Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

C18 Fire Pump 597 BKW 800 BHP 1750 RPM PDF

Caricato da

Denis JimenezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

C18 Fire Pump 597 BKW 800 BHP 1750 RPM PDF

Caricato da

Denis JimenezCopyright:

Formati disponibili

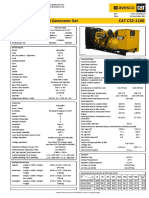

C18 ACERT Fire Pump

Tier 2 597 bkW/800 bhp @ 1750 rpm

CATERPILLAR ENGINE SPECIFICATIONS

I-6, 4-Stroke-Cycle Diesel Bore......................................................145.0 mm (5.71 in) Stroke.....................................................183.0 mm (7.2 in) Displacement.................................... 18.1 L (1,104.53 in3) Aspiration...............................Turbocharged Aftercooled Compression Ratio...................................................16.3:1 Rotation (from flywheel end).............. Counterclockwise Weight, Net Dry (approximate)............ 1769 kg (3900 lb)

Image shown may not reflect actual engine

FEATURES

Emissions & Regulations Meets U.S. EPA Tier 2 and CARB emissions requirements. FM approved. UL listed - US and Canada. Meets NFPA 20 requirements. Worldwide Supplier Capability Caterpillar - Casts engine blocks, heads, cylinder liners, and flywheel housings - Machines critical components - Assembles complete engine - Factory-designed systems built at Caterpillar ISO 9001:2000 certified facilities Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable product. Testing Prototype testing on every model: - proves computer design - verifies system torsional stability - functionality tests every model Every Caterpillar engine is dynamometer tested under full load to ensure proper engine performance. Full Range of Attachments Wide range of bolt-on system expansion attachments, factory designed and tested. Unmatched Product Support Offered Through Worldwide Caterpillar Dealer Network More than 1,800 dealer outlets Caterpillar factory-trained dealer technicians service every aspect of your industrial engine 99.7% of parts orders filled within 24 hours worldwide Caterpillar parts and labor warranty Preventive maintenance agreements available for repair before failure options Scheduled Oil Sampling program matches your oil sample against Caterpillar set standards to determine: - internal engine component condition - presence of unwanted fluids - presence of combustion by-products Web Site For all your industrial power requirements, visit www.cat-industrial.com.

15 December 2009

1:43 PM

C18 ACERT Fire Pump

Tier 2 597 bkW/800 bhp @ 1750 rpm

Instrumentation Instrument panel, LH Engine oil pressure gauge Voltmeter gauge Water temperature gauge Tachometer / engine hour meter Lube System Crankcase breather, front valve cover Oil cooler, RH (dual) Oil filter, RH Oil pan, front sump Oil filler, LH front Oil dipstick, LH front Oil pump Mounting System Front and rear support Power Take-Offs Flywheel stub shaft Protection System Stop-Start System, automatic (compatible with NFPA 20 requirements, able to be energized from either of two battery sources and capable of manual starter actuation) Starting System 24 volt, LH electric starting motor Jacket water heater (3 kW, 120-240 volt) General Vibration damper and guard Paint, Caterpillar fire pump red Lifting eyes Automatic variable timing, electronic Electronic installation kit, 70 pin connector (connectors, pins, sockets) Literature, Owner and Operator's Manual

STANDARD ENGINE EQUIPMENT

Air Inlet System Dual turbocharger: front and rear inlet, 127.0 mm (5.0 in) Separate Circuit Aftercooled (SCAC) Charging System Charging alternator 24 volt, 50 amp Control System Dual Electronic Control Modules (ECMs) - primary and secondary Electronic governing, PTO speed control Programmable ratings Cold mode start strategy Automatic altitude compensation Power compensation for fuel temperature Programmable low and high idle and total engine limit (TEL) Electronic diagnostics and fault logging Engine monitoring and protection system (speeds, temperature, pressure) J1939 Broadcast (diagnostic, engine status and control) Cooling System Thermostats and housing, vertical outlet Jacket water pump, gear driven, centrifugal Heat exchanger (installed) Expansion tank Exhaust System Exhaust manifold, dry Dual turbo: exhaust elbow, dry 203 mm (8 in) Flywheels and Flywheel Housing Flywheel, SAE #1 Flywheel housing, SAE #1 SAE standard rotation Fuel System Electronic unit injector Fuel filter, secondary, mid-mount (LH 2 micron high performance) Fuel transfer pump, LH front Fuel priming pump, LH mid-mount Fuel sample valve, mounted on fuel filter base Primary filter / water separator

