Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

USAFA TR 2005 04 Z Panel Compression

Caricato da

sovsepCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

USAFA TR 2005 04 Z Panel Compression

Caricato da

sovsepCopyright:

Formati disponibili

USAFA-TR-2005-4

Compression Buckling of Z-Stiened Aluminum

Panels, with and without Corrosion Grindouts

James M. Greer, Jr., Daniel W. Hill, and Scott A. Fawaz

Center for Aircraft Structural Life Extension

U.S. Air Force Academy CO 80840

(719) 333-3618, DSN 333-3618

Ron Logan

Northrop Grumman Corporation Integrated Systems

AGS & BMS, Melbourne FL

(321) 951-6803

Center for Aircraft Structural Life Extension

Department of Engineering Mechanics

United States Air Force Academy

Colorado Springs, Colorado 80840

January 2005

APPROVED FOR PUBLIC RELEASE; DISTRIBUTION UNLIMITED

DEAN OF THE FACULTY

UNITED STATES AIR FORCE ACADEMY

COLORADO 80840

USAFA-TR-2005-4

USAFA-TR-2005-4

This article, Compression Buckling of Z-Stiened Aluminum Panels, with and with-

out Corrosion Grindouts, is presented as a competent treatment of the subject, wor-

thy of publication. The United States Air Force Academy vouches for the quality of

the research, without necessarily endorsing the opinions and conclusions of the authors.

Therefore, the views expressed in this article are those of the authors and do not reect

the ocial policy or position of the United States Air Force, Department of Defense, or

the US Government.

This report has been cleared for open publication and public release by the appropriate

Oce of Information in accordance with AFI 61-202 and USAFA FOI 190-1. This report

may have unlimited distribution.

i

USAFA-TR-2005-4

EXECUTIVE SUMMARY

This eort is funded by the Aging Aircraft Squadron of the Aeronautical Enterprise

Program Oce (ASC/AAA, Col P.J. Clark). The prime contractor for the Air Vehicle

Health Management program, of which this eort is a part, is S&K Technologies, Inc.,

Dayton, OH (Mr. Kevin Boyd).

Twenty-seven Z-stiened panels, intended to simulate upper wing skin panels of the

Boeing 707, were tested to failure in compression to determine buckling strength. Pristine

panels and panels with machined grindouts (with various depths up to 62.6% of the

panel skin thickness) were tested to failure. Nine panels each of three congurations

were fabricated for testing. The results showed a degradation of buckling strength with

grindout depth that could be modeled with a modied Johnson-Euler method and a

modied Gerards method for long and short panels respectively. The panels with the

lower slenderness ratio (short panels) were degraded more by a given grindout depth than

were their more slender counterparts. However, it was found that span-wise grindouts

along the center stienereven deep onesdo not have a severe eect on strength.

Even at over 60% grindout depth, the worst degradation was less than a 12% reduction

in strength.

A small number of panels were tested with deep chord-wise grindouts. These tests

showed that the strength of the panel was dramatically reduced by these grindouts, which

were transverse to the loading direction.

ii

USAFA-TR-2005-4

Table of Contents

Executive Summary ii

List of Figures iv

List of Tables v

List of Symbols vi

1 Introduction 1

2 Background 1

2.1 The Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 Approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.3 Previous Experimental Work . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Specimen Fabrication and Instrumentation 5

3.1 Fabrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Experimental Results 9

4.1 Test Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.1 Span-Wise Grindouts . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.2 Chord-Wise Grindouts . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Errors in Experimental Values . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Modeling Panel Behavior 14

5.1 Long Panels (C1 and C2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Short Panels (C3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Modeling Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Conclusions 18

Acknowledgements 19

Appendix: Sample Calculations A1

A.1 Johnson-Euler Method A1

A.1.1 Damaged Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3

A.2 Method of Gerard A3

A.2.1 Damaged Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A4

iii

USAFA-TR-2005-4

List of Figures

1 Approximate gage locations of Hickman and Dow. . . . . . . . . . . . . . 2

2 Gage locations of Friedman. . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Gage locations of Butler, et al. . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Cross section of stiened panels. . . . . . . . . . . . . . . . . . . . . . . . 5

5 Step-tapered grindout geometry. . . . . . . . . . . . . . . . . . . . . . . . 6

6 Typical linear buckling analysis of panel. . . . . . . . . . . . . . . . . . . 7

7 Initial and nal strain gage locations. . . . . . . . . . . . . . . . . . . . . 8

8 Typical long panel behavior of a gage pair. . . . . . . . . . . . . . . . . . 8

9 Set up for panel buckling experiments. . . . . . . . . . . . . . . . . . . . 9

10 Typical damage progression with load. . . . . . . . . . . . . . . . . . . . 10

11 Panel strength as a function of grindout depth for 3 congurations with

span-wise grindouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12 Comparison of C1 panel results with modied Johnson-Euler method. . . 15

13 Comparison of C2 panel results with modied Johnson-Euler method. . . 15

14 Comparison of C3 panel results with modied method of Gerard. Dotted

line indicates Johnson-Euler model for this panel. . . . . . . . . . . . . . 17

iv

USAFA-TR-2005-4

List of Tables

1 Properties of panel materials. . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Panel specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Buckling test results for three panel congurations. . . . . . . . . . . . . 11

4 Buckling test results for chord-wise grindout panels. . . . . . . . . . . . . 13

A.1 Calculation of stiener crippling load using the Johnson-Euler method. . A1

A.2 Calculation of segment section properties. . . . . . . . . . . . . . . . . . A2

A.3 Calculation of new segment section properties. . . . . . . . . . . . . . . . A3

v

USAFA-TR-2005-4

List of Symbols

A

e

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . eective skin area

A

s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . skin segment cross-sectional area

A

tot

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . section cross-sectional area, A

s

+A

w

A

w

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single stiener cross-sectional area

b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . stiener spacing

C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . panel conguration #1

C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . panel conguration #2

C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . panel conguration #3

c . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . end-xity condition

d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . crosshead displacement

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Youngs modulus

E

c

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Youngs modulus (compressive)

H

w

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . stiener height

I

ox

. . . . . . . . . . . . . . . . . . . . . . . . stiener section second area moment about its own centroid

K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . slenderness ratio

L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . original panel length

L

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . equivalent length based on end-xity condition

m. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gerard equation parameter

P

cc

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . stiener crippling load

P

co

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . segment Johnson-Euler allowable load

P

max

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . max recorded load during test

P

s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . load at skin buckling

t

s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . skin thickness

t

w

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . stiener thickness

t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . equivalent skin thickness, A

tot

/b

W

e

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . eective skin width

W

fi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . inboard ange width

W

fo

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . outboard ange width

Y

c

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . section centroid

y . . . . . . . . . . . . . . . . . . . . . . . . distance referenced from outboard surface of outboard ange

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gerard equation parameter

g

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . depth of grindout as pct of skin thickness

L/L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . change in length per unit length at P

max

P

max

. . . . . . . . . . . . . . . . . . . . . . . . . change in max load carrying capability due to damage

i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . axial strain in stiener i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . radius of gyration

cc

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . stiener crippling stress

co

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . segment Johnson-Euler allowable stress

cy

s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . compressive yield strength of the skin material

cy

w

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . compressive yield strength of the stiener material

U

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . material tensile ultimate strength

Y

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . material tensile yield strength

vi

USAFA-TR-2005-4

1 Introduction

The objective of this investigation was to determine the eect of corrosion grindouts on

the compressive strength of B-707 upper wing skin panels. Three representative geome-

tries were considered. One conguration represented the minimum strength wing panel

(40 ksi, Conguration #1, or C1), and one represented the maximum strength wing panel

(64 ksi, Conguration #3, or C3). A third conguration was also tested. These panels,

denoted Conguration #2 (C2), were mistakenly manufactured with thicker stieners,

but were tested nonetheless to provide additional data for this study. Two pristine pan-

els in each conguration were tested, and damage was introduced into each of the other

panels in the form of uniform spanwise grindouts. These grindouts ranged from 35% to

63% of the panel skin thickness, and were meant to simulate severe in-service corrosion

grindouts.

