Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cems Study of Oxide Layers Formed On Stainless Steel

Caricato da

Piranha TourniquetTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cems Study of Oxide Layers Formed On Stainless Steel

Caricato da

Piranha TourniquetCopyright:

Formati disponibili

Hyperfine Interactions 57 (1990) 2023-2028

2023

CEMS STUDY OF OXIDE LAYERS FORMED ON STAINLESS STEEL (SUS304 A N D SUS316) Kiyoshi N O M U R A and Yusuke U J I H I R A Faculty of Engineering, The University of Tokyo, Hongo 7-3-1, Bunkyo-ku, Tokyo 113, Japan

Stainless steel (SUS304 and SUS316) was chemically treated and heated at various temperatures, and the oxide films formed on the surface were analyzed by conversion electron Mrssbauer spectrometry (CEMS). Three magnetic components of iron species were detected in the top oxide layers of stainless steels heated below 600 ~ and the fine particles of iron oxides were initially produced in the inner oxide layers of the samples heated at temperatures higher than 700 ~ C. Only paramagnetic iron species were detected in the oxide layers of the stainless steels prepared by chemical treatment.

1. Introduction It is known that the heat treatment and chemical oxidation of stainless steel at certain conditions improve corrosion resistance of the substrate by forming the colored films. Colored stainless steel of type SUS304 becomes golden at 400 o C, orange at 5 0 0 ~ red to purple at 6 0 0 ~ purple at 700 ~ and blue above 7 0 0 ~ [1]. X-ray photoelectron spectrometric studies on the colored films on stainless steel treated chemically were reported by Ansell et al. [2]. We reported recently that oxide film on stainless steel works as a p H sensor [3]. Stewart et al. [4] applied C E M S to the analysis of the oxide layer on the enriched S7Fe thin foil of stainless steel (type SUS310), which was oxidized at high temperatures ( > 700~ and reported the formation of a-Fe203 in the chromium depleted layer. But few M r s s b a u e r spectrometric studies have been carried out on the formation of oxide films on stainless steel which was oxidized at low temperature ( < 700 o C) and by chemical procedure.

2. Experimental section

Sheets of austenic stainless steel (type SUS304 and SUS316) were degreased in acetone, and heated in air for 1 hour at 400, 500, 600, 700, and 800 o C. SUS316 contains 3% M o in addition to similar constituent of SUS304, which is composed of 18% Cr, 8% Ni, and Fe balance. The other oxide films were also prepared by immersing stainless steels in the mixture of 2.5 m o l / d m 3 chromic acid and 5.0 9 J.C. Baltzer A.G. Scientific Publishing Company

2024

K. Nomura et al. / CEMS of oxide layers on steel

m o l / d m 3 sulfuric acid at 70~ 800 MBq of the 5VCo(Rh) source and a gas flow counter [5] were used. Care was taken to prevent samples from electrical charging during the measurement by contacting the substrate to the counter wall. Some data were fit to the sum of Lorentzian.