16 November 2009

3:05 PM

C18 ACERT Fire Pump

Tier 2 597 bkW/800 bhp @ 1750 rpm

PERFORMANCE CURVES

DM9854-01 IND - E - DM9854-01

Performance curve is not shown since fire pump technical data is published at constant speed (rpm). Below data is shown from 100% load to 10% load.

Engine Speed Engine Power rpm kW 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 597 537 477 447 418 358 60 298 239 179 149 119 60 358

Torque Nm 3255 2929 2604 2441 2278 1953 325 1627 1302 976 814 651 325 1953

BSFC g/kW-hr Fuel Rate L/hr 212.5 213 215.8 217.5 218 219.2 339.9 221 225.3 234.4 242.6 257.4 339.9 219.2 151.1 136.3 122.8 116.0 108.5 93.5 24.2 78.6 64.1 50.0 43.1 36.6 24.2 93.5

16 November 2009

3:05 PM

C18 ACERT Fire Pump

Tier 2 597 bkW/800 bhp @ 1750 rpm

PERFORMANCE CURVES

DM9854-01 IND - E - DM9854-01

Performance curve is not shown since fire pump technical data is published at constant speed (rpm). Below data is shown from 100% load to 10% load.

Engine Speed Engine Power Engine Torque BSFC lb/bhp-hr rpm bhp lbft 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 1750 800 720 640 600 560 480 80 400 320 240 200 160 80 480 2401 2160 1921 1800 1680 1440 240 1200 960 720 600 480 240 1440 .349 .350 .355 .358 .358 .360 .559 .363 .370 .385 .399 .423 .559 .360

Fuel Rate gal/hr 39.9 36.0 32.4 30.6 28.7 24.7 6.4 20.8 16.9 13.2 11.4 9.7 6.4 24.7

16 November 2009

3:05 PM

C18 ACERT Fire Pump

Tier 2 597 bkW/800 bhp @ 1750 rpm

Engine Performance Diesel Engines 7 liter and higher All rating conditions are based on SAE J1995, inlet air standard conditions of 99 kPa (29.31 in. Hg) dry barometer and 25C (77F) temperature. Performance measured using a standard fuel with fuel gravity of 35 API having a lower heating value of 42,780 kJ/kg (18,390 btu/lb)when used at 29 C (84.2 F) with a density of 838.9 g/L.

RATINGS AND CONDITIONS

Standby Fire Pump Ratings represent the output which may be utilized to drive stationary fire pumps where the pumping equipment has been sized according to NFPA 20 standards. Engine rating is FM approved and UL listed (US and Canada).

Engine Dimensions

(1) Length (2) Width (3) Height 1889.0 mm (74.37 in) 1091.0 mm (42.95 in) 1379.7 mm (54.32 in) Note: Do not use for installation design. See general dimension drawings for detail (Drawing # 3222516). null ).

Performance Number: DM9854-01 Feature Code: C18DF03 Arr. Number: 3149714 Materials and specifications are subject to change without notice. 15474965

2009 Caterpillar All rights reserved. The International System of Units (SI) is used in this publication. CAT, CATERPILLAR, SAFETY.CAT.COM their respective logos, "Caterpillar Yellow," and the POWER EDGE trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Potrebbero piacerti anche

- Spec Sheet Industry 170HP Tot 450HPDocumento34 pagineSpec Sheet Industry 170HP Tot 450HPJonh BladerNessuna valutazione finora

- C15 Acert Spec SheetDocumento4 pagineC15 Acert Spec SheetMalasquez Leon XavierNessuna valutazione finora

- Cat® Engine Specifications: C18 Acert Industrial EngineDocumento5 pagineCat® Engine Specifications: C18 Acert Industrial EngineAsif MehmoodNessuna valutazione finora

- 3512B 1500RPM 1300KW BrochureDocumento4 pagine3512B 1500RPM 1300KW BrochuresalembatopNessuna valutazione finora