2 Background

2.1 The Problem

Current guidance for corrosion repairs to USAF aircraft includes the requirement to

remove the visible products of corrosion. Removal of these products is often accomplished

by grinding the surface of the material until pristine material is exposed. If the depth of

the grindout exceeds a certain percentage of the thickness of the material, the material

must be replaced. The limits specied in the Technical Orders for a particular aircraft are

based on engineering judgement and analysis. The current eort attempts to quantify,

through experiment, the degradation in buckling strength caused by a uniform grindout.

2.2 Approach

In this study, grindouts of known depth were made along the length of a panel stiener,

and the panel was tested to failure. Panels with no grindouts were are also tested

for reference. The panels were manufactured by Valco Manufacturing, Inc. of Duncan,

Oklahoma. Panels were received with four of ve stieners attached (riveted) to the skin,

with the center stiener drilled, but not attached. These center stieners were attached

after surface grindouts were machined into the specimen. The few panels meant for

baseline testing (pristine panels) were received with all ve stieners attached.

2.3 Previous Experimental Work

Signicant relevant work has been done in the area of buckling of rib-stiened panels as

has some analytical work on corroded plates by Lakhote, Pandey, and Sherbourne [1],

and by Roorda, Srivastava, Maslouhi, and Sherbourne [2]. However, none of this work

has involved the sort of simulated grindout damage applied in the current eort. Still, it

should be mentioned that Lakhote, et al. [1], in their analytical work on at, unstiened

panels with deep, centrally-located square grindouts, found that a correct assessment of

the pre-buckling redistribution of stresses is required to avoid seriously overestimating the

reduction in buckling strength. As will be shown in the current work, even deep grindouts

1

USAFA-TR-2005-4

Figure 1: Approximate gage locations of Hickman and Dow [3], [4] based on text of

references and two gures. (Six-stiener panel shown; fastener pitch/size not to scale.)

caused relatively small reductions in buckling strength, and this stress redistribution in

damaged panels could be an important consideration in any future analytical work.

This section describes previous relevant work with a focus on the instrumentation

and methods used to determine the initial panel buckling load. This skin buckling load

is often much less than the maximum load a stiened panel can ultimately carry.

Hickman and Dow [3], [4] of NACA instrumented their six-stiener panels with ...four

6

1

2

-inch resistance-type wire strain gages mounted on the quarter points along the length

of the second and fth stieners. (They also performed tests on four- and ve-stiener

panels.) These gages, which are not described further in their reports, were used to

detect shortening per unit length of the panels. Although not described in the text,

Figure 3 of Reference [3] and Figure 2 of Reference [4] both appear to show strain gage

instrumentation on the panel skin (see Figure 1). These were likely used for detecting

what the authors call the local buckling load using the strain-reversal method of Hu,

Lundquist, and Batdorf [5]. In this method, local buckling is said to have occurred

when a plot of the strains near the crest of a buckle rst shows a decreasing strain with

increasing load. (How the crest location was predicted or determined is not described.)

These gages (if that is, in fact, what they are) are located on the stiener side of the skin

between stieners and near, but not always at, the mid-length line of the panels.

2

USAFA-TR-2005-4

Figure 2: Gage locations from Figure 2 of Reference [7]. White boxes indicate gages

mounted on outer-most surface of Z-stiener. Black boxes indicate gages mounted on

at side of panel. (2) indicates two gages in this location, one on each side of the skin.

Fastener pitch/size not to scale.

Rothwell [6] measured the test panels for imperfections prior to testing, but collected

no data other than maximum load carried during the displacement-controlled tests.

Friedman, et al. [7] took strain and displacement measurements on their four-stiener,

Z-stiened aluminum panels. Two strain gages were placed opposite each other on each

side of the skin half-way between rivet rows and centered along the length. A strain gage

was also placed on the top (outer-most) surface of each Z-stiener, and these were also

centered along the length (aligned with the skin gages). An additional gage was placed

on the non-stiener side of the skin, centered along the length, and directly underneath

the vertical part of each Z-stiener. Finally, two more gages were placed opposite each

other on each side of the skin half-way between the central row of gages and the panel

end

1

, centered on the width of the panel. Therefore, a total of 16 gages were used to

instrument a four-stiener panel (see Figure 2).

In their book, Singer, Arbocz, and Weller [8] suggest a number of methods to deter-

mine critical (buckling) load in plates under compression, including the aforementioned

1

Actually, these two gages were placed half-way between the central row of gages and the beginning

of the potting for the panel end.

3

USAFA-TR-2005-4

Figure 3: Gage locations from Figures 2 and 3 of Reference [9]. Stiener gages are located

on the vertical ange of the L-stieners. Fastener pitch/size not to scale.

technique of Hu, et al. [5]. They also describe a method of detecting buckling by observing

the inection in the curve of the algebraic compressive strain average,

A

=

1

2

(

1

+

2

),

versus axial load, where

1

and

2

are strains at the same location on opposite sides of

the skin. Again, these strains are taken at a crest of a buckle.

Butler, et al. [9] instrumented their panels at mid-length, with one gage on each sti-

ener and one gage centered on the stiener side of the skin between stieners. Additional

gages were placed to detect skin buckling (see Figure 3). The stieners were L-shaped,

and the stiener gages were placed 10 mm and 3 mm from the edge of the stiener for

the three-stiener and four-stiener panels, respectively. The gages served two purposes:

(1) comparison with the optimization code used in their study and (2) monitoring the on-

set and advance of buckling. They found the strain gage information to be more accurate

than load versus end displacement plots.

Aalberg, et al. [10] did not use strain gages in their tests, but chose instead to monitor

load versus displacement. They also measured out-of-plane displacement continuously

throughout their displacement-controlled tests (displacement was approximately 1 mm

per minute).

After this review of the relevant literature, it was decided to instrument the panels

as described in Section 3.2.

4

USAFA-TR-2005-4

3 Specimen Fabrication and Instrumentation

3.1 Fabrication

Panels were manufactured by Valco Manufacturing, Inc. of Duncan, Oklahoma. Twenty-

seven panels were manufactured in three congurations. All panels consisted of a skin

sheet with ve evenly spaced Z-stieners. Panel congurations are shown in Figure 4.

The skin was of 7075-T6 aluminum sheet material. The stieners were formed

(bent) from 7075-0-BARE coil stock, then solution heat treated and aged per the SAE

AMS2770G specication to the T62 temper before attaching them to the skin. The bend

radii for the stieners was 4.3 mm (0.17 in). The material properties for the aluminum

used to fabricate the panels are listed in Table 1. In addition to certications provided

by the aluminum manufacturers, Valco conducted in-house conductivity and hardness

testing to conrm material properties.

Table 1: Properties of panel materials.

E

U

Y

Component GPa (Msi) MPa (ksi) MPa (ksi)

Skin (7075-T6) 71.7 (10.4) 582.6583.3 (84.584.6) 515.8517.1 (74.875.0)

Stiener (7075-T62) 71.7 (10.4) 568.8 (82.5) 508.9509.5 (73.873.9)

Aluminum MS20470AD4-5 rivets, 2017 alloy, 1/8 in diameter, were used at 1/2 in

pitch to attach the stieners. The close rivet spacing essentially eliminated inter-rivet

buckling as a concern.

The panels are approximately half-scale versions of the actual aircraft wing skin. They

were scaled down to accommodate the capacity of the load frames used in the testing.

Figure 4: Cross section of stiened panels. Measurements are in Table 2.

5

USAFA-TR-2005-4

Table 2: Panel specications for Figure 4. Dimensions are mm (in).

Cong t

s

t

w

W

fi

W

fo

H

w

b L

1 2.03 (0.080) 1.78 (0.070) 16.3 (0.64) 16.3 (0.64) 37.1 (1.46) 106 (4.19) 531 (20.9)

2 2.03 (0.080) 2.03 (0.080) 16.3 (0.64) 16.3 (0.64) 37.1 (1.46) 106 (4.19) 531 (20.9)

3 2.03 (0.080) 2.03 (0.080) 15.2 (0.60) 15.2 (0.60) 28.2 (1.11) 54.4 (2.14) 279 (11.0)

Panels were received assembled, except for those panels that were to receive grindouts.

