Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Simulation of A Wet Sulfuric Acid Process (WSA)

Caricato da

Ahmed AliDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Simulation of A Wet Sulfuric Acid Process (WSA)

Caricato da

Ahmed AliCopyright:

Formati disponibili

Al-Khwarizmi Engineering Journal

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013)

Simulation of a Wet Sulfuric Acid Process (WSA) for Utilization of Acid Gas Separated from Omani Natural Gas

Ahmed Jawad Ali Al-Dallal

Department of chemical engineering / college of engineering / university of sahaar (Received 2 April 2013; accepted 6 October 2013)

Abstract

In this study, a proposed process for the utilization of hydrogen sulphide separated with other gases from omani natural gas for the production of sulphuric acid by wet sulphuric acid process (WSA) was studied. The processwas simulated at an acid gas feed flow of 5000 m3/hr using Aspen ONE- V7.1-HYSYS software. A sensitivity analysis was conducted to determine the optimum conditions for the operation of plant. This included primarily the threepacked bed reactors connected in series for the production of sulphur trioxidewhich represented the bottleneck of the process. The optimum feed temperature and catalyst bed volume for each reactor were estimated and then used in the simulation of the whole process for two cases namely 4 and 6 mole% SO2 stream fed to the first catalytic reactor. The 4mole% SO2 gaves the highest conversion (98%) compared with 6 mole% SO2 (94.7%). A valuable quantity of heat was generated from the process. This excess heat could also be transformed into power in a turbine or used as a heating media in neighbouring process units. Keywords: Simulation, Acid Gases, WSA, Sulphuric Acid Production.

1. Introduction

Most of natural gases contain H2S as a major impurity. H2S isa highly toxic and corrosive gas and considered as one of the majorsources for the environmental problems such as acid rains. Therefore, in order to utilize these fuels for chemical processing or energygeneration, the H2S concentration in these gases must be reducedto very low levels [1]. Acid gas removal process is a very important industrial operation, which has been described elsewhere. The main processes used are based on absorption, and the selectivity of the solvent with respect to acid gasses is based on an affinity of the chemical or physical type. Adsorption is also used for intensive purification. Gas permeation has a substantial potential, but today, industrial applications are limited. The different processes for separation of acid gases from natural gas is well represented by Zulkifli[2].

Numerous different methods exist for the treatment of gaseous effluents that containboth acid compounds H2S and CO2.The selection of an optimum method for theelimination is not easy and, in many cases, to obtain the degree of purification of gas desired, it is necessary to combine different processes. For the evaluation of the methods of utilization, the following variables, amongothers, must be taken into account [3]: - Concentration of H2S in the gas to be utilized. - Pressure, temperature and composition of the gas. - Ratio of H2S to CO2. - Volume of gas to be processed. - Total H2S load - Off-gas specifications for the process output. - Economic considerations. - Environmental implications. The acid gas after separation from Omani natural gas contains hydrogen sulfide, carbon

Ahmed Jawad Ali Al-Dallal

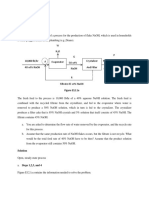

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013) technology has had certainrestrictions with regards to SO2 concentration in the feed gas, and the overall conversionof SO2 by catalytic means has been limited to approximately 99.7%.The WSA process is applied in all industries where the removal of sulphur is an issue.Typical applications include [5-8]: - H2S-containing gases from amine units. - Sour water stripper gases. - Regeneration of spent sulphuric acid from alkylation. - Treatment of stack gases from boilers fired by heavy residues and petroleum coke. - In the viscose fibre industry for treatment of hydrogensulphide and carbon disulphide containing off-gases. - In the non-ferrous metallurgical industry for treatmentof SO2 containing off-gases from a variety of process units. There are many advantages why one should use the WSA process for acid-gas treatment. The process does not generate any waste products or waste water and does not use any absorbents. Firstly the process produces sulfuric acid, which is a more valuable compound in comparison to elemental sulfur. Secondly the process uses the water content in the process gas and air introduced, which enables production of high purity concentrated sulfuric acid. The block diagram for the WSA process is shown in Figure 1.

dioxide, water vapor and small quantity of methane [4] . The aim of this study is to perform a case study on the application of the WSA process for the utilization of H2S in the acid gas to produce sulfuric acid using wet sulfuric acid process (WSA) and to determine the optimum conditions for this process.

2. The WSA Process

The WSA (Wet gas Sulphuric Acid) processis an effective and in some cases superior alternative to the Claus process for the production of sulphur from sulphur containing gases[1].It is a process for the conversion of sulphurous streams into sulphuric acid developed by Haldor Tops e A/S, Denmark. Since its introduction in the 1980s, the WSA process were recognised as an efficient process for recovering sulphur from various sources in the form of commercial quality sulphuric acid. The WSA process is a catalytic process producing 93!98 wt% acid [5].Up to 2009, Tops e WSA plants have been in operation foralmost 30 years, and close to 80 plants were sold[6]. It has found widespread application in the metallurgical, steel industry (coking plant), power and cellulose industry, but the majority of applications are within the refinery and petrochemical industry[7]. In spite of its unique features andability to treat gases without any prior drying, the WSA

Fig. 1. A Block Diagram of the Various Steps in the WSA Process.

59

Ahmed Jawad Ali Al-Dallal

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013) converter of some 6 ! 7vol%. This limitation of course can be overcome by dilution of the gas withatmospheric air, but this will increase the process gas volume and thereby thedimensions of the plant.

