Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cytec Cymel Resins

Caricato da

Harshad PorwalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cytec Cymel Resins

Caricato da

Harshad PorwalCopyright:

Formati disponibili

CYMEL Resins

For Coating and Specialty Applications

Introduction

This brochure provides product characteristics, compositional information and brief general comments on the use of CYMEL resins used in industrial coatings. Cytec is a leading global supplier of crosslinking agents and offers a broad line of CYMEL resins based on melamine, urea, benzoguanamine and glycoluril. These resins are used in many industrial finishes, including high solids solvent-based and waterborne coatings. Cytec's expertise in crosslinking technology is part of our corporate heritage and the foundation to our leadership in supplying the market for amino resins. Cytec's goals in research and development Several factors drive Cytec's research and development efforts. Cytec focuses on gaining a fundamental understanding of the technical challenges encountered by our customers as they work towards improving their formulations. Cytec also focuses on offering solutions quickly and cost-effectively. Equally important is our commitment to developing new products that fulfill long-standing needs of the industries we serve and helping those industries advance technologically. Our technical specialists routinely visit customer locations, worldwide, to assist them in resolving problems and accelerating development of better products.

Table of Contents High Solids Methylated Melamine Resins .........................2 Highly Methylated Melamine Resins .............................2 Methylated High Imino Melamine Resins .....................3 Partially Methylated Melamine Resins ...........................3 High Solids Mixed Ether Melamine Resins .......................4 Highly Alkylated Melamine Resins ................................4 High Imino Melamine Resins ........................................5 Butylated Melamine Resins ................................................6 n-Butlyated Melamine Resins ........................................6 Highly n-Butylated Melamine Resins ............................6 n-Butylated High Imino Melamine Resins.....................7 Iso-Butylated Melamine Resins......................................7 High Solids Urea Resins .....................................................8 Methylated Resins .........................................................8 Butylated Resins ............................................................8 Butylated Urea Resins .......................................................10 n-Butylated Urea Resins...............................................10 iso-Butylated Urea Resins ............................................11 Benzoguanamine and Glycoluril Resins ..........................12 Benzoguanamine Resins...............................................12 Glycoluril Resins .........................................................13

High Solids Methylated Melamine Resins

Highly Methylated Melamine Resins

Highly methylated melamine resins consist of commercial versions of hexamethoxymethylmelamine (HMMM). They differ primarily in their degree of alkylation and monomer content. All are efficient crosslinking agents for hydroxyl, carboxyl and amide functional polymers. The practical equivalent weight for most of the resins is 130-180. Advantages are low VOCs; high film flexibility and toughness when used with inherently flexible backbone resins; excellent formulation stability, especially in waterborne systems formulated at a pH of 8-9; good mar resistance; and good intercoat adhesion properties. As typical with melamine resins, all are low in color and color development, have excellent exterior durability and good heat resistance. Because of their high extent of alkylation, the resins in

this series require the addition of a strong acid catalyst for acceptable cure response when baked at 125-150C. Typically, 0.2- 0.4% p-toluene sulfonic acid based on total binder solids is recommended. The optimum concentration of acid catalyst depends on the basicity of the other components in the formulation and should be determined experimentally. Using a blocking amine for the acid catalyst and adding a stabilizing alcohol to the formulation can enhance formulation stability.

Methylated High Imino Melamine Resins

Methylated high imino melamine resins are partially methylolated and highly alkylated. These characteristics result in resins containing a significant concentration of alkoxy/imino or high NH functionality. The advantages are fast cure response at 120-150C without the need for strong acid catalysts, fast cure response in waterborne formulations, high film hardness, and low formaldehyde release on cure. In addition to reacting with hydroxyl, carboxyl and amide functionality on polymers, these resins also self-condense readily. Therefore, their practical equivalent weight is typically 180-240. They too, can be stabilized by adding amine and stabilizing alcohol to the formulation. Compared to their highly alkylated counterparts, the imino resins usually result in slightly less flexible coatings and slightly higher VOCs when used in solvent-based systems.

Partially Methylated Melamine Resins

Partially methylated melamine resins are highly methylolated and partially alkylated. They cure well at 125-150C without the need to add a strong acid catalyst. The acidity of most polymers used in thermoset coatings is sufficient to catalyze their reaction. Their film performance properties are similar to those of the high imino resins in the previous category. In addition to reacting with the hydroxyl, carboxyl and amide functionality of polymers they, too, can self-condense readily. Their practical equivalent weight is also 180-240. As with all melamine resins, they can be stabilized by adding amine and stabilizing alcohol to the formulation. The major limitation of these products is high formaldehyde release on baking, primarily due to their high free methylol content.

High Solids Methylated Melamine Resins

Product Name Former Name Non Volatile % 45C for 45 Solvent Monomer Content % approx. Viscosity G-H 25C Viscosity mPa.s. 25C Viscosity mPa.s. 23C Density Lbs/Gal approx. Density KgM3 approx. Flashpoint C Water Solubility Xylene Solubility Comments

Highly Methylated Melamine Resins

CYMEL 300 CYMEL 303LF CYMEL 303 ULF

98 minimum 98 minimum 98 minimum

76 59 59

Waxy solid Y-Z2 Y-Z2

2600-5000 2600-5000

3000-6000

10.0 10.0 10.0

1200 1200 1200

>100 >100 >100

Insoluble Insoluble Insoluble

Complete Complete Complete

Closest in composition to HMMM in product line. FF specification <0.3%. FF specification <0.1%.

