Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ergonomics Study Template

Caricato da

chethan626Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ergonomics Study Template

Caricato da

chethan626Copyright:

Formati disponibili

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks Areas of Concern (Station, Operation and Problem

Statement)

Lifting of heavy Loads Dropping Frames though crane can be counted as pulling of heavy loads, The friction in the Carrying & / or Holding heavy loads wheels of the crane over track has to be reduced Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Inconsistent Illumination Summers, Humidity is a concern. Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related)

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Study of Ergonomic Risk Factors (Assembly Line2) Working Environment Factors Factor Risks Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc) Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement)

Wearing Helmet during summer is a issue for the operator.

PPE

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement) Has to bend whlie laying out the nylon bunch,Height of the trolley is low , Trolley has to be made of adjsutable height for different models.DDU weighs around 5 kgs which has to be lifted and carry to frame.

Due to trolley height.

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement) Has to bend whlie fastening the brackets,Height of the trolley is low , Trolley has to be made of adjsutable height for different models.

Due to trolley height.

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement) Has to bend whlie fastening the FUPD,Height of the trolley is low , Trolley has to be made of adjsutable height for different models.

PROBLEM WITH NUT RUNNERS FREQUENT BREAKDONS, AND ADDS PRESSURE ON PLAM WHILE HOLDING AND OPERATING.

Due to trolley height.

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement)

HAMERRING STUDS BRNGS PAIN IN SHOULDERS ANRM MORE FREQUENTLY

Due to trolley height.

HAMMERING OF STUDS

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement)

HAMERRING STUDS BRNGS PAIN IN SHOULDERS ANRM MORE FREQUENTLY

Due to trolley height.

HAMMERING OF STUDS

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement) Has to bend whlie fastening the P/S,Height of the trolley is low , Trolley has to be made of adjsutable height for different models.

PROBLEM WITH NUT RUNNERS FREQUENT BREAKDONS, AND ADDS PRESSURE ON PLAM WHILE HOLDING AND OPERATING.

Due to trolley height.

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement) Has to bend whlie fastening and positioning U bolts,

PROBLEM WITH NUT RUNNERS FREQUENT BREAKDONS, AND ADDS PRESSURE ON PLAM WHILE HOLDING AND OPERATING.

Due to trolley height.

DUE TO TORQUING M/C.

High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Wearing Helmet during summer is a issue for the operator.

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement)

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads Carrying & / or Holding heavy loads Pushing or Pulling heavy loads Load Difficult to Grip Difficult Approach (while collection or use) No or poor Aids to handle heavy loads No tool available Misfit tools Improper condition (not as per spec, freq BD Tool Use etc) Uncomfortable to use Heavy and not counterbalanced High on Vibration without any dampeners Bending below Knees Stretching above shoulders Extended arms during collection or working Posture Twisting of trunk, neck, arm and wrist Crouching / Squatting Constrained posture for considerable time Continuous standing on a hard surface Lack of space to move and work Uncomfortable Height of working surface Uneven/ wet/ slippery/ obstructed walking surface Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings Fast, repetitive and small cycle actions Usage of excessive Force Excessive whole body or partial body Vibrations Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc)

PPE

PPE Uncomfortable PPEs Ineffective PPEs

Areas of Concern (Station, Operation and Problem Statement)

Study of Ergonomic Risk Factors (Assembly Line2) Factors Factor Risks

Lifting of heavy Loads

Carrying & / or Holding heavy loads

Pushing or Pulling heavy loads

Difficult to Grip

Load

Difficult Approach (while collection or use)

No or poor Aids to handle heavy loads

No or poor Aids to handle heavy loads

No tool available

Misfit tools

Improper condition (not as per spec, freq BD etc)

Tool Use

Uncomfortable to use

Heavy and not counterbalanced

High on Vibration without any dampeners

Bending below Knees

Bending below Knees

Stretching above shoulders

Posture

Extended arms during collection or working

Twisting of trunk, neck, arm and wrist

Crouching / Squatting

Constrained posture for considerable time

Continuous standing on a hard surface

Lack of space to move and work

Uncomfortable Height of working surface

Uneven/ wet/ slippery/ obstructed walking surface

Obstructed view of job Work System Working around sharp edges or unsafe Design surroundings