The inlets sulphurous gases are fed to a combustor where they are mixed with combustion air. In the combustor the hydrogen sulphide isconverted to sulphur dioxide according to thefollowing exothermic reaction[9]: H2S + 3/2 O2 " H2O + SO2 ...(1) In case there is some methane in the acid gas (as in our case), it will be combusted according to the following reaction: CH4 +2O2" CO2 + 2H2O ...(2) The process gas leaving the combustor iscooled in a waste heat boiler. The cooledSO2 containing gas is fed to the SO2 converterwhere it is converted to SO3 in three adiabaticcatalytic beds. In the converter the SO2 isoxidized to SO3 according to the following reaction: SO2 + 1/2 O2 # SO3 ...(3) The reaction is a temperature and pressuredependent equilibrium reaction. In order toachieve a high conversion the reaction is cooledin two inter-beds[8]. After the third catalyst bed theprocess gas is cooled by boiler water. During thiscooling part of the formed SO3 reacts with thewater vapour present in the process gasaccording to the following exothermic hydrationreaction: SO3 (g) + H2O (g) " H2SO4 (g) ...(4) Being a single-contact process, the SO2/SO3 equilibrium curve limits the conversion totypically 99.4 - 99.7%[6]. This limitation can be overcome by scrubbing the tail gas withcaustic or hydrogen peroxide, but this means additional investment and operatingcosts. After the SO2 converter the process gas is fed tothe WSA condenser were it is cooled by ambientair. During the cooling the remaining hydrationreaction and condensation of the sulphuric acidtakes place: H2SO4 (g) " H2SO4 (l) ...(5) The condensed hot sulphuric acid is furthercooled in a heat exchanger cooled by coolingwater. The acid is of commercial quality. Theclean process gas leaves the condenser at the top.The heat released by all the exothermic reactions in the WSA plant is recovered in the form of steam. Because of considerations concerning construction materials in the WSA condenser,is not possible to handle gases with sulphuric acid dew points higher than around260$C[6]. This corresponds to a content of SO2 inlet to the SO2 60

3. Simulation of WSA Process

WSA process is simulated with AspenONE7.1-Engineering (HYSYS) using the actual composition of theacid gas produced after separation from Omani natural gas [4] as shown in Table 1:

Table 1, Feed acid gas composition. Component H2S CO2 CH4 H2O Composition Mole% 16.7 73.0 0.20 10.1

Although some authors refer to the H2S acid gas separated from natural gas by amine process but actually there is no data available in literature about this application. In any case, all the required operating data necessary to complete the simulation are collected from different sources [6,9,10].The air introduced to the process is assumed to be at 40 oC and with 70% relative humidity according to Omanclimate. The most important part of this process is the SO2 oxidation reactors. There are commercially three reactors in series. Each reactor is occupied by different quantity of catalyst. The SO2 oxidation catalyst is based on a silica carrier (diatomeous earth) impregnated with a mixture of sodium, potassium and vanadium [10].The VKWSA catalysts are specially developed for use in humid process gases [6]. The top layer of catalyst in the first bed consists of 25 mm daisy shaped particles which provide good capacity for accumulation of dust without creating excessive pressure drop. The remaining catalyst consists of either 9 mm or 12 mm daisies. Due to the exothermal reaction, the outlet temperature from the first bed may reach around 600$C. The gas is cooled by superheating of high pressure steam

Ahmed Jawad Ali Al-Dallal

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013) in the first bed consists of 25 mm daisy shaped particles which provide good capacity for accumulation of dust without creating excessive pressure drop. The remaining catalyst consists of either 9 mm or 12 mm daisies. Due to the exothermal reaction, the outlet temperature from the first bed may reach around 600$C. The gas is cooled by superheating of high pressure steam and the gas flows to the second bed. After the second bed the gas is cooled again by superheating of high pressure steam and the conversion is continued in the third bed. At the outlet of the third bed the conversion has reached more than 95%. The gas is then cooled to around 300$C by production of high pressure steam, whereby part of the SO3 reacts with H2O to form H2SO4 vapour. The typical properties of the VK-WSA series catalyst specially manufactured for the WSA process are shown in Table 2.[11]:

Table 2, Typical properties of the VK-WSA series catalyst. Catalyst VK-WSA

and the gas flows to the second bed. After the second bed the gas is cooled again by superheating of high pressure steam and the conversion is continued in the third bed. At the outlet of the third bed the conversion has reached more than 95%. The gas is then cooled to around 300$C by production of high pressure steam, whereby part of the SO3 reacts with H2O to form H2SO4 vapour. The typical properties of the VK-WSA series catalyst specially manufactured for the WSA process is shown in Table 2. [11]:

4. Simulation of WSA Process

WSA process is simulated with AspenONE7.1-Engineering (HYSYS) using the actual composition of theacid gas produced after separation from Omani natural gas [4] as shown in Table 1:

Table 1, Feed acid gas composition. Component H2S CO2 CH4 H2O Composition Mole% 16.7 73.0 0.20 10.1

Description Diameter (outer/inner), (mm) Length , (mm) Chemical composition V2O5, (wt%) K, (wt%) Na, (wt%) 6-8 7 - 12 1-2 25/9 22-28 12/4 10-14

Although there is some authors refer to the H2S acid gas separated from natural gas by amine process but actually there is no data available in literature about this application. In any case, all the required operating data necessary to complete the simulation are collected from different sources[6,9,10].The air introduced to the process is assumed to be at 40 oC and with 70% relative humidity according to Omanclimate. The most important part of this process is the SO2 oxidation reactors. There are commercially three reactors in series. Each reactor is occupied by different quantity of catalyst. The SO2 oxidation catalyst is based on a silica carrier (diatomeous earth) impregnated with a mixture of sodium, potassium and vanadium[10].The VKWSA catalysts are specially developed for use in humid process gases [6]. The top layer of catalyst 61