- Cat-3508b - DSDocumento2 pagineCat-3508b - DSfwklNessuna valutazione finora

- Cat C 15 AccertDocumento4 pagineCat C 15 AccertRobles JmrNessuna valutazione finora

- Cat 3406C 380HP D RatingDocumento4 pagineCat 3406C 380HP D RatingDian Aprilia II100% (1)

- Cat 3306B DITA PropulsionDocumento40 pagineCat 3306B DITA PropulsionStroe VladNessuna valutazione finora

- Cat 12Documento4 pagineCat 12Surya Chala PraveenNessuna valutazione finora

- 6BT5.9-DM Non-Certified Ratings SSDocumento2 pagine6BT5.9-DM Non-Certified Ratings SStempro100% (1)

- c6.6 Acert M200 PDFDocumento2 paginec6.6 Acert M200 PDFANA MARIA MEZA SANABRIANessuna valutazione finora

- Every Ton.: Non-Certified Engines For Mining ApplicationsDocumento4 pagineEvery Ton.: Non-Certified Engines For Mining ApplicationsCarlos andres Revelo gomezNessuna valutazione finora

- Qsx15 BrochureDocumento8 pagineQsx15 BrochureferminNessuna valutazione finora

- Governor (Types I, II, IV, and V) - CheckDocumento5 pagineGovernor (Types I, II, IV, and V) - CheckDaniel TekleNessuna valutazione finora

- Remove Install Overhaul Turbo PDFDocumento3 pagineRemove Install Overhaul Turbo PDFOskars ŠtālsNessuna valutazione finora

- P11X21EN New Global Engine Range - 280851Documento16 pagineP11X21EN New Global Engine Range - 280851Jan HendriksNessuna valutazione finora

- Specifications KTA38 G DRIVEDocumento2 pagineSpecifications KTA38 G DRIVEMehdi ChakrouneNessuna valutazione finora

- Performing A Multiple Cylinder Cutout TestDocumento14 paginePerforming A Multiple Cylinder Cutout TestHarzanyi MaldonadoNessuna valutazione finora

- Injector Flow Curve - Tech CornerDocumento3 pagineInjector Flow Curve - Tech CornerRoman AdamNessuna valutazione finora

- Inyector E7 PDFDocumento5 pagineInyector E7 PDFBryan TulpaNessuna valutazione finora

- Tad 722 GeDocumento2 pagineTad 722 GePaulo César Managó100% (1)

- Water PumpsDocumento119 pagineWater PumpsLesly LeslyNessuna valutazione finora

- Fire Fighting Pump TigrisDocumento14 pagineFire Fighting Pump TigrisLyyzza MamboNessuna valutazione finora

- Belaz 75137 Usa and CanadaDocumento2 pagineBelaz 75137 Usa and CanadabasNessuna valutazione finora

- TR50D Optimizing Maintenance ManualDocumento436 pagineTR50D Optimizing Maintenance ManualMuhammad NovanNessuna valutazione finora

- QST30 MineriaDocumento4 pagineQST30 MineriaElio Custodio Huachaca100% (1)

- Cummins Kta38 M: Unit Injector Low RPM High Torque Heat Exchanger or Keel CoolingDocumento2 pagineCummins Kta38 M: Unit Injector Low RPM High Torque Heat Exchanger or Keel CoolingMuhammad rizkiNessuna valutazione finora

- Motores QST30Documento4 pagineMotores QST30maguilla7Nessuna valutazione finora

- KTA50 M2 1600hkDocumento2 pagineKTA50 M2 1600hkGabriel Andres ValenciaNessuna valutazione finora

- V222TIDocumento2 pagineV222TIcmendezNessuna valutazione finora

- QSK19 M 660hkDocumento2 pagineQSK19 M 660hkAinur Bamol Namsembilan100% (1)

- Lovol - Engine - Catalogue - IEP Power (FILTERS, PARTS, DATASHEET, CURVES)Documento32 pagineLovol - Engine - Catalogue - IEP Power (FILTERS, PARTS, DATASHEET, CURVES)Wilson SuárezNessuna valutazione finora

- 1 Defence University, College of EngineeringDocumento41 pagine1 Defence University, College of EngineeringGetachew TikueNessuna valutazione finora

