Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ga-201 Centrif Pumps

Caricato da

Carlos Luis Esquerdo MarcanoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ga-201 Centrif Pumps

Caricato da

Carlos Luis Esquerdo MarcanoCopyright:

Formati disponibili

PDVSA

ENGINEERING DESIGN MANUAL

VOLUME 14 ENGINEERING SPECIFICATION

PDVSA N

TITLE

GA201

CENTRIFUGAL PUMPS

1 0

REV.

MAR.93 MAY.86

DATE

GENERAL REVISION FOR APPROVAL

DESCRIPTION DATE

30

L.T. J.S.

R.P. J.G.

APPD. DATE

A.N. E.S.

APPD.

PAG. REV.

APPD.BY Jos Gilarrante

MAR.86 APPD.BY Eduardo Santamaria

MAR.86

E PDVSA, 1983

ESPECIALISTAS

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 1

Indice norma

Index

1 SCOPE AND REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 REFERENCE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 PDVSA Engineering Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 3

4

3 CLASSIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 GENERAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 PERFORMANCE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . 6 MECHANICAL CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 MECHANICAL SEALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 AUXILIARY PIPING AND CONNECTIONS . . . . . . . . . . . . . . . . . . . . . 9 BEARING LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 DRIVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 ELECTRIC MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 STEAM TURBINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 GEARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 SHOP TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 PREPARATION FOR SHIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 MEDIUMDUTY API CENTRIFUGAL PUMPS ADDITIONAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 16.3 16.4 16.5 16.6 16.7 16.8 16.9 16.10 16.11 16.12 16.13 16.14 16.15 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nozzles and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . External Nozzle Forces and Moments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rotating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Wear Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dynamics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mounting Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 5 5 6 8 9 10 10 10 11 11 11 12 13

13 14 14 14 15 17 17 17 18 18 18 20 20 20

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 2

Indice norma

16.16 16.17 16.18 16.19 16.20 16.21 16.22 16.23

Piping and Appurtenances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydrostatic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NPSH Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Proposal Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Contract Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 21 21 22 22 22 23 23

17 HEAVYDUTY API CENTRIFUGAL PUMPS ADDITIONAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 Deletions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.2 Additions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.3 Substitutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

23 24 28

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 3

Indice norma

SCOPE AND REGULATIONS

1.1

This specifications covers the minimum requirements to be met by Seller in the design, fabrication, inspection and testing of centrifugal pumps, their drivers and auxiliaries. This specification requires compliance with all applicable Venezuelan codes and regulations.

1.2

REFERENCE SPECIFICATIONS

2.1

Following standards, codes, and specifications, including applicable addenda, shall form a part of this specifications, except as modified herein. American Petroleum Institute (API) 610 Centrifugal Pumps for General Refinery Services. American National Standards Institute (ANSI) Pipe Flanges and Flanged Fittings Chemical Plant and Petroleum Refinery Piping Specification for Horizontal End Suction Centrifugal Pumps for Chemical Process E101 Vertical Turbine Pumps Line Shaft and Submersible Types Hydraulic Institute Standards Centrifugal Pumps Section American Gear Manufactures Association (AGMA) 6011G92 Specification for High Speed Helical Gear Units. (Revision of ACMA 421.06). 6010E88 Standard for Spur, Helical, Herringbone, and Bevel Enclosed Drives (Revision of AGMA 420.04). American Society for Testing and Materials (ASTM) A395 B111 B169 B171 Standard Specification for Ferritic Ductile Iron Pressure Retaining Castings for Use at Elevated Temperatures. Standard Specification for Copper and CopperAlloy Seamless Condenser Tubes and Ferrule Stock. Standard Specification for Aluminum Bronze Plate, Sheet, Strip and Rolled Bar. Standard Specification for CopperAlloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers. B16.5 B31.3 B73.1M

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 4

Indice norma

B584

Standard Specification for Copper Alloy Sand Castings for General Applications. National Electric Manufactures Association (NEMA) SM 23 Steam Turbines for Mechanical Drive Service American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII Rules for Construction of Pressure Vessels Par. UG84 Charpy Impact Test Section IX Qualification Standard for Welding and Brazing Procedures, Welders, Brazers and Welding and Brazing Operators QW482 Suggested Format for Welding Procedure Specification QW483 Suggested Format for Procedure Qualification Record American Welding Society (AWS) A2.4 Standard Symbols for Welding, Brazing and NonDestructive Examination.

2.2

PDVSA Engineering Specifications

Oil Mist Lubrications Systems Piping Materials General Purpose Steam Turbines Technical Specification for TEFC Squirrel Cage Induction Motors 500 HP and Below General Purpose Application of API 541 Formwound Squirrelcage Induction Motors 250 Horsepower and Larger Special Purpose Application of API 541 Formwound Squirrelcage Induction Motors 250 Horsepower and Larger Equipment Noise Control Site Data Utility Data Welding Procedures PDVSAG260 PDVSAH221 PDVSAG203R PDVSAN251

PDVSAN268

PDVSAN269 PDVSASN252 PDVSASD251 PDVSASD252R PDVSAPI060102

2.3

The requirements of this specification are additions to API 610. PAragraph numbers in parenthesis ( ) refer to those used in API 610.

CLASSIFICATION

3.1

General service pumps shall be manufacturers standard, except as modified by this specification.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 5

Indice norma

3.2

Mediumduty API centrifugal pumps shall be in accordance with API 610, except as modified by this specification. The requirements of specification PDVSAGA201 and API610 shall apply where they are more stringent than the requirements for medium duty pumps, section 16.0. Heavyduty API centrifugal pumps shall be in accordance with API 610, except as modified by this specification. The requirements of specification PDVSAGA201 and API610 shall apply where they are more stringent than the requirements for heavy duty pumps, section 17.0. Horizontal and vertical inline chemical service pumps shall be per ANSI B73.1 and B73.2. The applicable standards will be specified in the Pump Data Sheets. All pumps shall comply with applicable portions of the Hydraulic Institute Standards and with additional requirements of this specification.

3.3

3.4 3.5 3.6

GENERAL REQUIREMENTS

4.1

Pumps, drivers and auxiliaries shall be suitable for unsheltered outdoor installation, and for startup and operation at specified minimum and maximum design ambient temperatures. Pump units shall be furnished complete with pump, driver, gear if required, couplings and guards, mounted on a common baseplate with all required auxiliaries and piping. Vertical pumps (except inline type) shall be furnished with mounting plates, suitable for grouting or attachment to pit cover, as specified. Pumps, drivers and auxiliaries shall comply with Engineering Specification Equipment Noise Control, PDVSASN252.

4.2

4.3 4.4

PERFORMANCE CHARACTERISTICS

5.1 5.2

(2.1.4) Pumps with constant speed drivers shall be capable of at least five percent (5%) increase in head at rated conditions with the installation of a new impeller. (2.1.11) The pump head at shutoff shall be approximately 110%, but not exceed 120% of head at the specified capacity point. Low capacity, high head pumps may be exempt from these requirements with the approval of Owner.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 6

Indice norma

5.3 5.4 5.5

Pumps operating in parallel shall have equal head rises from normal capacity to shutoff. (2.1.9) All pums shall be suitable for continuous operation at 30% of the design capacity. For vertical pumps, Seller shall determine total differential head and differential pressure based on specified discharge and suction pressure, specified differential liquid level, plus Sellers drop column and discharge head loss. Bowl performance curves shall be furnished. Sump pumps shall be capable of generating the specified discharge pressure at minimum sump liquid level. (2.1.12) Specified normal pump capacity shall not exceed capacity at the efficiency point. Rated capacity, if higher than normal capacity, may exceed capacity the best efficiency point. Available NPSH (net positive suction head) values specified in the Data Sheets will be referred to the tope of the foundation for all pumps. (2.1.9) Required NPSH values shall be shown on proposal Data Sheets at the top of the foundation and at the first stage impeller centerline. (2.1.9) Required NPSH values shall not exceed available values over the entire range from minimum to rated flow. (2.1.9) At rated capacity, margins between required and available NPSH shall be at least 0.9 m (3 ft). (2.1.9) Seller shall show suction specific speed (NSS) on Pump Data Sheets. Suction specific speed shall be stated at maximum impeller diameter and best efficiency point (BEP). If the stated value exceeds the published values of the Hydraulic Institute, Seller shall demonstrate in his quotation that the pump operation will be free of any harmful vibrational effects over the full range of operating capacity from rated to Minimum Continuous GPM. This demonstration shall include actual shop performance data on vibration and/or noise.

