Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QT

Caricato da

solidwormTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QT

Caricato da

solidwormCopyright:

Formati disponibili

chapter 101: Section 5.

223 QW-100 GENERAL Such requirements take precedence over those of this Section, and the manufacturer or contractor shall comply with them. QW-100.1 A Welding Procedure Specification (WPS) is a written document that provides direction to the welder or welding operator for making production welds in accordance with Code requirements. Any WPSs used by a manufacturer or contractor that will have responsible operational control of production welding shall be a WPS that has been qualified by that manufacturer or contractor in accordance with Article II, or it shall be an AWS Standard Welding Procedure Specification (SWPS) listed in Appendix E and adopted by that manufacturer or contractor in accordance with Article V. Section IX of the ASME Boiler and Pressure Vessel Code relates to the qualification of welders, welding operators, brazers, and brazing operators, and the procedures that they employ in welding and brazing according to the ASME Boiler and Pressure Vessel Code and the ASME B31 Code for Pressure Piping. It is divided into two parts: Part QW gives requirements for welding and Part QB contains requirements for brazing. Other Sections of the Code may specify different requirements than those specified by this Section. Both WPSs and SWPSs specify the conditions (including ranges, if any) under which welding must be performed. These conditions include the base metals that are permitted, the filler metals that must be used (if any), preheat and postweld heat treatment requirements, etc. Such conditions are referred to in this Section as welding variables. When a WPS is to be prepared by the manufacturer or contractor, it must address, as a minimum, the specific variables, both essential and nonessential, as provided in Article II for each process to be used in production welding. In addition, when other Sections 1 of the Code require notch toughness qualification of the WPS, the applicable supplementary essential variables must be addressed in the WPS. The purpose for qualification of a WPS is to determine that the weldment proposed for construction is capable of providing the required properties for its intended application. Welding procedure qualification establishes the properties of the weldment, not the skill of the welder or welding operator. The Procedure Qualification Record (PQR) documents what occurred during welding the test coupon and the results of testing of the coupon. As a minimum, weld 7733.44 weld 7733.44 weld 7733.44 the PQR shall document the essential variables and other specific information identified in Article II for each process used during welding the test coupon and the results of the required testing. In addition, when notch toughness testing is required for procedure qualification,

the applicable supplementary essential variables for each process shall be recorded. //weld 7733.44// QW-100.2 In performance qualification, the basic criterion established for welder qualification is to determine the welder s ability to deposit sound weld metal. The purpose of the performance qualification test for the welding operator is to determine the welding operator s mechanical ability to operate the welding equipment. QW-100.3 Welding Procedure Specifications (WPS) written and qualified in accordance with the rules of this Section, and welders and welding operators of automatic and machine welding equipment also qualified in accordance with these rules may be used in any construction built to the requirements of the ASME Boiler and Pressure Vessel Code or the ASME B31 Code for Pressure Piping. However, other Sections of the Code state the conditions under which Section IX requirements are mandatory, in whole or in part, and give additional require

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 08 Face WidthDocumento1 pagina08 Face WidthsolidwormNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Fluid Statics: Manometers and Pressure MeasurementsDocumento1 paginaFluid Statics: Manometers and Pressure MeasurementssolidwormNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- 06 Helix AngleDocumento1 pagina06 Helix AnglesolidwormNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 07 Centre DistanceDocumento1 pagina07 Centre DistancesolidwormNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- And Liquid Viscosity: Stress ZDocumento1 paginaAnd Liquid Viscosity: Stress ZsolidwormNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

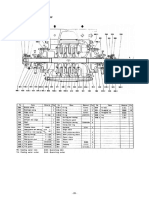

- Sectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NDocumento1 paginaSectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NsolidwormNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Changing Edge Direction: To View The Sense of An EdgeDocumento1 paginaChanging Edge Direction: To View The Sense of An EdgesolidwormNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 04 Normal ModuleDocumento1 pagina04 Normal ModulesolidwormNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Recommended: 72 Chapter 8: Performing Sample Case LessonsDocumento1 paginaRecommended: 72 Chapter 8: Performing Sample Case LessonssolidwormNessuna valutazione finora