Physical properties Bulk density (kg/m3) Attrition loss (%) Operating conditions Gas concentration, SO2 (mole%) Minimum O2/SO2 (mole/mole) 0 - 10 0.6 420-440 4-6 350-370 2!4

The thermal and electrical behaviour %K-NaV& catalyst series for SO2 oxidation (produced specially for the WSA process) is studied by Guo et al.[12]. There results showed the following reaction kinetics as a function of the partial pressures:

Ahmed Jawad Ali Al-Dallal

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013) the effect of temperature on this reaction kinetics and theirwork is represented by the following equations:

rSO2 =

a=

k 1 PSO2 PO2 (1 a )

m

( PSO2 + k2 PO2 + k3 PSO3 )

m

...(6)

PSO3 K p PSO2 PO2 0.5

...(7) ...(8) ...(9)

rSO3 = k4 C H 2O

C SO3

. ..(10) ...(11)

E k = A exp( ) RT 4905.5 log K p = 4.6455 T

k4 = 1.41 x 107 exp(13.5/RT)

The parameters used in above equations are shown in Table 3.

Table 3, Parameters used in the reaction rate equation [12]. Parameter Operating temperature range, oC 380 - 470 A1 E1[kJ/kmole] A2 E2 [kJ/kmole] A3 E3[kJ/kmole] m 3.035 x 107 1.69 x 105 1.943 x 10-7 -7.21 x 104 3.021 x 104 6.912 x 104 0.65 470 - 580 15.63 7.89 x 104 1.111 x 10-5 - 5.57 x 104 5.019 x 104 6.897 x 104 0.55

Where R is in Kcal/mole.K and rSO3 in cm6/mole.s We try to introduce this kineticsinside the three catalytic packed reactors connected in series used for the oxidation of SO2 in the simulation case using equations 10 and 11.We found that we need to increase the volume of reactors ten times to allow the vapour phase sulphuric acid formation to occur in these reactors. In this simulation we assume that all the vapour phase formation of sulphuric acid occurs after the third catalytic packed reactor according to different authors [5,7,8] . After the third reactor the effluent is cooled to 270 oC and then introduced to the condenser which represented in the simulation by a conversion reactor where we assumed that all SO3 will convert to H2SO4. In this simulation we try to apply two different concentration of SO2 fed to the catalytic packed reactors namely 4 and 6 mole% by regulating the flow of air fed to the system. More than 6 mole% SO2 will not be applicable since there is no enough oxygen for oxidation of SO2. Less than 4% will reduce the temperature in the reactor and reduce the efficiency of the heat utilization. In any case 4-6 mole% SO2 was normally used in commercial production of sulfuric acid by WSA process [5,7].

Many references stated that;the process which leave the last catalyst bed will typically contains SO3 plus water vapour[5,7,8]. This means that there are no remarkable reaction between SO3 and water vapour during the three catalytic reactors connected in series. After the last conversion stage, the gas is cooled and most of the SO3 reacts with water vapour and forms gas phase sulphuric acid and then the process gas goes to the WSA condenser where final hydration and condensation of acid takes place[5]. Only Almqvist et al. [14] assumed that the reaction which produces vapour sulphuric acid occurrs through the three catalytic packed reactors connected in series. The reaction kinetics for the formation of gaseous sulphuric acid was studied by different authors [15-18] . Only Jayne et al. [18] studied

5. Results and Discussion

The simulation sensitivity results for the effect of input temperatures for the three catalytic reactors on the fractional conversion of SO2 are shown in Figure 2 and 3 for 4 and 6 mole% SO2 respectively. The optimum feed temperature for 4% will be 430, 450 and 430 0C for the three reactors respectively. The optimum feed temperature for 6% will be 430, 460 and 440o Crespectively.

62

Ahmed Jawad Ali Al-Dallal

1.0 0.9 Fractional Conversion of SO2 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 250 300

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013)

PFR-1 PFR-2 PFR-3

350

400

450

500

550

Reactor Feed Temperature, 0C

Fig. 2. Effect of Reactor Feed Temperature on the Cumulative Fractional Conversion of SO2 in the Three Plug Flow Reactors (PFR s) Connected in Series at 4 Mole% SO2 in Feed.

1.0 0.9 Fractional Conversion of SO2 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 250 300 350 400 450 500 550 Reactor Feed Temperature, 0C PBR-1 PBR-2 PBR-3

Fig. 3. Effect of Reactor Feed Temperature on the Cumulative Fractional Conversion of SO2 in the Three Plug Flow Reactors (PFR s) Connected in Series at 6 Mole% SO2 in Feed.

The effect of reactor volume for the three catalytic reactors on the fractional conversion of SO2 were shown in Figures 4 and 5 for 4 and 6 mole% SO2 respectively. The optimum volumes

for 4 mole % SO2 is 3.5, 4.5 and 5.5 m3 for the three reactors respectively. The optimum reactorvolumes for 6% is 4.5, 5.5 and 6.5for the three reactors respectively.

63

Ahmed Jawad Ali Al-Dallal

1 0.9 Fractional Conversion of SO2 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 2

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013)

PBR-1 PBR-2 PBR-3

10

12

Reactor Volume, m3

Fig. 4. Effect of Reactor Volume on the Cumulative Fractional Conversion of SO2 in the Three Plug Flow Reactors (PFR s) Connected in Series at 4 Mole% SO2 in Feed.