High Imino Resins

CYMEL 323 CYMEL 325 CYMEL 327 CYMEL 328 CYMEL 385

78-82 78-82 88-92 83-87 76-81

iso-Butanol iso-Butanol iso-Butanol Water Water

58 46 60 55 63

Y-Z3 X-Z1 Z2-5

2000-4800 5500-11500

2500-7500 2500-4500 5100-16000 1000-3000 1000-1600

9.3 9.4 9.8

1120 1120 1180 1230 1250

33 37 444 94 >100

Complete Partial Complete Complete Complete

Partial Partial Partial Insoluble Insoluble

Very fast cure response. Does not require a strong acid catalyst. Low HCHO release. Fast cure response. Does not require a strong acid catalyst. Low HCHO release. Does not require a strong acid catalyst. Fast cure plus good stability. Similar in composition to CYMEL 327 resin, but supplied in water. Very fast cure in WB. Does not require a strong acid catalyst. Low HCHO release.

U-W

600-1000

10.4

Partially Methylated Melamine Resins

CYMEL 370 CYMEL 373 CYMEL 380

86-90 83-87 76-82

iso-Butanol Water iso-Butanol

40 50 40

Z2-5 Y-Z2 V-Z

5100-10200 2500-6000

9.8 10.5 9.6

1180 1260

46 >100 46

Partial Complete Partial

Partial Insoluble Partial

General purpose melamine resin. Fast cure. Does not require a strong acid catalyst. Similar performance to CYMEL 370 resin, but supplied in water. Same composition as CYMEL 370 resin, but supplied at lower solids and viscosity.

High Solids Mixed Ether Melamine Resins

Highly Alkylated Melamine Resins

The highly alkylated melamine resins in this category are similar to the commercial versions of hexamethoxymethylmelamine (HMMM) except for the type of alkylation alcohol. The resins contain combinations of methoxy sites and longer chain length alkoxy sites (ethoxy, n-butoxy or iso-butoxy). They also differ from each other in their degree of alkylation and monomer content. Longer chain length alkoxy sites impart lower viscosity, improved flow and leveling, and intercoat adhesion. All of the resins in the series are efficient crosslinking agents for hydroxyl, carboxyl and amide functional polymers. The practical equivalent weight for most is 140-200. Other advantages are low VOCs; high film flexibility and toughness when used with inherently flexible backbone resins; excellent formulation stability, especially in waterborne systems at a pH of 8-9 and good

mar resistance properties. Because of their high extent of alkylation, the resins in this series require the addition of a strong acid catalyst for acceptable cure response when baked at 125-150C. Typically, 0.2-0.4% p-toluene sulfonic acid based on total binder solids is recommended. The optimum concentration of acid catalyst depends on the basicity of the other components in the formulation and should be determined experimentally. The use of a blocking amine for the acid catalyst and the addition of a stabilizing alcohol to the formulation should enhance formulation stability.

High Imino Melamine Resins

The high imino melamine resins in this category are similar to those in the high imino methylated melamine series in that they are partially methylated and highly alkylated. They differ from methylated melamine resins in the type of alkylation alcohol, and they contain combinations of methoxy sites and n-butoxy sites. The butoxy sites impart improved flow and leveling and intercoat adhesion properties. As in the methylated series, their composition contains primarily alkoxy/imino or alkoxy/NH functionality. The advantages are fast cure response at 120-150C without the need for strong acid catalyst addition; fast cure response in waterborne formulations; high film hardness; and low formaldehyde release on cure. In addition to reacting with hydroxyl, carboxyl and amide functional polymers, the resins also self-condense readily. Therefore, their practical equivalent weight is typically 200-250. They, too, can be stabilized by amine and stabilizing alcohol addition to the formulation.

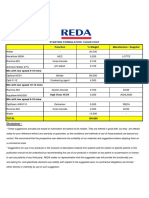

High Solids Mixed Ether Melamine Resins

Product Name Former Name Non Volatile % 45C for 45 Solvent Alkoxy Ratio approx. Monomer Content % approx. Viscosity G-H 25C Viscosity mPa.s. 25C Viscosity mPa.s. 23C Density Lbs/Gal approx. Density KgM3 approx. Flashpoint C Comments

Highly Alkylated Melamine Resins

CYMEL 1130 CYMEL 1133 CYMEL 1141 CYMEL 1161 CYMEL 1168

96 minimum 98 minimum 83-87 98 minimum 98 minimum

iso-Butanol

Me/nBu = 3/1 Me/nBu = 1/1 Me/isoBu = 3/2 Me/isoBu = 3/1 Me/isoBu = 1/1

36 64 30 75 65

Z-Z2 S-W W-Y U-X X-Z1

2700-4900 700-1500

3000-6000 1750-1950 1400-3000 1050-2000 2000-4500

9.4 9.0 9.0 9.2 8.9

1130 1080 1080 1130 1080

>100 >100 33 >100 >100

Used in e-coat and high solids coatings. Used in high solids coatings. Good film flexibility and recoat adhesion. Carboxy functionality. Excellent adhesion to metals. Excellent intercoat adhesion. Low VOCs. Methylated-isobutylated version of CYMEL 1133 resin. Excellent intercoat adhesion.

1000-1800 2200-3800

High Imino Melamine Resins

CYMEL 202

80-94

n-Butanol

Me/hBu = 3/2

52

Z-Z3

2800-6000

2500-7500

9.3

1090

>100

Low MW resin. Good balance of reactivity, film flex properties and humidity resistance.