For these panels, the manufacturer drilled the skin and stieners with rivet holes, but did

not attach the stieners. The grindouts were accomplished on the non-stiener side in the

form of a channel along the center rivet row. The center stiener was then attached with

the rivets. The grindouts and attachments were made using a at end mill. The target

grindout channel depths were of 30% and 50% skin thickness. The grindout edges were

step-tapered on a slope of 25:1 (per Northrop-Grumman criterion) as shown in Figure 5.

The actual depths of the grindouts are presented with the results in Section 4.

Figure 5: Step-tapered grindout geometry for simulated corrosion grindout. The grindout

runs the entire length of the panel.

3.2 Instrumentation

Instrumentation for initial tests involved 13 strain gages: one on each of the ve stien-

ers, four between stieners, and four located in pairs at predicted skin buckling locations.

After gaining some condence in the loading scheme, the number of gages was reduced

to ve, applied to the panels as shown in Figure 7. For the short panels, skin buck-

ling was more dicult to detect, so one additional pair of skin gages was used. The

micromeasurements CEA-13-250UN-120 gages were used in this eort.

The three stiener gages were used to determine whether the loading on the panel

was being evenly applied. Agreement of strains within 10% was taken as the criterion:

max {|

1

2

|, |

1

3

|, |

2

3

|}

(

1

+

2

+

3

) /3

100 10 (1)

Typically, this check was performed at low load levels (< 25% of the failure load), then

minor adjustments were made to the xed crosshead when necessary. Minor adjustments

were made for almost every panel test.

6

USAFA-TR-2005-4

Figure 6: Typical linear buckling analysis of panel. Panel displacements (greatly exag-

gerated) are indicated by the deformed geometry and the colors.

The pair of gages on opposite sides of the skin was used to detect skin buckling. They

were located through the use of a linear nite element buckling analysis, which indicated

the locations of crests in the deformed geometry during skin buckling. A typical analysis

result is shown in Figure 6.

The onset of skin buckling as measured by these gages was easily noticed in C1 and

C2 (long) panels (see Figure 8 for typical behavior). The skin buckling load was recorded

using the load reversal criterion of Hu, et al. [5]. On the short (C3) panels, the preferred

skin gage location fell into the grindout taper area for some grindout cases. For these

panels, the skin gage on the at side of the panel had to be moved 1/4 in to keep it out

of the grindout. Skin buckling occurred in these panels near the panel failure load, and

was dicult to detect visually. Also, the strain gages used to detect skin buckling would,

in some instances, give ambiguous readings due to the very high strains in the skin at

these high loads.

7

USAFA-TR-2005-4

Figure 7: Initial (a) and nal (b) Strain gage locations for buckling tests. Where two

gage numbers are indicated, one gage is located on each side of the skin. The suxes

B and C on some gages indicate alternate locations tried at various stages of the

program.

Figure 8: Typical long panel (C1 and C2) behavior of a gage pair located on opposite

sides of the skin at the same location. These were used to detect skin buckling. Gages 1

and 2 are located on opposite sides of the skin at the same location.

8

USAFA-TR-2005-4

4 Experimental Results

4.1 Test Set-Up

The buckling tests were performed on a Satec model 120HVL electromechanical test

machine having a capacity of 534 kN (120 kip). The load transducer was calibrated to

ASTM E4-03 [11] prior to the start of testing. Data were recorded by the Satec computer

controlling the machine (load and displacement) and by a LabVIEW

2

system recording

the strain gage output. The LabVIEW system also recorded the load and displacement

by measuring the voltages on two channels from the Satec machine. The test set-up is

shown in Figure 9.

Figure 9: Set up for panel buckling experiments.

4.2 Test Procedure

Panels were loaded in the stiener direction as shown in Figure 9. The upper (xed)

crosshead had a 7.6 cm by 15.2 cm (3 in by 6 in) hole in it, so a top plate was fabricated

from 12.7 mm- (0.500 in)-thick steel and bolted to the crosshead to cover the hole. The

plate surface was milled at to a tolerance of 0.025 mm (0.001 in). The bottom

(moving) crosshead surface was at and continuous. No potting or other modications

2

LabVIEW is a registered trademark of National Instruments Corporation.

9

USAFA-TR-2005-4

to the panel ends (beyond milling at) were performed. The panel ends rested directly

on the at metal supports (as in References [3] and [4]).

The tests were run under displacement-controlled conditions at a commanded rate

of 3.0 mm/min (0.12 in/min) to 10 kN, then 1.5 mm/min (0.06 in/min) to failure for

C1 and C2 panels. For C3 panels, the loading rates were 1.5 mm/min (0.06 in/min)

and 0.7 mm/min (0.028 in/min), respectively. These strain-rate based rates were chosen

based on guidance in ASTM E989a [12]. Loading of the specimen was occasionally

paused to inspect the specimen under load.

4.3 Test Results

The results are shown in Table 3 and Figure 11. The typical damage progression is shown

in Figure 10. In two tests, the skin buckling strain gages were mislocated on the panel,

so no skin buckling load is available.

Figure 10: Typical damage progression with load: (a) P = 0, (b) P > P

s

, (c) post-test.

Foil in photo (b) is a shim used to equalize load between stieners. These are C1/C2

panels.

For most tests, agreement of results between similar congurations with similar dam-

age was excellent. Of 25 tests, only 2 were rejected because of poor results. Panel 4

was rejected because is was realized after testing that it was mounted improperly in the

test machine (it was not chord-wise at at the beginning of the test). Panel 25 gave

an anomalous result, and subsequent material tests indicated it had inferior material

properties compared to other panels.

The panel shortening was calculated as

L/L|

Pmax

=

d|

P=P

max

d|

P=2.5 kip

L

(2)

By using 11.1 kN (2.5 kip) as the lower displacement bound, the initial settling

response (which varies signicantly from panel to panel) is removed.

10

USAFA-TR-2005-4

Table 3: Buckling test results for three panel congurations. All grindouts are span-wise.

Panel Cong

g

P

s

P

max

L/L|

P

max

Strength Chg

a

No. No. Pct kN (kip) kN (kip) strain Pct

1 1 0% 154 (35) 405.7 (91.21) 7120

2 1 0% 166 (37) 412.5 (92.73) 7700

4

b

1 37.4% 139 (31) 354.9 (79.80) 8273

5 1 34.8% 154 (35) 395.4 (88.90) 6885 3%

7 1 56.1% 118 (27) 376.7 (84.70) 7062 8%

8 1 57.4% 119 (27) 382.4 (85.97) 7316 7%

9 1 34.8% 150

c

(34) 396.6 (89.16) 7234 3%

10 2 Fixture Failure

11 2 0% 184 (41) 445.1 (100.07) 8180

12 2 0% 167 (38) 444.7 (99.97) 8270

13 2 36.1% 144 (32) 420.7 (94.58) 7750 5%

14 2 41.9% 148 (33) 425.2 (95.59) 7870 4%

15 2 36.4% NR

d

437.6 (98.38) 7860 2%

16 2 40.6% 163 (37) 432.7 (97.28) 7710 3%

17 2 52.9% NR 423.4 (95.20) 7820 5%

18 2 Fixture Failure

19 3 0% 388 (87) 422.2 (94.93) 11,030

20 3 0% 409 (92) 425.8 (95.73) 10,430

22 3 41.3% 326 (73) 384.9 (86.53) 10,210 9%

23 3 41.3% 302 (68) 383.8 (86.29) 9640 9%

25

b,e

3 56.1% 245 (55) 358.2 (80.52) 9782 16%

26 3 62.6% 251 (56) 375.7 (84.47) 10,680 11%

27 3 60.0% 234 (53) 370.1 (83.20) 10,227 13%

a

Compared to average of pristine results

b

Result discarded. See text.

c

Approximate

d

Not Recorded (see text)

e

This panel had an unusual surface nish. Hardness testing revealed a lower strength (about 10%) than

other panels.

11

USAFA-TR-2005-4

Figure 11: Panel strength as a function of grindout depth for 3 congurations with

span-wise grindouts.