3. Results and discussion

3.1. OXIDATION IN DRY AIR Oxide films on SUS304: The thickness of oxide films on SUS304 heated for 1 hour increased from 20 nm to 50 nm with the elevation of heating temperature up to 700 ~ C. Iron content in the oxide layer was far less than that in the bulk, but magnetically split peaks were clearly observed in the samples heated below 600 ~ C. The magnetic hyperfine field of iron compounds produced in the oxide films increased with the increase of heating temperature, whereas the intensity of internal magnetic hyperfine field did not always increase in accordance with the temperature. CEM spectrum of a sample heated at 500 ~ was measured at room and dry ice temperatures as shown in fig. 1. Three iron species [isomer shift ( I . S . ) = 0 . 3 7 m m / s , quadrupole splitting (Q.S.)=0.02 m m / s , and hyperfine field (Hm) = 53 T; I.S. = 0.5 r a m / s , Q.S. = 0.2 m m / s , Hin = 30T, and I.S. = 0.2 m m / s and Hin = 31 T] were observed. The species with largest Hin was attributed to a-Fe203 and the remaining two species to a poorly crystalline spinel compound such as (Ni, Fe)O(Cr, Fe)203. Only paramagnetic peaks (I.S. = 0.2 m m / s , Q.S = 0.6 m m / s ) were observed at room temperature in samples heated above 700~ and broad sextet [I.S. = 0 . 0 3 r a m / s , Q.S. = 0 . 8 6 m m / s , and average Hin = 30 T] and doublet [I.S. = 0 . 2 7 m m / s , Q.S. = 0 . 8 6 m m / s ] at dry ice temperature as shown in fig. 2. The doublet observed at room temperature was considered due to superparamagnetism of fine iron oxide beneath the chromium oxide layer. It may also be mixed with chromium, nickel and iron to form (Fe, Cr)203 and NiO (Fe, Cr)203 at the initial oxidation stage, a-Fe203 was produced though the decomposition of the intermediate mixed c o m p o u n d s by a long heating duration. It is considered that the growth of ~-Fe20 ~ in the chromium oxide layer destroyed the smoothened top oxide layers. Oxide films on SUS316: CEM spectra of SUS316 heated at various temperatures for 1 hour are shown in fig. 3. Three iron species, which had hyperfine fields of 28, 34, and 53 T, were found in the sample heated at 4 0 0 ~ These are considered to be due to F e ( I I I ) / F e ( I I ) pairs in octahedral sites and Fe(III) in tetrahedral sites of spinel compounds such as (Fe, Ni)O(Fe, Cr)203, and Fe(III) in columdum structure of o~-Fe203 and (Fe, Cr)203. Schematic changes of oxide films on SUS316 as a function of heating temperature were similar to those of SUS304. However, more iron remained at the outermost surface on SUS316 than on SUS304 heated under 600 ~ Superparamagnetic doublet also was observed

K. Nomura et al. / C E M S of oxide layers on steel

2025

a)

[

[ t I

i

, ]

I

{ t

I11

~

c-

_d

I... ;

tn

cz~ : O ' (._)

b)

.!

I , i

! i

F

.

f

. 9

"

l~

!.I

.

l

.,

',

-I0

i -5

'

10

Ve[oclty

(minis)

Fig. 1. Room and dry ice temperature C E M spectra of oxide films on SUS304 stainless steel heated

for 1 hour at 5 0 0 o C. a) Room temperature, b ) D r y ice temperature.

in the room temperature CEM spectra of the samples heated at the higher temperature than 700 ~ C. There is not an inherent difference of oxide structures between SUS304 and SUS316, although the outermost oxide layer of SUS316 contained more iron species than that of SUS304 as well as m o l y b d e n u m oxide which was distributed in whole oxide layers of SUS316.

3.2. W E T OXIDATION OF STAINLESS STEELS

Stainless steels were treated in a mixed solution of 2.5 m o l / d m 3 C r O 3 and 5 m o l / d m 3 H2SO 4 for several tens of minutes. In the coloring region, chromium

2026

K. Nomura et aL / CEMS of oxide layers on steel

a)

+1

I

I

;!

r!

P

.+_,

rL-J

_d

v

: b)

c

0 'i

.+_,

,I

i

(D

I! +

I ,i

_-;.

; , .,-:

i I~ ,::.'!.. ,. ,..,

.:.~,

"+i" " , _. :.r

_ ,-;z_

.+."f ".w":"

. _ _ ..~_L~,~ ~: _ . ~ . . . .

":.;.~-.

,~'," '. :'i'

I I

~

\,.

~7,_.~

C-~-;~..-.~

"M. .......

'_ . . . . .

-lO

-s

1o

Volocily (mm/s)

Fig. 2. R o o m

and dry ice tcmpcraturc C E M spcctra of oxide films on S U S 3 0 4 stainless steel hcated for I hour at 900 o C.

was a little enriched, iron decreased slightly on the outmost oxide films and nickel existed uniformly in the oxide films. Small amounts of sulfur was detected in the top oxide layer. Only a doublet (I.S. = 0.4 m m / s , Q.S. = 1.0 m m / s at RT) appeared in the CEM spectra measured both at room and dry ice temperatures, This iron product was considered to be iron oxyhydroxide containing chromium and nickel. The intensity of the doublet decreased from 20% to 10% with the increase of the immersion time although the chemical state of iron in the oxide film did not change significantly. The oxide films on SUS316 treated in a chromate solution gave the same CEM spectra as those on SUS304. I.S. and Q.S. of the doublet

K. Nomura et al. / C E M S of oxide layers on steel

2027

600"12

9 _ _ -. 9

9 ~ "C

"

'

'

500"12

~ 0 "C

~"~"%~,

I I I I I I I

~',

I i I" I

,"

I I

I

I i

I 'tt'"~i"~'"l"';

i i i i I i I I I I f l l l l I l l l l l l l

400"C

.

