Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cascade Refrigeration R134a

Caricato da

Rahul PatilCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cascade Refrigeration R134a

Caricato da

Rahul PatilCopyright:

Formati disponibili

PROPRIETARY MATERIAL. 2011 The McGraw-Hill Companies, Inc.

. Limited distribution permitted only to teachers and educators for course

preparation. If you are a student using this Manual, you are using it without permission.

11-52

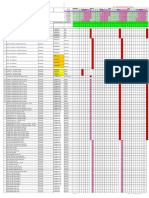

11-66 A two-stage cascade refrigeration cycle with a flash chamber with refrigerant-134a as the working fluid is

considered. The mass flow rate of the refrigerant through the high-pressure compressor, the rate of refrigeration, the COP

are to be determined. Also, the rate of refrigeration and the COP are to be determined if this refrigerator operated on a

single-stage vapor-compression cycle under similar conditions.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) From the refrigerant-134a tables (Tables A-11 through A-13)

kJ/kg.K 9377 . 0

kJ/kg 51 . 244

C 10 @ 1

C 10 @ 1

= =

= =

g

g

s s

h h

kJ/kg 07 . 261

kPa 450

2

1 2

2

=

)

`

=

=

s

h

s s

P

kJ/kg 76 . 263

51 . 244

51 . 244 07 . 261

86 . 0

2

2

1 2

1 2

=

=

h

h

h h

h h

s

C

q

kJ/kg 81 . 68

kJ/kg 81 . 68

kJ/kg 93 . 135

kJ/kg 93 . 135

kJ/kg 53 . 257

7 8

kPa 450 @ 7

5 6

kPa 1600 @ 5

kPa 450 @ 3

= =

= =

= =

= =

= =

h h

h h

h h

h h

h h

f

f

g

3557 . 0

kPa 450

kJ/kg 93 . 135

6

6

6

=

)

`

=

=

x

P

h

The mass flow rate of the refrigerant through the high pressure compressor is determined from a mass balance on the flash

chamber

kg/s 0.1707 =

=

0.3557 1

kg/s 11 . 0

1

6

7

x

m

m

Also,

kg/s 06072 . 0 11 . 0 1707 . 0

7 3

= = = m m m

(b) The enthalpy at state 9 is determined from an energy balance on the mixing chamber:

kJ/kg 54 . 261 kJ/kg) 53 kg/s)(257. (0.06072 kJ/kg) 76 kg/s)(263. (0.11 kg/s) 1707 . 0 (

9 9

3 3 2 7 9

= + =

+ =

h h

h m h m h m

Then,

kJ/kg 9393 . 0

kJ/kg 54 . 261

kPa 450

9

9

9

=

)

`

=

=

s

h

P

kJ/kg 41 . 288

kPa 1600

4

9 4

4

=

)

`

=

=

s

h

s s

P

kJ/kg 78 . 292

54 . 261

54 . 261 41 . 288

86 . 0

4

4

9 4

9 4

=

=

h

h

h h

h h

s

C

q

1

2 5

8

0.45 MPa

s

T

4

1.6 MPa

6

9

A

B

3

7

10C

4s

2s

PROPRIETARY MATERIAL. 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course

preparation. If you are a student using this Manual, you are using it without permission.

11-53

The rate of heat removal from the refrigerated space is

kW 19.33 = = = kJ/kg ) 81 . 68 51 kg/s)(244. 11 . 0 ( ) (

8 1 7

h h m Q

L

(c) The power input and the COP are

kW 45 . 7 kJ/kg ) 54 . 261 78 kg/s)(292. 1707 . 0 ( kJ/kg ) 51 . 244 76 kg/s)(263. 11 . 0 (

) ( ) (

9 4 1 2 7 in

= + =

+ = h h m h h m W

2.59 = = =

45 . 7

33 . 19

COP

in

L

W

Q

(d) If this refrigerator operated on a single-stage cycle between the same pressure limits, we would have

kJ/kg.K 9377 . 0

kJ/kg 51 . 244

C 10 @ 1

C 10 @ 1

= =

= =

g

g

s s

h h

kJ/kg 85 . 287

kPa 1600

2

1 2

2

=

)

`

=

=

s

h

s s

P

kJ/kg 90 . 294

51 . 244

51 . 244 85 . 287

86 . 0

2

2

1 2

1 2

=

=

h

h

h h

h h

s

C

q

kJ/kg 93 . 135

kJ/kg 93 . 135

3 4

kPa 1600 @ 3

= =

= =

h h

h h

f

kW 18.54 = = = kJ/kg ) 93 . 135 51 kg/s)(244. 1707 . 0 ( ) (

4 1

h h m Q

L

kW 60 . 8 kJ/kg ) 51 . 244 90 kg/s)(294. 1707 . 0 ( ) (

1 2 in

= = = h h m W

2.16 = = =

60 . 8

54 . 18

COP

in

L

W

Q

Discussion The cooling load decreases by 4.1% while the COP decreases by 16.6% when the cycle operates on the single-

stage vapor-compression cycle.

Q

H

Q

L

1

2s

3

4

s

T

2

W

in

1.6 MPa

10C

Potrebbero piacerti anche

- Tutorial 9 Solutions 1Documento5 pagineTutorial 9 Solutions 1Henry TranNessuna valutazione finora

- HW5Documento6 pagineHW5YTK96Nessuna valutazione finora

- Thermo 5th Chap09 P132Documento34 pagineThermo 5th Chap09 P132Ahmad AlgarniNessuna valutazione finora

- Thermo HWDocumento6 pagineThermo HWMuhammad Fawwad ObaidaNessuna valutazione finora

- Thermo 5th Chap09 P101Documento27 pagineThermo 5th Chap09 P101Ahmad AlgarniNessuna valutazione finora

- Total Energy: International Series in Heating, Ventilation and RefrigerationDa EverandTotal Energy: International Series in Heating, Ventilation and RefrigerationNessuna valutazione finora

- Chapter10 PDFDocumento10 pagineChapter10 PDFSaadMunirNessuna valutazione finora

- Carbon Dioxide Thermodynamic Properties Handbook: Covering Temperatures from -20° to 250°C and Pressures up to 1000 BarDa EverandCarbon Dioxide Thermodynamic Properties Handbook: Covering Temperatures from -20° to 250°C and Pressures up to 1000 BarNessuna valutazione finora

- c08 - Pending 8.36Documento262 paginec08 - Pending 8.36SeungMin LeeNessuna valutazione finora

- Solution #9Documento7 pagineSolution #9KinnonPangNessuna valutazione finora

- Thermo 5th Chap10 P001Documento29 pagineThermo 5th Chap10 P001welberTonetoMotaNessuna valutazione finora

- A Modern Course in Statistical PhysicsDa EverandA Modern Course in Statistical PhysicsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Assumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. AnalysisDocumento2 pagineAssumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. AnalysisAhmad ZikriNessuna valutazione finora

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringDa EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNessuna valutazione finora

- HW Chapter 7 solutions entropy & energy changesDocumento4 pagineHW Chapter 7 solutions entropy & energy changesgoodfellas121Nessuna valutazione finora

- Thermodynamics homework solutions for mechanical engineering courseDocumento5 pagineThermodynamics homework solutions for mechanical engineering coursemuru0105Nessuna valutazione finora

- C 10Documento107 pagineC 10نواف عبداللهNessuna valutazione finora

- Thermo 5th Chap10 P067Documento25 pagineThermo 5th Chap10 P067Ahmad AlgarniNessuna valutazione finora

- Answers: 0.2467 1421.06kJ/kg 9.09kJ/kg 46%Documento16 pagineAnswers: 0.2467 1421.06kJ/kg 9.09kJ/kg 46%Marianne DevillenaNessuna valutazione finora

- Solution Week 9Documento6 pagineSolution Week 9Ariadne ChuaNessuna valutazione finora

- R-12 Refrigeration Cycle ProblemsDocumento17 pagineR-12 Refrigeration Cycle ProblemsAlexis CarpenaNessuna valutazione finora

- HVAC Assignment 1 Solutions (Updated)Documento11 pagineHVAC Assignment 1 Solutions (Updated)Aleena Amin KhuwajaNessuna valutazione finora

- Ejercicio para CompararDocumento4 pagineEjercicio para CompararCamila SarabiaNessuna valutazione finora

- Revision SolutionDocumento19 pagineRevision SolutionHassan Abo NagaNessuna valutazione finora

- H S S X S S HDocumento4 pagineH S S X S S HahmadskhanNessuna valutazione finora

- Multi-stage compression power calculationsDocumento8 pagineMulti-stage compression power calculationsallovid0% (1)

- hw3 4,563,587,567,575,593,687,698,6102,739,763,797Documento11 paginehw3 4,563,587,567,575,593,687,698,6102,739,763,797megha_23Nessuna valutazione finora

- Solution#2 ThermoDocumento5 pagineSolution#2 ThermoPisjal LanNanNessuna valutazione finora

- THERMODYNAMICS SOLUTIONSDocumento62 pagineTHERMODYNAMICS SOLUTIONSanthonytichaona100% (1)

- JuasDocumento49 pagineJuasAndrés RodríguezNessuna valutazione finora

- Gas CycleDocumento9 pagineGas CycleYahya Tawakal100% (1)