4.3.1 Span-Wise Grindouts

Pristine C1, C2, and C3 panels were tested to establish baseline strength values. Pan-

els with grindouts of various depths were then tested to determine the degradation in

strength due to these grindouts. It must be remembered that this result assumes these

important conditions: (1) the grindout runs parallel to and directly over the center sti-

ener and is symmetric with respect to the fastener row, (2) the loading is uniaxial and

parallel to the stiener, (3) the stiener is securely reattached to the panel after the

grindout is applied (i.e., no loose rivets), and (4) the stiener is undamaged.

The results indicate a slight degradation in buckling strength due to the grindouts,

with the C3 panels being the most aected.

4.3.2 Chord-Wise Grindouts

A small number of extra panels were available for testing, and these were used to make

an assessment of chord-wise grindouts on panel strength.

The chord-wise grindouts were much more damaging to the panels than were the

span-wise. Three reasons for this are (1) the span-wise grindout aects the integrity of

only one stiener bay, while the chord-wise grindout aects all stiener bays, (2) the

chord-wise grindout admits another failure mode, namely inter-rivet buckling, which can

12

USAFA-TR-2005-4

fail the rivets locally leading to zero eective skin width in that area, and (3) the chord-

wise damage has the eect of creating a hinge that leads to low-load out-of-plane skin

buckling along the grindout, which helps destabilize the stieners.

The results of the tests on panels with chord-wise grindouts are shown in Table 4.

These panels with grindouts exhibited skin buckling at very low loading, so no skin

buckling loads are shown for these panels.

Table 4: Buckling test results for chord-wise grindout panels.

Panel Cong

g

P

s

P

max

L/L|

Pmax

No. No. Pct kN (kip) kN (kip) strain

1 1 0% 154 (35) 405.7 (91.21) 7120

2 1 0% 166 (37) 412.5 (92.73) 7700

3 1 44.7% NR

a

202.5 (44.53) 4813

6 1 48.6% NR 209.8 (47.18) 4139

19 3 0% 388 (87) 422.2 (94.93) 11,030

20 3 0% 409 (92) 425.8 (95.73) 10,430

21 3 70% NR 259.1 (58.26) 8427

24 3 70% NR 241.4 (54.28) 9109

a

Not Recorded (see text)

4.4 Errors in Experimental Values

Sources of error in these experiments include load cell accuracy, strain gage accuracy,

evenness of panel loading, grindout channel accuracy, and panel imperfections (other

than grindouts). In addition, the detection of skin buckling is somewhat inexact. Because

of the data collection rate, the specimen loading rate, the uncertainly in gage location,

and the somewhat arbitrary choice of the instant of buckling (change in sign of strain

slope) the skin buckling load should be considered to be no better than about 5 kN

(1 kip) in accuracy (this represents approximately 1% of the buckling load).

Load cell accuracy aects P

s

and P

max

data values. During calibration, an accuracy

of 0.5% for both accuracy and repeatability was noted. However, this accuracy includes

a coverage factor that provides a condence level of 95%. During the actual calibration

runs, the maximum absolute error seen was 21.547 lb at a load of 84 000 lb, or 0.0026%.

Strain gages of the type used have a typical accuracy of 5%. This would aect

load leveling prior to each test and the measurement of L/L|

Pmax

at the conclusion of

each test. As was mentioned in Section 3.2, strain variation between stieners was used

as a measure of load evenness. This was typically done at or below 100 kip at strains

near 1000 . The strain gage error at these levels, at worst case, would widen the load

leveling range from 10% to 15%. Quantifying the eect of the load unevenness is

problematic, but the very high repeatability in pristine panel results indicates that the

load leveling was successful.

Even with the use of jigs specially made for the purpose, achieving the desired grindout

depth to a close tolerance was dicult. However, based on measurements taken at the

grindout ends, uniformity of the grindout along its length appeared to be good (i.e.,

13

USAFA-TR-2005-4

within typical machine shop tolerance of 0.003 in). Future plans include using an NDI

technique to better assess the uniformity of the grindout along its length.

The panel specications provided to Valco included requirements for sheet atness

( 3/16 in), lateral bow ( 1/16 in), squareness ( 3/32 in), thickness variation

(0.0025 in), width and length (1/16 in), and perpendicularity of stieners to the

sheet surface (1

). Panels were spot checked for compliance with these specications

and were found to be of very high quality and consistency (it was clear that they were

manufactured on computer-controlled equipment). Furthermore, since parallel panel ends

were of paramount importance, the panels were milled (in house) on the ends to ensure

they were parallel prior to testing (0.003 in vs. the 1/16 in specied). Panel imperfections

were, therefore, probably a small contributor to experimental errors.

To summarize, the errors in load measurement were extremely small, and so the

ultimate strength of each panel is very likely within 20 lb of that indicated in the results.

Because these results are reported based on the actual measured grindout depths, the

fact that the originally planned grindout depths of 30% and 50% of the skin thickness

were not achieved introduces no error in the results. Since the evenness of loading (as

determined by strain readings) could be o by as much as 15%, this becomes the most

signicant potential source of error in the results. However, the magnitude of this error

is impossible to quantify without signicant analytical or experimental work, and the

repeatability of the process and the results indicates that this error is likely small as well.

5 Modeling Panel Behavior

The ultimate strength of the pristine (no grindout) panels was calculated using stan-

dard analysis techniques. The Johnson-Euler method was used for C1 and C2 (long)

panels, and the method of Gerard was used for C3 (short) panels. The Johnson-Euler

method requires an end-xity condition to be assumed for the calculation of a slender-

ness ratio. For the panels in this study, an end-xity coecient of 3.75 was used. For

at-ended specimens tested between rigid at anvils, this value has been shown to be

appropriate [13].

5.1 Long Panels (C1 and C2)

The Johnson-Euler method was used for the longer (C1 and C2) panels (for a description

of this method, see, e.g., Ref [14]). This method calculates an allowable column stress,

co

, as a function of the column cross sectional crippling strength,

cc

, as

co

=

cc

_

1

cc

(L

/)

2

4

2

E

_

(3)

For C1 and C2 panels, the J-E strength is calculated to be 406.5 kN (91.4 kip) and

456.8 kN (102.7 kip), respectively. The actual strengths were found to be 409.2 kN

(92.0 kip) and 444.8 kN (100.0 kip) for respective errors of +0.7% and 2.6%.

For panels with grindouts, the analysis was identical, except that the skin thickness

for the entire center section was reduced to the minimum skin thickness in the bottom

of the grind-out. See Appendix 6 for some worked examples.

14

USAFA-TR-2005-4

Comparisons of these analyses to the experimental data are in Figures 12 and 13.

Figure 12: Comparison of C1 panel results with modied Johnson-Euler method.

Figure 13: Comparison of C2 panel results with modied Johnson-Euler method.

15

USAFA-TR-2005-4

5.2 Short Panels (C3)

The method of Gerard was used for the short (C3) panels (for a description of this

method, see, e.g., Ref [15] or Ref [16]). This method calculates the stiener yielding

stress,

cy

, as

cy

=

[

cys

+

cyw

(

t/t

s

1)]

t/t

s

(4)

and the section failure stress as

f

=

cy

_

g t

s

t

w

A

tot

E

cy

_

m

(5)

and therefore the section failure load as

P

f

=

f

A

tot

(6)

For the short panel, this leads to a failure strength of 478.2 kN (107.5 kip). The actual

failure strength of this conguration was 424.0 kN (95.32 kip), so the error in this method

for the pristine panel is +12.8%

3

.

For C3 panels with grindouts, the Gerard method was used again, except (as in the

long panel case) that the skin thickness for the entire center section was reduced to the

minimum skin thickness in the bottom of the grind-out. See Appendix 6 for some worked

examples.

A comparison of this analysis to the experimental data is in Figure 14.

3

The J-E method calculates a pristine strength of 427.9 kN (96.2 kip), an error of +0.9%, but the

J-E method does a very poor job modeling behavior of damaged short panels (see Section 5.3).

16

USAFA-TR-2005-4

Figure 14: Comparison of C3 panel results with modied method of Gerard. Dotted line

indicates Johnson-Euler model for this panel.

