Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Example Risk Assessment For Cold Storage Warehousing: Setting The Scene

Caricato da

ʞǝǝs Uǝ ƎpıɥTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Example Risk Assessment For Cold Storage Warehousing: Setting The Scene

Caricato da

ʞǝǝs Uǝ ƎpıɥCopyright:

Formati disponibili

Health and Safety Executive

Example risk assessment for cold storage warehousing

Setting the scene

Frozen Foods Ltd provide cold storage and distribution facilities (at temperatures between -18 and -30 C) at three locations. They serve customers of all sizes across a variety of sectors. Each location has 10 000 pallet spaces, uses fixed and mobile racking, and averages a throughput of 2500 pallets a week. Twenty people are employed in the warehouses, working a variety of shifts. Three members of staff are from an Eastern European country; only one speaks good English. At busy times, temporary staff from an employment agency may also be employed. The site manager did the risk assessment, which covers goods inward from the gate to the cold store, their storage and their despatch.

How was the risk assessment done?

The manager followed the guidance in Five steps to risk assessment (www.hse.gov.uk/pubns/indg163.pdf). 1 To identify the hazards, the manager:

walked around all the areas where the staff, contractors, customers and others may go, noting things that might pose a risk and taking HSEs guidance into account; talked through the issues with the safety representative, including how knowledge of risks and risk controls could effectively be communicated to the two staff members who did not speak good English, and on health and safety training for agency staff; talked to the two company first-aiders, to see if the health surveillance questionnaires they compile and distribute have thrown up any additional issues that need to be considered; talked to supervisors and other members of staff to learn from their detailed knowledge of particular jobs and areas and to discuss whether safe working procedures should be developed for certain jobs; and looked at the accident book to gather information on past problems.

responsible for each of the actions that were needed, and by when each action should be done. He wrote this down and, when each action was completed, ticked if off and recorded the date. The manager told staff about the risk assessment at a team meeting. The Eastern European member of staff who spoke good English translated for his countrymen, and checked that they understood it. The manager pinned up a copy of the risk assessment in the staff room, and made it part of the induction process for new staff. 5 The manager decided to review and update the assessment at least once a year or at any time when major changes to the workplace occurred, such as the introduction of a new plant or process.

Important reminder

This example risk assessment shows the kind of approach a small business might take. Use it as a guide to think through some of the hazards in your business and the steps you need to take to control the risks. Please note that it is not a generic risk assessment that you can just put your company name on and adopt wholesale without any thought. This would not satisfy the law and would not be effective in protecting people. Every business is different you need to think through the hazards and controls required in your business for yourself.

1 of 6 pages

2 The manager then wrote down who could be harmed by the hazards and how. 3 For each hazard, the manager wrote down what controls, if any, were in place to manage these hazards, and compared the controls to the good practice guidance on the HSE website. Where he did not consider existing controls good enough, he wrote down what else was needed to control the risk. 4 The manager discussed the findings with the safety representative. Then, to implement the findings of the risk assessment, the manager decided who was

looked at HSEs web pages for free health and safety advice and guidance for the warehousing industry (www.hse.gov.uk/warehousing/index.htm), and at HSG76 Warehousing and storage: A guide to health and safety (available from HSE Books, www.hsebooks.com/ or 01787 881165), particularly the chapter on temperature controlled storage;

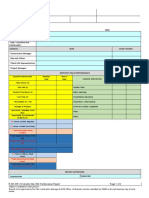

Example risk assessment: Cold storage warehousing

Health and Safety Executive

Company name: Frozen Foods Ltd Date of risk assessment: 1/10/07

What are the hazards? Extreme cold Accidental lock-in in the cold store

Who might be harmed and how? Employees and others may suffer death or serious injury from prolonged exposure to cold temperatures if accidentally locked in the cold store.

What are you already doing? Access to the store restricted to authorised, trained persons only. No entry signs clearly posted. Emergency exit provided, door fitted with strip heaters to ensure it does not freeze. Emergency lighting provided (mains powered, battery back-up). Daily check on emergency exit door to ensure it is not frozen shut. Emergency exit door instructions posted on illuminated board by exit. Two trapped worker alarms (battery operated, mains back-up) next to both exits. Supervisor ensures thorough check of building before it is locked. Alarms and emergency lighting regularly tested/maintained by competent person. Pre-employment health screening by a responsible person. Regular health surveillance by trained, responsible persons. System for referring to an occupational health professional staff whose health, following surveillance, is possibly being affected by cold work. Staff trained in risks of cold store working and to recognise symptoms of cold stress. The right personal protective equipment (according to advice in HSE guidance and suppliers recommendations) issued and staff trained in its use. Supervisors ensure PPE is worn. Only authorised, trained staff allowed in the cold store. Staff have regular warm-up breaks. Drying facilities for wet PPE.