1.0 0.9 Fractional Conversion of SO2 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 0 2 4 6 8 10 12 Reactor Volume, m3 PBR-1 PBR-2 PBR-2

Fig. 5. Effect of Reactor Volume on the Cumulative Fractional Conversion of SO2 in the Three Plug Flow Reactors (PFR s) Connected in Series at 6 Mole% SO2 in Feed.

The mole fraction of different component throughout the first plug flow reactor is shown in

Figure 5 and 6 for 4 mole% and 6 mole% SO2 respectively.

64

Ahmed Jawad Ali Al-Dallal

0.12 0.10 0.08 Mole Fraction 0.06 0.04 0.02 0.00 0.00

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013)

O2 SO2 H20 SO3

0.20

0.40

0.60

0.80

1.00

Packed Bed Reactor Height, m

Fig. 6. The Distribution of Mole Fraction of Different Component throughout the First Plug Flow Reactor (PBR-1) at a Feed of 4 Mole% SO2.

0.16 0.14 0.12 Mole Fraction 0.10 0.08 0.06 0.04 0.02 0.00 0.00 0.20 0.40 0.60 0.80 1.00 Packed Bed Reactor Height, m O2 SO2 H20 SO3

Fig.7. The Distribution of Mole Fraction of Different Component Throughout the First Plug Flow Reactor (PBR-1) at a Feed of 6 Mole% SO2.

The optimum conditions with respect to the volume of reactors and the feed temperature to the reactors were used in the simulation for the

two cases (4 mole% and 6 mole% SO2).The main results for the two simulation cases are shown in Table 4

65

Ahmed Jawad Ali Al-Dallal

Table 4, Main results of the process simulation.

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013)

Conversion at discharge from PFR s PBR-1 4% SO2 6% SO2 0.894 0.7736 PBR-2 0.967 0.9107 PBR-3 0.980 0.947

Total heat generated from the whole Process 9.95 x 107kJ/h 1.084 x 108kJ/h

wt% H2SO4 98.7 98.0

Production Rate of H2SO4kg/h 3620 3527

As shown in Table 4, the equilibrium conversions will reach a maximum value that cannot be exceeded even if we increase the volume of catalytic reactor which is the normal case for equilibrium reversible reaction. In general, the equilibrium conversion that can be reached for 4 mole% SO2 is relatively higher than 6 mole% SO2. The presence of excess oxygen raises the SO2 equilibrium conversion as mentioned before, but it is also an essential prerequisite for maintaining the activity of the vanadium catalyst. In any case working with 4 mole% SO2 will reduce the treatment efforts for the off-gas produced from this process. Haldor Topse A/S gave guarantee of a maximum of 2 kg SO2 emission per ton 100 % sulfuric acid produced for one of the cases studied [14]. Actually this value cans hardlyachieved in our case where about 16 kg of

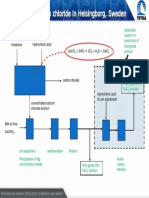

SO2 is produced per ton 100% sulfuric acid produced. This implied that extra tail gas treatment was necessary in order to achieve desired sulfur dioxide content in the stack gases. The overall process is exothermal and large amount of steam is produced in the heat exchangers, which is used for preheating of the feed gas and for addition of water if that is necessary. The excess heat can also be transformed into power in a turbine or used as a heating media in neighbouring process units[14].No remarkable difference in the heat generated and production capacity and concentration of sulphuric acid for both cases were observed (as shown in Table 4). The complete simulation flow sheet for the process using Aspen-ONE-HYSYS is shown in Figure 8.

Fig. 8. Simulation Flow Sheet for WSA Process.

66

Ahmed Jawad Ali Al-Dallal

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013) [2] Zulkifli, N. %Process Simulation and Improvement of Industrial acid gas removal unit (AGRU)& BSc Thesis, Faculty of Chemical & Natural Resources Engineering, Universiti Malaysia Pahang (2009). [3] Gomez, J. M. and Cantero,D. %Chapter 15Hydrogen Sulfide Removal From Gaseous Effluents& in E.R. Donati and W. Sand (eds.), Microbial Processing of Metal Sulfides, 287!309 (2007). [4] Private communication with TEBODINMuscat/Oman (2012). [5] Laursen, J. K. and. Jensen, F. E. %WSA Meeting industry demands by, Sulphur 312, 80-85 (2007). [6] Rosenberg, H, %WSA-DC ! Next Generation Topsoe WSA Technology for Stronger SO2 Gases and Very High Conversion&, The Southern African Institute of Mining and Metallurgy Sulphur and Sulphuric Acid Conference, 27-36 (2009). [7] Laursen, J. K., %Details advances in sulphur recovery by the WSA process-The process principles&, Hydrocarbon Engineering, August (2007). [8] Rosenberg, H., %Topse wet gas sulphuric acid (WSA) technology(an attractive alternative for reduction of sulphur emissions from furnaces and converters&, International Platinum Conference )Platinum Surges Ahead*, The Southern African Institute of Mining and Metallurgy (2006). [9] Wendt,A., %Optimisation of WSA technology", Department of Chemical Engineering, B.Sc. thesis, Lund University (2008). [10] Ole RudBendixen, %Sulphuric acid recovery from sulphurous waste streams& PTQ Q4, 1-7(1998). [11] LH/MSHJ, Haldor Topse A/S Product Sheet, Sulfuric Acid Catalyst VK-WSA (2007). [12] Guo, H. X., Han, Z. H. and Xie, K. C. %Mechanism and Kinetics of SO2 Oxidation on "K-V"and "K-Na-V" Catalyst Series: ( I ) Catalyst Behavior and Reaction Mechanism&, J. Chem. Ind. Eng. (China) 37, 244-256(1984). [13] Almirall, B. X., %Introduction to Wet Sulfuric Acid Plants Optimization Through Exergo economics& Master*s thesis, TechnisceUniversitatBerlin,June(2009). [14] Almqvist, M. Andersson, N. Holmqvist A. and J+nsson J., %Simulation of a WSA process for SO2 containing off gases from the metallurgical industry&, Lund 67