5.3 Modeling Summary

The slenderness ratios for panel congurations 1, 2, and 3 are 22, 22, and 17, respec-

tively. The behavior of the damaged longer panels (C1 and C2) is well described by

Johnson-Euler theory, while the method of Gerard does a much better job describing

the shorter panels behavior. Gerards method for stiened panels is a modied version

of his method for predicting the crippling stress of plates and is applicable when the

interfastener buckling and wrinkling stresses are greater than the crippling stress [15, p.

488] (as is the case for all the panel congurations with span-wise grindouts tested in

this study). Gerards method is for panels that buckle in the inelastic range. The C3

panels exhibit considerably more plastic deformation than do either the C1 or C2 panels

(see column 6 in Table 3).

This limited test program did not attempt to nd where the crossover point is, that

is, to nd the slenderness ratio at which one theory describes the behavior better than

the other.

No attempt was made to model the behavior of panels with chord-wise grindouts.

17

USAFA-TR-2005-4

6 Conclusions

The test results indicate that uniform grindouts along the stiener length, provided the

middle stiener (only) is aected, and the fastener is reattached snugly with new rivets,

caused only minor degradation in panel buckling strength. (Assessing degradation to

fatigue properties is the topic of ongoing work, but is not addressed here.) Moreover, by

modifying the analysis methods of Johnson, Euler, and Gerard, curves can be generated

that depict strength degradation as a function of grindout depth for these panels. The

shorter (C3) panels experienced signicantly more plasticity prior to collapse than did

the longer (C1 and C2 panels). It is for this reason that the Gerard method was more

appropriate, and better at modeling, the C3 panels. These curves give the structural

engineer a new tool for assessing the degradation in strength to B-707 upper wing skin

panels due to grindouts.

18

USAFA-TR-2005-4

Acknowledgements

The authors would like to thank Lt Col P. J. Clark of ASC/AAA and Mr. Kevin Boyd

of S&K Technologies, Inc. for their sponsorship of this eort. We also thank Mr. Stephan

Verhoeven, Mr. Cornelis Guijt (Engineers), Mr. Chad Moon, and Mr. Jonathan Ingram

(technicians) for their invaluable assistance on this project. Finally, we are indebted

to Mr. John Lobdell and MSgt Michael Nero (Department of Civil and Environmental

Engineering) for the generous use of their facilities for these tests.

19

USAFA-TR-2005-4

References

[1] R. Lakhote, M. Pandy, and A. Sherbourne, Buckling Behavior of Corroded Plates,

in Proceedings of the Fourteenth ASCE Engineering Mechanics Conference, (Austin,

TX), May 2000.

[2] J. Roorda, N. Srivastava, A. Maslouhi, and A. Sherbourne, Residual Strength of

Ship Structures with Corrosion-Induced Damage, Technical Report, Defense Re-

search Establishment Atlantic, Halifax, NS, Mar. 1996.

[3] W. A. Hickman and N. F. Dow, Data on the Compressive Strength of 75S-T6

Aluminum-Alloy Flat Panels with Longitudinal Extruded Z-Section Stieners,

Technical Note 1829, National Advisory Committee for Aeronautics, Langley Air

Force Base, VA, Mar. 1949.

[4] W. A. Hickman and N. F. Dow, Data on the Compressive Strength of 75S-T6

Aluminum-Alloy Flat Panels Having Small, Thin, Widely Spaced, Longitudinal Ex-

truded Z-Section Stieners, Technical Note 1978, National Advisory Committee for

Aeronautics, Langley Air Force Base, VA, Nov. 1949.

[5] P. C. Hu, E. E. Lundquist, and S. Batdorf, Eect of Small Deviations from Flatness

on Eective Width and Buckling of Plates in Compression, Technical Note 1124,

National Advisory Committee for Aeronautics, Langley Air Force Base, VA, 1946.

[6] A. Rothwell, An Experimental Investigation of the Post-Buckled Eciency of Z-

Section Stringer-Skin Panels, Aeronautical Journal, pp. 2933, Jan. 1981.

[7] R. Friedman, J. Kennedy, and D. Royster, Analysis and Compression Testing of

2024 and 8009 Aluminum Alloy Zee-Stiened Panels, Transactions of the ASME:

Journal of Engineering Materials and Technology, vol. 116, pp. 238243, Apr. 1994.

[8] J. Singer, J. Arbocz, and T. Weller, Buckling Experiments: Experimental Methods in

Buckling of Thin-Walled Structures; Basic Concepts, Columns, Beams, and Plates

- Volume I. West Sussex, England: John Wiley & Sons, 1998.

[9] R. Butler, M. Lillico, H. G.W., and N. McDonald, Experiments on Interactive

Buckling in Optimized Stiened Pnels, Struct Multidisc Optim, vol. 23, pp. 4048,

2001.

[10] A. Aalberg, M. Langseth, and P. Larsen, Stiened Aluminum Panels Subjected to

Axial Compression, Thin-Walled Structures, vol. 39, pp. 861885, 2001.

[11] ASTM, Standard Practices for Force Verication of Testing Machines, Standard

E403, American Society for Testing and Materials, West Conshohocken, PA, 2003.

[12] ASTM, Standard Test Methods of Compression Testing of Metallic Materials at

Room Temperature, Standard E989a, American Society for Testing and Materials,

West Conshohocken, PA, 2000.

20

USAFA-TR-2005-4

[13] R. Papirno, Inelastic Buckling of ASTM Standard E 9 Compression Specimens,

Journal of Testing and Evaluation, JTEVA, vol. 15, pp. 133135, May 1987.

[14] M. C.-Y. Niu, Airframe Structural Design. Hong Kong: Conmilit Press LTD, 1998.

[15] R. M. Rivello, Theory of Analysis of Flight Structures. New York: McGraw-Hill,

1969.

[16] G. Gerard, Handbook of Structural Stability: Part V - Compressive Strength of

Flat Stiened Panels, Technical Note 3785, National Advisory Committee for Aero-

nautics, Washington, Aug. 1957.

[17] D. J. Peery and J. J. Azar, Aircraft Structures. New York: McGraw-Hill, second ed.,

1982.

21

USAFA-TR-2005-4

This Page

Intentionally

Left Blank

22

USAFA-TR-2005-4

Appendix: Sample Calculations

The following examples indicate how the Johnson-Euler method and the method of

Gerard were used to calculate panel buckling strengths for pristine panels and panels

with span-wise grindouts. English units are used for these examples.

A.1 Johnson-Euler Method

The Johnson-Euler method was employed as follows (this analysis is for a C1 panel).

First, the stiener crippling allowable stress,

cc

, is calculated. The stiener is divided

into 3 segments. Segments 1, 2, and 3 are the inboard (next to the skin), vertical, and

outboard segments of the stiener, respectively.

Table A.1 shows how the crippling load is calculated [17].

Table A.1: Calculation of stiener crippling load using the Johnson-Euler method.

Edge b

i

t

i

b

i

t

i

cc

i

b

i

t

i

cc

i

Seg Cond (in) (in) (b/t)

i

(in)

2

_

cy

s

Ec

_

b

t

_

cc

i

/

cy

s

(psi) (lb)

1 Free 0.604 0.072 8.389 0.043 0.707 0.7491 55,320 2,406

2 Fixed 1.388 0.072 19.278 0.100 1.624 0.9591 70,831 7,079

3 Free 0.604 0.072 8.389 0.043 0.707 0.7491 55,320 2,406

Sum A

w

= 0.187 P

cc

= 11,890

The crippling stress is then

cc

= P

cc

/A

w

= 63, 613 psi (7)

The eective skin area, A

e

, is found by calculating the eective skin width, W

e

, which

is based on the stiener crippling stress, the material modulus, and the skin thickness:

2W

e

= 1.70t

s

E

c

cc

= 1.685 in (8)

and the eective skin area is then

A

e

= 2W

e

t

s

= 0.131 in

2

(9)

The segment section allowables may now be calculated as shown in Table A.2, where

Segment 4 is now the eective skin segment, and Segments 13 are the stiener segments

of Table A.1.

A1

USAFA-TR-2005-4

Table A.2: Calculation of segment section properties.