What further action is necessary?

Action by whom? Supervisors

Action by when? 04/10/07

Done First check done 04/10/07 02/10/07

Check instructions remain clearly visible. Periodic checks to ensure clear access to emergency exit maintained, and that door is operational.

Supervisors

04/10/07

Extreme cold Working in a subzero environment

Employees may suffer ill health or injury (eg frostbite) from prolonged exposure to sub zero temperatures (particularly those with certain pre-existing medical conditions). Extreme cold may also lead to gradual loss of awareness of risk.

Staff reminded to regularly check their PPE for wear and tear, to ensure it remains effective.

Manager

04/10/07

04/10/07

Example risk assessment: Cold storage warehousing

2 of 6 pages

Health and Safety Executive

What are the hazards? Accidental release of Group 2 refrigerant (ammonia)

Who might be harmed and how? Employees and others may suffer fatal respiratory irritation following exposure to ammonia. Exposure to even low concentrations can cause severe eye and throat irritation.

What are you already doing? Extraction and ventilation plant installed. System designed as per industry practice. Written scheme of examination for all refrigeration plant, including vapour detectors. Only authorised persons allowed in plant room and room locked when not in use. Plant examined as per written scheme by a competent person. Plant maintained by a competent person. High-hazard maintenance jobs (eg oil draining) are identified and done by competent people, such as qualified refrigeration specialists, following safe systems of work and using the correct equipment. Staff trained in the risks of ammonia and its effect on health. Emergency plan for ammonia release agreed, including victim rescue policy and policy for neighbouring properties, and discussed with local fire service. Staff trained in emergency plan. Vapour detectors near likely leakage points activate alarm and emergency extraction if workplace exposure limit (25 parts per million) reached. Water shower nearby for those exposed to an ammonia spray. Windsock to show wind direction in event of release (staff can gather upwind of leak). Pedestrians kept apart from moving vehicles by yellow lines, railings and marked walkways. Road surfaces in good condition. Measures in place to minimise reversing on site. Reversing aids (mirrors) in place. Hi-viz tabards and safety boots worn by all in yard/loading bay. Drivers hand in keys when vehicle parked. All visitors receive site rules and a site map. Sufficient number of trained banksmen on site, for each shift. Any reversing on site that is necessary is directed by a trained banksman, working from a safe position.

What further action is necessary?

Action by whom? Manager

Action by when? 04/10/07

Done 04/10/07

Ensure that any work on the system where there is a potential for ammonia release is done by at least two people (second person to help in an emergency). Set date for rehearsal of procedures in the event of an emergency alarm going off. Monthly checks on vapour detectors and alarms. Shower to be checked weekly.

Manager

04/10/07

04/10/07

Supervisors Supervisors

04/10/07 04/10/07

02/10/07 04/10/07

Workplace transport Vehicle movement in the yard and the loading bay deliveries and despatch.

Staff and visitors may suffer life-threatening injuries, such as fractures and internal damage, if they are struck by a vehicle.

Mark out safe area for visiting Manager to drivers during loading and arrange with unloading of their vehicle. facilities team Extra signage reminding staff/visitors not to enter site through the main gate, used by vehicles, but to use the marked pedestrian route. Manager to arrange with facilities team

15/11/07

25/10/07

15/11/07

25/10/07

Example risk assessment: Cold storage warehousing

3 of 6 pages

Health and Safety Executive

What are the hazards? Workplace transport Vehicle activity in the cold store

Who might be harmed and how? Staff and visitors may suffer lifethreatening injuries if they are struck by forklift trucks (FLTs) or other materials handling equipment (MHE).