Butylated Melamine Resins

n-Butlyated Melamine Resins

n-butylated resins in this category are very polymeric in nature. They differ in extent of methylolation, butylation and polymerization. In general, higher extents of methylolation and butylation result in more hydrophobic resins with lower viscosities, higher stability, slightly higher film flexibility, film gloss and adhesion but slower cure response. Higher extents of polymerization result in faster film property development but also in higher viscosities, and therefore higher VOCs. None of the resins in this category require the addition of a strong acid catalyst for adequate cure at 125-150C. Usually, the acidity of the other resin components in the formulation results in sufficient catalysis. In addition to reacting with hydroxyl, carboxyl and amide functionalities on polymers, these resins self-condense readily. Their practical equivalent weight is typically 220280 on a solids basis, High concentrations of the melamine resins in the formulation result in high film hardness and improved exterior durability but, possibly, lower film flexibility and lower adhesion properties. They, too, can be stabilized by adding amines and stabilizing alcohol to the formulation.

Highly n-Butylated Melamine Resins

Highly butylated melamine resins are similar to the commercial versions of hexamethoxymethylmelamine (HMMM), except they are n-butylated. They also are slightly more oligomeric than their methylated counterparts. The butylation or butoxy sites impart improved flow and leveling and intercoat adhesion properties. However, cure response is slower than that of the resins in the methylated category. Yet, highly butylated melamine resins, are efficient crosslinking agents for hydroxyl, carboxyl and amide functional polymers. The practical equivalent weight is 160-220. Other advantages are high film flexibility and toughness when used with inherently flexible backbone resins; excellent formulation stability; and good mar resistance properties. Because of their high extent of alkylation, the resins require the addition of a strong acid catalyst for acceptable cure response when baked at 125-150C. Typically 0.2-0.4% p-toluene sulfonic acid based on total binder solids is necessary. The optimum concentration of acid catalyst depends on the basicity of the other components in the formulation and should be determined experimentally. The use of a blocking amine for the acid catalyst and the addition of a stabilizing alcohol to the formulation should enhance formulation stability.

n-Butylated High Imino Melamine Resins

Butylated high imino melamine resins are similar to those in the high imino methylated melamine series; they are partially methylolated and highly alkylated. They differ from the high imino methylated melamine resins in that they are n-butylated. The butoxy sites impart improved flow and leveling and intercoat adhesion properties. As in the methylated series, their composition contains primarily alkoxy/imino or alkoxy/NH functionality. The advantages are fast cure response at 120150C without the need to add a strong acid catalyst; high film hardness; and low formaldehyde release on cure. In addition to reacting with hydroxyl, carboxyl and amide functionality on polymers, the resins self-condense readily. Therefore, their practical equivalent weight is typically 160-220. They can be stabilized by the addition of an amine and a stabilizing alcohol to the formulation.

iso-Butylated Melamine Resins

The iso-butylated melamine resins in this category are similar to polymeric n-butylated resins and differ only in that they are "iso" rather than "n"-butylated. It is generally believed that iso-butylated melamine resins cure faster than n-butylated resins, although differences in extent of methylolation, alkylation and polymerization are believed to be more significant factors with respect to cure response. The comments made previously concerning the n-butylated resins also apply to the iso-butylated resins.

Butylated Melamine Resins

Product Name Former Name Non Volatile % Solvent Viscosity G-H 25C Viscosity mPa.s. 25C Viscosity mPa.s. 23C Density Lbs/Gal approx. Density Kg/M3 approx. Hydrocarbon Tolerance approx. Acid Number Minimum Flashpoint C Comments

n-Butylated Melamine Resins

MELMAC 243-3 CYMEL 247-10

60-64 (3) 62-66 (3)

Aromatic Naptha n-Butanol

V-Y U-W

700-1600

8.65 8.65

350 (6) 1000 (6)

0-1.5 1.0 max

52 1.0 max

Good compatibility and solvent tolerance. Excellent compatibility, flow and leveling.

Highly n-Butylated Melamine Resins

CYMEL 1156 CYMEL MB-94

96 minimum (1) 94-97 (1)

n-Butanol

Z1-Z3 Y-Z1

2800-5600

3800-7500 2400-3800

8.7 8.7

8.7

>100 64

Good resistance properties when cured adequately. Very hydrophobic. Improves the water resistance of UF wood finishes. Very hydrophobic.

n-Butylated High Imino Melamine Resins

CYMEL 1158

78-82 (1)

n-Butanol

Z-Z3

3000-7000

3000-7000

8.8

8.8

400 (4)

47

High solids. Fast cure response. Low HCHO release.

iso-Butylated Melamine Resins

CYMEL MI-97-IX Dynomin MI-97-IX 68-72 (2) iso-But, Xylene P-T

480-760

1010

>200 (5)

1-3

33

Very fast curing. Good compatibility.

