Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

US4143639 Friction Heat Space Heater, Eugene Frenette

Caricato da

Bastien Gall de SilléDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

US4143639 Friction Heat Space Heater, Eugene Frenette

Caricato da

Bastien Gall de SilléCopyright:

Formati disponibili

United States Patent [191

Frenette

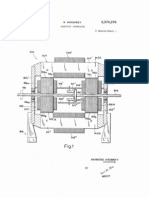

[54] FRICI'ION HEAT SPACE HEATER

[1 l] [45]

4,143,639

Mar. 13, 1979

OTHER PUBLICATIONS

[76] Inventor:

Eugene J. Frenette, Box 255, Derry,

NH. 03038

A.P.C. Application of Beldimano, Ser. No. 326,790,

published May ll, 1943.

Primary Examiner-William E. Wayner

Assistant Examiner-L. I. Schwartz Attorney, Agent, or FirmPearson & Pearson

[21] Appl. No.: 826,557

[22] Filed: Aug. 22, 1977

F24C 9/00

122/26

[57]

ABSTRACT

[51] Int. C1.2 .............................................

[52] US. Cl. . . . . . . . . . . . . . . . . . . . . . . . ..

A furnace or space heater is operable at low cost by a small electric motor which rotates an elongated cylin

drical drum on a vertical axis, within an elongated cy lindrical casing at a clearance of about one eighth of an

126/247;

[58]

Field of Search ......................... .. 126/247; 122/26

inch in the annular chamber formed therebetween. A

[56]

2,251,344 8/1941

References Cited

U.S. PATENT DOCUMENTS

Tesch ................. .. 126/247

supply of light lubricant normally occupies the lower

portion of the annular chamber but rises to fill the chamber during rotation of the drum. The casing is

enclosed in a housing, having a fan chamber containing

an electric motor and fan or blower. The motor shaft

2,467,425

4/1949

Gobb

236/10

may rotate both the fan and the drum.

FOREIGN PATENT DOCUMENTS

760213 2/ 1934 France ..................................... .. 122/26

8 Claims, 3 Drawing. Figures

"42

36

20 .

46

25_

21 d'

3|

as

31 53

22/

65/

I | 49

US. Patent

Mar. 13, 1979

Sheet 1 of2

4,143,639

1%

62

63

64

U.S. Patent

Mar. 13,1979

Sheet 2 of2

4,143,639

Fig. 3.

ll

4,143,639

mined diameter of about twelve inches and of predeter mined height of about thirty-two inches. FRICTION HEAT SPACE HEATER I Fixed within housing 21 by suitable brackets 25 and BACKGROUND OF THE INVENTION 26 is a hollow cylindrical casing, or outer drum, 27 It has heretofore been proposed in U.S. Pat. No. 5 which is of predetermined diameter less than the diame ter of the housing, such as ten inches, and is formed of 1,650,612 to Deniston of Nov. 29, 1927 to rotate a stack aluminum sheeting 28 for efficient transfer of heat. The of discs relative to a coaxial stack of ?xed discs on a cylindrical side wall 29, top wall 31 and bottom wall 32 horizontal axis within a casing to generate frictional of casing 27 are imperforate to form a sealed enclosure heat in hot water ?owing through the lower portion of the casing. In this heating device a supply of oil is con - -n except for the ?ller tube 33, which is closed by a remov tained in the upper portion of the casing to lubricate the able threaded cap 34. The casing '27 divides housing 21 into the lower air discs and to ?oat on the water at a predetermined level. heating chamber 35, which it occupies and an upper fan In US. Pat. No. 3,333,771 to Graham of Aug. 1, l967, chamber 36, there being an annular air chamber 37 a pair of vaned rotors are each enclosed within a cham formed between the cylindrical side wall 29 of the cas ber of a casing, and mounted to rotate in a vertical plane ing and the coaxial, concentric cylindrical side wall 38 on a horizontal axis as depicted in FIG. 7 thereof. As in of the housing 21. the Deniston patent water flows through the device and Air inlet means 39 is provided in the lower portion of is heated by friction. the housing 21 in the form of spaced apertures 41 ex In U.S. Pat. No. 4,004,553 to Stenstrom of Jan. 25, 1977 a single disc like rotor is revolved on a horizontal 20 tending around the cylindrical side wall 38 and air out let means 42 is provided in the top 43 of the housing in axis in a vertical plane, within a casing to heat water the form of apertures 44. The annular air chamber 37 passing through the device.