What are you already doing? Walkways clearly marked. Good lighting throughout. Mirrors at the end of aisles. All drivers trained and follow safe systems of work. Vehicles selected to minimise risk. Drivers do daily pre-use vehicle checks. FLTs/MHE maintained to manufacturers instructions and thoroughly examined every 6 months by competent person. Supervisors monitor driver performance. Generally good housekeeping shrinkwrap, pallet debris, strapping bands, spillages etc cleared away promptly. Entrance/exit doors regularly checked for ice and ice deposits removed. Floor in good condition, any damage quickly repaired. Pallets stored in designated area. Staff wear safety shoes with a good grip. All work at height (eg retrieving dislodged pallets, stock checking) is done by trained, authorised staff using personnel lifting equipment to a safe system of work. Control and use of ladders policy, monitored by supervisors. Climbing on racking strictly forbidden.

What further action is necessary?

Action by whom? Manager

Action by when? 04/10/07

Done 02/10/07

Instruct drivers not to leave keys in unattended vehicles (to prevent unauthorised use).

Slips and trips

Staff and others may suffer injuries such as fractures if they slip, eg on water or oil or trip over objects such as stock protruding into gangways.

Shift managers to draw up and monitor planned cleaning arrangements. Remind staff to keep doors closed to help prevent ice forming at entrances. Reminder to supervisors to check that safe systems of work are followed for all work at height. Post signs reminding staff never to climb racking. Remind staff that roll cages with defective wheels must be taken out of use for repair.

Shift managers

14/10/07

14/10/07

Shift managers

14/10/07

14/10/07

Falls from height

Staff may suffer severe or fatal injuries if they fall from any height.

Shift managers

14/10/07

14/10/07

Manager Shift managers

15/11/07 14/10/07

25/10/07 14/10/07

Manual handling

Staff may get injuries or back pain from handling heavy objects such as pallets.

All staff trained in safe manual handling techniques, particularly when picking goods by hand. All staff trained in safe use of roll cages. Roll cages with defective wheels taken out of use until repaired.

Example risk assessment: Cold storage warehousing

4 of 6 pages

Health and Safety Executive

What are the hazards? Falling goods

Who might be harmed and how? Staff may suffer injuries such as fractures and bruising from falling stock.

What are you already doing? Shrinkwrap policy on all inbound pallets. Policy to report broken or dislodged pallets in racking aisles. Racking selected according to the operating temperature and is to SEMA standard. Safe working load signage displayed. All racking inspected to an agreed programme, by a competent person, and maintained as necessary. Staff trained in use of machine. Dangerous moving parts are guarded according to manufacturers instructions, and staff do weekly check on guards. Emergency stop buttons provided. Machine maintained and inspected according to manufacturers instructions. Staff trained in use of machine, including a pre-use guard check. When not in use, safety perimeter chain put up with a No unauthorised use sign. Batteries charged in designated bay that is well ventilated. Safe system of work used. Job done by trained, authorised staff only. Refrigeration system, including fans, maintained in good condition according to a planned system of work. Current work practices minimise time spent in noisy areas. Electrical installation and all equipment is inspected according to a planned schedule. Staff report any concerns to shift manager who will take appropriate action.

What further action is necessary?

Action by whom? Shift managers

Action by when? 14/10/07

Done 14/10/07

Instruct staff to immediately report any concerns they have about the condition of racking to the manager or a supervisor.

Machinery Conveyor belt for unloading Pallet inverter

Staff using the machine may suffer injury from moving parts, particularly where belt meets rollers. Staff using the machine may be injured by moving parts.

No further action needed at this stage.

Draw up safe working procedure, including for clearing blockages, for use of pallet inverter. No further action at this stage.

Supervisors

31/10/07

30/10/07

Recharging MHE batteries (potential for explosion) Noise

Burns or fractures as material ejected could injure anyone nearby. Staff may suffer discomfort and potential hearing damage if working in noisy areas, eg near refrigeration fans. Staff may suffer shock and burns injuries from faulty electrical equipment or installation.

No further action at this stage.

Electricity

No further action at this stage.

Example risk assessment: Cold storage warehousing

5 of 6 pages

Health and Safety Executive

What are the hazards? Unfamiliarity with site risks

Who might be harmed and how? Visitors, including contractors, may suffer injury or ill health through lack of awareness of risks on site. Staff trapped could suffer fatal injury from smoke inhalation/ burns.

What are you already doing? Visitors to the cold store must be given appropriate PPE and accompanied by an authorised person. All work on site by contractors is done according to a permit-to-work system, monitored by supervisors. Fire risk assessment done as at www.communities.gov.uk/fire and necessary actions taken.