5.6 5.7

5.8 5.9 5.10 5.11 5.12

MECHANICAL CONSTRUCTION

6.1

(2.2.2) Casing design temperatures are normally based on maximum operating temperature plus 10% or 28 C (82 F), except where minimum temperature is more critical.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 7

Indice norma

6.2 6.3 6.4

6.4.1 6.4.2

(2.3.1.1) Pump suction and discharge nozzles shall be flanged. Flange ratings and facing will be specified in the Data Sheets. (2.3.1.3) Raisedface flanges on Owner s connections shall have the following finishes: Class 150 and Class 300 flanges for operating temperatures from 101 C to 400 C

will utilize asbestos gaskets and shall have flange finishes per ANSI B16.5.

All other flanges will utilize spiralwound, stainless steel asbestos gaskets and shall have a roughness of 125 to 200 AARH, unless specified otherwise in the individual line classes. (See 6.4.2.a) for definition of the term AARH (Arithmetical Average Roughness Height), refer to ANSI B16.5. a. AARH Surfaces are to be compared by sight and feel with standard roughness comparison specimen and not subject to rejection by tracer type instrument using stylus tracers and electrical amplification.

6.5 6.6 6.7 6.8 6.9

6.9.1 6.9.2

(3.2.2) All horizontal pumps shall be furnished with spacertype couplings and coupling guards. (2.5.7) Inline pumps with impellers mounted on extended motor shaft shall be furnished with shaft sleeves. Unless otherwise specified, material shall be per API 610, Appendix H and K or Owner specifications. (2.8.4.7) * Maximum allowable pump vibration amplitudes during shop tests and in the field shall be per API 610. Requirements for vertical pumps are as follows: Column and bowl assembly joints shall be flanged. Line shaft bearings shall be open, selflubricated except for solids carrying services (as shown on Data Sheets). For these services, bearings shall be lubricated from Owner s clean external source. Bowl shafts and head shafts shall be of corrosionresistant materials. Line shaft bearings shall be supported by corrosionresistant spiders. Shaft sleeves of stainless steel shall be provided at each bearing unless the line shaft be of such material.

6.9.3 6.9.4

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 8

Indice norma

6.9.5 6.9.6 6.9.7 6.9.8

If required, coupling shall have provisions for impeller axial clearance adjustment. If enclosed impellers are furnished, replaceable bowl wear rings are required. Line shafts under 75 mm (3 in) in diameter may be joined by threaded couplings. Larges shafts shall employ split hub rigid couplings. Pumps taking suction from open sumps shall be furnished with corrosionresistant suction strainers. Strainer openings shall correspond to minimum widths of pumps internal fluid passages. (2.8.4.13) Pump vibration shall not exceed the values show in paragraph (2.8.4.7), (2.8.4.8) and (2.8.4.9) from minimum continuous stable flow as quoted by the Pump Seller up to rated flow. Satisfactory vibration level shall be demonstrated on test. (2.5.4) Impellers for multistage pumps shall be individually secured against axial movement in either direction along the shaft. (2.9.1.7.1) Thrust collars for hydrodynamic thrust bearings shall be replaceable. (3.2.7) Coupling shall be dynamically balanced when required to meet the vibration criteria of paragraphs (2.8.4.7), (2.8.4.8), and (2.8.4.9). (3.3.1.3) All drivertrain pads on the baseplate shall be machined to allow for installation of stainless steel laminated shim packs, 3 millimeter (0.118 in) minimum thickness under the driver train. When the pump vendor provides the driver, a set of stainless steel shim packs 3 millimeter (0.118 in) minimum thickness shall be included.

6.10

6.11 6.12 6.13 6.14

MECHANICAL SEALS

7.1 7.2 7.3 7.4

(2.7.1.1) Mechanical seals shall be furnished for all pumps unless prohibited by service conditions. (2.7.1.10) Pump Seller shall furnish seal flush coolers or other means of seal cooling to maintain acceptable temperatures in the seal chamber. (2.7.1.10) High temperature bellowstype seals shall be furnished for pumping temperatures above 315 C. (2.7.1.13) Seal plates in flammable or toxic services shall be furnished with nonsparking throttle bushings to minimize leakage upon complete seal failure, and with quench and drain connections.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 9

Indice norma

7.5

(2.7.1.12) If external seal fluid reservoirs are required for tandem or auxiliary seals, Seller shall furnish reservoirs, associated piping and instruments for the API plan specified. (2.7.1.11) Throttle bushings shall be furnished in end plates of tandem seals for flammable and toxic services. (2.7.1.12) Pump Seller shall show the seal chamber circulation rate and pressure on the Data Sheet under Auxiliary Piping for both internally and externally flushed seals.

7.6 7.7

AUXILIARY PIPING AND CONNECTIONS

8.1 8.2 8.3 8.4 8.5 8.6 8.7 8.8 8.9

(3.5.1.1) Pump Seller shall furnish all auxiliary piping for lubrication, cooling and seal flush mounted on the pump and/or baseplate. (3.5.4.1) Cooling water piping shall terminate in single inlet and outlet connections for each pump/driver unit. (3.5.4.4) Seller shall supply hand control valves in each cooling water inlet and sight flow indicators in each outlet. (3.5.4.4) For branched cooling water systems, hand control valves and sight flow indicators shall be furnished in each branch. (3.5.2.5) Piping and controls for external seal flush will be supplied by Owner. (3.5.1.4) External bearing flush lines for vertical pumps shall be manifolded to a single connection located outside the suction vessel or sump. (3.5.1.2) Valved vents shall be furnished for horizontal pump casings which are not selfventing and for vertical pump seal chambers, if required. (3.5.1.2) All horizontal and inline pumps, except those having lined casings or in erosive services, shall be furnished with casing drain connections. (3.5.1.2) Casing drains for pumps in flammable or toxic services and pump with drivers over 75 kW shall be valved. All other casing drains shall be plugged. (3.5.2.9) Drain and vent valves, fittings and plugs shall be at least equivalent to pump casings in material and pressure/temperature ratings. For cast iron casings, these components shall be carbon steel.

8.10

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 10

Indice norma

BEARING LUBRICATION

9.1 9.2 9.3

(2.10.1) All horizontal pumps shall have oillubricated bearings, unless specified otherwise. (2.10.3) Pumps with nonpressurized oil lubrication shall be furnished with constant level oilers with transparent containers and protecting wire cages. (2.10.3.1) For pumps, gears and/or drivers requiring pressure lubrication, a common, factory assembled lube oil system, either baseplate or consolemounted, shall be furnished per Figure D6 of API 610. (2.10.3.1) Pressure switches shall be singlepole, doublethrow type.

9.4

10 DRIVERS

10.1 10.2

(3.1.1) Unless otherwise specified in the Data Sheet, pump drivers shall be furnished and mounted by the pump manufacturer. (3.1.4) Motor ratings, including motor service factor, shall be at least equal to the following percentage of rated pump power.

Motor Nameplate Rating, hp 25 and less 30 hp to 75 100 hp and over Percent of Rated Pump Power 125 115 110

10.3 10.4

(3.1.10) Turbine drivers shall be rated for at least 110% of rated pump power at rated speed. (3.1.1) (3.1.4) Driver rating for pumps operating in parallel, boiler feed and cooling water services, and other services if specified, shall be at least equal the maximum power of rated impeller (end of capacity curve), in addition to the requirements of paragraph 10.2.

11 ELECTRIC MOTORS

11.1

Motor drivers shall comply with Engineering Specifications PDVSA N251 Technical Specification for TEFC Squirrel Cage Induction Motors 500 HP and Below, PDVSA N268 General Purpose Application of API 541 Formwound Squirrelcage Induction Motors 250 Horsepower and Larger o PDVSA N269 Special Purpose Application of API 541 Formwound Squirrelcage Induction Motors 250 Horsepower and Larger.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 11

Indice norma

11.2 11.3

(3.2.9) Sleeve bearing motors shall be furnished with couplings designed to limit axial movement of motor rotors. (3.1.9) Motor thrust bearings for vertical pumps shall be designed for thrust loads generated over the entire pump operating range.