SUMMARY OF THE INVENTION the fan chamber 36. Unlike the above mentioned patents wherein thin 25 A reversible electric motor 45 is mounted in the fan chamber 36 with an eight bladed fan 46 fast on one end discs or vanes, in single or stack con?guration, comprise 47 of the motor shaft 48, each blade being of about 25 the rotor, in this invention an elongated, cylindrical pitch and the motor being about one horse power for smooth surfaced, inner drum is the rotor. Thedrum is rotating the shaft 48 at between l8003600 R.P.M. rotated in a horizontal plane on a vertical axis within an elongated cylindrical, smooth surfaced casing, or outer 30 The other end 49 of motor shaft 48 extends into the air heating chamber 35 to rotate the hollow, cylindrical drum, to form an annular sealed, liquid, chamber there drum 51 which is supported in suitable bearings 52 for between having a clearance of about one eighth of an

connects the air inlet means to the air outlet means of

rotating around the central, vertical axis of the casing 27 inch. A quart of relatively light oil is captive in the and housing 21. annular chamber and at rest occupies only the bottom thereof. However upon rotation of the drum, by an 35 The inner drum 51 is sealed and hollow and includes the top wall 53, bottom wall 54 and cylindrical side wall electric motor of about one horse power, the oil rises to 55, the walls being of stainless steel. The exterior cylin fill the chamber due to the pumping action of the drum. drical surface 56 of the cylindrical side wall 55 is Thus friction heat is generated not by two metal, or other, surfaces contacting each other, but by they smooth as is the interior, cylindrical surface 57 of the contact of the opposing surfaces with the oil which not 40 aluminum of the cylindrical side wall 29 of casing 27 and the surfaces 56 and 57 are at about one eight inch only lubricates but generates heat.

A portable space heater is formed by enclosing the

casing and drum in the lower chamber of a housing and

clearance from each other to form a narrow, annular

liquid receptacle 58 therebetween.

It should be noted that the annular liquid receptacle

58 is not a passage through which liquid to be heated is

' continually ?owed, as in the above mentioned prior art

patents. Instead it is a sealed chamber and .is provided with a supply of liquid lubricant 59 such as a quart-of No. 10 oil which normally rests in the horizontal space, separate electric motor blow ambient air around the 50 or shallow liquid receptacle 61 between the bottom wall casing for discharge into a heating system. 54 of the drum 51 and the bottom wall 32 of the casing BRIEF DESCRIPTION OF THE DRAWING 27. It has been found that the best results are obtained FIG. 1 is a front elevational view of the portable when the lubricant 59 is Quaker State F-L-M-A-T space heater of the invention, in half section; FIG. 2 is a top plan view in section on line 22 of 55 Fluid, Ford Motor Company Quali?cations No. 2P 670306 M 2633F. Unlike prior patents, no water is in FIG. 1; and contact with the oil. FIG. 3 is a view similar to FIG. 1 of the device of the

a separate motor. For use as a furnace an air blower and

drawing ambient air inwardly and around the heated outer surface of the casing for fan discharge back into the ambient atmosphere by a large diameter, eight bladed fan driven by the drum motor, or preferably by

invention in its preferred form.

DESCRIPTION OF A PREFERRED EMBODIMENT FIGS. 1 and 2 illustrate one embodiment of the fric tion heat heater 20 of the invention which includes an

The motor 45 is connected to a thermostat 62, of any well known type by cord 63 and to a source of electric

ity by male plug 64 so that it is energized under the control of ambient temperature by the signals of the thermostat.

In operation the motor 45 drives the drum 51 at a substantial speed, which causes the oil 59 to rise up into

same. The heat of friction between the inner drum 51

upstanding, hollow, cylindrical housing 21 formed of

porting it on a ?oor 24 of a building. The space heater

imperforate sheet metal 22 and having legs 23 for sup 65 the, annular liqud receptacle 58 to substantially ?ll the

20 is portable and in the portable embodiment illus trated in FIGS. 1 and 2 the housing 21 is of predeter

and outer drum, or casing 27 is transferred by the oil

while it prevents wear on the surfaces 56 and 57 so that

4,143,639

the exterior aluminum surface 65 of the ?xed outer drum 27 becomes heated. Meanwhile the large diame

necting said annular liquid receptacle and said shallow

liquid receptacle to outside said outer drum.

; 4. A heater as speci?ed in claim 1 plus:

ter, multibladed fan 46 is drawing ambient air through the air inlet means 39, thence up through the annular air chamber 37 and past the elongated heated surface 65 for

discharge through the air outlet means 42 back into the

room.

housing means extending around said outer drum,

including an air inlet and an air outlet and

< an electric motor operated fan within said housing for

drawing air into said inlet, circulating said air

around said outer drum and blowing air out of said

As shown in FIG. 3, it is preferable to provide a

separate electric motor 70, usually about 5 HP. and

driving an air blower 71, these being mounted in a

outlet.

lower air chamber 72 for driving ambient air upwardly

in an annular flow path in chamber 37 from the air inlet

means 73 to the air outlet means 74. Air outlet means is

ing:

5. An odor-less, flameless, noiseless, heater compris

an inner, cylindrical, sealed, hollow metal drum tele scoped within an outer cylindrical, hollow, metal

the intake duct 75 of a hot air heating system 76 so that the heater 20 becomes a furnace rather than a space

drum, said drums having upstanding cylindrical side walls

spaced apart with a ?xed clearance of about one eighth of an inch to form an annular, vertical, liq

heater, the separate electric motor 70 enables the ther

mostat 62 to initiate rotation of the drum until a prede termined temperature is reached in the aluminum outer

uid, receptacle and having bottom walls spaced

apart a predetermined distance to form a shallow,

20

drum 27, whereupon the thermostat automatically de

energizes the drum motor 45 while continuing to rotate the separate fan, or ?ower motor such as 70, to furnish hot air to the room or heating system 76 until the casing 27 cools to a predetermined temperature. I claim: 25 1. An odor-less, combustion-less, quiet beater com~

horizontal liquid receptacle

an electric motor operably connected to one said drum to rotate the same on a vertical axis relative to the other at a substantial speed, and

a supply of oil normally occupying only said shallow liquid receptacle but rising into said annular liquid

receptacle, when one said drum is so rotated, to transfer frictional heat to said drums. 6. A combination as speci?ed in claim 5 wherein: said oil is a light oil and is normally in contact with both the bottom wall of said inner drum and the bottom wall of said outer drum.

prising:

an inner, elongated, upstanding, hollow drum jour

nalled within an outer, elongated, upstanding, hol low drum journalled within an outer, elongated 30

upstanding drum to rotate in a horizontal plane on a vertical axis; said inner drum having an outer, circumferential face

7. A combination as speci?ed in claim 5 plus:

a housing extending around said telescoped drums

and

spaced from the inner circumferential face of said outer drum by a ?xed clearance of about one eighth 35 of an inch to de?ne an annular liquid receptacle

therewith;

said inner drum having a lower diametrical face spaced from the lower diametrical face of said outer drum to de?ne a shallow liquid receptacle

electric motor operated fan means in said housing for drawing ambient air into said housing, around said drums and dischargeing it out of said housing. 8. The method of generating heat in an odorless,

?ame-less noiseless manner by means of an outer, sta

tionary, member and an inner member, rotatably

mounted within said outer member, there being a sup ply of oil within said outer member, said method com

therewith;

a supply of oil normally occupying only said shallow liquid receptacle but adapted to be raised upwardly into said annular liquid receptacle when said inner

drum is rotated on said vertical axis at substantial

45

prising the steps of

forming said members as hollow drums, one tele

scoped within the other, and both upstanding verti

cally so that the inner drum rotates on a central vertical axis relative to the outer drum and so that

speed;

and electric motor means for rotating said inner drum on said vertical axis within said outer drum to heat said oil and transfer heat to the outer face of said

outer drum.

there is a clearance space between drums of only about one eighth of an inch in width, limiting the supply of oil within said outer drum to a

2. A heater as speci?ed in claim 1 wherein: said inner drum and said outer drum are both cylin

predetermined quantity so that it normally occu pies only the bottom of the said clearance space and then rotating said inner drum at substantial speed

within said outer drum to heat said oil, cause it to rise up into said clearance space and transfer heat to said outer drum.

# i i i i

drical in con?guration.

3. A heater as speci?ed in claim 1 wherein said inner 55 drum is a sealed hollow cylinder and said outer drum is a sealed hollow cylinder except for an oil conduit con

65

UNITED STATES PATENT OFFICE

CERTIFICATE OF CORRECTION

Patent No.

Invento?s)

4,143,639

Dated March 13, 1979

Eugene J ., Frenette

It is certified that error appears in the above-identified patent and that said Letters Patent are hereby corrected as shown below:

Cole 3, line 22 for flower

read"blower"

Claim 1, line 26 for beater

read"heater"

Claim 1, lines 30-31 Cancel the second occurrence of "journalled within an outer elongated

upstanding drum"

Signed and Scaled this

Twenty-sixth Day Of Jane I979

[SEAL]

Arrest: DONALD W. BANNER

RUTH C. MASON

Arresting O?icer

Commissioner of Patents and Trademarks

Potrebbero piacerti anche

- Fuelless Self Running GeneratorDocumento2 pagineFuelless Self Running Generatorsolomon mekonnenNessuna valutazione finora

- Non-Conventional Free Energy Devices Examples and Practical ApplicationsDocumento4 pagineNon-Conventional Free Energy Devices Examples and Practical ApplicationsSivakumar SelvarajNessuna valutazione finora

- Shaolin Hou Quan (Monkey Fist) PDFDocumento12 pagineShaolin Hou Quan (Monkey Fist) PDFBastien Gall de SilléNessuna valutazione finora

- Vasiliev OV Electricity and Unusual FeaturesDocumento93 pagineVasiliev OV Electricity and Unusual FeaturesPopescu George BogdanNessuna valutazione finora

- A Practical Guide To Free Energy' Devices: What Is An Electrolyser?Documento47 pagineA Practical Guide To Free Energy' Devices: What Is An Electrolyser?lucas123Nessuna valutazione finora

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinDa EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinNessuna valutazione finora

- Dissipation of Electric EnergyDocumento2 pagineDissipation of Electric EnergyRolling76Nessuna valutazione finora

- Magnetron Water Powered Lawnmower Engine PlansDocumento2 pagineMagnetron Water Powered Lawnmower Engine Plansshawnleegabriel100% (3)

- MEG TheoryDocumento17 pagineMEG Theorybill gavenda100% (1)

- World of Free EnergyDocumento8 pagineWorld of Free EnergyLilian B M FerreiraNessuna valutazione finora

- The Mini Romag GeneratorDocumento14 pagineThe Mini Romag GeneratorJVH1978Nessuna valutazione finora

- As Works (Devays) of (Tarielya) To (Kapanadze) .: Moral AspectDocumento64 pagineAs Works (Devays) of (Tarielya) To (Kapanadze) .: Moral AspectchigoNessuna valutazione finora

- Manual Book HHO GENERATOR Fuel EfficientDocumento56 pagineManual Book HHO GENERATOR Fuel EfficientLuis Enrique Jarquin AramburoNessuna valutazione finora

- Switching A Normal' Load. Energizing A Load Begins With A Switching Device in The OpenDocumento5 pagineSwitching A Normal' Load. Energizing A Load Begins With A Switching Device in The OpendenramrNessuna valutazione finora

- Kungfu Hou Qan - Forme 8 PDFDocumento179 pagineKungfu Hou Qan - Forme 8 PDFBastien Gall de SilléNessuna valutazione finora

- Lakhovsky's CoilDocumento9 pagineLakhovsky's Coillaurentiu75100% (4)

- The TransformerDocumento21 pagineThe TransformerAshok KumarNessuna valutazione finora

- 2 5416087904969556847 PDFDocumento480 pagine2 5416087904969556847 PDFArvindhanNessuna valutazione finora

- MAGLEV Wind Mill Power GenerationDocumento16 pagineMAGLEV Wind Mill Power GenerationNagabhushanaNessuna valutazione finora

- VideosDocumento268 pagineVideosTun DuttaNessuna valutazione finora

- CaterDocumento20 pagineCaterCesare Di Girolamo0% (1)

- A Self-Powered GeneratorDocumento16 pagineA Self-Powered Generatorkwag100% (1)

- Build A 3-Band Shortwave Converter For Your CarDocumento2 pagineBuild A 3-Band Shortwave Converter For Your CarbobbyunlockNessuna valutazione finora

- Hybrid Tech Eat On Fuel CellDocumento13 pagineHybrid Tech Eat On Fuel CellhhojonNessuna valutazione finora

- Energy at the Surface of the Earth: An Introduction to the Energetics of EcosystemsDa EverandEnergy at the Surface of the Earth: An Introduction to the Energetics of EcosystemsNessuna valutazione finora

- The Free Energy Secrets of Cold ElectricityDocumento2 pagineThe Free Energy Secrets of Cold ElectricityZuppout100% (1)

- Motionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreDocumento6 pagineMotionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreRolling76Nessuna valutazione finora

- The Richard Clem EngineDocumento24 pagineThe Richard Clem EngineDimple Soni100% (1)

- Blockchain Deck PDFDocumento65 pagineBlockchain Deck PDFsankhaNessuna valutazione finora

- KeelyNet 2009 - The Clem Engine Reborn - 11-08-09Documento11 pagineKeelyNet 2009 - The Clem Engine Reborn - 11-08-09overyounityNessuna valutazione finora

- Excavation PermitDocumento2 pagineExcavation PermitRajesh Kumar SinghNessuna valutazione finora

- S Earl EnergyDocumento9 pagineS Earl Energydrunken_klownNessuna valutazione finora

- Zilano Important Older DS Posts AbridgedDocumento147 pagineZilano Important Older DS Posts Abridgedscolem26100% (1)

- Pugh PDFDocumento13 paginePugh PDFRandall Marsh100% (1)

- Charles Nelson Pogue - US Patent - 1759354Documento18 pagineCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- Muammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesDocumento29 pagineMuammer Yildiz - Over-Unity Homopolar Electrical Generator - Patent, ArticlesMohd FakhriNessuna valutazione finora

- Bedini SGDocumento75 pagineBedini SGBastien Gall de SilléNessuna valutazione finora

- Radiant EnergyDocumento4 pagineRadiant EnergyGilberto ManhattanNessuna valutazione finora

- Howto Cold FusionDocumento52 pagineHowto Cold FusionDimitris BarbadimosNessuna valutazione finora

- General Leasing and Managing AuthorityDocumento14 pagineGeneral Leasing and Managing AuthorityKatharina SumantriNessuna valutazione finora

- Dony WatssDocumento49 pagineDony WatssvbugaianNessuna valutazione finora

- The MR Preva ExperimentDocumento5 pagineThe MR Preva ExperimentMihai Daniel100% (2)

- Fluid Flywheel: Auto MechDocumento6 pagineFluid Flywheel: Auto MechsalmapratyushNessuna valutazione finora

- A Noobs Guide To UfopoliticsDocumento18 pagineA Noobs Guide To UfopoliticsPraveen240679Nessuna valutazione finora

- Top 10 OU Revised 3.1docxDocumento11 pagineTop 10 OU Revised 3.1docxBill ClarkeNessuna valutazione finora

- Nomenclature Practice ProblemsDocumento4 pagineNomenclature Practice ProblemsMax DavidsonNessuna valutazione finora

- 3 Ijeeerfeb20173Documento10 pagine3 Ijeeerfeb20173TJPRC PublicationsNessuna valutazione finora

- Clem Engine Paper PresentationDocumento6 pagineClem Engine Paper PresentationDankamialNessuna valutazione finora

- D14 Updated 24 Dec 2007 PDFDocumento14 pagineD14 Updated 24 Dec 2007 PDFVinayak SanghaniNessuna valutazione finora

- Power Generation by Foot Step Method - Rack and PinionDocumento13 paginePower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- 2016 04 22 17 09 16Documento8 pagine2016 04 22 17 09 16shubhamNessuna valutazione finora

- Furnace Boosting DesignDocumento8 pagineFurnace Boosting Designasitchawla100% (1)

- Tesla Switch GuideDocumento32 pagineTesla Switch GuideRagnarLothbrokNessuna valutazione finora

- Starlite PDFDocumento35 pagineStarlite PDFPuturrú De FuáNessuna valutazione finora

- Charles Pogue Carb. PDFDocumento27 pagineCharles Pogue Carb. PDFTomislav JovanovicNessuna valutazione finora

- 4B Negros Oriental Tourism Key Players ListDocumento1 pagina4B Negros Oriental Tourism Key Players ListHelena May IsaacNessuna valutazione finora

- CHEMALLOY - A New Alloy For The Science StudentDocumento2 pagineCHEMALLOY - A New Alloy For The Science StudentPeter Benedikt WeberNessuna valutazione finora

- Geet Reactor RodDocumento11 pagineGeet Reactor RodthenjhomebuyerNessuna valutazione finora

- The E-Stress GeneratorDocumento12 pagineThe E-Stress GeneratorMikkel RevesenNessuna valutazione finora

- 2Documento2 pagine2Aman SodhiNessuna valutazione finora

- Bill Williams Gas Splitter Dry CellDocumento4 pagineBill Williams Gas Splitter Dry CellCiprian ALNessuna valutazione finora

- Site Map Site Search: Neutral Plates - QuestionsDocumento2 pagineSite Map Site Search: Neutral Plates - QuestionsChandra NurikoNessuna valutazione finora

- PWMcircuit 08Documento10 paginePWMcircuit 08kcarringNessuna valutazione finora

- Tesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megDocumento9 pagineTesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megNISHANT KumarNessuna valutazione finora

- HPT (Ieee, 2005)Documento7 pagineHPT (Ieee, 2005)Muhammad Hadi MustajabNessuna valutazione finora

- Ijiset V6 I8 18Documento5 pagineIjiset V6 I8 18TeotiaNessuna valutazione finora

- March 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorDocumento8 pagineMarch 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorVlad AdrianNessuna valutazione finora

- Gray 4595975Documento7 pagineGray 4595975MANNAJANELAGUNANessuna valutazione finora

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsDa EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsNessuna valutazione finora

- How I Control Gravity PDFDocumento7 pagineHow I Control Gravity PDFwroueaweNessuna valutazione finora

- Permatex, Inc - Ultra Gasket Sealant 1ozDocumento3 paginePermatex, Inc - Ultra Gasket Sealant 1ozjaredf@jfelectric.comNessuna valutazione finora

- Amsoil Synthetic CVT Fluid (CVT)Documento2 pagineAmsoil Synthetic CVT Fluid (CVT)amsoildealerNessuna valutazione finora

- Bradycardia AlgorithmDocumento1 paginaBradycardia AlgorithmGideon BahuleNessuna valutazione finora

- Data Sheet HFE-7000 Prod SpecDocumento6 pagineData Sheet HFE-7000 Prod Specsshaffer_9Nessuna valutazione finora

- Aswani Construction R 07102013Documento3 pagineAswani Construction R 07102013Balaji RathinavelNessuna valutazione finora

- Competency Competency Multiple Choice Multiple Choice ComputationDocumento4 pagineCompetency Competency Multiple Choice Multiple Choice ComputationAaron James LicoNessuna valutazione finora

- Chemical Engineering: ReactionDocumento59 pagineChemical Engineering: Reactionnluvwjm7275Nessuna valutazione finora

- Me22 M1a1Documento2 pagineMe22 M1a1Jihoo JungNessuna valutazione finora

- DexaDocumento36 pagineDexaVioleta Naghiu100% (1)

- Trombly - Pump Status PDFDocumento8 pagineTrombly - Pump Status PDFilhamNessuna valutazione finora

- Manufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Documento2 pagineManufacturer: Jaguar Model: S-Type 2,5 Engine Code: JB Output: 147 (200) 6800 - 6/9/2022 Tuned For: R-Cat Year: 2002-05 V9.200Official Feby AfriwanNessuna valutazione finora

- Monthly Hse Report Nhai Org inDocumento12 pagineMonthly Hse Report Nhai Org inPhilip S. GongarNessuna valutazione finora

- Clase No. 24 Nouns and Their Modifiers ExercisesDocumento2 pagineClase No. 24 Nouns and Their Modifiers ExercisesenriquefisicoNessuna valutazione finora

- TOCDocumento14 pagineTOCAthirah HattaNessuna valutazione finora

- Civil Aviation Authority of BangladeshDocumento1 paginaCivil Aviation Authority of BangladeshS.M BadruzzamanNessuna valutazione finora

- Datasheet Lm311Documento10 pagineDatasheet Lm311Ed FreemanNessuna valutazione finora

- Imperial SpeechDocumento2 pagineImperial SpeechROJE DANNELL GALVANNessuna valutazione finora

- Composition and Digestibility of Cattle Fecal WasteDocumento7 pagineComposition and Digestibility of Cattle Fecal WasteIonela HoteaNessuna valutazione finora

- Timbers Lesson 2Documento18 pagineTimbers Lesson 2bright possibleNessuna valutazione finora

- Chrono Biology SeminarDocumento39 pagineChrono Biology SeminarSurabhi VishnoiNessuna valutazione finora

- FPGA-based System For Heart Rate Monitoring PDFDocumento12 pagineFPGA-based System For Heart Rate Monitoring PDFkishorechiyaNessuna valutazione finora

- Flaxseed Paper PublishedDocumento4 pagineFlaxseed Paper PublishedValentina GarzonNessuna valutazione finora

- Cat 4401 UkDocumento198 pagineCat 4401 UkJuan Ignacio Sanchez DiazNessuna valutazione finora

- Security Officer Part Time in Orange County CA Resume Robert TalleyDocumento2 pagineSecurity Officer Part Time in Orange County CA Resume Robert TalleyRobertTalleyNessuna valutazione finora

- UWSAs 2008-09 Projects Report (Final)Documento48 pagineUWSAs 2008-09 Projects Report (Final)David SabaflyNessuna valutazione finora