(1) = Foil solids 45 at 45C (2) = Pan solids 60 at 100C (3) = Pan solids 120 at 105C

(4) = Naptha tolerance (5) = HC tolerance, mls of 150 octane tolerated by 10g of resin @ 25C (6) = HC tolerance, lbs of heptane/toluene (3/1) tolerated by 100 lbs of resin @ 25C

High Solids Urea Resins

Methylated Resins

Methylated urea resins were designed for waterborne and solvent-based formulations for interior and non-UV resistant applications. They differ from each other primarily in their extent of methylolation and methylation. As with other amino resins for coatings, higher extents of alkylation result in improved compatibility with most binders, improved stability; and better flow and leveling, but slower cure response. None of these resins require the addition of a strong acid catalyst for acceptable cure response at 125C. The acidity of the other components in a formulation usually is sufficient for catalysis. For very low temperature cure systems, those for wood finishes, for example, a 2-component formulation is necessary. In such formulations, the acid catalyst is added to the fully-formulated system just prior to use. If the bake temperature is around 70C, a concentration of 1-2% on total binder solids of a strong or weak acid is recommended. In general, urea resins react with the hydroxyl, carboxyl and amide functional sites on polymers, but they also have a high tendency for self-condensation. Their practical equivalent weight is in the range of 180260. The use of a blocking amine for the acid catalyst and the addition of a stabilizing alcohol to the formulation enhances formulation stability. The latter approach is recommended for 2-component formulations.

Butylated resins

The one resin in this category, CYMEL U-80 resin, is similar in composition to several of the methylated resins, except that its alkylation alcohol is n-butanol. This resin is also recommended for interior and non-UV resistant coatings; it is used primarily in solvent-based systems. It is very hydrophobic and stable but slower curing than its methylated counterparts. A strong acid catalyst is recommended for acceptable cure response at 125C. Other formulation details are the same as those given for methylated resins.

High Solids Urea Resins

Product Name Former Name Non Volatile % Solvent Viscosity G-H 25C Viscosity mPa.s. 25C Viscosity mPa.s. 23C Density Lbs/Gal approx. Density Lbs/Gal approx. Flashpoint C Water Solubility Xylene Solubility Comments

Methylated Resins

CYMEL U-64 CYMEL U-65 CYMEL UM-15 Beetle or UFR 64 Beetle or UFR 65 Dynomin UM-15 88-94 (1) 96 minimum (1) 96 minimum (1) isopropanol V-Y Z3-6 1200-2500 3800-5600

6800-17000

9.8 10.3

1200

26 >100 76

Complete Complete Complete

Partial Partial Partial

Similar performance to CYMEL U-65 resin only lower HCHO release. Good compatibility and cure response. Good compatibility and cure response.

Butylated Resins

CYMEL UM-80 Beetle or UFR 80 96 minimum (1) n-Butanol X-Z1 120--3400 1700-4500 8.9 1100 >100 Insoluble Complete Very hydrophobic. Excellent water resistance properties when cured properly.

(1) = Foil solids 45 at 45C (2) = Pan solids 120 at 105C

10

Butylated Urea Resins

11

n-Butylated Urea Resins

The urea resins in this category are all partially n-butylated and very polymeric in nature. They differ in extent of methylolation, butylation, and polymerization. In general, higher extents of methylolation and butylation result in more hydrophobic resins with lower viscosities, higher stability, and slightly higher film toughness, film gloss and adhesion but slower cure response. Higher extents of polymerization result in faster film property development but also in higher viscosities and, therefore, higher VOCs. None of the resins require the addition of a strong acid catalyst for adequate cure at 125C. Usually, the acidity of the other resin components in the formulation is

sufficient for catalysis. In addition to reacting with hydroxyl, carboxyl and amide functional polymers, the resins also selfcondense readily. Their practical equivalent weight is typically 220-300 on a solids basis. High concentrations of the urea resins in the formulation result in high film hardness, but, possibly, lower film toughness and lower adhesion properties. They can be stabilized by amine and stabilizing alcohol addition to the formulation. As with other urea resins, they are recommended for interior, non-UV resistant applications. The most typical applications are interior container coatings and 2-component solvent-based wood finishes, In the latter application, the acid catalyst is added to the fully-formulated system just prior to use. A concentration of 1-2% on total binder

solids of a strong or weak acid is recommended for systems that require low bake temperatures - typically less than 70C.

iso-Butylated Urea Resins

The iso-butylated urea resins in this category are similar to the polymeric n-butylated resins, except that they are iso-butylated rather than n-butylated. It is generally believed that iso-butylated urea resins cure faster than n-butylated resins, although differences in extent of methylolation, alkylation and polymerization are believed to be more significant factors with respect to cure response. Iso-butylated urea resins perform in much the same way as n-butylated urea resins. That is, high concentra-

tions of these resins in the formulation result in high film hardness, but, possibly, lower film toughness and lower adhesion properties. Iso-butylated resins can be stabilized by adding amine and stabilizing alcohol to the formulation. They are recommended for interior and nonUV resistant applications, as well.

Butylated Urea Resins

Product Name Former Name Non Volatile % Solvent Viscosity G-H 25C Viscosity mPa.s. 25C Viscosity mPa.s. 23C Density Lbs/Gal approx. Density Kg/M3 approx. Hydrocarbon Tolerance approx. Acid Number Minimum Flashpoint C Comments

n-Butylated Urea Resins

CYMEL U-21-511 CYMEL U-93-210 CYMEL U-216-10-LF CYMEL U-227-8 CYMEL U-1050-10 CYMEL U-1052-8 CYMEL U-1054 CYMEL UB-25-BE CYMEL UB-30-B Beckamine 21-511 Beckamine 93-210 Beetle or UFR 216-10 Beetle or UFR 227-8 Beetle or UFR 1050-10 Beetle or UFR 1052-8 Beetle or UFR 1054 Dynomin UB-25-BE Dynomin UB-30-B 58-62 (2) 60-64 (2) 58-62 (3) 49-55 (3) 58-62 (3) 54-58 (3) 58-62 (3) 61-65 (5) 63-67 (5) n-But, Ethanol n-But, Xylene n-Butanol n-But, Xylene n-Butanol n-But, Xylene n-But, Ethanol n-But, Ethanol n-Butanol K-N V-Y S-V X-Z1 Z-Z2 R-U U-Z1 U-Y Z5-6

1700-4500

8.55 8.65 8.65 8.4 8.4 8.65 8.8

1000

200 (10) 250 (10) 350 (7) 100 (7) 100 (7) 350 (7) 16 (9) 15 (9) 15 (9)

2-5 2-5 0.5-2 1-4 1-4 2-2.7 5-7 1.5-3.5 1-3

32 35 45 22 41 34 33 27 37

Exempt solvent version of CYMEL U-21-510 resin. Good compatibility, low viscosity. Suitable for epoxy systems. CYMEL U-216 resin supplied in n-butanol. General purpose butylated urea formaldehyde resin. CYMEL U-1050 resin supplied in n-butanol. Fast-curing, compatible resin. Suitable for epoxy systems. Fast-curing, compatible resin. Suitable for epoxy systems. Fast-curing resin for wood finishes and general metals. Fast-curing resin for wood finishes and general metals.

1000-3000 13000-25000

1020 1030

iso-Butylated Urea Resins

CYMEL U-662 CYMEL U-663 CYMEL U-1051 CYMEL UI-19-I CYMEL UI-21E CYMEL UI-27-EI CYMEL UI-38-I (1) = Foil solids 45 at 45C (2) = Pan solids 90 at 105C (3) = Pan solids 120 at 105C Beetle BE 662 Beetle BE 663 Beetle or UFR 1051 Dynomin UI-19-I Dynomin UI-21-E Dynomin UI-27-EI Dynomin UI-38-I 58-62 (4) 60-64 (4) 58-62 (3) 61-64 (5) 76-80 (5) 58-62 (5) 67-71 (5) iso-But, Xylene iso-Butanol iso-But, Xylene iso-Butanol Ethanol Ethanol, iso-But iso-Butanol

X-Z1 Z4-5 Y-Z1 K-O Z4-6

1000-2000 2000-4000

1200-2400 2400-4500

8.45

1010 1000

16 (8) 27 (8) 200 (7) 9 (9) 6 (9) 15 (9) 20 (9)

0.75-1.5 0.75-1.5 2-10 0.5-2 0-1 1-3 2-4

25 30 27 34 25 24 38

Medium-high reactivity. Recommended for wood finishes. Low HCHO emission. Medium-high reactivity. Recommended for wood finishes. Low HCHO emission. Fast cure and excellent compatibility. Fast curing resin for wood finishes. Low formaldehyde emission. Good cure speed. General purpose resin. Good cure speed. Compatible with nitrocellulose systems. Used in primers and topcoats for metal substrates. High resistivity.

8700-16000

1020 1010 1010 1030

350-600 12000-20000

(4) = Pan solids 120 at 120C (5) = Pan solids 60 at 100C (6) = Pan solids 90 at 90C

(7) = HC Tolerance, lbs of heptane/toluene (3/1) tolerated by 100 lbs of resin solution at 25C (8) = ASTM Tolerance, cc of solvent tolerated by 5g of resin at 20C (9) = HC Tolerance, mls of iso-octane tolerated by 10g of resin at 25C (10) = Mineral Spirits Tolerance

12

Benzoguanamine and Glycoluril Resins

13

Benzoguanamlne Resins

Benzoguanamine resins are similar to melamine-based resins in that they, too, are triazine based, but in this instance, the triazine has a benzene group substitution. Therefore, they are less functional than melamine-based resins, and are not UV resistant. Benzoguanamine resins are noted for their enhanced film flexibility, or toughness, and for their chemical resistance. They are typically used in primers, container coatings, and appliance finishes. Usually, highly alkylated, monomeric benzoguanamine resins result in higher film flexibility than that which can be achieved with other types of resins, but they also require the addition of a strong acid catalyst for adequate cure at temperatures greater than 125C. Their practical equivalent

weights are slightly higher than the practical weights of their melamine counterparts and range from 160-220. The less alkylated polymeric resins only require the acidity of the other components in the formulation to cure adequately at greater than 125C, but they have higher VOCs in a solvent-based formulation. Their practical equivalent weights are also slightly higher than those of their melamine counterparts and range from 200-260 on a solids basis. The use of a blocking amine and the addition of a stabilizing alcohol to the formulation should enhance formulation stability.

Glycoluril Resins

Glycoluril resins are similar to their melamine resins counterparts in that they, too, are based on a ring structure, glycoluril. Similar to benzoguanamine resins, they are less functional than melamine resins but are UV resistant and can be used in exterior coatings. Their advantages are film toughness and flexibility, ability to adhere to metals, and low formaldehyde release on curing. There are two categories in the product line, unalkylated methylol glycoluril resins, and those which are highly alkylated. CYMEL 1172 is unalkylated, and was designed for water-based coatings with low temperature cure performance properties. The highly alkylated resins, CYMEL 1170 and CYMEL 1171 resins, were designed to replace HMMM where there is a desire to improve film flexibility. The same comments concerning highly alkylated monomeric melamine resins also apply to the alkylated glycoluril resins.

Benzoguanamine and Glycoluril Resins

Product Name Former Name Non Volatile % 45C for 45 Solvent Alkoxy Ratio approx. Viscosity G-H 25C Viscosity mPa.s. 25C Viscosity mPa.s. 23C Density Lbs/Gal approx. Density Kg/M3 approx. Flashpoint C Water Solubility Xylene Solubility Comments

Benzoguanamine Resins

CYMEL 1123 CYMEL 5010

98 minimum (1) 64-68 (2)

n-But, Xylene

Me/Eth = 55/45

Z1-4

3800-10200

9.7

1170

>100

Insoluble Insoluble

Complete Complete

Methylated, ethylated, highly monomeric resin. Strong acid catalyst required. Excellent film flex. n-Butlyated, polymeric general purpose resin.

n-Butyl

G-M

1050

27

Glycoluril Resins

CYMEL 1170 CYMEL 1171 CYMEL 1172

98 minimum (1) 90 minimum (1) 43-47 (2)

n-Butanol n-Butanol Water

n-Butyl Me/Eth = 1/1 Unalkylated

Z-Z2 Z1-3

3000-6000 3800-7500 >50

8.9 10.0 10.1

1070 1200 1210

>100 66 >100

Insoluble

Complete Partial Insoluble

Highly butylated, highly monomeric resin. Very hydrophobic. Excellent film flex. Highly methylated-ethylated, monomeric resin. WB or solvent-based finishes. Low formaldehyde emissions. Unalkylated resin for WB finishes. Fast curing.

Complete Complete

(1) = Pan solids 120 at 120C (2) = Foil solids 45 at 45C (3) = Pan solids 120 at 105C

Contact Us

NORTH AMERICA

EUROPE

1950 Lake Park Drive Smyrna, Georgia 30080 Tel: 1-800-433-2873 (USA) Tel: 1-678-255-4691 (outside USA) Fax: 1-678-255-4789

MEXICO

Square Marie-Curie 11 1070 Anderlecht Brussels Tel: 32 2 560 4511 Fax: 32 2 560 4521

ASIA PACIFIC/CHINA Cytec de Mexico, SA de CV

Km. 40, Carretera Guadalajara-La Barca Atequiza, Jalisco CP45860 Mexico Tel: 52 376 737 4100 Fax: 52 376 737 4105

LATIN AMERICA Cytec Brasil Especialidades Qumica Ltda.

30A Jun Yao International Plaza 789 Zhao Jia Bang Road, Xuhui District Shanghai 200032 Tel: 86 21 6422 8920 Fax: 86 21 6422 8980

Global Product Referral

Av. Dr. Cardoso de Melo, 1450 - Conj: 401/402 04548-005 - Vila Olimpia Sao Paulo, SP - Brasil Tel: 55 11 3048 8000 Fax : 55 11 3048 8040

Tel.: 1-800-652-6013 (USA) Tel.: 1-973-357-3193 (Outside USA) custinfo@cytec.com

Email: custinfo@cytec.com

Worldwide Contact Info: www.cytec.com

US Toll Free 800-652-6013

Tel 973-357-3193

Cytec Industries Inc. in its own name and on behalf of its affiliated companies (collectively, "Cytec") decline any liability with respect to the use made by anyone of the information contained herein. The information contained herein represents Cytec's best knowledge thereon without constituting any express or implied guarantee or warranty of any kind (including, but not limited to, regarding the accuracy, the completeness or relevance of the data set out herein). Cytec is the sole owner or authorized user of the intellectual property rights relating to the information communicated. The information relating to the use of the products is given for information purposes only. No guarantee or warranty is provided that the product is adapted for any specific use. The user or purchaser should perform its own tests to determine the suitability for a particular purpose. The final choice of use of a product remains the sole responsibility of the user.

TRADEMARK NOTICE: The indicates a Registered Trademark in the United States and the or * indicates a Trademark in the United States. The mark may also be registered, the subject of an application for registration or a trademark in other countries.

LCR-0805-B-EN-NA-03B

2010 Cytec Industries Inc. All rights reserved.

Potrebbero piacerti anche

- MODAFLOWDocumento24 pagineMODAFLOWuzzy2100% (1)

- Paten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenDocumento4 paginePaten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenSepvan ValeriNessuna valutazione finora

- Additives, Driers, Accelerators and Catalysts: For Coatings, Paints, Composites, Printing Inks and AdhesivesDocumento16 pagineAdditives, Driers, Accelerators and Catalysts: For Coatings, Paints, Composites, Printing Inks and AdhesivesAnanthanarayananNessuna valutazione finora

- Munzing Masterbatch AdditivesDocumento8 pagineMunzing Masterbatch AdditivesThea Athalia CandraNessuna valutazione finora

- OMG Americas - Additives BrochureDocumento8 pagineOMG Americas - Additives BrochureUsama AwadNessuna valutazione finora

- Industrial and Institutional Care ClariantDocumento21 pagineIndustrial and Institutional Care Clariantdaniel_12Nessuna valutazione finora

- Resins For: Vehicle Refinish & Commercial Transportation CoatingsDocumento6 pagineResins For: Vehicle Refinish & Commercial Transportation CoatingsEmilio HipolaNessuna valutazione finora

- FoamStar ST 2412 August 2018 R3 ED2Documento2 pagineFoamStar ST 2412 August 2018 R3 ED2APEX SONNessuna valutazione finora

- Brochure Matting Agents EDocumento60 pagineBrochure Matting Agents Efrox123Nessuna valutazione finora

- Paints and CoatingsDocumento10 paginePaints and CoatingsJesus Erazo100% (1)

- EDM - 012 Additives For Wood and Furniture Coatings PDFDocumento8 pagineEDM - 012 Additives For Wood and Furniture Coatings PDFEugene PaiNessuna valutazione finora

- Incozol 2 DataDocumento2 pagineIncozol 2 DataJeffrey Bempong100% (1)

- NUPLEX Plastics NU 006 Resins Automotive Plastics 14-15Documento6 pagineNUPLEX Plastics NU 006 Resins Automotive Plastics 14-15Emilio HipolaNessuna valutazione finora

- DowDocumento20 pagineDowJohn Mcaulay100% (1)

- Akzonobel Formulation 2C 75 01Documento1 paginaAkzonobel Formulation 2C 75 01culiniNessuna valutazione finora

- Architectural EN-VINAVIL PDFDocumento36 pagineArchitectural EN-VINAVIL PDFSeafar YachtingNessuna valutazione finora

- Dow Surfactants: Reference ChartDocumento5 pagineDow Surfactants: Reference CharttmlNessuna valutazione finora

- Aerosol 101 Formulation Considerations Allen PriceDocumento48 pagineAerosol 101 Formulation Considerations Allen PriceAmalia RahmasariNessuna valutazione finora

- Diagram 1: Gibbs Equation On ElasticityDocumento8 pagineDiagram 1: Gibbs Equation On ElasticityManoj Lalita GoswamiNessuna valutazione finora

- SC2889 PDFDocumento15 pagineSC2889 PDFA MahmoodNessuna valutazione finora

- Technical Data Sheet: Rexin DP 127Documento1 paginaTechnical Data Sheet: Rexin DP 127sriatul2006Nessuna valutazione finora

- EvonikDocumento20 pagineEvonikMohit Singhal0% (1)

- Long Durability Exterior CoatingDocumento1 paginaLong Durability Exterior CoatingAmit BholaNessuna valutazione finora

- Glossy FillersDocumento6 pagineGlossy Fillerskensley oliveira100% (1)

- Can Coating Formulations (Sheet 1 To 4)Documento3 pagineCan Coating Formulations (Sheet 1 To 4)No NameNessuna valutazione finora

- Pigment Dispersion: Theodore G. VernardakisDocumento19 paginePigment Dispersion: Theodore G. VernardakisSyafri GtNessuna valutazione finora

- Shieldex Wash Primer - AC 3Documento2 pagineShieldex Wash Primer - AC 3nanoNessuna valutazione finora

- Optifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintDocumento16 pagineOptifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintAPEX SONNessuna valutazione finora

- Rheology Modifiers Product Recommendations For EuropeDocumento2 pagineRheology Modifiers Product Recommendations For EuropeHamood AbdoNessuna valutazione finora

- Cong Thuc SonDocumento23 pagineCong Thuc Sonvanhung68Nessuna valutazione finora

- Rhodoline 642 PDFDocumento2 pagineRhodoline 642 PDFhemya7Nessuna valutazione finora

- Wanhua Interior Coating SolutionsDocumento28 pagineWanhua Interior Coating SolutionsThanh Vu100% (1)

- Optical BrightnersDocumento4 pagineOptical Brightnerseaglator100% (1)

- Soyol Polyol FormulationsDocumento3 pagineSoyol Polyol FormulationsurethanNessuna valutazione finora

- BASF Polyurethanes Your Preferred Partner For Growth and SuccessDocumento4 pagineBASF Polyurethanes Your Preferred Partner For Growth and SuccessGovardhan RaviNessuna valutazione finora

- Attagel 50: AttapulgiteDocumento2 pagineAttagel 50: AttapulgiteAPEX SON100% (1)

- DYNAPOL BADGE Free AlternativsDocumento2 pagineDYNAPOL BADGE Free AlternativsAlptekinNessuna valutazione finora

- BASF Rigid Foam enDocumento14 pagineBASF Rigid Foam enSathya PrakashNessuna valutazione finora

- Tego® Addbond - For Maximum AdhesionDocumento8 pagineTego® Addbond - For Maximum AdhesionDanail AkuzovNessuna valutazione finora

- UC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFDocumento24 pagineUC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFchayanunNessuna valutazione finora

- Prototype Formulation For Car Polish: AutomotiveDocumento2 paginePrototype Formulation For Car Polish: AutomotiveRoman100% (2)

- DYNOL 607 - G - Surfactant 0717 EN OIDocumento2 pagineDYNOL 607 - G - Surfactant 0717 EN OIJian WenNessuna valutazione finora

- Economic PaintDocumento1 paginaEconomic PaintForeverNessuna valutazione finora

- Finco GroutDocumento2 pagineFinco GroutaselabollegalaNessuna valutazione finora

- 07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiDocumento62 pagine07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiForeverNessuna valutazione finora

- BASF (India) LTD PDFDocumento37 pagineBASF (India) LTD PDFchinmoyd1Nessuna valutazione finora

- Byk-066 N enDocumento2 pagineByk-066 N enΒασίληςΜουρατίδηςNessuna valutazione finora

- ADEKA Surfactants-productsList 1111 PDFDocumento16 pagineADEKA Surfactants-productsList 1111 PDFichsanNessuna valutazione finora

- Surfactant AnalysisDocumento5 pagineSurfactant Analysisjuli_radNessuna valutazione finora

- Clear CoatDocumento1 paginaClear CoatForeverNessuna valutazione finora

- Starting Formulation 1kDocumento1 paginaStarting Formulation 1kForever100% (1)

- Economic Paint RedaDocumento1 paginaEconomic Paint RedaForeverNessuna valutazione finora

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDocumento32 pagineOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONNessuna valutazione finora

- Antifouling ArticleDocumento16 pagineAntifouling ArticleAbbas Ali100% (1)

- Inz EH (Grey) - 035 (Roof Coating) - GenericDocumento2 pagineInz EH (Grey) - 035 (Roof Coating) - GenericVaittianathan MahavapillaiNessuna valutazione finora

- Rheofibre - BasfDocumento2 pagineRheofibre - BasftheshadowknightNessuna valutazione finora

- Handbook of Vinyl FormulatingDa EverandHandbook of Vinyl FormulatingRichard F GrossmanValutazione: 3 su 5 stelle3/5 (1)

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Da EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Nessuna valutazione finora

- Study of Friction Using The Concept of An "Offset Printer"Documento3 pagineStudy of Friction Using The Concept of An "Offset Printer"Ravi NiitNessuna valutazione finora

- Group A5 - EXP 9 Activated Carbon Adsorption Isotherm & KineticsDocumento16 pagineGroup A5 - EXP 9 Activated Carbon Adsorption Isotherm & KineticsKabilashini Mana Mohan100% (2)

- Screw Thread MeasurementDocumento56 pagineScrew Thread MeasurementAbhishek Kumar100% (1)

- Horizontal CurveDocumento2 pagineHorizontal CurveAmar DanialNessuna valutazione finora

- Transfer Function Method of Measuring In-Duct Acoustic Properties. I. TheoryDocumento8 pagineTransfer Function Method of Measuring In-Duct Acoustic Properties. I. TheoryGoh Jenn HsenNessuna valutazione finora

- 1st Symposium On Naval HydrodynamicsDocumento468 pagine1st Symposium On Naval Hydrodynamicsfairwinds88Nessuna valutazione finora

- 020 Cadmium AcetateDocumento6 pagine020 Cadmium Acetateeng20072007Nessuna valutazione finora

- Shiva Prasad Ext. 7571: (Shivap (At) Phy - Iitb.ac - inDocumento38 pagineShiva Prasad Ext. 7571: (Shivap (At) Phy - Iitb.ac - inTavishi SinghNessuna valutazione finora

- Is.1893 Codebook PDFDocumento25 pagineIs.1893 Codebook PDFArbaz HussainNessuna valutazione finora

- Commercializing Process TechnologiesDocumento11 pagineCommercializing Process TechnologiesBramJanssen76Nessuna valutazione finora

- Phy102 Practise Problems For Exam2Documento4 paginePhy102 Practise Problems For Exam2Renz Dane TametaNessuna valutazione finora

- Jurnal PiezoelektrikDocumento4 pagineJurnal PiezoelektrikMutia TiaraNessuna valutazione finora

- Autodesk Revit Mep Fundamentals: 8 Hrs 8:30am - 5:30pmDocumento1 paginaAutodesk Revit Mep Fundamentals: 8 Hrs 8:30am - 5:30pmbambangNessuna valutazione finora

- Low-Speed Aerodynamics, Second Edition PDFDocumento29 pagineLow-Speed Aerodynamics, Second Edition PDFWei Gao100% (1)

- SPH ManualDocumento73 pagineSPH Manualdwdg100% (1)

- Ma2264 - Numerical MethodsDocumento26 pagineMa2264 - Numerical MethodsSUNILKHUNTIA1988Nessuna valutazione finora

- Cold Thermogenesis 1 - Theory To Practice BeginsDocumento32 pagineCold Thermogenesis 1 - Theory To Practice BeginsCătălinStoicescuNessuna valutazione finora

- Casing DesignDocumento12 pagineCasing DesignRisTy FrogGiesaa AmaNeeNessuna valutazione finora

- Acros Organics Acta N°009Documento20 pagineAcros Organics Acta N°009Atomer FormationNessuna valutazione finora

- Geometric Determination of Coordinated Centers of Curvature in Network Mechanisms Through Linkage ReductionDocumento7 pagineGeometric Determination of Coordinated Centers of Curvature in Network Mechanisms Through Linkage ReductionAnonymous LU3Dz3TKtVNessuna valutazione finora

- Primary 4 Maths Syllabus (MOE) : Content Primary 4 1 Whole NumbersDocumento5 paginePrimary 4 Maths Syllabus (MOE) : Content Primary 4 1 Whole NumbersyvonneNessuna valutazione finora

- Niels Henrik David BohrDocumento4 pagineNiels Henrik David BohrValerie Ann FranciscoNessuna valutazione finora

- Errata Alexander Sadiku 3rdedition Chris MackDocumento3 pagineErrata Alexander Sadiku 3rdedition Chris MackDr-Jihad BaghdadiNessuna valutazione finora

- Non Destructive TestingDocumento4 pagineNon Destructive Testingأحمد دعبسNessuna valutazione finora

- Coupled Bubble Plume Reservoir Model 3 DDocumento16 pagineCoupled Bubble Plume Reservoir Model 3 DAnita MayasariNessuna valutazione finora

- United States Patent (191: Schweier Et A)Documento5 pagineUnited States Patent (191: Schweier Et A)Maya RamlahNessuna valutazione finora

- Barbosa 2007Documento5 pagineBarbosa 2007Maevi OttonelliNessuna valutazione finora

- Hooke's LawDocumento5 pagineHooke's LawVikash Kumar SinghNessuna valutazione finora

- Henkel Worldwide Sealing Guidelines PDFDocumento32 pagineHenkel Worldwide Sealing Guidelines PDFrocky2400100% (1)

- Synthesis of FlavanoneDocumento5 pagineSynthesis of FlavanonefikarisvitaNessuna valutazione finora