What further action is necessary?

Action by whom?

Action by when? 31/10/07

Done 29/10/07

Discuss with supervisors if Manager the permit-to-work system is operating effectively and if there is scope to improve it. No further action at this stage.

Fire

Assessment review date: 1/10/08

Example risk assessment: Cold storage warehousing Published by the Health and Safety Executive 11/10

6 of 6 pages

Potrebbero piacerti anche

- CHCAGE002 Student Assessment Booklet (ID 121389)Documento61 pagineCHCAGE002 Student Assessment Booklet (ID 121389)Hardeek Mota33% (12)

- Risk Assessment For Cold Storage WarehousingDocumento6 pagineRisk Assessment For Cold Storage WarehousingJohn Kurong100% (3)

- Cooling TowerDocumento6 pagineCooling Towerʞǝǝs Uǝ Ǝpıɥ100% (4)

- Site Visitor Management PlanDocumento8 pagineSite Visitor Management Planhanshul sisodiyaNessuna valutazione finora

- Planned Inspection - FIRE SAFETY ChecklistDocumento5 paginePlanned Inspection - FIRE SAFETY ChecklistJose Aguilos BotanaNessuna valutazione finora

- Personal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationDocumento4 paginePersonal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationAnge JuanNessuna valutazione finora

- Risk Management in Construction ProjectsDocumento17 pagineRisk Management in Construction ProjectsMohammed Raafat100% (1)

- 9 - Aerial Lifts and Scissor Lifts THA-AHADocumento5 pagine9 - Aerial Lifts and Scissor Lifts THA-AHAJojolas100% (2)

- Security Management Standard - Physical Asset Protection ANSI - ASIS PAP AMERICAN NATIONAL STANDARD - 1 - 部分2Documento20 pagineSecurity Management Standard - Physical Asset Protection ANSI - ASIS PAP AMERICAN NATIONAL STANDARD - 1 - 部分2安靖Nessuna valutazione finora

- Ansi/assp Z590.3-2011 (R2016)Documento56 pagineAnsi/assp Z590.3-2011 (R2016)Bayu Putra100% (2)

- Maintenance of Flats: Example Risk Assessment ForDocumento5 pagineMaintenance of Flats: Example Risk Assessment FordwayjayNessuna valutazione finora

- Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?Documento6 pagineExample Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?Blas de LezoNessuna valutazione finora

- General Office Cleaning: Example Risk Assessment ForDocumento3 pagineGeneral Office Cleaning: Example Risk Assessment Forisak23Nessuna valutazione finora

- Contractor Safety Performance Report: Al-Khafji Joint OperationsDocumento1 paginaContractor Safety Performance Report: Al-Khafji Joint OperationsHassan64041Nessuna valutazione finora

- Avoid Spot Treat HeatDocumento1 paginaAvoid Spot Treat HeatZulfa NurmanitaNessuna valutazione finora

- How To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8Documento8 pagineHow To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8tzryadNessuna valutazione finora

- HSE RequirementDocumento10 pagineHSE Requirementyudiyana16Nessuna valutazione finora

- Sample Weekly Cleaning Schedule For Shop FloorDocumento13 pagineSample Weekly Cleaning Schedule For Shop FloorBalaje RajNessuna valutazione finora

- Safety HandbookDocumento52 pagineSafety HandbookfumsmithNessuna valutazione finora

- LPG-BUS-HSE-IST-0007 - Safety Data Sheet - Liquefied Petroleum GasDocumento10 pagineLPG-BUS-HSE-IST-0007 - Safety Data Sheet - Liquefied Petroleum GasElias Jarjoura100% (1)

- FIN-03. Receiving ProcedureDocumento5 pagineFIN-03. Receiving ProcedureVu Dinh ThietNessuna valutazione finora

- M010-MSI-HSE-00-PLN-02007 - Rev5 Heat Stress & Summer Working Plan PDFDocumento66 pagineM010-MSI-HSE-00-PLN-02007 - Rev5 Heat Stress & Summer Working Plan PDFEldhose VargheseNessuna valutazione finora

- 00 5S Shop Floor ChecklistDocumento3 pagine00 5S Shop Floor ChecklistYen NguyenNessuna valutazione finora