- Size MMK 40, 50, 65 Tuffing Box Housing: Type HW SDocumento1 paginaSize MMK 40, 50, 65 Tuffing Box Housing: Type HW SsolidwormNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- To Set Axis of Revolution, Flow Direction, and View Rotation LinesDocumento1 paginaTo Set Axis of Revolution, Flow Direction, and View Rotation LinessolidwormNessuna valutazione finora

- Fluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressureDocumento1 paginaFluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressuresolidwormNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Cadtranslator™ User Guide: Translating The Max 5 Case 55Documento1 paginaCadtranslator™ User Guide: Translating The Max 5 Case 55solidwormNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 66 Chapter 8: Performing Sample Case LessonsDocumento1 pagina66 Chapter 8: Performing Sample Case LessonssolidwormNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- S Pare PartsDocumento1 paginaS Pare PartssolidwormNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Stub shaft details and packing requirementsDocumento1 paginaStub shaft details and packing requirementssolidwormNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- 3Documento7 pagine3solidwormNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- 4.2.3. Re-Assembly of Pumps With End Suction NozzleDocumento2 pagine4.2.3. Re-Assembly of Pumps With End Suction NozzlesolidwormNessuna valutazione finora

- 1Documento7 pagine1solidwormNessuna valutazione finora

- 2Documento7 pagine2solidwormNessuna valutazione finora

- Fluids 5: Buoyancy and Continuity EquationDocumento1 paginaFluids 5: Buoyancy and Continuity EquationsolidwormNessuna valutazione finora

- Bhabani P.Mohanty Fluid Engineering DevelopmentDocumento1 paginaBhabani P.Mohanty Fluid Engineering DevelopmentsolidwormNessuna valutazione finora

- 5Documento7 pagine5solidwormNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Essentials of Turbo Machinery in CFD: Ideen SadrehaghighiDocumento9 pagineEssentials of Turbo Machinery in CFD: Ideen SadrehaghighisolidwormNessuna valutazione finora

- Personal Computer) : Includes: Drop Box, The Cloud, and Any Other Site Off of Your Personal Computer)Documento6 paginePersonal Computer) : Includes: Drop Box, The Cloud, and Any Other Site Off of Your Personal Computer)IAmDanaNessuna valutazione finora

- VibrationDocumento2 pagineVibrationsolidwormNessuna valutazione finora

- Test loop configurationsDocumento1 paginaTest loop configurationssolidwormNessuna valutazione finora

- Near Net ShapeDocumento30 pagineNear Net ShapesolidwormNessuna valutazione finora

- General Requirements:: 1062 16 Pump TestingDocumento1 paginaGeneral Requirements:: 1062 16 Pump TestingsolidwormNessuna valutazione finora

- WrapupDocumento24 pagineWrapupsolidwormNessuna valutazione finora

- Alkyl HalideDocumento54 pagineAlkyl HalideNelvianaNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Instruction and Technical Manual for CentrifugesDocumento56 pagineInstruction and Technical Manual for CentrifugesDiana RaieNessuna valutazione finora

- Alpha ProfileDocumento2 pagineAlpha ProfileGovind SinghNessuna valutazione finora

- HP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced MaterialsDocumento4 pagineHP-PN4291A-5 - Dielectric Constant Measurement of Rough-Surfaced Materialssirjole7584Nessuna valutazione finora

- Flashing CalculationsDocumento8 pagineFlashing CalculationsjcmarabouNessuna valutazione finora

- 1010750-Steam Quality TestingDocumento11 pagine1010750-Steam Quality TestingHendra Hadriansyah100% (1)