12 STEAM TURBINES

12.1 12.2 12.3 12.4

Steam turbines shall comply with Engineering Specification General Purpose Steam Turbines, PDVSA G203R. (3.1.10) Turbine governors shall be hydraulic relaytype, as minimum. For pumps operating in parallel, turbine governors shall be NEMA Class C. Flange facings shall comply with paragraph 6.3.

13 GEARS

13.1 13.2

Gear units shall comply with Engineering Specification Special Purpose Gear Units, PDVSAG202OR. (3.1.1) Gear nameplate ratings shall be at least equal to the driver rated power, including driver service factor.

14 SHOP TESTS

14.1 14.2 14.3 14.4 14.5 14.6

(4.1.1) Inspection by Owner s representative is required. (4.3.2.1) All pumps shall have hydrostatic and running/performance tests. Test equipment and procedures shall be in accordance with the Hydraulic Institute Standards. (4.3.4.1) NPSH test are required if specified or if the available NPSH exceeds that required by the pump at rated capacity by less than 0.9 m (3 ft). (4.3.4.1.1) NPSH tests, if required, shall be conducted at a minimum of five capacity points from minimum to maximum flow. (4.3.4.1.2) During NPSH tests, onset of cavitation shall be indicated by 3% drop in differential head.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 12

Indice norma

14.7 14.8 14.9 14.10 14.11 14.12

(4.3.3.2.1) Performance tests shall be conducted at a minimum of five capacity points from shutoff to maximum flow. (4.3.3.3.3) Acceptable tolerances of actual vs. guaranteed pump performance shall be per API 610. Vibration levels shall be measured during shop running/performance tests. (4.3.3.1.1) Contact mechanical seals shall be used during shop tests unless seal design is unsuitable for the test conditions. (4.4.3) Pumps shall not be released for shipment until shop test data and performance test curves are approved by Owner. (2.11.4) For pumping temperatures below 29 C (20 F), carbon steel materials shall be impacttested per ASME code Section VIII, Division 1, Par. UG84. Certified impact test reports shall be furnished to Seller. (4.3.3.3.1) Turbine driven pumps shall be operated on mechanical test up to the overspeed trip speed of the governor for a minimum of 5 minutes. Vibration level shall not exceed the value of rated conditions by more than 13 micrometers (0.5 mils).

14.13

15 PREPARATION FOR SHIPMENT

15.1

(4.4.3.4) Unpainted surfaces shall be protected from corrosion during shipment and subsequent outdoor/indoor storage by coating with rust preventive equal to those shown.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 13

Indice norma

RUSTBAN GRADE (1) SURFACE PETROLATUM BASE (HOT APPLICATION) 324 SOLVENT CUTBACK 373,397,385 OIL TYPE

Exterior, machined Interior:

a. Machined or Threaded b. Equipment in Lube and Seal Oil System

Spare Parts (2) 324, 373,397,385

357,623 357,623 357,623

Notes: 1. Grade selection to be based on expected exposure, removability requirements, etc. 2. After coating, suitable time shall be allowed for the protective film to set (cooling down of hotdip products and solvent evaporation of solventcutback products). The coated parts shall then be wrapped in heavy moistureproof paper. 3. The oil type rust preventive listed are medium viscosity (300800 SSU at 100 F, or 57150 cSt at 40 C) products that provide film suitable coating for normal condition Rust Ban 335,337, and 353 are acceptable for application where a low viscosity rust preventive is required.

16 MEDIUMDUTY API CENTRIFUGAL PUMPS ADDITIONAL REQUIREMENTS

16.1

(1.1.1) This engineering specification covers mandatory requirements for single and twostage horizontal and vertical centrifugal pumps having rated service conditions between 29 C to 150 C (20 to 300 F) and not exceeding either 21.1 kg/cm2 (300 psig), 110 cu. meters/hour (500 GPM) or 3600 rpm.

16.2

16.2.1

General

(2.1.7) Pumps designed with mechanical seals shall combine the use of throat bushings, wear rings, impeller balance holes and flushing line arrangements to ensure a stuffing box pressure in excess of suction pressure, ensure that the temperature and pressure in the stuffing box prevents vaporization, and provide a continuous flow through the seal chamber.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 14

Indice norma

16.3

16.3.1

Performance

(2.1.11) a. b. The head curve for the pump shall be continuously rising from the specified capacity point to shutoff point. Pumps for parallel operation shall have equal head rise to shutoff.

16.3.2 16.3.3

(2.1.6) General dimensions of ANSI B73.1 are preferred for single stage horizontal pumps. (2.1.2) Manufacturers shall minimize the number of pump and subassembly types furnished for particular project.

16.4

16.4.1 16.4.2 16.4.3 16.4.4

Casing

(2.2.5) Radially split case pumps are required for all services. (2.2.2) If more than 3 mm (1/8) corrosion allowance is required, it shall be specified. (2.2.3) All pumps shall be single casing type. (2.2.7) Casings of inline pumps shall be split perpendicular to the shaft and shall not require rigid support from the foundation. The design of inline pums shall permit removal of rotor without disconnecting the main piping.

16.5

16.5.1 16.5.2

Nozzles and Connections

(2.3.2.10) A selfventing pump is one that is designed to prevent the buildup of vapor within the impeller, which would cause loss of suction on starting. (2.3.2) a. Drilled or tapped openings in the high velocity areas are not permitted if the specified corrosion allowance of the pump casing is more than 3 mm (1/8) or if the pump is in acid or erosive service. Suction and discharge nozzles and stuffing boxes are not considered high velocity areas. Bosses for future casing drain opening shall be provided. Unless prohibited by 16.5.2a, the pump casing shall be furnished with a driller and tapped drain opening. The opening shall be plugged unless a valved drain is specified. Unless an internal passage is provided in the pump, connections for mechanical seal selfflushing lines shall be made on either the suction and/or discharge nozzle, or the pump casing, if drilling and tapping of the pump casing is permitted.

b.

c.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 15

Indice norma

d. e. 16.5.3 a. b. c.

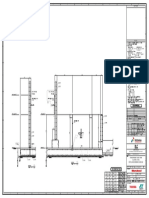

All required vents shall be valved. Gate valves per PDVSA H221 shall be used for vents and drains. Connections for seal oil lines shall be 10 mm (3/8 in) NPS or larger. Valved vent and drain connections shall be braced. Bracing design shall be as follows: 1. Gusseting material for welded gussets shall be of the same nominal chemistry as the connected parts except that carbon steel may be used for gusseting materials with P numbers 1,3,4 and 5. 2. Connections shall be braced in two planes with gussets having a minimum thickness of 5 mm (3/16), minimum with 19 mm (3/4), as show in figure (1) Fig 1.

Equipment Wall Two plane gusseting Two plane gusseting ( Approx. 90 apart.)

(2.3.2.2)

Equipment Wall

9 in max. (225 mm)

3. Heat treatment and hardness requirements for gusset attachment welds shall be as specified for non pressure attachments to piping and equipment, for respective ends of the gussets. 16.5.4 16.5.5 (2.3.2.8) Flange ratings, facing, and finish will be specified in the Data Sheets. (2.3.2.9) Flanged suction and discharge nozzles shall be integral with the casing.

General Note: Bracing detail appliable to extended body type valve, or compact body valve plus nipple (as illustrated)

8 in. max. (200 mm)

Min. distance to satisfy Cloarance requirements Acceptable bracing desing for equipment only where pipe bend necesary

16.6

16.6.1

External Nozzle Forces and Moments

(2.4) The following criteria shall also apply to steel or alloy steel pumps having discharge nozzle greater than 100 mm (4 in NPS), and for cast iron pumps in all sizes. (2.4) a. For steel or alloy steel pumps having a discharge diameter greater than 100 mm (4 in NPS), and for cast iron pumps, each nozzle shall be capable of withstanding forces from external piping loads as follows:

16.6.2

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 16

Indice norma

1. For forces parallel to the nozzle axis: F < 200 lbf per nominal inch 2. For forces perpendicular to the nozzle axis F < 100 lbf per nominal inch Each nozzle shall be designed to withstand a moment imposed at the nozzle flange from external piping as determined by the following formula: M=SxZ Where: M = Design Moment, lbf.in S = Nozzle bending stress limitation, psi, equivalent to the lesser of: 1, 5 Sh a. Carbon or alloy steel pumps: 0, 75 Sh or D 18.000 b. Cast Iron pumps: 0, 75 Sh or D Sh = Allowable hot stress for the pump casing material, psi (stresses per ANSI B31.3 Appendix A, Table 1) D = Nominal nozzle size, in. Z = Section module of pipe, in3, for pipe of Diameter D, and thickness equivalent to: a. ANSI Class 400 or lower rating flanges: SCH STD. Note: b. ANSI Class 600 or higher rating flanges: SCH XS In calculations using SI terms for Nozzle Force (F) and Design Moment (M, per sub par. a. and b. above).

SPECIFIED TERM F < 200, lbf/in F < 100, lbf/in M, lbf in. 1, 5 Sh D 18, 00 D Sh, psi D, in. Z, in. 3 ACCEPTABLE METRIC EQUIVALENT F < 35.6 N/mm F < 17.8 N/mm M, N.m 0.26 Sh D 3100 D No change. Use ANSI B31.3 values, psi (25) x in. = mm (1.64 x 105) x in3. = m3

b.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 17

Indice norma

16.7

16.7.1 16.7.2 16.7.3 16.7.4

Rotating Elements

(2.5.3) Only solid hub impellers are acceptable. (2.5.6) Shaft sleeves are required on all pumps having impellers mounted on extended motor shafts. (2.5.6) Shaft sleeves shall also extend beyond seal end plate on pumps employing throttle bushings. (2.5.10) Tolerance on shaft diameter shall not exceed 0,025 mm (0,001 in) and on sleeve diameter through the stuffing box shall not exceed +0.000 to 0.05 mm (+0,000 to 0,002 in).

16.8

16.8.1

Wear Rings

(2.6.1) a. b. Renewable casing and impeller wear rings are required for all closed and semiopen impellers in services containing abrasive solids. If specified, provision shall be made for flushing wear rings and throat bushings. Flushed wear rings shall have a circumferential groove to ensure distribution of flushing liquid. The axial position of the groove shall be selected to ensure equal flow to the high and low pressure sides of the wear rings.

16.8.2

(2.6.6) Pump clearances shall be manufacturers standard for the pump materials and the specified service.

16.9

16.9.1 16.9.2 16.9.3 16.9.4

Mechanical Seals

(2.7.1.5) Seal plates for carbon steel and cast iron casings with specified corrosion allowances over 3 mm (1/8 in) shall be 18 Cr. 8 Ni. (2.7.1.6) The stationary seal member shall be mounted in the seal plate with a circumferential Oring or other flexible sealing element. (2.7.1.7) Seal plates shall be labeled to identify cooling, flushing, vent, and drain connections. (2.7.1.12) a. b. c. Flushing connections for vertical inline pumps shall be made at the seal plate to eliminate vapor pockets in the stuffing box. Minimum flushing fluid piping size shall be 10 mm (3/8 in NPS). Seal plates shall be drilled for flushing. Where flushing through the seal plate is non standard for the manufactures, alternate arrangements require approval by the Owner s Engineer.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 18

Indice norma

16.9.5 16.9.6 16.9.7

(2.7.1.10) The Flushing fluid of stuffing box shall not be water cooled. (2.7.1.14) Deflectors shall also be furnished on vertical inline pumps. (2.7.1.16) An Orings is not an acceptable gasket.

16.10 Dynamics

16.10.1 (2.8.4.1) Manufacturer s standard procedure for static and dynamic balancing is acceptable provided the vibration conforms to the limit specified in par (2.8.4.7), (2.8.4.8) and (2.8.4.9). (2.8.4.7), (2.8.4.8) and (2.8.4.9) Total dynamic shaft deflection (radial hydraulic force plus vibration double amplitude) under maximum hydraulic load shall not exceed 0,05 mm (0,002 in) at the stuffingbox face.

16.10.2

16.11

16.11.1 16.11.2 16.11.3

Bearings

(2.9.1.1) Antifriction thrust bearings shall be single row, angular contact, arranged to accommodate thrust in either direction, duplex mounting minimum. (2.9.1.3) The use of snap rings for locating antifriction thrust bearing is not acceptable. and/or transmitting loads for

(2.9.2.2) Adjustable constant level oilers with transparent containers and protecting wire cages shall be provided for feeding nonpressurized oillubricated bearings. (2.9.2.5) Bearing oil temperature limits shall not be kept or controlled with water cooling. (2.9.2.8) Oil mist lubrication, when specified, shall be per Engineering Specification, Oil Mist Lubrication Systems, PDVSAG260. Note: Pumps shall be designed for operation with both dry sump lubrication (i.e., pure mist) and purge mist. However, initial operation shall be with purge mist.

16.11.4 16.11.5

16.12 Materials

16.12.1 (2.11.1.4) Steel casings are required for any pump located within process unit areas handling a stream containing any flammable or toxic materials. If special nonferrous materials are required, the Owner shall specify the casing material. Cast iron casings may be used for pumps located outside process unit areas per API 610. 16.12.2 (2.11.2.2) Chaplets in casings other than cast iron not completely fused into pressure casings or other defects shall be replaced by weld metal equivalent to

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 19

Indice norma

the casing composition. No other repair method is permitted. Casings shall be heat treated following any major repairs. 16.12.3 (2.11.2.3) For water service only, the repair of leaking chaplets in Gray Iron pressure casings is permissible by plugging in accordance with par. 8.2, of ASTM A395. Repair of other defects in cast iron pressure casings by impregnation welding, burning, brazing, etc. is not permissible. (2.11.3) a. When submittal of welding procedure specification and procedure qualification records (ASME QW482 and QW483 or equal) is required, these shall be submitted to Owner s welding engineer prior to start of fabrication. Welding shall not proceed until these documents are returned to the manufacturer with authorization to proceed. These submittals shall comply with document Welding Procedures, PDVSA PI060102 and additional requirements listed below. Welder s performance qualifications shall conform to the requirements of Section IX of the ASME Code. Compliance with these requirements and Owner s authorization of welding procedure specifications and procedure qualifications records shall in no way relieve the manufacturer of the responsibility of providing welds which are sound and suited to the service for which they are intended. 1. Welding symbols shall be in accordance with AWS A2.4. 2. A typical weld map or sketch shall be submitted showing all typical joints and the welding procedures to be used on each joint. This typical weld map or sketch may include more than one tag item number, so long as each tag item is clearly identified on the page. 3. A welding summary sheet for each item shall be submitted, listing all the welding procedures to be used, record material identity, thickness, impact testing, and PWHT. These sheets may apply to more than one tag item but each item must be clearly identified. 4. A separate one page welding description data sheet for each welding procedure submitted shall also be submitted. b. Welding procedures shall be submitted to the Owner for authorization to proceed for: 1. Major weld repairs of alloy steel pressure containing castings when the repair is to be accomplished at a location other than the foundry and/or after machining has commenced. 2. Fabrication welding of alloy steel pump cases of alloy steel piping systems. 3. Fabrication welds to pressure containing carbon steel forgings. c. Welding procedures are not required to be submitted to the Owner for:

16.12.4

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 20

Indice norma

1. Carbon steel (except forgings). 2. Seal welds of screwed connections. 3. Weld to nonpressure containing parts.

16.13 Drivers

16.13.1 (3.1.13) Drivers for vertical inline pumps shall be aligned and dowelled by the pump Seller in his shop to ensure proper fitup and shaft mating.

16.14 Couplings

16.14.1 16.14.2 16.14.3 (3.2.2) Coupling material shall be of steel, and of the nonlubricated, lamined disc type with stainless steel discs. (3.2.2) Spacer type couplings shall be furnished only where required for removing the rotor whithout dismantling the main piping. (3.2.14) Coupling guards shall be fabricated from 2.8 mm (0.108 in) galvanized steel sheet. Guards shall be provided with hinged door for inspection of flexible elements.

16.15 Mounting Plates

16.15.1 16.15.2 (3.3.1.8) Grouting holes are required only on fabricated baseplates and may be manufacturer s standard size. (3.3.1.5) a. b. 16.15.3 Pumps having a discharge nozzle larger than 100 mm (4 in NPS) shall also meet these requirements. Shaft displacement, measured at the coupling shall be maximum of 0.13 mm (0.005 in) when subject to the loads designated by this paragraph.

(3.3.1.5) The Seller shall make available optional heavier baseplate and pedestal support assemblies, designated 2X for twice as rigid and 4X for four times as rigid. The characteristic of these assemblies shall be to limit shaft displacement, measured at the coupling, to 0.13 mm (0.005 in) for: 2X = Twice the external forces 4X = Four times the external forces

16.15.4 16.15.5 16.15.6

(3.3.1.13) Not applicable. (3.3.1.14) Baseplates shall include driver alignment jacking bolts for all motor driven pumps greater than 75 kW. (3.3.1.1) Pumps in corrosive services shall have provisions to collect and drain packing or seal leakage. Corrosion resistance of the drain system shall be equal to the pump casing.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 21

Indice norma

16.16 Piping and Appurtenances

16.16.1 16.16.2 (3.5.1.2) Pumps shall be designed to operate without cooling. (3.5.2.9) Required vents and drains shall be supplied in compliance with the followings: a. b. 16.16.3 A nipple shall be supplied, socket welded or screwed and seal welded to the case. The vent and/or drain shall terminate with a socket welded steel gate, valve, Vogt SW # 2081 or similar.

(3.5.2.11) Piping material and corrosion allowance shall be equal to the casing. Carbon or alloy steel piping and flanges shall be provided with cast iron pump casings.

16.17 Inspection

16.17.1 16.17.2 The term Inspector, as used in this specification, refers to the Owner s representative. (4.1.6) Inspection shall include verification of the equipment dimensions, examinations of test data and checking preparation for shipment.

16.18 Hydrostatic Test

16.18.1 (4.3.2.1) Pump casings and covers shall be hydrostatically tested at 1.5 times the maximum discharge pressure or plus 50 psig whichever greater. All hydrostatic test shall be maintained for a minimum of 30 min. Large and heavier casting may require a longer testing period. (4.3.2.1b) Not applicable.

16.18.2

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 22

Indice norma

16.19 Performance Test

16.19.1 16.19.2 16.19.3 16.19.4 (4.3.3) All pumps shall be operated for at least one hour at rated speed and capacity. (4.3.3.2.2) Test records shall also include measured shaft vibration amplitudes. (4.3.3) The purchasers driver shall not be used for shop testing. (4.3.3.3.3) In no case shall the minus tolerance allowance for shutoff head exceed 2%. The shutoff head with the positive tolerance allowance included shall not exceed 120% of the head at rated capacity.

16.20 NPSH Test

16.20.1 16.20.2 (4.3.4.1) NPSH tests based on suction valve throttling are not acceptable. (4.3.4.1) A 1% drop in head shall indicate cavitation.

16.21 Preparation for Shipment

16.21.1 (4.4.3.5) Unpainted surfaces shall be protected from corrosion during shipment and subsequent outdoor/indoor storage by coating with rust preventive equal to those show below.

SURFACE RUSTBAN GRADE (1) PETROLATUM SOLVENTCUTBAC BASE (HOT K APPLICATION) 324 373,397,385 OIL TYPE

Exterior, machined Interior:

a. Machined or Threaded b. Equipment in Lube and Seal Oil System

Spare Parts (2) 324, 326 373,397,385

357,623 357,623 357,623

Notes: 1. Grade selection to be based on expected exposure, removability requirements, etc. 2. After coating, suitable time shall be allowed for the protective fils to set (cooling down of hotdip products and solvent evaporation of solventcutback products). The coated parts shall then be wrapped in heavy moistureproof paper. 3. The oil type rust preventive listed are medium viscosity (300800 SSU a 100 F, or 57150 cSt a 40 C) products that provide a suitable coating for normal

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 23

Indice norma

condition Rust Ban 335,337, and 353 are acceptable for application where a low viscosity rust preventive is required.

16.22 Proposal Data

16.22.1 (5.1.a) a. b. 16.22.2 Owner shall submit the standard data sheet (Appendix A) with his inquiry. Data sheets shall specify minimum corrosion allowance required in the pump casing.

(5.1.f) Seller shall submit extra costs for baseplate and pedestal support systems for horizontal pumps designated at 2X and 4X per paragraph 16.15.3 when the following conditions exist: 1. (Dd + Ds) x (T38) > 41,000 Dd = nominal nozzle size, discharge, mm Ds = nominal nozzle size, suction, mm T = pump design temperature, C 2. Dd > 100 mm (4 in) Where 3. As specified by Owner based on evaluated piping layout considerations.

16.23 Contract Data

16.23.1 (5.2.3) Crosssectional dimensioned drawings of the stuffing box, seal, gland, shaft sleeve, and proposed flushing arrangement for the mechanical seal furnished shall be provided. A parts list/bills of materials shall be furnished for all equipment supplied and shall include pattern stock, or production drawing numbers and materials of construction. The list shall completely identify each part so the Owner may determine part interchangeability with other equipment furnished by the same manufacturer. Antifriction bearings and other standard purchased items shall be identified by the original manufacturer s number.

17 HEAVYDUTY API CENTRIFUGAL PUMPS ADDITIONAL REQUIREMENTS

The requirements given for medium duty centrifugal pumps should be modified according to the following instructions before they can be applied to heavy duty centrifugal pumps.

17.1

Deletions

Delete following requirements from the Set of Requirements Given for Medium Duty Centrifugal Pumps.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 24

Indice norma

16.1.1; 16.3.3; 16.7.4; 16.9.4c; 16.9.6; 16.10.1; 16.14.2; 16.15.6.

17.2

Additions

Add following requirements to the Set of Requirements Given for Medium Duty Centrifugal Pumps.

17.2.1

Scope a. (1.1.1) Seller qualification. Pumps rated over 375 kW (500 HP) shall be supplied by Sellers qualified by experience to manufacture the units proposed. To qualify, a Seller must have at least two pumps of comparable rating and design performing satisfactorily in a similar service.

17.2.2

Nozzles and Connections a. (2.3.1.1) Flanged suction connections shall be suitable for the maximum suction pressure and pumping temperature. The ANSI permissible hydrostatic test pressure of suction flanges shall be equal to, or greater than, the pump casing hydrostatic test pressure.

17.2.3

Rotating Elements a. (2.5.13) The shaft stiffness requirements for multistage horizontal pumps shall be the same as for one and two stage horizontal pumps.

17.2.4

Mechanical Seals a. (2.7.1.6) 1. Multistage, vertical pumps and between bearings type horizontal pumps shall be provided with cartridgetype seals with the shaft sleeve installed from outside the stuffing box. The seals shall be removable without disturbing the driver. 2. For services where temperature precludes use of 0ring, details of shaft sealing arrangement shall be submitted to Owner for approval by Owner s Engineer. 3. The stationary seal member shall be mounted in the seal plate with a circumferential 0ring or other flexible sealing element. b. c. d. (2.7.1.7) Seal plates shall be labeled to identify cooling water, flushing vent, and drain connections. (2.7.1.9) Builtin seal designs are unacceptable. (2.7.1.1) Mechanical seals shall be furnished in all centrifugal pumps operating below 400 C except for services where they will have limited operating life. Hightemperature mechanical seals shall be provided for pumps in service above 315 C. A hightemperature seal is a seal which

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 25

Indice norma

will operate continuously at the design pumping temperature without the use of externally cooled flushing liquids. e. f. 17.2.5 (2.7.2.5) Flexible hose to the quench gland is not acceptable. (2.7.1.1) Firewater pumps shall have packing.

(2.8.4.9) For vertical pumps, the pump shaft or shaft sleeve runout as measured by hand, shall not exceed 0,05 mm (0,002 in) total indicator reading before and after the mechanical running test. Bearings a. (2.9.1.7) & (2.7.1.10) Application of pump cooling water shall be as follows. Pumps with nonpressurized bearing lubrication, and pumping temperatures under 200 C (400 F) shall be designed to operate continuously without use of cooling water for bearings, pedestals, and stuffing boxes. Bearing oil temperatures shall not exceed 82 C (180 F) based on specified operating conditions and 43 C (110 F) ambient and shall assume no credit for motor cooling air. Cooling water may be used for cooling seal flush liquid where required to assure proper mechanical seal operation. b. (2.9.3.2) All vertical pumps with thrust bearings shall be equipped with oil lubricated bearings. (2.10.3) Where pressure lubrication is furnished, low oil pressure shutdown devices shall be provided; lowpressure alarms shall be provided when specified. Where very low operating speed are anticipated, these speeds will be specified, and lubrication of the pump shall be given special consideration. Pumps with pressure oil systems shall have the following items included in the oil system: 1. Main and auxiliary pumps. The following arrangements are acceptable: a. b. Shaftdriven main and motor or turbine driven auxiliary pumps. Motordriven main and steamturbinedriven auxiliary pumps.

17.2.6

17.2.7

Lubrication a.

2. The auxiliary lube oil pump shall be controlled to automatically startup in and provide oil pressure to maintain safe operation upon failure of the main pump or reduction in pressure for other reasons. 3. Horizontal pumps shall have positive suction heads an suction lines sloped to vent to the reservoir. 4. The standby pump shall not shutdown by itself. required. Manual shutdown is

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 26

Indice norma

5. A separate oil cooler of the shell and tube type. 6. Materials of construction for coolers in fresh water cooling service shall be carbon steel. Materials for salt water cooling service shall be as follows:

SHELL CHANNELS & COVERS Materials Acid Resisting Bronze or Aluminum Bronze Spec. ASTM B584 Alloy C92200 ASTM B169 Alloy C61400 TUBE SHEETS Materials Spec. ASTM B171 Naval Brass Alloy 464 Admiralty Brass Alloy 443 444 or 445 TUBES Materials Inhibited Spec. ASTM B111

Carbon Steel

7. A cartridge filter with a carbon steel pressure casing and with maximum clean pressure drop of 0.35 kg/cm2 to filter particles exceeding 5 m in size. Filter shall be located downstream of the lube oil cooller. 8. Piping arrangement shall not permit bypassing oil around the filter. 9. A pressure gauge (valved for removal) for each pressure level, and a means to indicate differential pressure across the filter. 10. Dial type thermometers before and after the oil coolers. 11. An oil reservoir with the following characteristics: a. Capacity to adequately settle moisture and foreign matter to avoid frequent refilling, and adequate allowance for the contents of the system when drained. Provisions to eliminate air and to minimize flotation of foreign matter to pump suction. Fill connections, level indicators, and breathers suitable for outdoor use. Sloped bottoms and connections for complete drainage. Cleanout openings as large as practical. Reservoir material shall be 300 series stainless steel.

b. c. d. e. f.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 27

Indice norma

g.

When required, a steamheating coil external to reservoir, or a lowwatt density, thermostatically controlled electrical immersion heater, shall be provided for heating the oil prior to startup in cold weather. The heating device shall be enought able to heat oil from minimum site ambient temperature to manufacturer s minimum required temperature in 4 hours. Reservoir shall be fitted with support clips for thermal insulation. The Owner will furnish and install any insulation. An oilreservoir breather with suitable filter. The oil filter elements and oil reservoir breather elements shall have a 5 m absolute rating.

h.

12. Austenitic stainless steel lube oil piping downstream of the lube oil filter. 13. Sight flow indicators on each bearing drain line. 17.2.8 Couplings a. (3.2.8.10) In services with pumping temperatures up to 150 C (300 F), vertical inline pumps of either one piece extended motor shaft construction or coupled shaft design are acceptable. With pumping temperature 150 C (300 F) and above, inline pumps shall be of rigidly coupled, separate pump and driver shaft design.

17.2.9

Piping and Appurtenances a. b. c. (3.5.4.2) Cooling water shall be per Manufacturer standard. (3.5.4.4) The use of sight flow indicators shall be per Manufacturer standard. (3.5.4.1) 1. Carbon steel shall be chemically cleaned with an inhibited acid solution to remove weld spatter, rust, scale, etc. Mechanical cleaning methods shall be used in addition to chemical cleaning to achieve the above described results. 2. Stainless steel shall be mechanically cleaned at welds so all foreign material is removed. (3.5.2.4) Materials for sealflushing liquid coolers shall be per the following:

COOLING MEDIA Fresh Water Salt Water Air TUBE COIL Type 316 Stainless Steel or Monel Monel Type 316 Stainless Steel with Aluminum or Stainless Steel Fins CASING (OR SHELL) Carbon Steel Carbon Steel

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 28

Indice norma

Cooling water shall be on the casing side. Minimum tube wall thickness shall be 1,24 mm (0,049 inch). 17.2.10 Proposal Data a. (5.1.a) Seller s filledout proposal data sheet shall show wear ring clearances and diameters of proposed pumps for pumping temperature 260 C (500 F) or higher. (5.1.f) Seller shall submit cooler design details. (5.1.h) For pumps rated over 375 KW (500 HP), Seller s proposal shall include proof of compliance with par. 1.2. (5.1.h) If high temperature mechanical seals are proposed, per par. (2.7.1.11), Seller shall submit an installation list demonstrating satisfactory experience.

b. c. d.

17.3

Substitutions

Add to the following Requirements those, in the set of requirements given for medium duty centrifugal pumps.

17.3.1

Performance a. (2.1.2) Pumps handling cold liquids, at 45 C (112 F) or lower, shall be vertical pumps or submerged pumps. Vertical pumps shall have a vapor space with a heat dam and seal oil drip catching device with drain between the mechanical seal and the pumped liquid.

17.3.2

Casing a. (2.2.3) Areas of multistage horizontal and double case pumps which are normally subjected to suction pressure shall be designed to permit, as a minimum, a hydrostatic test pressure equal to the maximum casing discharge pressure. (2.2.7) Casings of inline pumps shall be split perpendicular to the shaft and shall not require the rigid support of a foundation. The design of inline pumps shall permit removal of the rotor without disconnecting the main piping. Casing joint gaskets for pumping temperatures above 315 C (600 F) shall be metaljacketed and shall be confined at the vertical split.

b.

17.3.3

Nozzles and Connections a. (2.3.2.9) Flange connections shall be designed for through bolting.

17.3.4

Wear Rings a. (2.6.1) Casings shall be fitted with renewable wearing rings.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 29

Indice norma

17.3.5

Mechanical Seals a. (2.7.1.10) If cooling is required to maintain the mechanical seal within its temperature limitations, the pump Seller shall provide water cooled stuffing boxes or a cooler to cool flushing fluid from the pump discharge.

17.3.6

Dynamics a. (2.8.4.7), (2.8.4.8) & (2.8.4.9) The peaktopeak amplitude of vibration during shop test and field operation shall not exceed the following values:

PEAKTOPEAK AMPLITUDE (Unfiltered)

MAXIMUM rev/min 5000 5000 to 20000 20000

SPEED rev/s 83 83 to 335 335

ANTIFRICTION mils 2.5

BEARINGS (1) mm 0.06

SLEEVE mils 2.0 10000 Shaft Speed Rev min 0.5

BEARINGS (2)(3)(4) mm 0.05 167 Shaft Speed Rev s 0.013

Notes: 1. Measured on bearing housing. 2. Measured on shaft (adjacent to the bearing) and includes runout. 3. If vibration cannot be measured on the shaft, vibration shall be measured on the bearing housing and these same limits apply. 4. For vertical pumps without antifriction bearings, these same limits apply as measured on the lower bearing housing of the driver and on the driver adapter frame. 17.3.7 Bearings a. 17.3.8 (2.9.2.5) Cooling coils shall be inhibited admiralty brass. Pipe connections inside the bearing housing are prohibited.

Mounting Plates a. (3.3.1.8) Baseplate grouting holes shall be accessible without removing the machinery and shall permit filling of the entire cavity under the baseplate without trapping air pockets. (3.3.1.13) Pedestal cooling shall not be provided.

b. 17.3.9

Piping and Appurtenances a. (3.5.1.2) When auxiliary piping is common to both pump and driver, the Owner will specify the extend of piping to be supplied by each Seller.

ENGINEERING SPECIFICATION

PDVSA GA201 REVISION FECHA

PDVSA

.Men Principal

CENTRIFUGAL PUMPS

Indice manual Indice volumen

MAR.93

Pgina 30

Indice norma

17.3.10

Hydrostatic Test a. (4.3.2.1) Suction sections of multistage horizontal and doublecase pumps shall have a hydrostatic test pressure equal to maximum casing discharge pressure. (4.3.2.1.b) Mechanical seal flushing liquid coolers shall be hydrostatically tested to the same pressure as the pump casing.

b.

Potrebbero piacerti anche

- Ebara Vertical Inline Pump - LPDADocumento8 pagineEbara Vertical Inline Pump - LPDAGeorge CobraNessuna valutazione finora

- 2.1 Duct Design PP 1Documento42 pagine2.1 Duct Design PP 1joshuatamNessuna valutazione finora

- Lodal Pump BLEVE Mar2011Documento47 pagineLodal Pump BLEVE Mar2011khaiseah9225Nessuna valutazione finora

- AgitatorDocumento8 pagineAgitatorMugesh KannaNessuna valutazione finora

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDocumento4 pagineVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNessuna valutazione finora

- Wastecorp PlungerDocumento18 pagineWastecorp PlungerAlexander MedinaNessuna valutazione finora

- Installation, Operation, and Maintenance ManualDocumento40 pagineInstallation, Operation, and Maintenance ManualRamadan RashadNessuna valutazione finora

- Q245R PDFDocumento2 pagineQ245R PDFAnonymous 9zykaX6T100% (1)

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Documento14 pagineA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNessuna valutazione finora

- ChecklistDocumento2 pagineChecklistdassayevNessuna valutazione finora

- F 683 - 99 - Rjy4my05oq - PDFDocumento28 pagineF 683 - 99 - Rjy4my05oq - PDFRománBarciaVazquezNessuna valutazione finora

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocumento18 pagineCentrifugal Pump Basics: Terms Commonly Used in The Pumping Industrysuraj7266Nessuna valutazione finora

- Brosjyre ChemineerDocumento14 pagineBrosjyre ChemineerRaul DiazNessuna valutazione finora

- Baru Gas Plant DemandDocumento4 pagineBaru Gas Plant DemandBop AlberthaNessuna valutazione finora

- Flowserve ANSI-Pumps PDFDocumento68 pagineFlowserve ANSI-Pumps PDFArup MahantaNessuna valutazione finora

- Operating, Installation & Maintenance Manual For Hydraulic Power PackDocumento3 pagineOperating, Installation & Maintenance Manual For Hydraulic Power PackchethanNessuna valutazione finora

- Whrs ManualDocumento41 pagineWhrs ManualAKHLESH JHALLARENessuna valutazione finora

- B0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WDocumento1 paginaB0054827-4 Erection Arrangement DRB-XCL PC Fired Burner C.WNanang Cesc UttaNessuna valutazione finora

- Water SoftenersDocumento11 pagineWater Softenersadel rihanaNessuna valutazione finora

- LPG Spec by EsdmDocumento73 pagineLPG Spec by EsdmronaldopasaribuNessuna valutazione finora

- Practical Guidelines For Determining Electrical Area ClassificationDocumento17 paginePractical Guidelines For Determining Electrical Area ClassificationOmar AzzainNessuna valutazione finora

- Actuators Price ListDocumento2 pagineActuators Price ListJack ChavanNessuna valutazione finora

- Key Plan: Atmospheric Flash Tank Cluster 1 Fcrs Detail and Member ScheduleDocumento1 paginaKey Plan: Atmospheric Flash Tank Cluster 1 Fcrs Detail and Member SchedulegoyamapiNessuna valutazione finora

- 2006-09 - Conveyor Belt Basic Rules and Procedures For Tracking and TrainingDocumento7 pagine2006-09 - Conveyor Belt Basic Rules and Procedures For Tracking and TrainingZoebair0% (1)

- CR QapDocumento2 pagineCR QapSimbu ArasanNessuna valutazione finora

- Dosing PumpDocumento10 pagineDosing PumpniceseshaNessuna valutazione finora

- ChecklistDocumento3 pagineChecklistAndy Noven KrisdiantoNessuna valutazione finora

- 20 RR NOV 300Q-5 Technical Data SheetsDocumento2 pagine20 RR NOV 300Q-5 Technical Data SheetsJorge SoriaNessuna valutazione finora

- Organic Rankine Cycle As Efficient Alternative To PDFDocumento9 pagineOrganic Rankine Cycle As Efficient Alternative To PDFGuilherme SixeNessuna valutazione finora

- SCP Series Technical DataDocumento8 pagineSCP Series Technical DataJaldhij PatelNessuna valutazione finora

- RUHRPUMPEN Pump - VTP - B - EN PDFDocumento8 pagineRUHRPUMPEN Pump - VTP - B - EN PDFhenryNessuna valutazione finora

- Intruction Manual FSADocumento10 pagineIntruction Manual FSAtrantuan74Nessuna valutazione finora

- Dust Collector Installation ProcedureDocumento9 pagineDust Collector Installation Procedureadil shidiq100% (1)

- 1 - Transmittal No. R0051734-CTCDocumento7 pagine1 - Transmittal No. R0051734-CTCNanang Cesc UttaNessuna valutazione finora

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Documento5 pagineSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNessuna valutazione finora

- Service Activity Reports Complete PS3-PS4Documento45 pagineService Activity Reports Complete PS3-PS4Mohamed MusaNessuna valutazione finora

- Ahlstar Presentation PDFDocumento56 pagineAhlstar Presentation PDFBladimir Quintero LopezNessuna valutazione finora

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDocumento11 pagine1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- Goulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpDocumento12 pagineGoulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpJean Peak100% (1)

- Performance Data CurveDocumento57 paginePerformance Data Curveedwin nolberto100% (1)

- Coti GIW Rep 26x28LSA PDFDocumento3 pagineCoti GIW Rep 26x28LSA PDFjohan diazNessuna valutazione finora

- Data Sheet: Cpi (Corrugated Plate Interceptor)Documento1 paginaData Sheet: Cpi (Corrugated Plate Interceptor)wahyu hidayatNessuna valutazione finora

- Bangladesh MGI 300TD Continuous Polyester Production Line Bottle FlakeDocumento44 pagineBangladesh MGI 300TD Continuous Polyester Production Line Bottle Flakeswapon kumar shillNessuna valutazione finora

- Technical Sales Guide GlobalPAC Inv (T1)Documento129 pagineTechnical Sales Guide GlobalPAC Inv (T1)bride junior tchuensuNessuna valutazione finora

- C0M-07 FRP Tank-VesselDocumento2 pagineC0M-07 FRP Tank-VesselHong Trung DuongNessuna valutazione finora

- Hansun Water MakerDocumento97 pagineHansun Water MakeralexNessuna valutazione finora

- Technical Data Design Sheets - Tornado Da Fa PDFDocumento14 pagineTechnical Data Design Sheets - Tornado Da Fa PDFMilena Lemus FonsecaNessuna valutazione finora

- Diaphragm Pump Seminar ReportDocumento58 pagineDiaphragm Pump Seminar ReportMahaManthraNessuna valutazione finora

- Design & Selection Criteria For StrainersDocumento4 pagineDesign & Selection Criteria For StrainersKamal ChokshiNessuna valutazione finora

- Static Pressure Calculation SheetDocumento24 pagineStatic Pressure Calculation SheetMuhammad ZubairNessuna valutazione finora

- Tutorial Centrifugal PumpDocumento14 pagineTutorial Centrifugal PumpManea GrosuNessuna valutazione finora

- Demin Tank ReportDocumento69 pagineDemin Tank Reportshahroze mustafaNessuna valutazione finora

- C Tuthill PDFDocumento37 pagineC Tuthill PDFRaulEfrainCharrezCastilloNessuna valutazione finora

- Vertical Turbine PumpDocumento28 pagineVertical Turbine Pumpkarthikraja21Nessuna valutazione finora

- Cruisair Seawater PumpsDocumento2 pagineCruisair Seawater PumpsorlandoNessuna valutazione finora

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Documento6 pagine1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNessuna valutazione finora

- Ga 201Documento31 pagineGa 201venezuelanNessuna valutazione finora

- API Specification 16C: Choke and Kill EquipmentDocumento5 pagineAPI Specification 16C: Choke and Kill EquipmentJitendra BhosaleNessuna valutazione finora

- Steelco Vs MC: Medium Capacity Steam SterilizerDocumento43 pagineSteelco Vs MC: Medium Capacity Steam SterilizerGuillermo Jesus Avila Arrieta100% (1)

- Nic Ad ManualDocumento34 pagineNic Ad ManualSajjad Shamim100% (1)

- GRP Stress AnalysisDocumento13 pagineGRP Stress AnalysisCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Main Engine 3516C 1920 BKW 1600 RPM SpecDocumento6 pagineMain Engine 3516C 1920 BKW 1600 RPM SpecCarlos Luis Esquerdo Marcano100% (1)

- 5150bhp Handysize Asd Tug BoatDocumento1 pagina5150bhp Handysize Asd Tug BoatCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- 5150bhp Handysize Asd Tug Maker ListDocumento4 pagine5150bhp Handysize Asd Tug Maker ListCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Iso 8217 2017Documento2 pagineIso 8217 2017Carlos Luis Esquerdo Marcano100% (2)

- 5150bhp Handysize Asd Tug Spec OutlineDocumento1 pagina5150bhp Handysize Asd Tug Spec OutlineCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- PROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01Documento8 paginePROJECT STANDARDS and SPECIFICATIONS Offshore Piping Fabrication and Installation Rev01totongopNessuna valutazione finora

- PPI - Handbook of Polyethylene Pipe (2nd ED)Documento626 paginePPI - Handbook of Polyethylene Pipe (2nd ED)card89100% (5)

- Nytimes1912papyrusarticle PDFDocumento2 pagineNytimes1912papyrusarticle PDFCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Bronze Ball Valve 600 WOGDocumento35 pagineBronze Ball Valve 600 WOGCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Catalogue Ipsi EpDocumento70 pagineCatalogue Ipsi EprachedscribNessuna valutazione finora

- Contact UKVIDocumento1 paginaContact UKVICarlos Luis Esquerdo MarcanoNessuna valutazione finora

- HDPE Temp Effects PDFDocumento14 pagineHDPE Temp Effects PDFCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Leki Pipeline SpecificationsDocumento23 pagineLeki Pipeline SpecificationsCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Baskets TrainersDocumento0 pagineBaskets TrainersCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- PRS Swivel Ring FlangeDocumento2 paginePRS Swivel Ring FlangeCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- SolidsHandouts4 PDFDocumento4 pagineSolidsHandouts4 PDFmahreza189Nessuna valutazione finora

- Fathom 7 0 Modules Guide PDFDocumento202 pagineFathom 7 0 Modules Guide PDFCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- QC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprDocumento160 pagineQC Technical Specification - Schedule 5 BCT 14 Jan 13 PoprCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Hydrotest Procedure For PipelineDocumento12 pagineHydrotest Procedure For PipelineCarlos Luis Esquerdo Marcano100% (3)

- Fathom 7 0 Modules Guide PDFDocumento202 pagineFathom 7 0 Modules Guide PDFCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Impulse 4.0 Quick Start SIDocumento79 pagineImpulse 4.0 Quick Start SIMohammed EljammalNessuna valutazione finora

- Titan 3.0 Quick StartDocumento77 pagineTitan 3.0 Quick StartCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Standard Cement LiningDocumento3 pagineStandard Cement Liningjungzki100% (1)

- Valvulas Three Way 80000Documento12 pagineValvulas Three Way 80000pca97Nessuna valutazione finora

- Catalogogeneralpolyken PDFDocumento9 pagineCatalogogeneralpolyken PDFCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Basket Strainers: Flow Rate vs. Pressure Drop (Clean Screen)Documento11 pagineBasket Strainers: Flow Rate vs. Pressure Drop (Clean Screen)Carlos Luis Esquerdo MarcanoNessuna valutazione finora

- Piping FabDocumento1 paginaPiping FabCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Appointment and Confirmation LetterDocumento2 pagineAppointment and Confirmation LetterCarlos Luis Esquerdo Marcano100% (1)

- Fractional DestilationDocumento6 pagineFractional DestilationCarlos Luis Esquerdo MarcanoNessuna valutazione finora

- Imbibition WaterDocumento4 pagineImbibition WaterArun Gupta100% (3)

- Qualice Solutions - Brochure PDFDocumento16 pagineQualice Solutions - Brochure PDFjamilvoraNessuna valutazione finora

- Module 7Documento25 pagineModule 7ajmalNessuna valutazione finora

- Design Modules For A Pipe Line ProjectDocumento38 pagineDesign Modules For A Pipe Line ProjectThiru MuruganNessuna valutazione finora

- Wey Knife Gate Valve Models NA, A1 & W1Documento4 pagineWey Knife Gate Valve Models NA, A1 & W1cvfNessuna valutazione finora

- Parker VOAC F11-F12 Technical DocumentDocumento44 pagineParker VOAC F11-F12 Technical DocumentPablo Soto100% (1)

- 50 58 Eng Concrete TestingDocumento92 pagine50 58 Eng Concrete TestingJimmy LopezNessuna valutazione finora

- Miniature PlantDocumento22 pagineMiniature PlantSarmad Tariq67% (3)

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocumento42 pagineOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNessuna valutazione finora

- GM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDocumento100 pagineGM THM 4L80E ATRA MANUAL Repair Rebuild Book Transmission Guide 4L80 E PDFDaniel GonzalezNessuna valutazione finora

- ASCO SolenoidDocumento10 pagineASCO Solenoidsharib26Nessuna valutazione finora

- Catalogo WOODWARD PDFDocumento40 pagineCatalogo WOODWARD PDFrepelind100% (2)

- Massey Ferguson Tractor Hydraulic PartsDocumento9 pagineMassey Ferguson Tractor Hydraulic PartsJohn Mendoza Pacheco100% (3)

- Flex Separation Systems P Separators 605 615 PDFDocumento4 pagineFlex Separation Systems P Separators 605 615 PDFJoshua MOUNOWAH100% (1)

- Cat FlowAids CFAEN 0120 Rev09 PDFDocumento36 pagineCat FlowAids CFAEN 0120 Rev09 PDFthanh nguyenNessuna valutazione finora

- Tyco Fig.110-190 Ball Valves DatasheetDocumento24 pagineTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- 8300g Njex Manual 2-2011Documento126 pagine8300g Njex Manual 2-2011Santiago Cabarcas L. de UrquizoNessuna valutazione finora

- Selecting Your Valve: Type of Valve and Its Functionality Service ConditionsDocumento1 paginaSelecting Your Valve: Type of Valve and Its Functionality Service ConditionsCTHNessuna valutazione finora

- Fopx 605Documento62 pagineFopx 605Aleksanrd Mihailov0% (1)

- Instruction Manual - PMC Mixing MachineDocumento9 pagineInstruction Manual - PMC Mixing MachineAlex BaleqNessuna valutazione finora

- Plumbing Code 2012 ICC IPC Full Text PDFDocumento194 paginePlumbing Code 2012 ICC IPC Full Text PDFGabriel TorresNessuna valutazione finora

- Wilden h1500 Saniflo Hygienic Metal Eom PDFDocumento32 pagineWilden h1500 Saniflo Hygienic Metal Eom PDFSrinivas BobbyNessuna valutazione finora

- MR Heater Mhu80 ManualDocumento48 pagineMR Heater Mhu80 Manualp0t2g047100% (1)

- Washington State Department of Ecology Spill Prevention, Preparedness and ResponseDocumento19 pagineWashington State Department of Ecology Spill Prevention, Preparedness and ResponseyeNessuna valutazione finora

- H 0092 20 102416 - 1.1Documento82 pagineH 0092 20 102416 - 1.1Gregorio Cerdano VicenteNessuna valutazione finora

- BMW Automatic TransmissionDocumento67 pagineBMW Automatic TransmissionMario Tasev100% (27)

- Catalogo Valvulas Parker 2020Documento476 pagineCatalogo Valvulas Parker 2020Daniel PachecoNessuna valutazione finora

- Flare Gas Recovery Using Gas EjectorDocumento8 pagineFlare Gas Recovery Using Gas Ejectoremmanuel limaNessuna valutazione finora

- Isolation Valves TBE PGV Rev 0Documento1 paginaIsolation Valves TBE PGV Rev 0eko123Nessuna valutazione finora

- Johnson Pump SPX FLOWDocumento85 pagineJohnson Pump SPX FLOWCWen Teow100% (1)