Width Height A y Ay Ayy I

ox

Seg (in) (in) (in)

2

(in) (in)

3

(in)

4

(in)

4

1 0.640 0.072 0.0461 0.0360 0.0017 0.0001 0.0000

2 0.072 1.316 0.0948 0.7300 0.0692 0.0505 0.0137

3 0.640 0.072 0.0461 1.4240 0.0656 0.0934 0.0000

4 1.685 0.078 0.1306 1.4988 0.1957 0.2933 0.0001

Totals 0.3175 0.3321 0.4373 0.0138

() A Ay Ayy I

ox

The segment section centroid is Y

c

= Ay/A = 1.046 in, and the segment area

moment is I = I

ox

+ Ayy Y

2

c

A = 0.104 in

4

. To complete the segment allowable

stress, we need the slenderness ratio, K, of the segment

K =

L

=

L

c

= 18.89 (10)

where L = 20.9 in, =

_

I/A = 0.571 in, and c, the end xity coecient, is 3.75. The

Johnson-Euler stress,

co

, and strength, P

co

, allowables are then given by

recall

cc

= 63, 613 psi (11)

co

=

cc

_

1

cc

(L

/)

2

4

2

E

c

_

= 60, 095 psi (12)

P

co

=

co

A = 19, 078 lb (13)

This leads to a panel allowable of

(P

co

)

panel

=

co

A

panel

= 90, 526 lb (14)

where A

panel

= (N 1)A + A

w

+ t

s

W

fo

= 1.506 in

2

.

This answer can be iterated upon by using

co

as

cc

in Eq (8), creating a rened W

e

:

2W

e

= 1.70t

s

E

c

co

= 1.733 in (15)

and the new eective skin area is then

A

e

= 2W

e

t

s

= 0.134 in

2

(16)

a 2.9% increase. The new segment section allowables may now be calculated as above

(Table A.3).

A2

USAFA-TR-2005-4

Table A.3: Calculation of new segment section properties.

Width Height A y Ay Ayy I

ox

Seg (in) (in) (in)

2

(in) (in)

3

(in)

4

(in)

4

1 0.640 0.072 0.0461 0.0360 0.0017 0.0001 0.0000

2 0.072 1.316 0.0948 0.7300 0.0692 0.0505 0.0137

3 0.640 0.072 0.0461 1.4240 0.0656 0.0934 0.0000

4 1.733 0.078 0.1343 1.4988 0.2013 0.3017 0.0001

Totals 0.3212 0.3378 0.4457 0.0138

() A Ay Ayy I

ox

The new segment section centroid is Y

c

= Ay/A = 1.051 in, and the new segment

area moment is I = I

ox

+AyyY

2

c

A = 0.104 in

4

. The new slenderness ratio becomes

K =

L

=

L

c

= 18.94 (17)

and the Johnson-Euler stress,

co

, and strength, P

co

, allowables are now given by

recall

cc

= 63, 613 psi (18)

co

=

cc

_

1

cc

(L

/)

2

4

2

E

c

_

= 60, 079 psi (19)

P

co

=

co

A = 19, 300 lb (20)

This leads to a panel allowable of

(P

co

)

panel

=

co

A

panel

= 91, 408 lb (21)

where A

panel

= (N 1)A + A

w

+ t

s

W

fo

= 1.521 in

2

. Because the column allowables

changed only 0.026% in this iteration, we can consider this answer satisfactory.

A.1.1 Damaged Panels

For the damaged panels, the calculation is the same, except that the skin thickness, t

s

is

reduced to that corresponding to the maximum grindout depth, and is assumed to act

over the entire (single) segment. That would need to rst be accounted for in Eq (8)

and carried through all calculations for the damaged segment (only). Other segments

would be calculated as above. For a C1 panel with a 57% grindout, for example, these

calculations would result in a panel allowable of P

co

= 84, 810 lb.

A.2 Method of Gerard

The following calculation is for a C3 (short) panel, which represents the 64 ksi allowable

panel on the B-707.

A3

USAFA-TR-2005-4

Recall that the stiener yielding stress is given by

cy

=

[

cy

s

+

cy

w

(

t/t

s

1)]

t/t

s

(22)

where

cy

s

=

cy

w

= 73.85 ksi and t

s

= 0.0775 in. The area of the skin for one bay

is b t

s

= (2.14)(0.0775) = 0.1659 in

2

. The area of the stringer cross section is t

w

=

0.1975 in

2

, so A

tot

= t

s

+ t

w

= 0.3634 in

2

. The average thickness of the panel,

t, is

given by A

tot

/b = 0.3634/2.14 = 0.1698 in. These values give a stiener yielding stress

of

cy

= 73.850 ksi. (In these panels, the skin and stiener materials have the same

properties, so

cy

=

cy

s

=

cy

w

).

This value allows the calculation of the section failure stress

f

=

cy

_

g t

s

t

w

A

tot

E

cy

_

m

(23)

where = 0.56 (Gerard parameter for formed Z stieners), g = 8 (Gerard parameter for

Z-stiened panel), E = 10.4 Msi, m = 0.85 (Gerard parameter for formed Z-stiener).

These values yield a result of

f

= 63.31 ksi, and a section failure load of

P

f

=

f

A

tot

= 23 ksi (24)

The panel failure load is then calculated as

P

max

= 5P

f

(b W

fi

)t

s

f

= 107.5 kip (25)

where the term (b W

fi

)t

s

f

accounts for the fact that this panel does not consist of 5

complete bays.

A.2.1 Damaged Panels

For the panels with grindouts, the method is the same, with the following modications.

Eq (22) becomes

cy

=

[

cy

s

+

cy

w

(

/t

s

1)]

/t

s

(26)

where the asterisk (*) indicates the impact of changing the skin thickness to t

s

= (1G)t

s

,

where G is the fraction of skin removed at the bottom of the grindout. Similarly, Eq (23)

becomes

f

=

cy

_

_

g t

s

t

w

A

tot

_

E

cy

_

_

m

(27)

and Eqs (24) and (25) become

P

f

=

f

A

tot

(28)

P

max

= 4P

f

(b W

fi

)t

s

f

P

f

(29)

where P

max

is the strength of the damaged section. This strength is used with the

strength of the undamaged sections to calculate the new strength for the entire panel.

A C3 panel with a 50% grindout, for example, would have a strength of

P

max

= 4P

f

(b W

fi

)t

s

f

P

f

= 97.2 kip (30)

where t

s

= (1 0.5)(t

s

), P

f

= 23 kip (as before), and P

f

= 12.8 kip.

A4

Potrebbero piacerti anche

- Collapse analysis of externally prestressed structuresDa EverandCollapse analysis of externally prestressed structuresNessuna valutazione finora

- Pmos ReportDocumento183 paginePmos ReportkshitijscribdNessuna valutazione finora

- Erbium-Doped Fiber Amplifiers: Fundamentals and TechnologyDa EverandErbium-Doped Fiber Amplifiers: Fundamentals and TechnologyValutazione: 5 su 5 stelle5/5 (3)

- Aero3110 DBT Group 15Documento22 pagineAero3110 DBT Group 15Atitat RattanachataNessuna valutazione finora

- Semiparametric Regression for the Social SciencesDa EverandSemiparametric Regression for the Social SciencesValutazione: 3 su 5 stelle3/5 (1)

- U.S. Navy Wire Rope Handbook Vol 2Documento149 pagineU.S. Navy Wire Rope Handbook Vol 2Gary J. Davis, P. E.100% (1)

- nchrp045 Final ReportDocumento97 paginenchrp045 Final ReportMahmoud HamadaNessuna valutazione finora

- Application of Optimal Control Theory to Enhanced Oil RecoveryDa EverandApplication of Optimal Control Theory to Enhanced Oil RecoveryValutazione: 4.5 su 5 stelle4.5/5 (3)

- Buckling CheckDocumento163 pagineBuckling Checkmyusuf_engineerNessuna valutazione finora

- XFLR GuidelinesDocumento71 pagineXFLR GuidelinesTeo Qing RenNessuna valutazione finora

- Investigation of the Chirajara Bridge CollapseDa EverandInvestigation of the Chirajara Bridge CollapseNessuna valutazione finora

- All 2 PDFDocumento152 pagineAll 2 PDFroyson316Nessuna valutazione finora

- 318-14 CrossReference 2011to2014Documento162 pagine318-14 CrossReference 2011to2014SumanthNessuna valutazione finora

- Precast Segmental Box Girder Bridge ManualDocumento122 paginePrecast Segmental Box Girder Bridge ManualMohamed Talat Ramadan100% (4)

- Incompressible Flow Turbomachines: Design, Selection, Applications, and TheoryDa EverandIncompressible Flow Turbomachines: Design, Selection, Applications, and TheoryNessuna valutazione finora

- Internship ReportDocumento49 pagineInternship ReportŞevki SağlamNessuna valutazione finora

- Info-Gap Decision Theory: Decisions Under Severe UncertaintyDa EverandInfo-Gap Decision Theory: Decisions Under Severe UncertaintyValutazione: 5 su 5 stelle5/5 (1)

- Laterite and Lateritic SoilsDocumento96 pagineLaterite and Lateritic SoilsTina HahnNessuna valutazione finora

- Large Deviations for Gaussian Queues: Modelling Communication NetworksDa EverandLarge Deviations for Gaussian Queues: Modelling Communication NetworksNessuna valutazione finora

- tm5 822 13Documento50 paginetm5 822 13Tin Aung KyiNessuna valutazione finora

- Error-controlled Adaptive Finite Elements in Solid MechanicsDa EverandError-controlled Adaptive Finite Elements in Solid MechanicsNessuna valutazione finora

- BookDocumento216 pagineBookZahoor AhmadNessuna valutazione finora

- Kanvinde - Shear Transfer in Exposed Column Base PlatesDocumento159 pagineKanvinde - Shear Transfer in Exposed Column Base PlatesksuscribdacctNessuna valutazione finora

- Wind Turbine Blade DesignDocumento99 pagineWind Turbine Blade DesignNeelabh Gupta100% (1)

- Simulation of Bolted Joint With Frictional Contacts: Robin NykänenDocumento61 pagineSimulation of Bolted Joint With Frictional Contacts: Robin NykänenJoshua KarthikNessuna valutazione finora

- Project Report - DviDocumento61 pagineProject Report - DviJeffrey BakerNessuna valutazione finora

- Goitia HasierDocumento236 pagineGoitia Hasierthomas duncan eelesNessuna valutazione finora

- Reportdunphy PDFDocumento190 pagineReportdunphy PDFGothama_GENessuna valutazione finora

- CIE 5060 Study and Comparison of Shell Design CodesDocumento190 pagineCIE 5060 Study and Comparison of Shell Design CodesDavid MiddletonNessuna valutazione finora

- SolidWorks Flow Simulation 2012Documento90 pagineSolidWorks Flow Simulation 2012Cabalfb Baguio50% (2)

- Mechanics and Design of Reinforced Concrete Victor E.saoumaDocumento0 pagineMechanics and Design of Reinforced Concrete Victor E.saoumaleemindjanNessuna valutazione finora

- Propeller Theories Kerwin - Notes PDFDocumento234 paginePropeller Theories Kerwin - Notes PDFSaeed JavdaniNessuna valutazione finora

- A Worked Example On Aircraft DesignDocumento108 pagineA Worked Example On Aircraft DesigndhursNessuna valutazione finora

- Structural Analysis - Beams, Trusses EtcDocumento79 pagineStructural Analysis - Beams, Trusses EtcСергей Кравченко100% (1)

- Concrete Crack Repair ManualDocumento62 pagineConcrete Crack Repair ManualShamsul Bahrin Sulaiman100% (1)

- Rep HS Model PDFDocumento216 pagineRep HS Model PDF-Nessuna valutazione finora

- Structural Geology Laboratory Manual: Third EditionDocumento166 pagineStructural Geology Laboratory Manual: Third Editionforscribd1981100% (1)

- Structural Geology Lab ManualDocumento165 pagineStructural Geology Lab ManualSebastian CardonaNessuna valutazione finora

- Two Stage Opamp DesignDocumento18 pagineTwo Stage Opamp DesignHajime100% (1)

- Fatigue Behavior of Dented 1-42Documento42 pagineFatigue Behavior of Dented 1-42rodholfhoNessuna valutazione finora

- Gowthaman ThesisDocumento90 pagineGowthaman Thesisscramjet007Nessuna valutazione finora

- Tech RefDocumento720 pagineTech Refahmed_497959294Nessuna valutazione finora

- Thesis PDFDocumento112 pagineThesis PDFkhoulood vend23Nessuna valutazione finora

- Thesis PDFDocumento112 pagineThesis PDFKamgning AbrahamNessuna valutazione finora

- A Finite Element Approach To Reinforced Concrete Slab DesignDocumento170 pagineA Finite Element Approach To Reinforced Concrete Slab Designingeni0sNessuna valutazione finora

- Determination of The Paris Curve For A TWIP Steel For Body-in-White ApplicationsDocumento94 pagineDetermination of The Paris Curve For A TWIP Steel For Body-in-White ApplicationsMatteo de'Giovanetti100% (1)

- Slip Critical Bolted Connectionsa Reliability Analysis For The Design at The Ultimate Limit StateDocumento163 pagineSlip Critical Bolted Connectionsa Reliability Analysis For The Design at The Ultimate Limit Statejuanpalomo74Nessuna valutazione finora

- 2011 10 RepettiDocumento59 pagine2011 10 Repettimonsterh5Nessuna valutazione finora

- AE1222 2021 GROUP E10E CompressionPanelDesignReportDocumento60 pagineAE1222 2021 GROUP E10E CompressionPanelDesignReportBowmigow100% (1)

- Design and Manufacturing of Composite Insulator PDFDocumento8 pagineDesign and Manufacturing of Composite Insulator PDFjha_nitinNessuna valutazione finora

- Basic Control System 1Documento151 pagineBasic Control System 1idhoidoNessuna valutazione finora

- ServiceBoomInspectionandRepair PDFDocumento58 pagineServiceBoomInspectionandRepair PDFDiana HernandezNessuna valutazione finora

- Rock Foundations EM-1110!1!2908Documento120 pagineRock Foundations EM-1110!1!2908Maria ValleNessuna valutazione finora

- Wiggers S.L., Pedersen P. Structural Stability and Vibration. An Integrated Introduction by Analytical and Numerical Methods.2018. 160pDocumento169 pagineWiggers S.L., Pedersen P. Structural Stability and Vibration. An Integrated Introduction by Analytical and Numerical Methods.2018. 160ptrueverifieduser100% (2)

- Obis Son: and Is PhasesDocumento154 pagineObis Son: and Is PhasesNiranjan YadavNessuna valutazione finora

- Spse01546 S 1050 - enDocumento232 pagineSpse01546 S 1050 - engocoolonNessuna valutazione finora

- Panthera Brochure6Documento12 paginePanthera Brochure6sovsepNessuna valutazione finora

- DaedalusDocumento10 pagineDaedalussovsepNessuna valutazione finora

- hp54 2003Documento13 paginehp54 2003sovsepNessuna valutazione finora

- Ask 21 Flight SimDocumento33 pagineAsk 21 Flight Simsovsep100% (1)

- Face Sheet Wrinkling NASADocumento49 pagineFace Sheet Wrinkling NASAsovsepNessuna valutazione finora

- NASA 17 XV 15 Tilt Rotor Research AircraftDocumento222 pagineNASA 17 XV 15 Tilt Rotor Research AircraftÁlvaro Conti Filho100% (1)

- AC CastemDocumento51 pagineAC CastemsovsepNessuna valutazione finora

- A Worked Example On Aircraft DesignDocumento108 pagineA Worked Example On Aircraft DesigndhursNessuna valutazione finora

- Ceasiom TutorialDocumento23 pagineCeasiom TutorialsovsepNessuna valutazione finora

- Vibration and Aeroelasticity - Zhanming QinDocumento246 pagineVibration and Aeroelasticity - Zhanming Qinsumanth_iNessuna valutazione finora

- Blender Eng Rid Long 1Documento25 pagineBlender Eng Rid Long 1goldenthangamNessuna valutazione finora

- Teenie DrwaingsDocumento29 pagineTeenie Drwaingssovsep100% (1)