- 6ey17w PDFDocumento1 pagina6ey17w PDFfajee_faridNessuna valutazione finora

- Air Compressor PDS175 BrochureDocumento1 paginaAir Compressor PDS175 BrochureTom Karewur100% (1)

- Cheking Fuel mx13Documento5 pagineCheking Fuel mx13Robles JmrNessuna valutazione finora

- Generator Set Performance: ApplicationDocumento8 pagineGenerator Set Performance: Applicationpurnomno sidiNessuna valutazione finora

- DX700LC PDFDocumento20 pagineDX700LC PDFA Ramos GabyNessuna valutazione finora

- Cat C32-1100 en PDFDocumento1 paginaCat C32-1100 en PDFOsanebi Chukwudi LuckyNessuna valutazione finora

- Spesifications of Hino Ranger FM 260,320 Series (6X4)Documento5 pagineSpesifications of Hino Ranger FM 260,320 Series (6X4)MuhaiminNessuna valutazione finora

- 03 Mechanical AdjustmentDocumento25 pagine03 Mechanical AdjustmentHải Lưu MinhNessuna valutazione finora

- Cummins n855 Engine Specs PDF FreeDocumento6 pagineCummins n855 Engine Specs PDF Freema.powersourceNessuna valutazione finora

- CD300M Dri-Prime® Pump: Features and Benefits SpecificationsDocumento2 pagineCD300M Dri-Prime® Pump: Features and Benefits Specificationsahmedomar_953724702Nessuna valutazione finora

- QSK60 G6 PDFDocumento2 pagineQSK60 G6 PDFShahzad Ali100% (2)

- EURO-II-Tatra 8X8 T815 1R-50T-4150Documento1 paginaEURO-II-Tatra 8X8 T815 1R-50T-4150Satish ReddyNessuna valutazione finora

- INSITE - 6.4 Overview Rev For HHIDocumento99 pagineINSITE - 6.4 Overview Rev For HHIsengottaiyanNessuna valutazione finora

- 4 Stroke Petrol Engine1699240011Documento7 pagine4 Stroke Petrol Engine1699240011Masoud doski100% (1)

- QSK19 DM PDFDocumento2 pagineQSK19 DM PDFSoumya Ranjan Nayak100% (2)

- 6HYM ETE BrochureDocumento2 pagine6HYM ETE BrochureRudy PriatnaNessuna valutazione finora

- Catálogo de Productos MarinosDocumento102 pagineCatálogo de Productos MarinosYoni Sanchez HernandezNessuna valutazione finora

- HD150 Smanual Completed - MasterDocumento35 pagineHD150 Smanual Completed - Masterjacklyn ade putraNessuna valutazione finora

- Kta38 G5Documento2 pagineKta38 G5Patricio Andres Ibañez ConchaNessuna valutazione finora

- Governor (Types I, II, and Some III) - AdjustDocumento8 pagineGovernor (Types I, II, and Some III) - AdjustDaniel TekleNessuna valutazione finora

- Petroleum Engine Caterpillar Engine Specifications: V-8, 4-Stroke-Cycle DieselDocumento4 paginePetroleum Engine Caterpillar Engine Specifications: V-8, 4-Stroke-Cycle DieselRichard Gregorio Huamani HuamanNessuna valutazione finora

- Cat 3512 1280HP A RatingDocumento4 pagineCat 3512 1280HP A RatingingjoseosunaNessuna valutazione finora

- Motor Caterpillar 3516BDocumento5 pagineMotor Caterpillar 3516BCesar Calle JimenezNessuna valutazione finora

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Documento4 pagineCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborNessuna valutazione finora

- (Lehw0191-00) 3512c (HD) Ataac With DGBDocumento4 pagine(Lehw0191-00) 3512c (HD) Ataac With DGBvictor.ciprianiNessuna valutazione finora

- G3512 SpecDocumento4 pagineG3512 SpecnunkpNessuna valutazione finora

- Cat C18 SpecSheetDocumento4 pagineCat C18 SpecSheetmschaefer_zf100% (1)

- E7700 10 10 13 - Prozesstechnik - WebDocumento24 pagineE7700 10 10 13 - Prozesstechnik - WebDenis JimenezNessuna valutazione finora

