Faith Vol. 1Documento39 pagineThe Logic of Faith Vol. 1Domenic Marbaniang100% (2)

- Moventas PH2900.2 - FinésDocumento13 pagineMoventas PH2900.2 - FinésDaniel Fuhr100% (1)

- Computer Shortcut Keys SystemDocumento5 pagineComputer Shortcut Keys SystemNo RebelNessuna valutazione finora

- Compiler Reference GuideDocumento1.174 pagineCompiler Reference GuideПавел НиколаевичNessuna valutazione finora

- Wordpress The Right WayDocumento62 pagineWordpress The Right WayAdela CCNessuna valutazione finora

- Sorting in ALV Using CL - SALV - TABLE - SAP Fiori, SAP HANA, SAPUI5, SAP Netweaver Gateway Tutorials, Interview Questions - SAP LearnersDocumento4 pagineSorting in ALV Using CL - SALV - TABLE - SAP Fiori, SAP HANA, SAPUI5, SAP Netweaver Gateway Tutorials, Interview Questions - SAP LearnerssudhNessuna valutazione finora

- QuestionsDocumento9 pagineQuestionsPlutoNessuna valutazione finora

- The Impact of Credit Risk On The Financial Performance of Chinese BanksDocumento5 pagineThe Impact of Credit Risk On The Financial Performance of Chinese Banksvandv printsNessuna valutazione finora

- BFC3042 BFC31802Documento13 pagineBFC3042 BFC31802Zuliyah ZakariaNessuna valutazione finora

- Mulligan Vs ART PDFDocumento4 pagineMulligan Vs ART PDFwernsickleNessuna valutazione finora

- PlaxisDocumento6 paginePlaxisRehan HakroNessuna valutazione finora

- Jib Cranes 20875644 Colour CatalogueDocumento30 pagineJib Cranes 20875644 Colour Cataloguepsingh1996Nessuna valutazione finora

- Franks 2009Documento11 pagineFranks 2009bhanu0% (1)

- Chapter Two Second Order Ordinary Differential Equation (SOODE)Documento11 pagineChapter Two Second Order Ordinary Differential Equation (SOODE)BennyNessuna valutazione finora

- Parametric Modeling A Simple ToolDocumento6 pagineParametric Modeling A Simple ToolFatimeh ShahinNessuna valutazione finora

- AK TPM Overview TechnionDocumento27 pagineAK TPM Overview Techniongdfeiu dionwdnNessuna valutazione finora

- Smart SYS S2301500R48 - DatesheetDocumento2 pagineSmart SYS S2301500R48 - DatesheetWill F Alves0% (1)

- Mining Engineering Syllabus PDFDocumento5 pagineMining Engineering Syllabus PDFihateu1Nessuna valutazione finora

- DYA Series 2018Documento22 pagineDYA Series 2018Abo MohammedNessuna valutazione finora

- Sachin BiradarDocumento2 pagineSachin Biradardecoo.cocooNessuna valutazione finora

- HowToExcel Ebook - 50 Tips To Master Excel 2017-06-11Documento41 pagineHowToExcel Ebook - 50 Tips To Master Excel 2017-06-11Lakshmi MeruvaNessuna valutazione finora

- 7805 Regulator DescriptionDocumento4 pagine7805 Regulator DescriptionyeateshwarriorNessuna valutazione finora

- Compiled Question File FSPDocumento22 pagineCompiled Question File FSPsyed aliNessuna valutazione finora

- Blockchain Spec PDFDocumento18 pagineBlockchain Spec PDFblueNessuna valutazione finora

- Fiat Bravo Training ManualDocumento111 pagineFiat Bravo Training ManualJa Ja75% (4)

- C Programming StringDocumento5 pagineC Programming StringJohn Mark CarpioNessuna valutazione finora

- ICT & ICT LabDocumento22 pagineICT & ICT LabM Asif 72 2MNessuna valutazione finora

- Building Construction Technology: A Useful Guide - Part 1Da EverandBuilding Construction Technology: A Useful Guide - Part 1Valutazione: 4 su 5 stelle4/5 (3)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDa EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNessuna valutazione finora

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDa EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyValutazione: 4 su 5 stelle4/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDa EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedValutazione: 5 su 5 stelle5/5 (1)

- Civil Engineer's Handbook of Professional PracticeDa EverandCivil Engineer's Handbook of Professional PracticeValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDa EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDa EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishValutazione: 4 su 5 stelle4/5 (3)

- Estimating Construction Profitably: Developing a System for Residential EstimatingDa EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNessuna valutazione finora

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDa EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseValutazione: 5 su 5 stelle5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsDa EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsValutazione: 1 su 5 stelle1/5 (4)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesDa EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNessuna valutazione finora

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDa EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEValutazione: 4 su 5 stelle4/5 (1)

- Real Life: Construction Management Guide from A-ZDa EverandReal Life: Construction Management Guide from A-ZValutazione: 4.5 su 5 stelle4.5/5 (4)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDa EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyValutazione: 4 su 5 stelle4/5 (1)

- Field Guide for Construction Management: Management by Walking AroundDa EverandField Guide for Construction Management: Management by Walking AroundValutazione: 4.5 su 5 stelle4.5/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDa EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftValutazione: 5 su 5 stelle5/5 (5)