6. Conclusions

The following conclusions can be withdrawn from this study: - Wet sulphuric acid process (WSA) was used successfully for the production of sulfuric acid by utilization of hydrogen sulphide separated from Omani natural gas. - A sensitivity analysis was conducted to determine the optimum conditions for the plantoperation. This includes primarily the three packed bed reactors connected in series for the production of sulphur trioxide which represent the bottleneck of the process. - The optimum feed temperature and catalyst bed volume for each reactor for production of SO3 was found and then impended for the simulation of the whole process for two cases namely 4 and 6 mole% SO2 stream fed to the first catalytic reactor. The 4 mole% SO2 gives the highest conversion (98%) compared with 6 mole mole% SO2 (94.7%). - A valuable quantity of heat was generated from the process. This excess heat could also be transformed into power in a turbine or used as a heating media in neighboring process units.

Symbols

A CH20 E Kp k m P PSO2 PO2 PSO3 R rSO2 rSO3 T Frequency factor Water vapour concentration [mole/cm3]CSO3SO3 concentration [mole/cm3] Activation energy[kJ/kmol] Rate constant Equilibrium constant[atm!5] Partial pressure exponent Pressure[atm] Partial pressure of SO2[atm] Partial pressure of O2[atm] Partial pressure of SO3[atm] Gas constant [= 8.314 kJ/kmol K] intrinsic rate of reaction[kmol/kg cat s] rate of reaction for vapour sulphuric acid formation [cm6/mole.s] Temperature [K]

7. References

[1] Strauss, W., Industrial Gas Pergamon Press, Oxford (1975). Cleaning.

Ahmed Jawad Ali Al-Dallal

Al-Khwarizmi Engineering Journal, Vol. 9, No. 3, P.P. 58- 69 (2013) [17] Wang, X., Jin, Y. G., Suto, M., Lee, L. C. and O'Neal, H. E., %Rate constant of the gas phase reaction of SO3 with H2O, J. Chem. Phys. 89, 4853!4860(1988). [18] Jayne ,J. T., P+schl ,U, Chen ,Y-m, Dai , D., Molina ,L.T., Worsnop , D.R., Kolb ,C.E. and Molina, M.J., %Pressure and Temperature Dependence of the Gas-Phase Reaction of SO3with H2O and the Heterogeneous Reaction of SO3 with H2O/H2SO4Surfaces& J. Phys. Chem. A101, 10000!10011(1997).

University, Faculty of Engineering LTH, Department of Chemical engineering HaldorTopsoe A/S&, KET050, (2008). [15] Reiner, T; Arnold, F %Laboratory investigations of gaseous sulfuric acid formation via SO3 + H2O + M -> H2SO4 + M: Measurement of the rate constant and product identification&, J Chem. Phys. 101, 7399!7407(1994). [16] Derek D Stuart, %Acid Dewpoint Temperature Measurement And Its Use in Estimating Sulfur Trioxide Concentration& ISA 55th Analysis Division Symposium, New Orleans, Session 3.3, 1 !12(2010).

68

(2013) 69 -58 .;<= :3$)9"% :9)!-*"% ./1)24"% +56%&7"% .!-+

!# $%&( )*,%

HI'"%,= G"D,= BCD0EF (WSA) (:A8,= (>*8?,"; 6)0*8:<,= 4'"& /"023 ()+-., !"#"%' H2"-.,= H.):?,= G"D,= P' BKMO-,=

7/8: ;2/< / !"$&'( 056 / -./0103'( !"$&'( )+,

H+R S=KT U-&=

(NCV,=

lA`9 j`Lik .i`@f<= .fG:g<= _`P<= UA bKde ?=_`a ^A NZ[]@<= UGWXERGY<= RGLHK:S NOPLDQ C9KLMA CGI@J CD=EF >@B 568:<= 024 ./ .AspenONE- {A`iK; s=RzLD`; 5000 m3/h FXR8; .xA`8<= _`PI< .@w9 u/RB RtJ CGI@f<= 024 ?`S`8A rB (WSA) . C:qK<= CMHKg<`; nGLHK:p<= }A`f<`; CI@8@<= C%O$<= ?OJ`]@<= NX(= s`M@<= ./ }@&H =24X. ^t[@<= }GP&L< "I$@<= XK <= RHR8L< CGD`~8<= }GI8B |=KW= n<2S rB .V7.1- HYSYS }J`]A }S rGMIL< "I$@<= +E=K8<= CWEF "<= }\ZL<= rB. CGI@fI< C:~t<`; CW`W)<= utJ }$@B .L<= >HK:p<= RG~Se 6<`% j`Lik .<=ZL<= "IJ CqZ;K@<=X )]8@<= CH2PB E`GLS 4 & 6 mole% SO2 `@4 UGL<`8< `YLAK; CGI@f<= +`S`8A ./ `M9Q `YA=RzLDe rB 6G9 }J`]@<= }p< )]8@<= }A`f<= CG@S RHR8B n<2SX +R9 "IJ }d=F ?`GI@fI< CwGLi +E=K8<= UA +K:LfA CG@S RG<ZB rB (94.7%) 6% SO2 ^A CiE`MA ( , 89 ) NZ8B C:~i "IJe "gJe. 4% SO2 NX(= }J`]@I< .+EX`wA ?=R9Z< UGz~L<= ?`GI@J ./ `YA=RzLD= Up@H Xe ?`tG;EZB }d=F C.`q "<= +R-=)<= +E=K8<= 024 }HZ8B `xHe Up@HX. +R9Z<=