- 460-119 Hoja de Especificaciones.Documento2 pagine460-119 Hoja de Especificaciones.Denis JimenezNessuna valutazione finora

- Hydac SCADocumento6 pagineHydac SCADenis JimenezNessuna valutazione finora

- Dse4610 Dse4620 Data SheetDocumento2 pagineDse4610 Dse4620 Data SheetDenis Jimenez0% (1)

- E79000-2-04-13 FS Buch WWWDocumento291 pagineE79000-2-04-13 FS Buch WWWDenis JimenezNessuna valutazione finora

- 3612tale Jgd6 DesignDocumento1 pagina3612tale Jgd6 DesignDenis JimenezNessuna valutazione finora

- E2000 0 03 11 - SYSTEMTECHNIK - WWWDocumento8 pagineE2000 0 03 11 - SYSTEMTECHNIK - WWWDenis JimenezNessuna valutazione finora

- 1303-1512 SSPF Final InoxidableDocumento16 pagine1303-1512 SSPF Final InoxidableDenis JimenezNessuna valutazione finora

- E7710 1 06 11 - Leitungsfilter ProzessDocumento8 pagineE7710 1 06 11 - Leitungsfilter Prozessvikram_007Nessuna valutazione finora

- Inline Process FiltersDocumento7 pagineInline Process FiltersDenis JimenezNessuna valutazione finora

- Filter Bound CatalogDocumento248 pagineFilter Bound CatalogDenis JimenezNessuna valutazione finora

- 1403013194Documento1 pagina1403013194Denis JimenezNessuna valutazione finora

- Filter Bound CatalogDocumento248 pagineFilter Bound CatalogDenis JimenezNessuna valutazione finora

- Fluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDocumento12 pagineFluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDenis JimenezNessuna valutazione finora

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocumento20 pagineBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNessuna valutazione finora

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDocumento12 pagineAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezNessuna valutazione finora

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDocumento12 pagineAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezNessuna valutazione finora

- E18061 2 0 11 13 - HNS3000Documento2 pagineE18061 2 0 11 13 - HNS3000Denis JimenezNessuna valutazione finora

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocumento20 pagineBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNessuna valutazione finora

- E5601 PTKDocumento4 pagineE5601 PTKDenis JimenezNessuna valutazione finora

- E831BDocumento4 pagineE831BDenis JimenezNessuna valutazione finora

- 105388Documento4 pagine105388Denis JimenezNessuna valutazione finora

- 1403013194Documento1 pagina1403013194Denis JimenezNessuna valutazione finora

- E5601 13 04 07 - PT Neu2Documento5 pagineE5601 13 04 07 - PT Neu2Denis JimenezNessuna valutazione finora

- E2902 4 03 13 - Pumpen Uebersicht - LQDocumento20 pagineE2902 4 03 13 - Pumpen Uebersicht - LQDenis Jimenez0% (1)

- E7109 4-03-12 RFLD Guss KatalogversionDocumento8 pagineE7109 4-03-12 RFLD Guss KatalogversionDenis JimenezNessuna valutazione finora

- E831BDocumento4 pagineE831BDenis JimenezNessuna valutazione finora

- Pastillas HSH 1v 1t 5wDocumento1 paginaPastillas HSH 1v 1t 5wDenis JimenezNessuna valutazione finora

- E7113 4 03 12 - NFD KatalogversionDocumento8 pagineE7113 4 03 12 - NFD KatalogversionDenis JimenezNessuna valutazione finora

- E7113 4 03 12 - NFD KatalogversionDocumento8 pagineE7113 4 03 12 - NFD KatalogversionDenis JimenezNessuna valutazione finora

- R2S Turbo SystemsDocumento22 pagineR2S Turbo SystemsderekrichnerNessuna valutazione finora

- Tyreman CalculationDocumento9 pagineTyreman CalculationMukti AliNessuna valutazione finora

- Jeep Grand Cherokee WJ Electrical Wiring DiagramDocumento576 pagineJeep Grand Cherokee WJ Electrical Wiring Diagramdascalumihaipuiu85% (97)

- Cars Insurance Project SamuelDocumento21 pagineCars Insurance Project Samuelsneha sharmaNessuna valutazione finora

- 3.4 Hyundai - Mạch Điện 2020 Engine D6HA (Euro-5)Documento11 pagine3.4 Hyundai - Mạch Điện 2020 Engine D6HA (Euro-5)1360Nguyễn Hoàng NhậtNessuna valutazione finora

- TJ89PE5CDocumento1 paginaTJ89PE5Cblago956Nessuna valutazione finora

- Mine Resistant Ambush Protected (MRAP) Vehicle: Vehicle Management Codes: C507, L290 - L296Documento80 pagineMine Resistant Ambush Protected (MRAP) Vehicle: Vehicle Management Codes: C507, L290 - L296abduallah muhammadNessuna valutazione finora

- Petrol Engine Twin Camshaft Setting-Locking Tool KitsDocumento9 paginePetrol Engine Twin Camshaft Setting-Locking Tool KitsCristian CernaNessuna valutazione finora

- CCG125Documento88 pagineCCG125Arnold M Olaya RomeroNessuna valutazione finora

- 3K Service Manual 4th Gen SM4013EN 200906Documento308 pagine3K Service Manual 4th Gen SM4013EN 200906tejonmxNessuna valutazione finora

- 2020 Volkswagen Id 3Documento708 pagine2020 Volkswagen Id 3Dave FullerNessuna valutazione finora

- Bell Uh-1 Iroquois & Ah-1 HueycobraDocumento21 pagineBell Uh-1 Iroquois & Ah-1 HueycobraGiora MinorNessuna valutazione finora

- Washer C/Rail-Bosch Siemens: Ref/-F00VC17503 F00RC00309Documento2 pagineWasher C/Rail-Bosch Siemens: Ref/-F00VC17503 F00RC00309Merabet KhaledNessuna valutazione finora

- MitsubishiDocumento7 pagineMitsubishiJhon Sanchez LopezNessuna valutazione finora

- Tuono V4 - Technical SpecificationsDocumento1 paginaTuono V4 - Technical SpecificationsDONALD DHASNessuna valutazione finora

- Lab Sheet - Wheel BalancingDocumento2 pagineLab Sheet - Wheel BalancingAkmal DanialNessuna valutazione finora

- Fb275btb ManualDocumento2 pagineFb275btb ManualClodoaldo De Melo PereiraNessuna valutazione finora

- T CP ZTHDocumento63 pagineT CP ZTHgoomba100% (2)

- Cdin Reviewer HahaDocumento6 pagineCdin Reviewer HahaJanelle AustriaNessuna valutazione finora

- GSX-R1000 (UF/Z/ZUF) L3: Parts CatalogueDocumento277 pagineGSX-R1000 (UF/Z/ZUF) L3: Parts CatalogueRea Cleare TampusNessuna valutazione finora

- Jeep Parts List 2003 KJDocumento533 pagineJeep Parts List 2003 KJlilfroger100% (3)

- Office ComparisonDocumento44 pagineOffice ComparisondeenoumNessuna valutazione finora

- Himalayan 2 PDFDocumento20 pagineHimalayan 2 PDFJulian GallegoNessuna valutazione finora

- AXODDocumento51 pagineAXODWin CardonaNessuna valutazione finora

- Year MOBDII Generic Communication Protocols by Manufacturer OdelsDocumento6 pagineYear MOBDII Generic Communication Protocols by Manufacturer Odelsroberto caiadoNessuna valutazione finora

- Audi Cam Lobe TSBDocumento7 pagineAudi Cam Lobe TSBCosmicdancer RudraNessuna valutazione finora

- TFG Rodrigo Vazquez CasillasDocumento181 pagineTFG Rodrigo Vazquez CasillasJhon Jaider Suarez MonsalveNessuna valutazione finora

- Welcome To The Seminar On MICROTURBINESDocumento13 pagineWelcome To The Seminar On MICROTURBINESAnonymous vxNf3n3yMNessuna valutazione finora

- Manual de Taller Corsa Diesel 1.7Documento4 pagineManual de Taller Corsa Diesel 1.7Uzuma Naru0% (2)

- PC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineDocumento12 paginePC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineJohn MkCito KINessuna valutazione finora