9 9

'I

,.

,

7~'C

:.

I I IG I -4 I I T -2 I I 0 I I 2 I r 4 i i 6 i i 8 i i 10 1 -B I l l l -6 l l l l -A -2 I l l l [ l 4 l l 6 8

l -10

I -8

Velocity (mm/a)

Fig. 3. CEM spectra of oxide films on SUS316 stainless steel heated at 400, 500, 600, 700, 800, and

900 ~C. tended to decrease with a temperature of chromate solution. More iron was included in oxide layers of SUS316 than those of SUS304. Molybdenum was present uniformly in the oxide layers of SUS316, although the intensity of fluorecent Mo X-ray tended to decrease with the increase of immersion time. These oxide layers of our samples treated in a chromate solution were different from oxide layers on stainless steel treated under a boiler condition [6].

4. Conclusion

Oxide films, formed on stainless steels by the thermal treating up to 700 ~ or chemical treatingin a chromate solution, showed various shiny colors. The former oxides gave magnetic hyperfine fields in the CEM spectra and the latter gave paramagnetic peaks. At least two iron oxides were observed on the top oxide films on stainless steels heated under 600~ whereas iron oxides could be produced in high dispersed form beneath the chromium rich oxide layers on stainless steel heated at higher temperatures than 700 ~ C. These iron states in the initial oxide films formed on SUS304 and SUS316 heated and chemically treated were clarified by CEMS measurements.

2028

K. Nomura et al. / C E M S of oxide layers on steel

References

[1] [2] [3] [4] [5] [6] R. Nemoto and K. Horioka, Iron & Steel 71 (1985) S1254. R.O. Ansell, T. Dickinson and A.F. Pover, Corrosion. Sci. 18 (1978) 249. K. Nomura and Y. Ujihira, Anal. Chem. 60 (1988) 2565. I. Stewart and M.J. Tricker, Corrosion. Sci. 26 (1986) 1041. K. Nomura and Y. Ujihira, Hyp. Int. 41 (1988) 681. J. Ensling, J. Fleish, R. Grimm, J. Gruber and P. Giitlich, Corrosion Sci. 18 (1978) 979.

Potrebbero piacerti anche

- Speakout Elementary WBDocumento97 pagineSpeakout Elementary WBPiranha Tourniquet0% (1)

- ReadmeDocumento10 pagineReadmePiranha TourniquetNessuna valutazione finora

- ReadmeDocumento1 paginaReadmeHanif ShaikhNessuna valutazione finora

- The Reaction of H Si O With A Chromium Oxide Surface: A Model For Stainless Steel Surface Modi®cationDocumento7 pagineThe Reaction of H Si O With A Chromium Oxide Surface: A Model For Stainless Steel Surface Modi®cationPiranha TourniquetNessuna valutazione finora

- Reuter, M A 2006Documento79 pagineReuter, M A 2006Piranha TourniquetNessuna valutazione finora

- Equipment H&S Documentation For Talysurf 120L 2015-2016Documento5 pagineEquipment H&S Documentation For Talysurf 120L 2015-2016Piranha TourniquetNessuna valutazione finora

- 1 Ivanova Dimitriev 181 PDFDocumento12 pagine1 Ivanova Dimitriev 181 PDFSercan EkiliNessuna valutazione finora

- Precipitation of Sulfide Inclusions in Steel Structure and Their Effect On Local Corrosion ProcessesDocumento6 paginePrecipitation of Sulfide Inclusions in Steel Structure and Their Effect On Local Corrosion ProcessesPiranha TourniquetNessuna valutazione finora

- Rudrake Amit P 200802 M.sc. (Eng)Documento151 pagineRudrake Amit P 200802 M.sc. (Eng)Piranha TourniquetNessuna valutazione finora

- XPS TableDocumento4 pagineXPS TableEki SetijadiNessuna valutazione finora

- AN52108 E XPSStainlessSteel0411M HDocumento2 pagineAN52108 E XPSStainlessSteel0411M HPiranha TourniquetNessuna valutazione finora

- 96-DETC/DFM-1270: Designing For Material Separation: Lessons From Automotive RecyclingDocumento11 pagine96-DETC/DFM-1270: Designing For Material Separation: Lessons From Automotive RecyclingPiranha TourniquetNessuna valutazione finora

- Science Manuscript Word TemplateDocumento4 pagineScience Manuscript Word TemplatePiranha TourniquetNessuna valutazione finora

- Comparative Analysis of Scrap Car Recycling Management PoliciesDocumento7 pagineComparative Analysis of Scrap Car Recycling Management PoliciesPiranha TourniquetNessuna valutazione finora

- Comparative Analysis of Scrap Car Recycling Management PoliciesDocumento7 pagineComparative Analysis of Scrap Car Recycling Management PoliciesPiranha TourniquetNessuna valutazione finora

- 1 s2.0 S1878029612005452 MainDocumento7 pagine1 s2.0 S1878029612005452 MainPiranha TourniquetNessuna valutazione finora

- Recycling Versus Incineration: An Energy Conservation AnalysisDocumento17 pagineRecycling Versus Incineration: An Energy Conservation AnalysisPiranha TourniquetNessuna valutazione finora

- Resources, Conservation and Recycling Volume 60 Issue None 2012 [Doi 10.1016%2Fj.resconrec.2011.11.012] Vladimir Simic; Branka Dimitrijevic -- Production Planning for Vehicle Recycling Factories in the EU LegislDocumento11 pagineResources, Conservation and Recycling Volume 60 Issue None 2012 [Doi 10.1016%2Fj.resconrec.2011.11.012] Vladimir Simic; Branka Dimitrijevic -- Production Planning for Vehicle Recycling Factories in the EU LegislPiranha TourniquetNessuna valutazione finora

- Moving Up The Waste Hierarchy Car Boot Sales, Reuse Exchange andDocumento11 pagineMoving Up The Waste Hierarchy Car Boot Sales, Reuse Exchange andPiranha TourniquetNessuna valutazione finora

- DWG TrueView DWG Convert Conversion ReportDocumento1 paginaDWG TrueView DWG Convert Conversion ReportCosmin CinciNessuna valutazione finora

- Loto Et AlDocumento12 pagineLoto Et AlPiranha TourniquetNessuna valutazione finora

- Renewable and Sustainable Energy Reviews Volume 15 Issue 5 2011Documento5 pagineRenewable and Sustainable Energy Reviews Volume 15 Issue 5 2011Piranha TourniquetNessuna valutazione finora

- 640 TextschemeDocumento2 pagine640 TextschemeRafael Leonardo Asevedo CoronillaNessuna valutazione finora

- European Response To Issues in Recycling Car PlasticsDocumento14 pagineEuropean Response To Issues in Recycling Car PlasticsPiranha TourniquetNessuna valutazione finora

- HLTV ReadmeDocumento9 pagineHLTV Readmewillquem16100% (4)

- Metal RecyclingDocumento11 pagineMetal RecyclingzerayakobNessuna valutazione finora

- DWG TrueView DWG Convert Conversion ReportDocumento1 paginaDWG TrueView DWG Convert Conversion ReportCosmin CinciNessuna valutazione finora

- PET RecyclingDocumento15 paginePET RecyclingMonica LucasNessuna valutazione finora

- Iowa Automotive Recyclers - 6264 - ScannedDocumento2 pagineIowa Automotive Recyclers - 6264 - ScannedZach EdwardsNessuna valutazione finora

- 1 s2.0 S0921344997000189 MainDocumento11 pagine1 s2.0 S0921344997000189 MainPiranha Tourniquet100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Assessment 1 Form 5Documento12 pagineAssessment 1 Form 5Masitah Abu BakarNessuna valutazione finora

- Expansion JointDocumento10 pagineExpansion JointMohammed BaquarNessuna valutazione finora

- CSV Sect-58Documento7 pagineCSV Sect-58rajendrajhaNessuna valutazione finora

- Ultra Thin WhitetoppingDocumento21 pagineUltra Thin WhitetoppingDHRUV KDMC ProjectsNessuna valutazione finora

- The Chemistry Name GameDocumento18 pagineThe Chemistry Name GameBrandon Baxter100% (1)

- محاظرة 4Documento10 pagineمحاظرة 4iiHaiderNessuna valutazione finora

- Honeywell Sensing Temperature Sensors Line Guide 0 1109480Documento12 pagineHoneywell Sensing Temperature Sensors Line Guide 0 1109480X'mix ĐreamerNessuna valutazione finora

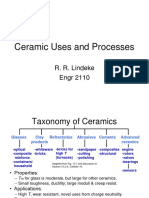

- Ceramic Uses and ProcessesDocumento22 pagineCeramic Uses and ProcessesWang Zheng FengNessuna valutazione finora

- Design and Analysis of Interpretation For Orthopedic Plate With Titanium AlloyDocumento9 pagineDesign and Analysis of Interpretation For Orthopedic Plate With Titanium AlloyIJRASETPublicationsNessuna valutazione finora

- Stain Removal GuideDocumento1 paginaStain Removal Guidekhamid arifNessuna valutazione finora

- Saep 1145Documento20 pagineSaep 1145Amit shah100% (1)

- Invincible Southern Extension Modification EA - ...Documento123 pagineInvincible Southern Extension Modification EA - ...Nicolás Andrés Bastián MonarcaNessuna valutazione finora

- FQP For Chimney 3 MechanicalDocumento4 pagineFQP For Chimney 3 MechanicalKuldeep ChakerwartiNessuna valutazione finora

- Waste Segregation & Disposal Management ProgramDocumento17 pagineWaste Segregation & Disposal Management ProgramHecate TNNessuna valutazione finora

- EDGE Materials Methodology Report v2.2Documento42 pagineEDGE Materials Methodology Report v2.2arqjoramirezNessuna valutazione finora

- Nickel-Cobalt Laterite Deposits on Maniang IslandDocumento7 pagineNickel-Cobalt Laterite Deposits on Maniang IslandAmira SiregarNessuna valutazione finora

- Ultragel II Technical Data SheetDocumento1 paginaUltragel II Technical Data Sheetjess, cNessuna valutazione finora

- Cópia de Column-Beam Bolted Splice Calculation - ASD AISC 9th - 22-Ago-2017Documento19 pagineCópia de Column-Beam Bolted Splice Calculation - ASD AISC 9th - 22-Ago-2017cludioNessuna valutazione finora

- Summer Internship Project On Durian Laminates PDFDocumento82 pagineSummer Internship Project On Durian Laminates PDFShubham MittalNessuna valutazione finora

- A Pseudo 3D Analysis of The Indentation Rolling Resistance ProblemDocumento12 pagineA Pseudo 3D Analysis of The Indentation Rolling Resistance ProblemPetros IosifidisNessuna valutazione finora

- 440 3R-12Table1 3Documento1 pagina440 3R-12Table1 316562306Nessuna valutazione finora

- Reaction of TryptophanDocumento2 pagineReaction of TryptophansasmithaNessuna valutazione finora

- Astm d3895Documento8 pagineAstm d3895Retno Witantri100% (1)

- Chemical Equilibrium: Problem Set: Chapter 16 Questions 25, 27, 33, 35, 43, 71Documento36 pagineChemical Equilibrium: Problem Set: Chapter 16 Questions 25, 27, 33, 35, 43, 71abdooufNessuna valutazione finora

- TRUEDocumento50 pagineTRUECLARISSA TAGUBANessuna valutazione finora

- 11 Chemistry Notes - The S-Block ElementsDocumento21 pagine11 Chemistry Notes - The S-Block ElementsAishwary yadav100% (1)

- Brocure DuPont ELVALOYDocumento3 pagineBrocure DuPont ELVALOYdonni canraNessuna valutazione finora

- Extraction and Purification of Bioactive CompoundsDocumento22 pagineExtraction and Purification of Bioactive CompoundsamirahNessuna valutazione finora

- Types of CrystalsDocumento12 pagineTypes of CrystalsSpace MonkeyNessuna valutazione finora

- DVC 99wierDocumento2 pagineDVC 99wierMohamed ElmakkyNessuna valutazione finora

![Resources, Conservation and Recycling Volume 60 Issue None 2012 [Doi 10.1016%2Fj.resconrec.2011.11.012] Vladimir Simic; Branka Dimitrijevic -- Production Planning for Vehicle Recycling Factories in the EU Legisl](https://imgv2-2-f.scribdassets.com/img/document/228566427/149x198/46129b6db0/1429166347?v=1)