69

Potrebbero piacerti anche

- Topsoe Wsa Process Principles 0Documento4 pagineTopsoe Wsa Process Principles 0Carlos de la TorreNessuna valutazione finora

- Topsoe Wsa Meet Industry DemandsDocumento6 pagineTopsoe Wsa Meet Industry DemandsBobie C. KurniawanNessuna valutazione finora

- Sulfuric Acid Manufacturing PlantDocumento6 pagineSulfuric Acid Manufacturing PlantmichsantosNessuna valutazione finora

- Overview of The ProcessDocumento10 pagineOverview of The ProcessChaitanya PottiNessuna valutazione finora

- Sulphuric Acid in Chemical TechnologyDocumento7 pagineSulphuric Acid in Chemical TechnologyShahzil RehmanNessuna valutazione finora

- Troubleshooting Guide For Sulfuric AcidDocumento27 pagineTroubleshooting Guide For Sulfuric AcidEduardo Magallon100% (1)

- Proses Wsa 1Documento19 pagineProses Wsa 1Lily DianaNessuna valutazione finora

- Kinetics and Modelling of The S02 To The SO3 ProcessDocumento23 pagineKinetics and Modelling of The S02 To The SO3 ProcessAbdullah KhanNessuna valutazione finora

- Msds Molten SulphurDocumento9 pagineMsds Molten SulphurLily DianaNessuna valutazione finora

- SAPDocumento16 pagineSAPsourav84Nessuna valutazione finora

- Low Temperature Corrosion in Boiler and Its PreventionDocumento5 pagineLow Temperature Corrosion in Boiler and Its PreventionKhurram ShahzadNessuna valutazione finora

- COBRAS 2015 HaldorTopsoe WSARioSecoDocumento25 pagineCOBRAS 2015 HaldorTopsoe WSARioSecoBambang HermawanNessuna valutazione finora

- Absorption of CO2 in Aqueous DiglycolamineDocumento10 pagineAbsorption of CO2 in Aqueous DiglycolamineLê Vinh HảoNessuna valutazione finora

- Oxidation of Sulfur Dioxide Heterogeneous CatalystDocumento13 pagineOxidation of Sulfur Dioxide Heterogeneous Catalysthafidz maNessuna valutazione finora

- Sulfuric Acid Manufacturing ProcessDocumento5 pagineSulfuric Acid Manufacturing ProcessamirahabidinNessuna valutazione finora

- Pra Perancangan Pabrik Diamonium Fosfat Dengan Proses Tennessee Valley Authority (TVA)Documento6 paginePra Perancangan Pabrik Diamonium Fosfat Dengan Proses Tennessee Valley Authority (TVA)Laras SubektiNessuna valutazione finora

- Sulfur Recovery PDFDocumento32 pagineSulfur Recovery PDFShaho Abdulqader Mohamedali0% (1)

- Lant in PT. Petrokimia Gresik: Flow Diagram of The Process To Making Sulfuric AcidDocumento3 pagineLant in PT. Petrokimia Gresik: Flow Diagram of The Process To Making Sulfuric AcidAnisa SudarmajiNessuna valutazione finora

- Lecture 1 - Sulfur and Sulfuric AcidDocumento9 pagineLecture 1 - Sulfur and Sulfuric AcidNayan HalderNessuna valutazione finora

- Sulphuric Acid Process Flow ChartDocumento1 paginaSulphuric Acid Process Flow ChartPoon CYNessuna valutazione finora

- Mass Balance For CS2 PlantDocumento3 pagineMass Balance For CS2 PlantAshish GoelNessuna valutazione finora

- 2014 Suphur Mag Article S-354-WasteHeatBoilers PMIDocumento4 pagine2014 Suphur Mag Article S-354-WasteHeatBoilers PMIEjaj SiddiquiNessuna valutazione finora

- Urea ModelingDocumento20 pagineUrea ModelingekmagisNessuna valutazione finora

- Packed Bed ColumnDocumento14 paginePacked Bed ColumnUmar DrazNessuna valutazione finora

- AbsorbtionDocumento16 pagineAbsorbtionLuciano EbangNessuna valutazione finora

- The Uhde Ammonia ProcessesDocumento2 pagineThe Uhde Ammonia ProcessesMohamed R BeialyNessuna valutazione finora

- Sulfuric Acid SimulationManualDocumento206 pagineSulfuric Acid SimulationManualpdaga1969138375% (4)

- Acid DewpointDocumento4 pagineAcid DewpointCowdrey IlanNessuna valutazione finora

- Absorption Flue GasDocumento62 pagineAbsorption Flue GasReza RhiNessuna valutazione finora

- Graduation-Project - Sulfuric AcidDocumento195 pagineGraduation-Project - Sulfuric AcidMuntazer QasimNessuna valutazione finora

- Liquid SO2.1Documento13 pagineLiquid SO2.1Musyafa WiryantoNessuna valutazione finora