- 8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseDocumento14 pagine8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseGeyko RuslanNessuna valutazione finora

- Using Bench Grinder (WS)Documento4 pagineUsing Bench Grinder (WS)John KalvinNessuna valutazione finora

- 1 EvacuationGuideDocumento17 pagine1 EvacuationGuideEmine GençNessuna valutazione finora

- Health and Safety - ManualDocumento156 pagineHealth and Safety - ManualedloradoNessuna valutazione finora

- Toolbox Talk: Ladder Safety: Using A Stepladder SafelyDocumento2 pagineToolbox Talk: Ladder Safety: Using A Stepladder SafelyAnge JuanNessuna valutazione finora

- STORAGEDocumento2 pagineSTORAGEashrafNessuna valutazione finora

- SWP Air CompressorDocumento2 pagineSWP Air Compressormyn maliQueNessuna valutazione finora

- TBT Manual HandlingDocumento1 paginaTBT Manual HandlingNishadh NishNessuna valutazione finora

- Warehouse Supervisor Cum Lesson PlannerDocumento56 pagineWarehouse Supervisor Cum Lesson Plannernayra khan67% (3)

- Essential Food Safety TrainingDocumento26 pagineEssential Food Safety TrainingMohamed azarudeenNessuna valutazione finora

- Fire Safety Requirements Part 3 - Trasport Storage Handeling and Installations of Liquified Petroleum GasDocumento47 pagineFire Safety Requirements Part 3 - Trasport Storage Handeling and Installations of Liquified Petroleum Gasadnan amal yusfarNessuna valutazione finora

- Delivery Assessment Schedule - Diploma PDFDocumento25 pagineDelivery Assessment Schedule - Diploma PDFBhavi0% (2)

- Canteen LPG Do's &Don'TsDocumento1 paginaCanteen LPG Do's &Don'Tsraveekas6148Nessuna valutazione finora

- Fire Safety Risk AssessmentDocumento3 pagineFire Safety Risk Assessmentudupiganesh3069Nessuna valutazione finora

- First Aid Box Fill ListDocumento34 pagineFirst Aid Box Fill Listzam110Nessuna valutazione finora

- Manual Order PickingDocumento16 pagineManual Order PickingAnonymous IVDjj2b7wNessuna valutazione finora

- NEBOSH International General Certificate Week 2 Element 6: Fire Hazards and ControlDocumento37 pagineNEBOSH International General Certificate Week 2 Element 6: Fire Hazards and ControlJaballa AliNessuna valutazione finora

- SAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XDocumento13 pagineSAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XWhina R AymaNessuna valutazione finora

- Heat Stress Training & CampaignDocumento11 pagineHeat Stress Training & CampaigndammyNessuna valutazione finora

- MachineGuardingSopTech 31Documento1 paginaMachineGuardingSopTech 31muthuswamy77Nessuna valutazione finora

- Daily Equipment Maintenance Checklist: Items Evaluators CommentDocumento1 paginaDaily Equipment Maintenance Checklist: Items Evaluators CommentCarwill TesdaNessuna valutazione finora

- Camp Inspection ReportDocumento4 pagineCamp Inspection ReportgkNessuna valutazione finora

- Basic Safety Requirement: Important Note (Mandatory Requirement)Documento9 pagineBasic Safety Requirement: Important Note (Mandatory Requirement)MahammadNessuna valutazione finora

- Mandatory Reporting Fields Date:: R-001-REV.01-Montly Site HSE Performance Report Page 1 of 2Documento2 pagineMandatory Reporting Fields Date:: R-001-REV.01-Montly Site HSE Performance Report Page 1 of 2Ravelle JacquireNessuna valutazione finora

- Template Site Specific ESH Safety SSEP PlanDocumento12 pagineTemplate Site Specific ESH Safety SSEP PlanNarendraNessuna valutazione finora

- Pallet Jack Safety: Wear Personal Protective EquipmentDocumento2 paginePallet Jack Safety: Wear Personal Protective EquipmentRadhaKrishnan R100% (1)

- Hazard Identification, Risk Assessment & Control: A H H E E E B M H H E E C L M H E E D) L L M H EDocumento9 pagineHazard Identification, Risk Assessment & Control: A H H E E E B M H H E E C L M H E E D) L L M H Eikram uddinNessuna valutazione finora