Fast, repetitive and small cycle actions

Usage of excessive Force

Excessive whole body or partial body Vibrations

Sudden movements, Jerks or Strokes (like Hammering) Inadequate Illumination Inconsistent Illumination Glare, Flicker or Shadows due to Improper Illumination High Noise Level Working Irritating Noise Environment Very Hot or Very Cold conditions (Climate or Job related) Inadequate air flow High levels of Humidity Exposed to Chemicals, Dust, Suspended particles etc Non-availability of PPEs (Helmets, Goggles, Gloves, Shoes, Ear Plugs, Masks etc) Uncomfortable PPEs Ineffective PPEs

PPE

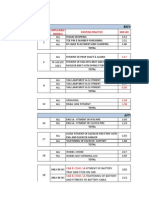

Areas of Concern (Station, Operation and Problem Statement) STN#1: FRAME DROPPING STN#2:DDU FITMENT PROB:Wt of ddu is more than 5kg has to carried manually (2 mts) STN#3: AIRTANK FITMENT PROB:Wt of AIR TANK is more than 10kg has to carried manually (2 mts) STN#4:LINKAGE FITMENT PROB:N/A STN#4:LEAF SPRING FITMENT PROB:N/A STN#5:POWER STEERING FITMENT PROB:Has to support the power steering manulally while fastening it on to the frame, load on palms and wrist. STN#6:AXLE FITMENT(REAR, FRONT, DUMMY) PROB:Inserting U bolts and locating is difficult. STN#6:PROPELLOR SHAFT FITMENT INVERSION MANIN CONVEYOR STN#7:TAIL LAMP FITMENT, SCAM BRAKE PIPE FITMENT,STEERING SPINDLE FITMENT STN#8:EXHAUSHT BRAKE PIPE AND SILENCER FITMENT PROB:CARRYING SILENCE IS HEAVY AND HAS BE FITTED BELOW KNEE LEVEL, DIFFICULTY IN FASTENING. STN#9:ENGINE DROP PROB:CARRYING SILENCE IS HEAVY AND HAS BE FITTED BELOW KNEE LEVEL STN#10:RADIATOR FITMENT STN#11:CAB / COWL DROP STN#12:AIR FILTER FITMET PROB:WT MORE THAN 5KG TO BE CARRIED FOR A DISTANCE OF 2 MTS STN#13:SPARE WHEEL MTG BRKT PROB:WT MORE THAN 5 KG TO BE CARRIED FOR A DISTANCE OF 2 MTS STN#14:BATTERY FITMENT STN#15:FUEL TANK MTG BRKT FITMENT PROB:WT MORE THAN 5 KG TO BE CARRIED FOR A DISTANCE OF 2 MTS STN#16:FUEL TANK FITMET PROB:BEND BELOW KNEE LEVEL TO LIFT AND MOUNT STN#17:TYRE FITMENT

PROB:HAS LIFT THE TYRE AND LOAD ON BODY WHILE LIFTING AND MOUNTING STN#18:BUMBER FITMENT PROB:WT MORE THAN 15 KG TO BE CARRIED FOR A DISTANCE OF 2-3 MTS STN#1: FRAME DROPPING STN#2:DDU FITMENT STN#3: AIRTANK FITMENT STN#4:LINKAGE FITMENT PROB:UNCOMFORTABEL TO HAMMER THE STUDS, HIGH VIBRATIONS STN#4:LEAF SPRING FITMENT PROB:UNCOMFORTABEL TO HAMMER THE STUDS, HIGH VIBRATIONS STN#5:POWER STEERING FITMENT STN#6:AXLE FITMENT(REAR, FRONT, DUMMY) PROB:Inserting U bolts and locating is difficult. STN#6:PROPELLOR SHAFT FITMENT INVERSION MANIN CONVEYOR STN#7:TAIL LAMP FITMENT, SCAM BRAKE PIPE FITMENT,STEERING SPINDLE FITMENT STN#8:EXHAUSHT BRAKE PIPE AND SILENCER FITMENT STN#9:ENGINE DROP PROB:Prob with torquing wrench,has to be toqued multiple times. STN#10:RADIATOR FITMENT STN#11:CAB / COWL DROP STN#12:AIR FILTER FITMET STN#13:SPARE WHEEL MTG BRKT STN#14:BATTERY FITMENT STN#15:FUEL TANK MTG BRKT FITMENT STN#16:FUEL TANK FITMET STN#17:TYRE NUT TORQUING PROB:HIGH VIBRATION STN#18:BUMBER FITMENT STN#1: FRAME DROPPING STN#2:DDU FITMENT / NYLON BUNCH LAYING OUT/ BRKTS FITMENTS PROB: CONSTARINED POSTURE i.e.BENDING THERE LOWER BACK DUE TO LOWER HIEGHT OF TROLLEY(0.75 MTS) STN#3: AIRTANK FITMENT PROB: CONSTARINED POSTURE i.e.BENDING THERE LOWER BACK DUE TO LOWER HIEGHT OF TROLLEY(0.75 MTS)