- Presentation Lumped Parameter Model, Conservation of Mass, Reaction (Group 6) FixDocumento16 paginePresentation Lumped Parameter Model, Conservation of Mass, Reaction (Group 6) FixPrayogo KuntoroNessuna valutazione finora

- Assignment 4 5Documento4 pagineAssignment 4 5maluNessuna valutazione finora

- Gas Absorption in Packed Tower (S1 2015) (Note)Documento51 pagineGas Absorption in Packed Tower (S1 2015) (Note)venkieeNessuna valutazione finora

- MATLAB ProjectsDocumento2 pagineMATLAB ProjectsNidhi ChauhanNessuna valutazione finora

- Types of SteamDocumento13 pagineTypes of SteamDuy Nguyen Duc100% (1)

- Ammonia and Urea Production PDFDocumento10 pagineAmmonia and Urea Production PDFئارام ناصح محمد حسێنNessuna valutazione finora

- Catalyst Poisoning or DeactivationDocumento2 pagineCatalyst Poisoning or Deactivationdimas setyawan100% (1)

- Ammonia The Next StepDocumento11 pagineAmmonia The Next StepmuralleroNessuna valutazione finora

- Case Study 109 Ammonia OxidationDocumento9 pagineCase Study 109 Ammonia OxidationkaalkankNessuna valutazione finora

- Catalytic Role of Process Dust in SO2-To-SO3 ConveDocumento9 pagineCatalytic Role of Process Dust in SO2-To-SO3 ConveabderrahimnNessuna valutazione finora

- Sulfuric AcidDocumento14 pagineSulfuric AcidAkh KreshnaNessuna valutazione finora

- Strategies For Reducing Start-Up Emissions From Sulfuric Acid PlantsDocumento19 pagineStrategies For Reducing Start-Up Emissions From Sulfuric Acid PlantsAbu Izzan Al BunyNessuna valutazione finora

- Vapour Pressure DataDocumento44 pagineVapour Pressure Dataramsrivatsan50% (2)

- Amine Recovery Unit (ARU) : E. BayanjargalDocumento12 pagineAmine Recovery Unit (ARU) : E. BayanjargalBayanjargal ErdeneeNessuna valutazione finora

- HimmelblauDocumento17 pagineHimmelblauadilla nitaaNessuna valutazione finora

- Thermal Efficiency of Turbine in A Thermal Power PlantDocumento6 pagineThermal Efficiency of Turbine in A Thermal Power PlantRavishankarNessuna valutazione finora

- Sulphonation and LABS Formulation Using SO3-AIR MethodDocumento3 pagineSulphonation and LABS Formulation Using SO3-AIR Methodaneece786Nessuna valutazione finora

- Dual ProcessDocumento2 pagineDual ProcessSiranjeevi DayalanNessuna valutazione finora

- Calculation of Sulphur Melting Steam RequirementDocumento2 pagineCalculation of Sulphur Melting Steam RequirementAnonymous jAQnoacHcNessuna valutazione finora

- Oleum 65%Documento12 pagineOleum 65%Yalamati Satyanarayana100% (1)

- Ammonia: Lecture: 6 Ammonia Dr. N. K. PatelDocumento10 pagineAmmonia: Lecture: 6 Ammonia Dr. N. K. PatelKrishna YeoleNessuna valutazione finora

- 2000 Ifa Neworleans GobbitDocumento14 pagine2000 Ifa Neworleans GobbitFajar ZonaNessuna valutazione finora

- 8.10 Sulfuric Acid 8.10.1 General1-2 Sulfuric Acid (H2SO4) Is ADocumento9 pagine8.10 Sulfuric Acid 8.10.1 General1-2 Sulfuric Acid (H2SO4) Is AgetaddNessuna valutazione finora

- Producción Del Ácido SulfúricoDocumento102 pagineProducción Del Ácido SulfúricoLuis Diego Cardenas PadillaNessuna valutazione finora

- Distillation ColumnDocumento49 pagineDistillation ColumngenergiaNessuna valutazione finora

- Chlorine: International Thermodynamic Tables of the Fluid StateDa EverandChlorine: International Thermodynamic Tables of the Fluid StateNessuna valutazione finora

- Halogen ChemistryDa EverandHalogen ChemistryViktor GutmannValutazione: 5 su 5 stelle5/5 (1)

- Gasification Based Topsoe WSA Process PrinciplesDocumento4 pagineGasification Based Topsoe WSA Process PrinciplesGopiNessuna valutazione finora

- Miscellaneous Treatment Processes PDFDocumento6 pagineMiscellaneous Treatment Processes PDFAhmed AliNessuna valutazione finora

- Problems: CHEM1020Documento45 pagineProblems: CHEM1020Ahmed AliNessuna valutazione finora

- Applications of Egg Shell and Egg Shell Membrane As AdsorbentsDocumento13 pagineApplications of Egg Shell and Egg Shell Membrane As AdsorbentsAhmed AliNessuna valutazione finora

- 04-Control of Volatile Organic Compounds (VOCs)Documento187 pagine04-Control of Volatile Organic Compounds (VOCs)Ahmed AliNessuna valutazione finora

- Heat ProblemsDocumento17 pagineHeat ProblemsAhmed AliNessuna valutazione finora

- Dedicated System For Production of Food Grade Product: Limestone Caco + 2Hcl Co + H O + Cacl Hydrochloric AcidDocumento1 paginaDedicated System For Production of Food Grade Product: Limestone Caco + 2Hcl Co + H O + Cacl Hydrochloric AcidAhmed AliNessuna valutazione finora