- Lec 13Documento5 pagineLec 13Ghazy alshyalNessuna valutazione finora

- New Australian Curriculum Senior Secondary ChemistryDocumento44 pagineNew Australian Curriculum Senior Secondary Chemistryapi-252350138Nessuna valutazione finora

- Extract Organometallic Chemistry PDFDocumento10 pagineExtract Organometallic Chemistry PDFj pooranaNessuna valutazione finora

- ANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleDocumento12 pagineANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleParmeshwarPaulNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 5468-Tank Cleaning ChecklistDocumento3 pagine5468-Tank Cleaning ChecklistMaaloul FakherNessuna valutazione finora

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocumento21 pagineUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharNessuna valutazione finora

- FlexEJ Brochure Elaflex 10 2011Documento41 pagineFlexEJ Brochure Elaflex 10 2011harlyganNessuna valutazione finora

- Is 10585 2002 PDFDocumento9 pagineIs 10585 2002 PDFmsreerajvarmaNessuna valutazione finora

- Advantages and disadvantages of mechanical fasteners and adhesive bondingDocumento6 pagineAdvantages and disadvantages of mechanical fasteners and adhesive bondingYankie Mike PaPa100% (1)

- Validation and Verification of Cleanning ProcessDocumento42 pagineValidation and Verification of Cleanning ProcessEva Pa'e ONessuna valutazione finora

- Sybron Endo Sealapex Root Canal SealerDocumento7 pagineSybron Endo Sealapex Root Canal Sealerenjoy enjoy enjoyNessuna valutazione finora

- Commiphora Myrrh A Phytochemical and Pharmacologic PDFDocumento17 pagineCommiphora Myrrh A Phytochemical and Pharmacologic PDFWaterfall ShapelessNessuna valutazione finora

- General Characteristics of Bacteria and MollicutesDocumento13 pagineGeneral Characteristics of Bacteria and MollicutesPrincess Mehra0% (1)

- Water WastewaterDocumento20 pagineWater WastewaterterryjoseeNessuna valutazione finora

- As 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveDocumento7 pagineAs 2278.1-2008 Aerosol Containers Metal Aerosol Dispensers of Capacity 50 ML To 1000 ML InclusiveSAI Global - APAC50% (2)

- Selective MediaDocumento10 pagineSelective Mediaprincess_likemist4Nessuna valutazione finora

- Constant HeadDocumento14 pagineConstant HeadfujiNessuna valutazione finora

- Method Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaDocumento4 pagineMethod Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaFendi Rang TigorNessuna valutazione finora

- Water Quality WSO Student Workbook Water Supply OperationsDocumento69 pagineWater Quality WSO Student Workbook Water Supply OperationsdikeNessuna valutazione finora

- BOF1Documento3 pagineBOF1Skartini DayNessuna valutazione finora

- Aldehyde, Ketones and Carboxylic AcidDocumento18 pagineAldehyde, Ketones and Carboxylic AcidPRADEEP CNessuna valutazione finora

- Thermogravimetric Analysis (TGA) Methodology of Calculating TheDocumento15 pagineThermogravimetric Analysis (TGA) Methodology of Calculating TheHamed HamidpourNessuna valutazione finora

- ME6008 WELDING TECHNOLOGY Part B IQDocumento1 paginaME6008 WELDING TECHNOLOGY Part B IQVikram mNessuna valutazione finora

- VOMGE Press Tool Design Course OverviewDocumento11 pagineVOMGE Press Tool Design Course OverviewjanakNessuna valutazione finora

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for Auditing Process Safety Management SystemsDa EverandGuidelines for Auditing Process Safety Management SystemsNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Safety Fundamentals and Best Practices in Construction IndustryDa EverandSafety Fundamentals and Best Practices in Construction IndustryNessuna valutazione finora

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- Guidelines for Implementing Process Safety ManagementDa EverandGuidelines for Implementing Process Safety ManagementNessuna valutazione finora

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (51)