- CCX 2.2Documento458 pagineCCX 2.2sovsepNessuna valutazione finora

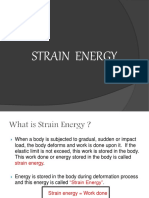

- Strain EnergyDocumento11 pagineStrain EnergyTemoor Abbas100% (1)

- 2 - Tension MemberDocumento72 pagine2 - Tension MemberYetty OktavianitaNessuna valutazione finora

- Typical Waterstop Properties: Hardness - ASTM D2240Documento4 pagineTypical Waterstop Properties: Hardness - ASTM D2240Dicky PramonoNessuna valutazione finora

- A Method To Model Wood by Using ABAQUS Finite Element SoftwareDocumento58 pagineA Method To Model Wood by Using ABAQUS Finite Element SoftwareAnonymous 7MdZQn1Nessuna valutazione finora

- D-Hardness Test (2019-2020)Documento19 pagineD-Hardness Test (2019-2020)Vipul MetaNessuna valutazione finora

- Solutions of Practice Problems - A6Documento13 pagineSolutions of Practice Problems - A6Nickshan NahenthiramNessuna valutazione finora

- 6 Hoek Brown ModelDocumento6 pagine6 Hoek Brown ModelVa Ni SkyNessuna valutazione finora

- 206.0, A206.0, and B206.0 : Al-Cu High-Strength Premium Casting AlloysDocumento4 pagine206.0, A206.0, and B206.0 : Al-Cu High-Strength Premium Casting Alloysmanjunath k sNessuna valutazione finora

- Current Advances in Materials and Processes Vol.26 No.2Documento9 pagineCurrent Advances in Materials and Processes Vol.26 No.2masoodkamaliNessuna valutazione finora

- Lab Sheet Impact TestDocumento8 pagineLab Sheet Impact TestAzam Johar0% (1)

- Advanced Solid Mechanics U SarvananDocumento385 pagineAdvanced Solid Mechanics U Sarvananமாறன் செங்கேணிNessuna valutazione finora

- Relationship Between: Tensile Properties of Fibres and Nonwoven FabricsDocumento5 pagineRelationship Between: Tensile Properties of Fibres and Nonwoven Fabricssasi kumar UNessuna valutazione finora

- Science5 Day 1 Week 1Documento9 pagineScience5 Day 1 Week 1Kate BatacNessuna valutazione finora

- Modelling of Bolted Connections by The Finite Element Method: September 2017Documento16 pagineModelling of Bolted Connections by The Finite Element Method: September 2017jhonatan romero castilloNessuna valutazione finora

- Design of Paper and Board Packages: After Lecture 13 You Should Be Able ToDocumento34 pagineDesign of Paper and Board Packages: After Lecture 13 You Should Be Able Tongocthang7117Nessuna valutazione finora

- Calculation of Section Modulus PDFDocumento4 pagineCalculation of Section Modulus PDFDeniz DasNessuna valutazione finora

- 4 Thick CylindersDocumento66 pagine4 Thick CylindersEswaran Parameswaran100% (3)

- Flat Plate - Roark & YoungDocumento15 pagineFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Finite Element Analysis PDFDocumento5 pagineFinite Element Analysis PDFchetan c patilNessuna valutazione finora

- Stress Based Topology Optimization of 30 Ton C Hook Using FEM.Documento48 pagineStress Based Topology Optimization of 30 Ton C Hook Using FEM.Aravind J100% (1)

- ProductFile 131206155656Documento1 paginaProductFile 131206155656Michael HajzerNessuna valutazione finora

- Numerical Computation of Support Characteristic Curves For Use in Tunnel Support Design and Their Application To The Characteristic Curve MethodDocumento6 pagineNumerical Computation of Support Characteristic Curves For Use in Tunnel Support Design and Their Application To The Characteristic Curve MethodHaha ZazaNessuna valutazione finora

- IC-AMCE 2020 Paper 9Documento1 paginaIC-AMCE 2020 Paper 9Prof. P. D. DeshmukhNessuna valutazione finora

- Chemistry Behind How Aerogels Are MadeDocumento3 pagineChemistry Behind How Aerogels Are MadepucNessuna valutazione finora

- Lab 3Documento7 pagineLab 3Mehmet Safa YılmazNessuna valutazione finora

- Bsce-4: Timber Second Floor Framing Plan and Design CriteriaDocumento3 pagineBsce-4: Timber Second Floor Framing Plan and Design CriteriaKurt Laurhon CabahugNessuna valutazione finora

- Engineering Physics: Structure of DiamondDocumento2 pagineEngineering Physics: Structure of Diamondrajesh.v.v.kNessuna valutazione finora

- Fairfield Atlas Limited: 6.1 - Minimum 5 Samples Per Heat Batch To Be CheckedDocumento3 pagineFairfield Atlas Limited: 6.1 - Minimum 5 Samples Per Heat Batch To Be CheckedAndras StegerNessuna valutazione finora

- Introduction To Designing Elastomeric Vibration IsolatorsDocumento26 pagineIntroduction To Designing Elastomeric Vibration IsolatorsDurukan Burak DilekNessuna valutazione finora

- Composites: Part B: Ali Nazari, Shadi RiahiDocumento9 pagineComposites: Part B: Ali Nazari, Shadi RiahitrawsNessuna valutazione finora

- Mental Math Secrets - How To Be a Human CalculatorDa EverandMental Math Secrets - How To Be a Human CalculatorValutazione: 5 su 5 stelle5/5 (3)

- A Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormDa EverandA Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormValutazione: 5 su 5 stelle5/5 (5)

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeDa EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticeValutazione: 4 su 5 stelle4/5 (2)

- Build a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Da EverandBuild a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Valutazione: 5 su 5 stelle5/5 (1)

- Quantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsDa EverandQuantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsValutazione: 4.5 su 5 stelle4.5/5 (3)

- Fluent in 3 Months: How Anyone at Any Age Can Learn to Speak Any Language from Anywhere in the WorldDa EverandFluent in 3 Months: How Anyone at Any Age Can Learn to Speak Any Language from Anywhere in the WorldValutazione: 3 su 5 stelle3/5 (80)

- Calculus Workbook For Dummies with Online PracticeDa EverandCalculus Workbook For Dummies with Online PracticeValutazione: 3.5 su 5 stelle3.5/5 (8)

- Mathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingDa EverandMathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingValutazione: 4.5 su 5 stelle4.5/5 (21)

- Mental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)Da EverandMental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)Nessuna valutazione finora

- Images of Mathematics Viewed Through Number, Algebra, and GeometryDa EverandImages of Mathematics Viewed Through Number, Algebra, and GeometryNessuna valutazione finora

- ParaPro Assessment Preparation 2023-2024: Study Guide with 300 Practice Questions and Answers for the ETS Praxis Test (Paraprofessional Exam Prep)Da EverandParaPro Assessment Preparation 2023-2024: Study Guide with 300 Practice Questions and Answers for the ETS Praxis Test (Paraprofessional Exam Prep)Nessuna valutazione finora

- Interactive Math Notebook Resource Book, Grade 6Da EverandInteractive Math Notebook Resource Book, Grade 6Nessuna valutazione finora

- Math Workshop, Grade K: A Framework for Guided Math and Independent PracticeDa EverandMath Workshop, Grade K: A Framework for Guided Math and Independent PracticeValutazione: 5 su 5 stelle5/5 (1)

- How Math Explains the World: A Guide to the Power of Numbers, from Car Repair to Modern PhysicsDa EverandHow Math Explains the World: A Guide to the Power of Numbers, from Car Repair to Modern PhysicsValutazione: 3.5 su 5 stelle3.5/5 (9)

- A-level Maths Revision: Cheeky Revision ShortcutsDa EverandA-level Maths Revision: Cheeky Revision ShortcutsValutazione: 3.5 su 5 stelle3.5/5 (8)

- A Guide to Success with Math: An Interactive Approach to Understanding and Teaching Orton Gillingham MathDa EverandA Guide to Success with Math: An Interactive Approach to Understanding and Teaching Orton Gillingham MathValutazione: 5 su 5 stelle5/5 (1)