- Design and Construction of Waste Paper' Recycling PlantDocumento12 pagineDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Extraction of Chlorophyll From Alfalfa PlantDocumento13 pagineExtraction of Chlorophyll From Alfalfa PlantAhmed AliNessuna valutazione finora

- Evap DesignDocumento16 pagineEvap DesignAhmed Ali100% (3)

- 1992 Lazaridis Daf Metal IonsDocumento16 pagine1992 Lazaridis Daf Metal IonsAhmed AliNessuna valutazione finora

- Design and Construction of Waste Paper' Recycling PlantDocumento12 pagineDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Soxhlet Ex.Documento2 pagineSoxhlet Ex.Ahmed AliNessuna valutazione finora

- Planetary Characteristics: © Sarajit Poddar, SJC AsiaDocumento11 paginePlanetary Characteristics: © Sarajit Poddar, SJC AsiaVaraha Mihira100% (11)

- BSN Curriculum 2012Documento1 paginaBSN Curriculum 2012Joana Bless PereyNessuna valutazione finora

- Density-Based Methods: DBSCAN: Density-Based Clustering Based On Connected Regions With High DensityDocumento3 pagineDensity-Based Methods: DBSCAN: Density-Based Clustering Based On Connected Regions With High DensityKingzlynNessuna valutazione finora

- (Q2) Electrochemistry 29th JulyDocumento21 pagine(Q2) Electrochemistry 29th JulySupritam KunduNessuna valutazione finora

- Philips Family Lamp UV CDocumento4 paginePhilips Family Lamp UV CmaterpcNessuna valutazione finora

- Ar ExportsDocumento1 paginaAr ExportsRais AlamNessuna valutazione finora

- Beauty Therapy Thesis SampleDocumento8 pagineBeauty Therapy Thesis Samplerachelvalenzuelaglendale100% (2)

- Caeneus and PoseidonDocumento77 pagineCaeneus and PoseidonSabrina CareyNessuna valutazione finora

- NHouse SelfBuilder Brochure v2 Jan19 LowresDocumento56 pagineNHouse SelfBuilder Brochure v2 Jan19 LowresAndrew Richard ThompsonNessuna valutazione finora

- 4th Six Weeks RecoveryDocumento8 pagine4th Six Weeks RecoveryAshley HighNessuna valutazione finora

- Lion's Path - Charles MuseeDocumento57 pagineLion's Path - Charles MuseeBob Sagat75% (4)

- Indian Standard: Methods of Chemical Testing of LeatherDocumento75 pagineIndian Standard: Methods of Chemical Testing of LeatherAshish DixitNessuna valutazione finora

- ME 175A Midterm SolutionsDocumento4 pagineME 175A Midterm SolutionsDavid ChonNessuna valutazione finora

- Industrial Training Report (Kapar Power Plant)Documento40 pagineIndustrial Training Report (Kapar Power Plant)Hakeemi Baseri100% (2)

- Local AnesthesiaDocumento55 pagineLocal AnesthesiaAhmed MagdyNessuna valutazione finora

- Energy Thesis StatementDocumento6 pagineEnergy Thesis Statementnicoledixonmobile100% (2)

- MFI 2 - Unit 3 - SB - L+SDocumento10 pagineMFI 2 - Unit 3 - SB - L+SHoan HoàngNessuna valutazione finora

- Tyre Industry in IndiaDocumento14 pagineTyre Industry in IndiaH Janardan PrabhuNessuna valutazione finora

- Qualitest Canada BrochureDocumento7 pagineQualitest Canada BrochureBala SingamNessuna valutazione finora

- Tabla QuimicaDocumento12 pagineTabla QuimicaPablo PasqualiniNessuna valutazione finora

- Instant Download Professional Nursing Practice Concepts Perspectives 7th Blais Hayes Test Bank PDF ScribdDocumento32 pagineInstant Download Professional Nursing Practice Concepts Perspectives 7th Blais Hayes Test Bank PDF ScribdDanielle Searfoss100% (10)

- IPC 4552 Cuprins - ENIG PDFDocumento3 pagineIPC 4552 Cuprins - ENIG PDFMarlon CornejoNessuna valutazione finora

- Cigarettes and AlcoholDocumento1 paginaCigarettes and AlcoholHye Jin KimNessuna valutazione finora

- Asme Code Qualification of Pipe Bends With Localized Wall Thinning PDFDocumento8 pagineAsme Code Qualification of Pipe Bends With Localized Wall Thinning PDFZhiqiang GuNessuna valutazione finora

- Em - Animals A To ZDocumento9 pagineEm - Animals A To ZgowriNessuna valutazione finora

- DHL Product Solutions Portfolio 2017Documento1 paginaDHL Product Solutions Portfolio 2017Hanzla TariqNessuna valutazione finora

- Math Diagnostic ExamDocumento4 pagineMath Diagnostic ExamMananquil JeromeNessuna valutazione finora

- Sunday Afternoon, October 27, 2013: TechnologyDocumento283 pagineSunday Afternoon, October 27, 2013: TechnologyNatasha MyersNessuna valutazione finora

- Sr. IBS DAS Consultant EngineerDocumento4 pagineSr. IBS DAS Consultant EngineerMohamed KamalNessuna valutazione finora

- Feasibility Study of Creating Spaces For Cultural Tourism Under The Floating Market Concept at Nong Han Lake, Sakon Nakhon, ThailandDocumento5 pagineFeasibility Study of Creating Spaces For Cultural Tourism Under The Floating Market Concept at Nong Han Lake, Sakon Nakhon, ThailandInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora