Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ppap For Neel Metal

Caricato da

shuklahouseTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ppap For Neel Metal

Caricato da

shuklahouseCopyright:

Formati disponibili

PPAP KIT FOR

MTG. BRACKET 15 LTR AIR TANK PART NO. F1F000914 (ON FVDP VEHICLES)

TO NEEL METAL PRODUCT LIMITED SIDCUL ,PANTNAGAR

FROM THUKRAL STEEL ENGINEERS TULSI DWAR ,KICCHA ROAD U.S.N.

Thukral Steel Engineers

DOCUMENTS INDEX FOR PPAP

PART No.:- F1F00914 #.0 PART NAME:- MIG. BRACKET -15 LTR AIR TANK S. No. REQUIREMENT Part Submission Warrant (PSW) Customer Specification Engineering Change Specification Design FMEA Process Flow Diagram Process FMEA Control Plan Pre Dispatch Inspection Report No. of Sample Product MSA / R &R Chemistry & Mechanical Test Report Third Party Chemical; LaboratoryTest report Checking Aid List Master Sample Calibration Certificate Calibration History Cards for Instrument Appearance Approval Report Bulk Material(if any) Record of Compliance (if any) Quality Management System Certificate for ISO 90012008 Reviewed By Amit Joshi Y Y Y Y Y Y N N N Y Approved By Prem Thukral Y N Y Y Y Y Y N N N Y Y Y Y N Y N STATUS ON :-

SUPPLIER :- Thukral Steel Engineers Required YES NO Y Y N N Y Y Y Y N Available YES NO Y Y N N

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Thukral Steel Engineers

STATUS ON :SUPPLIER :- Thukral Steel Engineers REMARKS

DOCUMENTS INDEX FOR PPAP

Approved By Prem Thukral

Thukral Steel Engineers

PART SUBMISSION WARRANT

Part Name

MTG.BRACKET-15 LTR AIR TANK

Yes No

Part Number

F1F00914 #.0 0

Dated Dated

Safety and/or Government Regulation

Engineering Drawing Change Level

11/5/2013

Additional Engineering Changes Shown on Drawing Number Checking Aid Number SUPPLIER MANUFACTURING INFORMATION Purchase Order No. Engineering Change Level SUBMISSION INFORMATION

Weight (kg) Dated

Thukral Steel Engineers

Supplier Name/Code

Dimensional

Materials/Function

Appearance

Tulsi Dwar , Kiccha road

Street Address

Customer Name/Division Buyer/Buyer Code

Neel Metal Products Limited /SIDCUL

Rudrapur/U.S.N/ U.K./263153

City/District/State/Pin code Note: Application

FVDP VEHICLES

Yes Yes No No

Does this part contain any restricted or reportable substances? Are plastic parts identified with appropriate ISO marking codes?

REASON FOR SUBMISSION Initial submission Engineering Change(s) Tooling: Transfer, Replacement, Refurbishment, or additional Correction of Discrepancy Tooling Inactive > than 1 year REQUESTED SUBMISSION LEVEL (Check one) Level 1 - Warrant only (and for designated appearance items, an Appearance Approval Report) submitted to customer. Level 2 - Warrant with product samples and limited supporting data submitted to customer. Level 3 - Warrant with product samples and complete supporting data submitted to customer. Level 4 - Warrant and other requirements as defined by customer. Level 5 - Warrant with product samples and complete supporting data reviewed at supplier's manufacturing location. SUBMISSION RESULTS The results for dimensional measurements These results meet all drawing and specification requirements: Mold / Cavity / Production Process DECLARATION I affirm that the samples represented by this warrant are representative of our parts, have been made to the applicable Production Part Approval Process Manual 3rd Edition Requirements. I further warrant these samples were produced at the production rate of EXPLANATION/COMMENTS: Print Name Prem Thukral Title Business Partner Phone No. 9760047600 Date FOR CUSTOMER USE ONLY (IF APPLICABLE) Approved Part Functional Approval: Rejected Other Fax No. 250 / 12 hours. I have noted any deviations from this declaration below. material and functional tests YES appearance criteria statistical process package NO (If "NO" - Explanation Required) Change to Optional Construction or Material Sub-Supplier or Material Source Change Change in Part Processing Parts produced at Additional Location Other - please specify

Blanking & shearing - punching - bending - welding - fastning - final inspection - packing

Supplier Authorized Signature

12/5/2013

Part Warrant Disposition:

Approved Waived

Customer Name

Customer Signature

Date

Thukral Steel Engineers

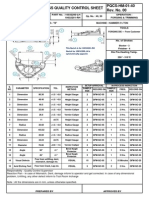

CUSTOMER SPECIFICATION

PART NAME: MTG. BRACKET-15 LTR AIR TANK PART NO. F1F00914 #.0 CUSTOMER: NEEL METAL PRODUCTS LIMITED , SIDCUL

S.no Item No. Dim. Type

PREPARED BY: Amit joshi CORE TEAM: Pryank , Ramu sharma .

Specification Length Width Hole Dim. Hole Location Hole Dim. Hole Location Length Width Hole Dim. Hole location Length Width Dimension 710 mm 25 mm 5 mm Dim : 9 0.1 mm ( From Outer Side )

DATE (ORIGIN): 15-05-2013 REV. NO: 00 REV DATE:

Customer Drawing For Reference

Blank Dim.

8.5 mm Dim : 57 0.1 mm ( from center line )

160 mm 40 mm 5 mm ( 9 mm countersunk height ) Dim : 56 0.1 mm( from centre line)

Blank Dim.

140 mm 35 mm 20 mm 55 mm(from center line) & 15 mm from outer side 111 mm

Blank Dim. Hole Dim. Hole location Arc radius

Rivet

Standard

10 X5 mm

Thukral Steel Engineers

PROCESS FLOW DIAGRAM

PART NAME: MTG. BRACKET-15 LTR AIR TANK PART NO. F1F00914 #.0 CUSTOMER:NEEL METAL PRODUCTS LIMITED , SIDCUL OPERATION & INSPECTION INSPECTION OPERATION STORAGE TRANSPORT DELAY PRODUCT CHARACTERISTICS MS Rack location defined Defined in each item flow chart Defined in each item flow chart Defined in each item flow chart Item 2 &3 ( Thick : 8-10 mm,No Welding Defect ) Properly Fit Free from burr, and sharp edges and other Weld defect PREPARED BY: Amit joshi CORE TEAM: Pryank , Ramu sharma . Process flow chart no: PFD/MTG.BRACKET /00 DATE (ORIGIN): 15-05-2013 REV. NO: 00 REV DATE:

OPER NO. DESCRIPTIION

EQUIPMENT AND FACILITY

INCOMING SOURCE OF VARIATION

10 20 30 40 50 60 70 80 100

Receiving of Material Storage

Material Test Certificate Predefined Location

Chemical Composition Handeling Inadequate Dimensions, Appearance Dimensions,location Dimensions Thick,Appearance Appearance Appearance

Blanking & Shearing Shear Cutter/Automate Punching Bending Welding Fastning & Assembly Final Inspection Dispatch to Customer CNC Turret Punch Press/Automate Bending M/c/Manual MMAW Rivited Inspection Room Dispatch Area

Thukral Steel Engineers

PROCESS FLOW DIAGRAM

Process flow chart no: PFD/MTG.BRACKET /00 DATE (ORIGIN): 15-05-2013 REV. NO: 00 REV DATE:

PROCESS CHARACTERISTICS / REMARKS

Receipt material Material Movement Component Movement Component Movement Component Movement Component Movement Component Movement Component Movement Standard Packing

Thukral Steel Engineers

POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

PROCESS PFMEA

FMEA NO. : FMEA/MTG. BRACKET/01 PART NAME :MTG. BRACKET- 15 LTR AIR TANK PART NO. : F1F00914 #.0 CORE TEAM : Mr.Pryank, Mr.Ramu Sharma , Mr. Satnam singh DATE (ORIG.) REVISION NO. : : 12/05/2013 00 -REVISION DATE :

CUSTOMER NAME : NEEL METAL PRODUCT LIMITED,SIDCUL PROCESS

PREPARED BY. :Amit Joshi C L A S S POTENTIAL CAUSE(S)/ MECHANISM(S) OF FAILURE O CURRENT PROCESS C CONTROLS PREVENTION C CURRENT PROCESS CONTROLS DETECTION

MTC, DIMENSIONAL AND VISUAL CHECK.

Opern No.

FUNCTIONS

POTENTIAL FAILURE MODE

POTENTIAL EFFECT(S) OF FAILURE

S E V

D E T

R P N

RECOMMENDED ACTION(S)

APPROVED BY : Prem Thukral RESPONSBILITY ACTION RESULTS & TARGET ACTIONS S O D COMPLETION TAKEN DATE

R P N

REQUIREMENTS

10

RECEIVING OF WRONG Material MATERIAL

Material being rejected

WRONG MATERIAL USED AT SUPPLIER END. DESIRE LOCATION NOT AVAILABLE SETTING DISTURB

SUPPLIER

20

STORAGE

Material at Improper Location Length over size

Material Mixup MATING PART NOT FIT PROPERLY PROBLEM AT CUSTOMER END MATING PART NOT FIT PROPERLY MATING PART NOT FIT PROPERLY MATING PART NOT FIT PROPERLY MATING PART NOT FIT PROPERLY PROBLEM AT CUSTOMER END PROBLEM AT CUSTOMER END IMPROPER STRENGTH IMPROPER STRENGTH

SEPARATE AREA DEFINED FOR EVERY CHECKLIST MATERIAL. LOCK PROVIDED SET UP APP &100% INSP APP &100% INSP APP &100% INSP APP &100% INSP APP &100% INSP APP &100% INSP SET UP APP &100% INSP

48

75

30

BLANKING & SHEARING Length Under Size.

SETTING DISTURB

LOCK PROVIDED

75

Improper Location

SETTING DISTURB

2 LOCK PROVIDED SET TOOL CHANGE FREQUENCY

56

Hole undersize 40 PUNCHING Hole Oversize

TOOL WORN OUT

56

TOOL WORN OUT IMPROPER CLEARENCE

SET TOOL CHANGE 2 FREQUENCY SET TOOL OR DIE 1 CHANGE FREQUENCY 2 LOCK PROVIDED

56

Burr

56

Length under size 50 BENDING Length over size .

SETTING DISTURB

50

SETTING DISTURB UNSKILLED WELDER AIR/HYDROGEN ENTRAPMENT & IMPROPER FLUX USED POWER/HEAT INPUT TO LOW IMPROPER HOLDING IN FIXTURE

LOCK PROVIDED WEDER TRANING PROVIDED PROPER SHIELDING & FLUX USED

SET UP APP &100% INSP APP &100% INSP APP &100% INSP

50

UNDER & CRACKS POROSITY & TRAPED SLAG

50

60

WELDING

50

IMPROPER PENITRATION

IMPROPER STRENGTH MATING PART NOT FIT PROPERLY DAMAGE COPONENT REACH TO THE CUSTOMER END.

PROPER APP &100% POWER/HEAT INPUT INSP PROVIDED APP &100% INSP

50

70

Fastning & Assembly

IMPROPER FASTNING

CARE WHILE 5 FIXTURING THE PART

50

90

PACKING

Job get damaged

IMPROPER PACKING METHOD

2 TRAINING

VISUAL INSPECTION

60

LEGENDS:

S = SEVERITY

O = OCCURRENCE, D = DETECTION, RPN = RISK PRIORITY NUMBER,

O AND S:(1) LOW-(10) HIGH, D=1~10 (10=REMOTE POSSIBILITY OF DETECTION)

Thukral Steel Engineers

CONTROL PLAN

Prototype Control Plan Number : Part Name : Part No. Customer Name : Part/ Process no. Process Name/ Operation Description Neel Metal Product Ltd. Machine, Device, Tool, Jig For Mfg. Material Test Certificate Chemical Composition Sheet Thickness C

MS

Pre-Launch

CP/MTG.BRACKET/01 MTG. BRACKET -15LTR AIR TANK F1F00914 #.0

Production

Core Team :Name Amit Joshi Pryank Ramu Sharma Deptt. Quality Process Process Sign.

Date ( Orig) Revision No. Revision Date : Prepared By :

: :

12/5/2013 0 -Amit Joshi Prem Thukral

Approved By : Methods

Characteristic Item no Product Process

Spl. Char. Class Product/process Specification/ Tolerance Evaluation/ Measurement Technique Material Test Certificate Micro Meter

Sample

Control Method

Reaction Plan

Size Per lot n=6

Freq. Per Lot Per Lot Raw Material Register Raw Material Register

10

Receiving of Material

All

2mm, 5 mm, 3 mm

20

Storage

Storage Area

All

Racks

Quantity

AS per Challan

100%

Lot

W.I. for Storage

Inform Head Store

Blanking & Shearing

Dimension

Dim : 709 - 711mm Dim : 26 - 24 mm

Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Standard Sample

n=7 n=7 n=7 n=7 n=7 n=7 n=7

Per Hour Per Hour Per Hour Per Hour Per Hour Per Hour Per Hour IIR IIR IIR

30

Blanking & Shearing

Bending m/c /Shear cutter

Dimension

Dim : 160 1 mm Dim : 40 1 mm Dim : 140 - 141mm

Blanking & Shearing

Dimension

Dim : 35 1 mm R : 111 0.1 mm

Dimension 1 Location

Dia : 5 - 5.1 mm Dia : 8.5 - 8.6 mm Dim : 9 0.1 mm ( From Outer Side )

Vernier Caliper Vernier Caliper Vernier Caliper

n=7 n=7 n=7 n=7 n=2 n=2 n=7

Every 2 hr Every 2 hr Every 2 hr Every 2 hr Every 2 hr Every 2 hr Every 2 hr

IIR IIR IIR IIR IIR IIR IIR

Dim : 57 0.1 mm ( from center Vernier Caliper line ) CNC Turret Punch Press/Automate

Dimension 2 Location

Dia : 5 0.1 mm Dim : 9.5 0.1 mm (counter sunk height) Dim : 56 0.1 mm(from centre line) Dia : 20 - 21 mm Dim : 15 1 mm outer side ) Dim : 55 1 mm Center Line) ( From (From

Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper

40

Punching

Inform Production & Quality Head

Dimension 3 Location

n=7 n=7

Every 2 hr Every 2 hr

IIR IIR

50 Bending 1

Bending m/c

Diameter Dimension 2 Dimension

R : 2.5 0.1 mm R : 8 0.1 mm R : 105 0.1 mm

Standard Sample Standard Sample Standard Sample

n=7 n=2

Every 2 hr Every 2 hr

IIR IIR Inform Production & Quality Head

60 Welding

MMAW

Dimension

17 - 0.15 mm

Vernier Caliper

n=7

Every 2 hr

IIR

Inform Production & Quality Head

70

Fastning & Assembly

Reviting m/c

Diameter Dimension

11 - 12 mm, 5 mm

Vernier Caliper Vernier Caliper

n=7 n=7

Every 2 hr Every 2 hr

IIR IIR

1.5 0.1 mm , 5 0.1 mm

Free from burr , sharp edges and other Weld Defect

Inform Production & Quality Head

80

Final Inspection

Inspection Room

All

Appearance

Visual

n=100%

Every Lot

No Recording

Inform Quality Head

90

Packing

Packaging Area

Quantity

250 Pcs

Every Lot

Inform Production & Quality Head

Thukral Steel Engineers

CONTROL PLAN

Prototype Control Plan Number : Part Name : Part No. Customer Name : Part/ Process no. Process Name/ Operation Description Neel Metal Product Ltd. Machine, Device, Tool, Jig For Mfg. Item no Characteristic Product Process

Pre-Launch

CP/MTG.BRACKET/01 MTG. BRACKET -15LTR AIR TANK F1F00914 #.0

Production

Core Team :Name Amit Joshi Pryank Ramu Sharma Spl. Char. Class Product/process Specification/ Tolerance Evaluation/ Measurement Technique Deptt. Quality Process Process Sign.

Date ( Orig) Revision No. Revision Date : Prepared By :

: :

12/5/2013 0 -Amit Joshi Prem Thukral

Approved By : Methods Sample

Control Method

Reaction Plan

Size

Freq. Inform Head Dispatch

100

Dispatch

Dispatch Area

THUKRAL STEEL ENGINEERS RUDRAPUR

DOC NO: TSE/7.5/F05/R0

PRE DISPATCH INSP. REPORT REFERENCE W.I/INSPECTION STD. NO.

PART NO . F1F00914 DISCRIPTION : MTG. BRACKET - 15 LTR AIR TANK

ON FVDP VEHICLES

ISSUE NO.:-00 ISSUE ON:-18/03/2013

JOB NO : CUSTOMER NAME : NEEL METAL PRODUCT LIMITED

DATE :

OBSERVATION /SAMPLE REMARKS INSP. ITEM

Dimension Dimension Dimension Dimension Dimension Dimension Dimension

S.N.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

DESCRIPTION

2mm, 5 mm, 3 mm

SPECIFICATION

Micro Meter

1

2,5,3 710 25 160 40 140 35 111 5 8.5 9 57 5 9.5

2

2,5,3 711 25 160 40 140 35 111 5 8.5 9 57 5 9.5

3

2,5,3 710 25 161 40 140 36 112 5 8.5 9 57 5 9.5

4

2,5,3 710 26 159 40 141 36 111 5 8.5 9 57 5 9.6

Dim 709 -711 mm Vernier Caliper Dim : 26 - 24 mm Vernier Caliper Dim : 160 1 mm Vernier Caliper Dim : 40 1 mm Dim : 140 141mm Dim : 35 1 mm R : 111 1 mm Dia : 5 - 5.1 mm Vernier Caliper Vernier Caliper Vernier Caliper Standard Sample Vernier Caliper

Dimension Dimension Dimension Dimension Dimension Dimension Dimension

Dia : 8.5 - 8.6 mm Vernier Caliper Dim : 9 0.1 mm Vernier Caliper Dim : 57 0.1 mm Vernier Caliper Dia : 5 0.1 mm Vernier Caliper

15

Dimension Dimension

Dim : 9.5 0.1 mm Vernier Caliper (counter sunk height) Dim : 112 0.1 mm(from centre Vernier Caliper line) Dia : 20 - 21 mm Vernier Caliper

112 20

112 20

112 21

112 20.5

16

Dimension 17 18 19 20 21 22 23 Dimension Dimension Dimension Dimension Dimension Dimension

Dim : 15 1 mm Vernier Caliper ( From outer side ) Dim : 55 1 mm (From Center Line) R : 2.5 0.1 mm R : 8 0.1 mm R : 105 0.1 mm 17 - 15 mm 5 x 10 mm

15

15

15

15

Vernier Caliper Standard Sample Standard Sample Standard Sample Vernier Caliper Vernier Caliper

55 2.5 8 105 17 5x10

56 2.5 8 105 17 5x10

56 2.5 8 105 15 5x10

56 2.5 8 105 16 5x10

24

Appereance

Free from burr , sharp edges and Visual other Weld Defect

ok

ok

ok

ok

ok

DISPOSITION ACCEPTED REJECTED ACCEPTED UNDER DEVIATION DATE .

CHECKED BY.

APPROVED BY.

Thukral Steel Engineers

R&R STUDY REPORT - VARIABLES

Part No. Part Name Characteristic Specification No. Of Trials Trial App. A Average Range B Average Range C Average Range Part Average Xbardiff= Rdbar = UCLR = LCLR = 1 2 3 1 2 3 1 2 3 IMTE No. MTG. BRACKET- 15 LTR AIR TANK IMTE Description DIAMETER Range 2 MM 2171MM Least Count 0.01 MM 3 No. Of Samples 10 Sample 1 2 3 4 5 6 7 217 217 217 217 217 218 218 218 218 218 218 217 217 217 218 217 217 217 217 217 217 217.6667 1 218 218 218 218 0 217 217 217 217 0 217.5556 217.33 1 218 217 217 217.33 1 217 217 217 217 0 217.22 217.33 1 218 217 217 217.33 1 217 217 217 217 0 217.22 217.33 1 217 217 217 217 0 217 217 217 217 0 217.11 217 217 0 217 217 217 217 0 217 217 217 217 0 217.33 1 217 217 218 217.33 1 217 217 217 217 0 217.22 217.33 1 217 217 218 217.33 1 217 217 217 217 0 217.22 F1F00914 #.0 Date Appraisers 15/05/2013 NS/AK/AB

No. Of Appraisers Average 8 218 217 217 217.33 1 217 217 218 217.33 1 217 217 217 217 0 217.22 218 217 217 217.33 1 217 217 218 9 218 217 217 217.3333 XBarA RBarA 1 217 217 218 10

217.3333 0.9

217.33 217.3333 XBarA 1 1 RBarA 217 217 217 217 217 217 217 0 217.22 217 XBarA 0 RBarA Xdbar 217.2222 Rp

217.3333 0.7

217 0 217.2222 0.555556

0.333333 0.533333 Rdbar * D4 Rdbar * D3

= =

1.376 0

Xbardiff = Max Xbar - Min Xbar Rdbar = Average of Rbar D4 = 3.27 For 2 Trials & 2.58 For 3 Trials D3 = 0 for 1 to 7 trials % Total Variation Trials 2 3 App 2 3 K1 % EV 4.56 3.05 K2 % AV 3.65 2.7 = = 100 [ EV / TV ] 217.86 %

Measurement Unit Analysis Repeatablity : Equipment Variation (EV) EV = Rdbar X K1 = 0.533333 X 3.05 0.0061 = Reproducibility : Appraiser Variation (AV) 2 2 AV = (Xbardiff X K2) - (EV / nr) = 0.0005 Repeatablity & Reproducibility (R&R) R&R = (EV2 + AV2 ) = 0.0061 Part Variation (PV) PV =Rp =

= =

100 [ AV / TV ] 17.86 %

Parts 2 3 4 5 6 7 8 9 10

X K3 0.0288

Total Variation (TV) 2 2 TV =(R&R + PV ) 0.0028

% R&R = 100 [ R&R / TV ] K3 = 218.59 % 3.65 2.7 2.3 % PV = 100 [ PV / TV ] 2.08 = 1028.57 % 1.93 1.82 1.74 No. of distinct catagories (ndc) = 1.41* (PV / R&R) 1.67 = 6.6348 1.62 = 5 Result ACCEPTABLE

Prepared By

Amit Joshi

Approved By

Prem Thukral

Prepared By

Approved By

Anish Bagga

Material Test Cert

t Certificate

Of

Of

item

Of

item no 1

Of

item no 2

Of item no. 3

Thukral Steel Engineers CHECKING AIDS

CUSTOMER NAME : PART NUMBER: PART DESCRIPTION: CUSTOMER APPROVAL/DATE : NEEL METAL PRODUCT LIMITED F1F00914 #.0

Format no. PPI/CA/ MTG.BRACKET/00

SUPPLIER NAME: SUPPLIER CODE : Thukral Steel Engineers

PART NAME :MTG. BRACKET- 15 LTR AIR TANK DIMENSION / CHARACTERISTICS MEASURING INSTRUMENT ID NO.

Micro Meter Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Standard Sample Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Vernier Caliper Standard Sample Standard Sample Standard Sample Vernier Caliper Vernier Caliper Visual Pcs 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM

S.NO.

RANGE / L.C.

0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM 0-25 / 0.01MM

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 25 26

Dim 2mm, 5 mm, 3 mm Dim : 709 - 711mm Dim : 26 - 24 mm Dim : 160 1 mm Dim : 40 1 mm Dim : 140 - 141mm Dim : 35 1 mm R : 111 0.1 mm Dia : 5 - 5.1 mm Dia : 8.5 - 8.6 mm Dim : 9 0.1 mm Dim : 57 0.1 mm Dia : 5 0.1 mm Dim : 9.5 0.1 mm (counter sunk height) Dim : 112 0.1 mm(from centre line) Dia : 20 - 21 mm Dim : 15 1 mm Dim : 55 1 mm R : 2.5 0.1 mm R : 8 0.1 mm R : 105 0.1 mm 17 - 0.15 mm 5 x 10mm Free from burr , sharp edges and other Weld Defect 50 Pcs ( From outer side ) (From Center Line)

DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION DIMENSION Visual Pcs

Date: 15/05/2013

Prepared by : AMIT JOSHI

Approved by : PREM THUKRAL

Potrebbero piacerti anche

- P13-Process For APQPDocumento6 pagineP13-Process For APQPBangali Singh100% (1)

- Ipc & Ipp Logbook or FlowDocumento8 pagineIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- MSIL Audit Cheklist 16Documento22 pagineMSIL Audit Cheklist 16Pravin Balasaheb GunjalNessuna valutazione finora

- F MR 20B 4M Criteria NewDocumento4 pagineF MR 20B 4M Criteria NewBangali Singh100% (1)

- Guideline 4M Change MatrixDocumento3 pagineGuideline 4M Change MatrixAman JasujaNessuna valutazione finora

- Machining PFMEADocumento8 pagineMachining PFMEASuraj RawatNessuna valutazione finora

- 1 2 3 - 4M Change Part TagDocumento4 pagine1 2 3 - 4M Change Part TagIt's me DJNessuna valutazione finora

- Process SheetDocumento8 pagineProcess SheetSuraj RawatNessuna valutazione finora

- Roles & Responsibilities Job Position: HOD-Quality AssuranceDocumento12 pagineRoles & Responsibilities Job Position: HOD-Quality AssurancemuthuselvanNessuna valutazione finora

- D10414410a Fmea MachiningDocumento13 pagineD10414410a Fmea MachiningSuraj RawatNessuna valutazione finora

- Evidences To Be Maintained As Per APQP For PMDocumento3 pagineEvidences To Be Maintained As Per APQP For PMSachin RamdurgNessuna valutazione finora

- F-PD-11 Tool Development Plan (Micro Plan)Documento3 pagineF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaNessuna valutazione finora

- Quality Manual: Organization ChartDocumento2 pagineQuality Manual: Organization ChartmuthuselvanNessuna valutazione finora

- CAPA Rust ProblemDocumento2 pagineCAPA Rust ProblemMohit SinghNessuna valutazione finora

- Fmea CastingDocumento8 pagineFmea CastingSuraj RawatNessuna valutazione finora

- 1 ApqpDocumento30 pagine1 ApqpVIPIN YADAVNessuna valutazione finora

- Machining Control PlannDocumento18 pagineMachining Control PlannSuraj RawatNessuna valutazione finora

- FRM-WS-11 DWM Check Sheet (Weld SHP)Documento2 pagineFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalNessuna valutazione finora

- DS-09-02 R0 Change Implementation MatrixDocumento3 pagineDS-09-02 R0 Change Implementation MatrixDhinakaran100% (1)

- Skill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredDocumento2 pagineSkill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredRavi YadavNessuna valutazione finora

- 4M Inspection ReportDocumento4 pagine4M Inspection ReportKaran Malhi100% (1)

- 5m+1e Change Matrix SOPDocumento2 pagine5m+1e Change Matrix SOPGirdhar Sahu100% (1)

- Apqp Time Plan: Risk AnalysisDocumento4 pagineApqp Time Plan: Risk AnalysisRakesh PandeyNessuna valutazione finora

- MACE Formats 1Documento46 pagineMACE Formats 1Ashish VaidNessuna valutazione finora

- QP - NPD - 07 Procedure For Change ManagementDocumento3 pagineQP - NPD - 07 Procedure For Change ManagementMASU BRAKE PADS QANessuna valutazione finora

- 4M Change Management Matrix-Rane NSK-signedDocumento1 pagina4M Change Management Matrix-Rane NSK-signednitin rathoreNessuna valutazione finora

- GM Machining CP REV 03Documento17 pagineGM Machining CP REV 03Suraj RawatNessuna valutazione finora

- Tier-2 Audit ChecksheetDocumento17 pagineTier-2 Audit ChecksheetSilambarasan KNessuna valutazione finora

- QMS Formats PDFDocumento11 pagineQMS Formats PDFBhavin SukhadiyaNessuna valutazione finora

- 4M Change Intimation Sheet Abnormal SituationDocumento1 pagina4M Change Intimation Sheet Abnormal SituationDhananjay Patil100% (1)

- 5s Zone Wise LeaderDocumento36 pagine5s Zone Wise LeadershalinmishraNessuna valutazione finora

- APQPDocumento3 pagineAPQPsam1hi5Nessuna valutazione finora

- Apqp Time Line PlanDocumento1 paginaApqp Time Line PlanPradeep Kumar KelembathNessuna valutazione finora

- D10414410A CP Rev 00Documento21 pagineD10414410A CP Rev 00Suraj RawatNessuna valutazione finora

- Training On VSA Check Sheet PDFDocumento151 pagineTraining On VSA Check Sheet PDFSwapnil Bachhav100% (2)

- MACE Green Activity Timing PlanDocumento1 paginaMACE Green Activity Timing PlanshinuNessuna valutazione finora

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoDocumento10 pagineFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapNessuna valutazione finora

- Ok Part NG: (Vendor Non-Conformance Report)Documento2 pagineOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNessuna valutazione finora

- Wi-Qa-05, Initial Flow ControlDocumento3 pagineWi-Qa-05, Initial Flow ControlSameer SaxenaNessuna valutazione finora

- IATF Objective Data Analysis - Quality - ExampleDocumento1 paginaIATF Objective Data Analysis - Quality - ExampleSachin RamdurgNessuna valutazione finora

- Xfmea Pfmea PDFDocumento8 pagineXfmea Pfmea PDFvinidesoNessuna valutazione finora

- Fr-scm-085 Packaging StandardDocumento3 pagineFr-scm-085 Packaging StandardKaramjit SinghNessuna valutazione finora

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocumento4 pagine8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNessuna valutazione finora

- Form30TM Advanced Product Quality Planning-APQPDocumento1 paginaForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiNessuna valutazione finora

- Poison Test PlanDocumento29 paginePoison Test PlanDinesh KumarNessuna valutazione finora

- Required Doc For IATFDocumento3 pagineRequired Doc For IATFAbhayNessuna valutazione finora

- Sr. No. Requirements: Ppap Check ListDocumento3 pagineSr. No. Requirements: Ppap Check Listkamlesh kuchekarNessuna valutazione finora

- Q411 - 8D ReportDocumento13 pagineQ411 - 8D ReportAnandha VasanNessuna valutazione finora

- 48 Point Ppap Check SheetDocumento39 pagine48 Point Ppap Check SheetSanjay KumarNessuna valutazione finora

- D10414410a Fmea CastingDocumento7 pagineD10414410a Fmea CastingSuraj RawatNessuna valutazione finora

- PQCS Tube Flange Rough - ForgingDocumento1 paginaPQCS Tube Flange Rough - ForgingBalram JiNessuna valutazione finora

- Past Defect History 2021Documento10 paginePast Defect History 2021RahulNessuna valutazione finora

- Format No - Qf-As-02 - Daily Production Log BookDocumento2 pagineFormat No - Qf-As-02 - Daily Production Log BookDisha ShahNessuna valutazione finora

- NP Chart RBD Engineers, Ahmedabad: Machine Capability Study For Milling Surface Finish With Decided Attribute MethodDocumento3 pagineNP Chart RBD Engineers, Ahmedabad: Machine Capability Study For Milling Surface Finish With Decided Attribute MethodDisha ShahNessuna valutazione finora

- CAPA Hole Burr (TSSR)Documento3 pagineCAPA Hole Burr (TSSR)Mohit Singh0% (1)

- Corrective Actions For Not Ok Charcteristics: Months - July13Documento1 paginaCorrective Actions For Not Ok Charcteristics: Months - July13shobha shelarNessuna valutazione finora

- Master TimingDocumento4 pagineMaster TimingPk NimiwalNessuna valutazione finora

- 06) - Fmea For 11190722 - DDocumento192 pagine06) - Fmea For 11190722 - DMONISHRAJNessuna valutazione finora

- 049-Itp For Lighting and Small Power (Building) PDFDocumento15 pagine049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Valve Inspection and TestDocumento10 pagineValve Inspection and TestshuklahouseNessuna valutazione finora

- Cyber Crime, Cyber Security in India: Mohammed Amjadh A SDocumento16 pagineCyber Crime, Cyber Security in India: Mohammed Amjadh A SshuklahouseNessuna valutazione finora

- Tests Conducted On Under Water Battery - YaduDocumento15 pagineTests Conducted On Under Water Battery - YadushuklahouseNessuna valutazione finora

- 5S Implementation in QA FunctionDocumento23 pagine5S Implementation in QA FunctionshuklahouseNessuna valutazione finora

- MINITAB Application For: Cause-and-Effect Diagram & Scatter DiagramDocumento14 pagineMINITAB Application For: Cause-and-Effect Diagram & Scatter DiagramshuklahouseNessuna valutazione finora

- Viscous Flow Through PipesDocumento20 pagineViscous Flow Through PipesshuklahouseNessuna valutazione finora

- Ishikawa Diagram and Scatter DigramDocumento14 pagineIshikawa Diagram and Scatter DigramshuklahouseNessuna valutazione finora

- 5.parāvartya - YojayetDocumento15 pagine5.parāvartya - YojayetshuklahouseNessuna valutazione finora

- Non-Destructive Testing MethodsDocumento30 pagineNon-Destructive Testing MethodsshuklahouseNessuna valutazione finora

- Mimics GuideDocumento480 pagineMimics Guideshuklahouse100% (1)

- Solving Every Sudoku Puzzle - Peter NorvigDocumento15 pagineSolving Every Sudoku Puzzle - Peter NorvigshuklahouseNessuna valutazione finora

- 15.antyayor Daśake PiDocumento3 pagine15.antyayor Daśake PishuklahouseNessuna valutazione finora

- 12 ĀnurũpyenaDocumento7 pagine12 ĀnurũpyenashuklahouseNessuna valutazione finora

- 9 PũranāpũraņābhyāmDocumento2 pagine9 PũranāpũraņābhyāmshuklahouseNessuna valutazione finora

- 10.calana - KalanābhyāmDocumento1 pagina10.calana - KalanābhyāmshuklahouseNessuna valutazione finora

- 6.sũnyam SāmyasamuccayeDocumento10 pagine6.sũnyam SāmyasamuccayeshuklahouseNessuna valutazione finora

- 4.ũrdhva TiryagbhyāmDocumento9 pagine4.ũrdhva TiryagbhyāmshuklahouseNessuna valutazione finora

- 8.sańkalana - VyavakalanābhyamDocumento2 pagine8.sańkalana - VyavakalanābhyamshuklahouseNessuna valutazione finora

- Kolmogorov Scales of TurbulenceDocumento38 pagineKolmogorov Scales of TurbulenceshuklahouseNessuna valutazione finora

- 2.ekadhikena PurvenaDocumento10 pagine2.ekadhikena PurvenashuklahouseNessuna valutazione finora

- Certificate Acknowledgement List of Figures NomenclatureDocumento2 pagineCertificate Acknowledgement List of Figures NomenclatureshuklahouseNessuna valutazione finora

- Attribute Gage R & R Effectiveness: Date: Name: Product: ProcessDocumento1 paginaAttribute Gage R & R Effectiveness: Date: Name: Product: ProcessshuklahouseNessuna valutazione finora

- MDD Paper Cone EquationsDocumento6 pagineMDD Paper Cone EquationsshuklahouseNessuna valutazione finora

- Ānurũpye Śũnyamanyat: Vedic MathematicsDocumento2 pagineĀnurũpye Śũnyamanyat: Vedic MathematicsshuklahouseNessuna valutazione finora

- Whay Vedic MathematicsDocumento2 pagineWhay Vedic MathematicsshuklahouseNessuna valutazione finora

- Attribute Measurement Study: A-1 A-2 A-3 B-1 B-2 B-3 C-1 C-2 C-3Documento2 pagineAttribute Measurement Study: A-1 A-2 A-3 B-1 B-2 B-3 C-1 C-2 C-3shuklahouseNessuna valutazione finora

- Gas Turbine Blade Cooling TechniqueDocumento18 pagineGas Turbine Blade Cooling Techniqueshuklahouse100% (1)

- Taenia SoliumDocumento40 pagineTaenia SoliumBio SciencesNessuna valutazione finora

- Edc Contractors Basic Safety Training: "New Normal" EditionDocumento8 pagineEdc Contractors Basic Safety Training: "New Normal" EditionCharles Rommel TadoNessuna valutazione finora

- Dmbi Assignment 2: Q.1. Explain STAR Schema. Ans-1Documento6 pagineDmbi Assignment 2: Q.1. Explain STAR Schema. Ans-1Kanishk TestNessuna valutazione finora

- Capsicums - Innovative Uses of An Ancient CropDocumento11 pagineCapsicums - Innovative Uses of An Ancient CropMaarioNessuna valutazione finora

- Accomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksDocumento1 paginaAccomplishment Report: Gass/Mfo Success Indicators Actual Accomplishments RemarksGlenn HernandezNessuna valutazione finora

- Posttraumatic Stress Disorder (PTSD) and War-Related StressDocumento56 paginePosttraumatic Stress Disorder (PTSD) and War-Related Stresshiggjp3Nessuna valutazione finora

- AGPT04I-09 Guide To Pavement Technology Part 4I Earthworks MaterialsDocumento47 pagineAGPT04I-09 Guide To Pavement Technology Part 4I Earthworks MaterialsLeandroNessuna valutazione finora

- Fiber Testing and OTDR Basics: Brett Isley Terriitory Sales ManagerDocumento54 pagineFiber Testing and OTDR Basics: Brett Isley Terriitory Sales ManagerTuppiNessuna valutazione finora

- Comparative Study of Conventional and Generative Design ProcessDocumento11 pagineComparative Study of Conventional and Generative Design ProcessIJRASETPublicationsNessuna valutazione finora

- Previous Years Questions (2020-1983) Segment-Wise: Ordinary Differential EquationsDocumento16 paginePrevious Years Questions (2020-1983) Segment-Wise: Ordinary Differential EquationsAniket bhaiNessuna valutazione finora

- Lisca - Lingerie Catalog II Autumn Winter 2013Documento76 pagineLisca - Lingerie Catalog II Autumn Winter 2013OvidiuNessuna valutazione finora

- Comsol ProfileDocumento4 pagineComsol ProfilePrashant KumarNessuna valutazione finora

- Fortified Rice FssaiDocumento8 pagineFortified Rice FssaisaikumarNessuna valutazione finora

- Op Amp AssignmentDocumento10 pagineOp Amp AssignmentJuan-Wian CoetzerNessuna valutazione finora

- VIC Routing Model PreprocessingDocumento11 pagineVIC Routing Model PreprocessingpchrisrlNessuna valutazione finora

- List Lagu EnglishDocumento7 pagineList Lagu EnglishRyn ZulfanNessuna valutazione finora

- Ebp Cedera Kepala - The Effect of Giving Oxygenation With Simple Oxygen Mask andDocumento6 pagineEbp Cedera Kepala - The Effect of Giving Oxygenation With Simple Oxygen Mask andNindy kusuma wardaniNessuna valutazione finora

- Poster - Combur10 Test Parameters PDFDocumento1 paginaPoster - Combur10 Test Parameters PDFAde FeriyatnaNessuna valutazione finora

- Catalogue Pièces Moteur R984Documento150 pagineCatalogue Pièces Moteur R984Eza IR100% (1)

- SN3308 Installation Manual Rev J PDFDocumento132 pagineSN3308 Installation Manual Rev J PDFsav33Nessuna valutazione finora

- LEC - 19 - Task of Bitcoin MinersDocumento36 pagineLEC - 19 - Task of Bitcoin MinersKarunesh AnandNessuna valutazione finora

- A World of Composite Technologies BrochureDocumento15 pagineA World of Composite Technologies Brochurethorsten_kasterNessuna valutazione finora

- E9sht I C C I W D SDocumento213 pagineE9sht I C C I W D SMAMBO95TLNessuna valutazione finora

- 02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingDocumento47 pagine02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingHattar MNessuna valutazione finora

- As You Face Life: Pray To God and Ask His GuidanceDocumento11 pagineAs You Face Life: Pray To God and Ask His GuidancesophiegarciaNessuna valutazione finora

- Teff Type-I Sourdough To ProduDocumento21 pagineTeff Type-I Sourdough To ProdudanaNessuna valutazione finora

- 100G OTN Muxponder: Cost-Efficient Transport of 10x10G Over 100G in Metro NetworksDocumento2 pagine100G OTN Muxponder: Cost-Efficient Transport of 10x10G Over 100G in Metro NetworkshasNessuna valutazione finora

- Hydrostatics-Assignment 3: MPI td9Documento2 pagineHydrostatics-Assignment 3: MPI td9whoeverNessuna valutazione finora

- 12 Elements of Firearms TrainingDocumento6 pagine12 Elements of Firearms TraininglildigitNessuna valutazione finora