STN#4:LINKAGE FITMENT PROB: CONSTARINED POSTURE i.e.BENDING THERE LOWER BACK DUE TO LOWER HIEGHT OF TROLLEY(0.75 MTS),CONTINOIS HAMMERING WITH EXTENDED ARMS STN#4:LEAF SPRING FITMENT PROB: CONSTARINED POSTURE i.e.BENDING THERE LOWER BACK DUE TO LOWER HIEGHT OF TROLLEY(0.75 MTS),CONTINOIS HAMMERING WITH EXTENDED ARMS STN#5:POWER STEERING FITMENT PROB: CONSTARINED POSTURE i.e.BENDING THERE LOWER BACK DUE TO LOWER HIEGHT OF TROLLEY(0.75 MTS),CONTINOIS HAMMERING WITH EXTENDED ARMS STN#6:AXLE FITMENT(REAR, FRONT, DUMMY) PROB:CONSTRAINED BODY POSTURE DUE TO INVISIBILITY OF LOCATING HOLES STN#6:PROPELLOR SHAFT FITMENT INVERSION MANIN CONVEYOR STN#7:TAIL LAMP FITMENT, SCAM BRAKE PIPE FITMENT,STEERING SPINDLE FITMENT PROB:HAS TO LEAN TOO MUCH SINCE S CAM FITMENT LOCATION OUT OF REACH. STN#8:EXHAUSHT BRAKE PIPE AND SILENCER FITMENT PROB:BENDING BELOW KNEE LEVEL THROUGH OUT FITMENT STN#9:ENGINE DROP PROB: VARIOUIS AKWARD POSTURES DUE TO UNREACH OF MANY MTG BOLTS STN#10:RADIATOR FITMENT STN#11:CAB / COWL DROP PROB: VARIOUIS AKWARD POSTURES DUE TO UNREACH OF MANY MTG BOLTS STN#12:AIR FILTER FITMET PROB:BEND BELOW KNEE LEVEL TO CARRY STN#13:SPARE WHEEL MTG BRKT STN#14:BATTERY FITMENT STN#15:FUEL TANK MTG BRKT FITMENT STN#16:FUEL TANK FITMET PROB:BEND LOWER BACK FOR CONIDERABLE TIME STN#17:TYRE FITMENT PROB:HAS LIFT THE TYRE AND LOAD ON BODY WHILE LIFTING AND MOUNTING STN#18:BUMBER FITMENT PROB:WT MORE THAN 15 KG TO BE CARRIED FOR A DISTANCE OF 2-3 MTS STN#1: FRAME DROPPING STN#2:DDU FITMENT / NYLON BUNCH LAYING OUT/ BRKTS FITMENTS PROB: UNCOMFORTABLE HEIGHT OF WORKING STN#3: AIRTANK FITMENT PROB: UNCOMFORTABLE HEIGHT OF WORKING STN#4:LINKAGE FITMENT

PROB: FAST AND REPETATIVE CYCLES, EXCESSIVE BODY VIBRATIONS STN#4:LEAF SPRING FITMENT PROB: FAST AND REPETATIVE CYCLES, EXCESSIVE BODY VIBRATIONS STN#5:POWER STEERING FITMENT PROB: UNCOMFORTABLE HEIGHT OF WORKING STN#6:AXLE FITMENT(REAR, FRONT, DUMMY) PROB:OBSTRUCTED VIEW OF JOB STN#6:PROPELLOR SHAFT FITMENT INVERSION MANIN CONVEYOR STN#7:TAIL LAMP FITMENT, SCAM BRAKE PIPE FITMENT,STEERING SPINDLE FITMENT PROB: UNCOMFORTABLE HEIGHT OF WORKING STN#8:EXHAUSHT BRAKE PIPE AND SILENCER FITMENT PROB: UNCOMFORTABLE HEIGHT OF WORKING STN#9:ENGINE DROP STN#10:RADIATOR FITMENT STN#11:CAB / COWL DROP STN#12:AIR FILTER FITMET STN#13:SPARE WHEEL MTG BRKT STN#14:BATTERY FITMENT STN#15:FUEL TANK MTG BRKT FITMENT STN#16:FUEL TANK FITMET STN#17:TYRE FITMENT BOLTS FASTENING PROB:EXCESSIVE BODY VIBRATIONS STN#18:BUMBER FITMENT High noise leve is a concers,Ear plugs can be provided. High temperature is a concern in Summers, Humidity is a concern.

Wearing Helmet during summer is a issue for the operator.

Potrebbero piacerti anche

- 21-05-2020online Learning - Circular 1 PDFDocumento8 pagine21-05-2020online Learning - Circular 1 PDFchethan626Nessuna valutazione finora

- ExcerciseDocumento11 pagineExcercisechethan626Nessuna valutazione finora

- Name: - Date: - Q.1 Match The Body PartsDocumento5 pagineName: - Date: - Q.1 Match The Body Partschethan626Nessuna valutazione finora

- Option Selling WorkshopDocumento10 pagineOption Selling Workshopchethan626Nessuna valutazione finora

- 20 04 2020academic - PlanDocumento2 pagine20 04 2020academic - Planchethan626Nessuna valutazione finora

- 21-05-2020online Learning - Circular 1 PDFDocumento8 pagine21-05-2020online Learning - Circular 1 PDFchethan626Nessuna valutazione finora

- Edgewonk's Math Cheat Sheet PDFDocumento1 paginaEdgewonk's Math Cheat Sheet PDFPrashant Tomar100% (1)

- National Guard Black Belt Training: Unclassified / FouoDocumento22 pagineNational Guard Black Belt Training: Unclassified / Fouochethan626Nessuna valutazione finora

- 1.05 Close Out ReportDocumento5 pagine1.05 Close Out ReportnsadnanNessuna valutazione finora

- Strike Call OI Put OI Cumulative Call Cumulative Put Total ValueDocumento13 pagineStrike Call OI Put OI Cumulative Call Cumulative Put Total Valuechethan626Nessuna valutazione finora

- SSGB PreworkDocumento16 pagineSSGB Preworkchethan626Nessuna valutazione finora

- Paper Id-14201326Documento8 paginePaper Id-14201326chethan626Nessuna valutazione finora

- Six Sigma ProjectDocumento31 pagineSix Sigma Projectchethan626Nessuna valutazione finora

- FmeaDocumento10 pagineFmeachethan626Nessuna valutazione finora

- Investment ExamplesDocumento25 pagineInvestment Exampleschethan626Nessuna valutazione finora

- Measurement Systems Analysis - How ToDocumento72 pagineMeasurement Systems Analysis - How Towawawa1100% (1)

- Factorial Analysis of Employee Satisfaction On Annual Performance Appraisal Practice at Tata Motors LTDDocumento6 pagineFactorial Analysis of Employee Satisfaction On Annual Performance Appraisal Practice at Tata Motors LTDchethan626Nessuna valutazione finora

- BayesDocumento1 paginaBayesgopitheprinceNessuna valutazione finora

- Handout 07 - GMP Batches AB - Managerial Ethics - XLRI 2014 - The Ethics of Executive Moral ReasoningDocumento48 pagineHandout 07 - GMP Batches AB - Managerial Ethics - XLRI 2014 - The Ethics of Executive Moral Reasoningchethan626Nessuna valutazione finora

- Week1 PDFDocumento10 pagineWeek1 PDFahmedr25681Nessuna valutazione finora

- Week1 PDFDocumento10 pagineWeek1 PDFahmedr25681Nessuna valutazione finora

- Mechanical EngineerDocumento67 pagineMechanical EngineersameerNessuna valutazione finora

- Ergo PDFDocumento1 paginaErgo PDFchethan626Nessuna valutazione finora

- Defects Summary - L1Documento32 pagineDefects Summary - L1chethan626Nessuna valutazione finora

- Before Inversion: STN Applicable Models Existing Practice Min WCDocumento4 pagineBefore Inversion: STN Applicable Models Existing Practice Min WCchethan626Nessuna valutazione finora

- Essay Intitutionlising of InnovationDocumento3 pagineEssay Intitutionlising of Innovationchethan626Nessuna valutazione finora

- Human Factors and ErgonomicsDocumento2 pagineHuman Factors and Ergonomicschethan626Nessuna valutazione finora

- Ergo IntroductionDocumento12 pagineErgo Introductionchethan626Nessuna valutazione finora

- Aberdeen Cost of QualityDocumento20 pagineAberdeen Cost of Qualitychethan626Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 6 - Hydraulic Axial Forces Acting On A Francis RunnerDocumento12 pagine6 - Hydraulic Axial Forces Acting On A Francis RunnerYuriPasenkoNessuna valutazione finora

- Wsat-Xee: Installation Use and Maintenance ManualDocumento68 pagineWsat-Xee: Installation Use and Maintenance ManualAncuta CosmanNessuna valutazione finora

- Danfoss Sc18clDocumento2 pagineDanfoss Sc18clYosephanderNessuna valutazione finora

- 9202Documento80 pagine9202leninks_1979Nessuna valutazione finora

- Lecture Notes - Forging CalculationDocumento21 pagineLecture Notes - Forging CalculationFabiano, Jr. BarcenalNessuna valutazione finora

- Hermetic Pumpen Kaelte e 11 2014Documento28 pagineHermetic Pumpen Kaelte e 11 2014goodspeed_phNessuna valutazione finora

- MHI Multi - 20R01EDocumento88 pagineMHI Multi - 20R01EMinh PhatNessuna valutazione finora

- BR BoilerHouseComponents enDocumento28 pagineBR BoilerHouseComponents enJosé Pedro MagalhãesNessuna valutazione finora

- Supercavitation Seminar ReportDocumento19 pagineSupercavitation Seminar ReportSeema NadigNessuna valutazione finora

- 1st Assignment For Piping EngineeringDocumento6 pagine1st Assignment For Piping EngineeringAthulNessuna valutazione finora

- Weightor & Load Cell ALEDocumento2 pagineWeightor & Load Cell ALEzackysipNessuna valutazione finora

- Domestic Commercial EngDocumento56 pagineDomestic Commercial EngDana LoreNessuna valutazione finora

- Section - 1: Page 1 of 3Documento3 pagineSection - 1: Page 1 of 3majjisatNessuna valutazione finora

- SveDocumento28 pagineSveseaqu3stNessuna valutazione finora

- Replacement Parts List: Indoor Air Handler (B5, GB5) SeriesDocumento12 pagineReplacement Parts List: Indoor Air Handler (B5, GB5) SeriesAlvaro GarciaNessuna valutazione finora

- TLB ServiceDocumento5 pagineTLB ServiceHugh O'Brien GwazeNessuna valutazione finora

- Información Del Filtro: 140K Motor Grader JPA00001-UP (MACHINE) POWERED BY C7 EngineDocumento4 pagineInformación Del Filtro: 140K Motor Grader JPA00001-UP (MACHINE) POWERED BY C7 EngineAutoservicio Fuller100% (1)

- LECTURE 5 Charles LawDocumento1 paginaLECTURE 5 Charles LawAna May RafalNessuna valutazione finora

- Guo 2005Documento16 pagineGuo 2005Taha SerwerNessuna valutazione finora

- Moment of InertiaDocumento16 pagineMoment of InertiaDiane Dinglasa TobiasNessuna valutazione finora

- TU5J4 (NFU) 1.6 16V Petrol Engine Wiring TU5J4 (NFU) 1.6 16V Petrol Engine Wiring Diagram DiagramDocumento6 pagineTU5J4 (NFU) 1.6 16V Petrol Engine Wiring TU5J4 (NFU) 1.6 16V Petrol Engine Wiring Diagram DiagramRuiNessuna valutazione finora

- Course: Advanced Thermodynamics For Chemical and Process EngineeringDocumento2 pagineCourse: Advanced Thermodynamics For Chemical and Process Engineeringnaytpuri montemayorNessuna valutazione finora

- Bill of Materials - Sheet1Documento1 paginaBill of Materials - Sheet1api-598103816Nessuna valutazione finora

- Module 2 1Documento12 pagineModule 2 1Gabriel CortesNessuna valutazione finora

- Hyundai en EngineDocumento78 pagineHyundai en EngineDo Kiet100% (1)

- Gates & DampersDocumento30 pagineGates & DampersMaximilianoRodrigoCabestreroNessuna valutazione finora

- MMS8T Crane ManualDocumento19 pagineMMS8T Crane Manualkatepol8264Nessuna valutazione finora

- Single Compression Cable Glands - Comet PDFDocumento2 pagineSingle Compression Cable Glands - Comet PDFdip461Nessuna valutazione finora

- General Physics - Worksheet II (2024)Documento3 pagineGeneral Physics - Worksheet II (2024)merrymesfin87Nessuna valutazione finora

- Fluid Mechanics History EssayDocumento16 pagineFluid Mechanics History EssayBorja MonDe YorkNessuna valutazione finora