- Sequence Identified Hazards Key Processes To Be Followed Precautions / PPE Required Planned Job Observations CommentsDocumento3 pagineSequence Identified Hazards Key Processes To Be Followed Precautions / PPE Required Planned Job Observations CommentsvictorNessuna valutazione finora

- SOP For Fire FightingDocumento6 pagineSOP For Fire FightingAhmad HassanNessuna valutazione finora

- Fire Risk Management-White PaperDocumento4 pagineFire Risk Management-White PaperAnandababuNessuna valutazione finora

- Toolbox Talks Forklift Safety EnglishDocumento1 paginaToolbox Talks Forklift Safety EnglishBayu Mandala PratamaNessuna valutazione finora

- Chemical - Regulations in India PDFDocumento50 pagineChemical - Regulations in India PDFSANDAMARNessuna valutazione finora

- Food Safety Fundamentals (Pamplet)Documento2 pagineFood Safety Fundamentals (Pamplet)Anith PutraNessuna valutazione finora

- Protecting Workers From Heat StressDocumento2 pagineProtecting Workers From Heat StressJohn Melanathy IINessuna valutazione finora

- Visitors Site Safety Induction Bris1Documento2 pagineVisitors Site Safety Induction Bris1Ardago LenggaNessuna valutazione finora

- Contractor Checklist Instructions GeneralDocumento3 pagineContractor Checklist Instructions GeneralleighbatesNessuna valutazione finora

- Workplace Housekeeping ChecklistDocumento2 pagineWorkplace Housekeeping ChecklistBrijgopal YadavNessuna valutazione finora

- SM City Cebu WP SignedDocumento2 pagineSM City Cebu WP SignedCris EnerioNessuna valutazione finora

- Aug Toolbox Talks Confined Spaces 0517Documento2 pagineAug Toolbox Talks Confined Spaces 0517WaSim AKramNessuna valutazione finora

- Fire Safety Audit - Zeeshan RestaurantDocumento6 pagineFire Safety Audit - Zeeshan RestaurantAbdurNessuna valutazione finora

- SOP Deep Cleaning of WashroomsDocumento4 pagineSOP Deep Cleaning of Washroomsshahnawaz2012-1Nessuna valutazione finora

- Chapter 2 ISO 9000Documento41 pagineChapter 2 ISO 9000Shishir GyawaliNessuna valutazione finora

- Example Risk Assessment For A Poultry Farm: Setting The Scene How Was The Risk Assessment Done?Documento4 pagineExample Risk Assessment For A Poultry Farm: Setting The Scene How Was The Risk Assessment Done?Olivera NovkovicNessuna valutazione finora

- G. Quality Plan or Quality Control ProgramDocumento1 paginaG. Quality Plan or Quality Control Programʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- F. CONSTRUCTION SAFETY PROGRAM OR SAFETY MANUAL PROCEDUREDocumento1 paginaF. CONSTRUCTION SAFETY PROGRAM OR SAFETY MANUAL PROCEDUREʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- Billing For Electrical Works 03-28-23Documento3 pagineBilling For Electrical Works 03-28-23ʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- Fire SuppresionDocumento1 paginaFire Suppresionʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- D. Temporary FacilityDocumento1 paginaD. Temporary Facilityʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- F. CONSTRUCTION SAFETY PROGRAM OR SAFETY MANUAL PROCEDUREDocumento1 paginaF. CONSTRUCTION SAFETY PROGRAM OR SAFETY MANUAL PROCEDUREʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- Pal Temporary Barracks PDFDocumento1 paginaPal Temporary Barracks PDFʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- Construction Management SpecificationDocumento5 pagineConstruction Management Specificationʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- DD - PLUMBING SYSTEM - DEC 21 2022 6db71 PDFDocumento44 pagineDD - PLUMBING SYSTEM - DEC 21 2022 6db71 PDFʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- As Built Fdas PDFDocumento1 paginaAs Built Fdas PDFʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- Manual TransmissionDocumento60 pagineManual Transmissionʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- Thermodynamics P K Nag Exercise Unsolved Problems SolvedDocumento265 pagineThermodynamics P K Nag Exercise Unsolved Problems SolvedRavinder Antil90% (40)

- Manansala Jay-Ren E. Solidworks DATE: AUGUST 6, 2014 Elective 2 Plate No. 7 RatingDocumento2 pagineManansala Jay-Ren E. Solidworks DATE: AUGUST 6, 2014 Elective 2 Plate No. 7 Ratingʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- BoilerDocumento17 pagineBoilerʞǝǝs Uǝ ƎpıɥNessuna valutazione finora

- LambersCPAReviewFAR PDFDocumento1.013 pagineLambersCPAReviewFAR PDFmonicaravi100% (5)

- Emergency Response PlanDocumento53 pagineEmergency Response PlansergioNessuna valutazione finora

- Risk Management - Unit 1Documento20 pagineRisk Management - Unit 1Mohammad Moazzam HussainNessuna valutazione finora

- Task Risk Assessment TemplateDocumento8 pagineTask Risk Assessment TemplateAnhVuVoNessuna valutazione finora

- Gaurav Singh RajputDocumento4 pagineGaurav Singh RajputGaurav Singh RajputNessuna valutazione finora

- Saphelp Grcrm101 en 13 De98bd929b45ac9cb6ad56d3ccb9c8 ContentDocumento194 pagineSaphelp Grcrm101 en 13 De98bd929b45ac9cb6ad56d3ccb9c8 ContentiuhiauhxaNessuna valutazione finora

- RA Excessive Noise .Vibration.Documento11 pagineRA Excessive Noise .Vibration.Ndifor Dinho0% (1)

- Element 1: Why We Should Manage Workplace Health and Safety Element 1Documento34 pagineElement 1: Why We Should Manage Workplace Health and Safety Element 1Shagufta MallickNessuna valutazione finora

- RA - 1 - For Site MobilizationDocumento14 pagineRA - 1 - For Site MobilizationIbrahim EsmatNessuna valutazione finora

- Chapter 8 PPT 4th EditionDocumento38 pagineChapter 8 PPT 4th EditionNhung KiềuNessuna valutazione finora

- The Dive Business Guide To Safe Diving OperationsDocumento25 pagineThe Dive Business Guide To Safe Diving OperationsWale OyeludeNessuna valutazione finora

- Anvil Group - Travel Risk Management 101 - EbookDocumento17 pagineAnvil Group - Travel Risk Management 101 - EbookRaluca FuioreaNessuna valutazione finora

- BCF Guide To The Safe Operation of Dispersion EquipmentDocumento44 pagineBCF Guide To The Safe Operation of Dispersion EquipmentSundrakumar RajuNessuna valutazione finora

- Risk Assessment For Use of Power ToolsDocumento2 pagineRisk Assessment For Use of Power ToolsRicardo DalisayNessuna valutazione finora

- Environmental Management Plan GuidelinesDocumento23 pagineEnvironmental Management Plan GuidelinesMianNessuna valutazione finora

- Checklist of ISO 27001 Mandatory Documentation enDocumento9 pagineChecklist of ISO 27001 Mandatory Documentation enRoshan JayakodyNessuna valutazione finora

- Mos - Earthing System - Thales ProjectDocumento16 pagineMos - Earthing System - Thales ProjectMohamed shabeebNessuna valutazione finora

- KRA 1.4 Plant and EquipmentDocumento13 pagineKRA 1.4 Plant and EquipmentSubburajMechNessuna valutazione finora

- Excavation Work ProcedureDocumento11 pagineExcavation Work ProcedureResearcher100% (1)

- Managing RisksDocumento42 pagineManaging RisksmafroewNessuna valutazione finora

- Risk Assessment Bank ParkDocumento2 pagineRisk Assessment Bank ParkJack BlackshawNessuna valutazione finora

- 5.-Safe Use of Falsework in Construction Cis-23-2021Documento29 pagine5.-Safe Use of Falsework in Construction Cis-23-2021HSE CREC100% (1)

- Admin ProfileDocumento8 pagineAdmin ProfileGjoko IvanoskiNessuna valutazione finora

- Unit IG2: Risk Assessment: Examiner Feedback: NEBOSH International General Certificate in Occupational Health and SafetyDocumento2 pagineUnit IG2: Risk Assessment: Examiner Feedback: NEBOSH International General Certificate in Occupational Health and SafetyM AbidNessuna valutazione finora

- Group Procedure - D5 - Management of Tailings and Water Storage Facilities v1.2Documento32 pagineGroup Procedure - D5 - Management of Tailings and Water Storage Facilities v1.2Francklin TokimitondrasoaNessuna valutazione finora