- SoluçãoDocumento16 pagineSoluçãoFrancisco Rafael CerónNessuna valutazione finora

- HW#1Documento7 pagineHW#1MahsaNessuna valutazione finora

- Chapter 10 Vapor and Combined Power CyclesDocumento29 pagineChapter 10 Vapor and Combined Power Cyclesnamsun100% (1)

- Sample Problems: Rankine CycleDocumento12 pagineSample Problems: Rankine CycleReiVanNessuna valutazione finora

- A7 - 20-SEP-2016 - RM001 - POCE5 - Module-4-Energy Balance-NumericalsDocumento17 pagineA7 - 20-SEP-2016 - RM001 - POCE5 - Module-4-Energy Balance-NumericalssantoshNessuna valutazione finora

- Chapter 11Documento6 pagineChapter 11Paulo AzañeroNessuna valutazione finora

- Refrigeration System Design CalculationsDocumento27 pagineRefrigeration System Design CalculationsGodisGood AlltheTimeNessuna valutazione finora

- Rumus Perhitungan Turbin UapDocumento17 pagineRumus Perhitungan Turbin Uapricki yusufNessuna valutazione finora

- Solutions 4 F14Documento5 pagineSolutions 4 F14nageshNessuna valutazione finora

- 27 36 and 84 87Documento34 pagine27 36 and 84 87Aub EnriquezNessuna valutazione finora

- CH 12Documento30 pagineCH 12hirenpatel_universal0% (3)

- Tutorial Sheet 02 Answers 2014Documento24 pagineTutorial Sheet 02 Answers 2014checkmeout803100% (1)

- Energy Balance CalculationDocumento2 pagineEnergy Balance CalculationSzelee KuekNessuna valutazione finora

- P P P P: M H H M H H H H M M H HDocumento2 pagineP P P P: M H H M H H H H M M H HNaganathan SivabalanNessuna valutazione finora

- Simple refrigeration cycle calculations and parametersDocumento10 pagineSimple refrigeration cycle calculations and parametersAlexis CarpenaNessuna valutazione finora

- Termo Isı 1011 Örnek4Documento13 pagineTermo Isı 1011 Örnek4Şafak MeçoNessuna valutazione finora

- Ciclo BraytonDocumento17 pagineCiclo BraytonNubia Bergamini100% (2)

- Lec2New Microsoft Office PowerPoint PresentationDocumento36 pagineLec2New Microsoft Office PowerPoint PresentationMeroNarutoNessuna valutazione finora

- EXAM - (M) 2018: Mechanical Engineering Paper - IIDocumento12 pagineEXAM - (M) 2018: Mechanical Engineering Paper - IISandeep PrajapatiNessuna valutazione finora

- Solution#2Documento5 pagineSolution#2Mohammad W. JeeNessuna valutazione finora

- 10 Steps To Starting A Business in Ho Chi Minh CityDocumento5 pagine10 Steps To Starting A Business in Ho Chi Minh CityRahul PatilNessuna valutazione finora

- Be An ExporterDocumento3 pagineBe An ExporterAvinash MahajanNessuna valutazione finora

- Importance of Solenoid ValvesDocumento16 pagineImportance of Solenoid ValvesRahul PatilNessuna valutazione finora

- Refrig Piping GuideDocumento1 paginaRefrig Piping GuideRahul PatilNessuna valutazione finora

- Information Booklet For WindDocumento16 pagineInformation Booklet For WindKaribasappa ChandrakanthNessuna valutazione finora

- S RV CalculatorDocumento4 pagineS RV CalculatorRahul PatilNessuna valutazione finora

- Container InfoDocumento7 pagineContainer InfoWasipfcNessuna valutazione finora

- Diagram Refrigeration SystemDocumento1 paginaDiagram Refrigeration SystemRahul PatilNessuna valutazione finora

- List of 233 Potential Sites for Wind Power Projects in IndiaDocumento8 pagineList of 233 Potential Sites for Wind Power Projects in IndiaRishi PatelNessuna valutazione finora

- Solenoid White PaperDocumento16 pagineSolenoid White PaperRahul PatilNessuna valutazione finora

- HVAC Design Industrial VentilationDocumento13 pagineHVAC Design Industrial VentilationNiong DavidNessuna valutazione finora

- Winter 2001 KollaschDocumento33 pagineWinter 2001 KollaschRahul Patil100% (1)

- Diagram Refrigeration SystemDocumento1 paginaDiagram Refrigeration SystemRahul PatilNessuna valutazione finora

- Internation Trade TermsDocumento2 pagineInternation Trade TermsRahul PatilNessuna valutazione finora

- Safety Valves and Double Stop ValvesDocumento24 pagineSafety Valves and Double Stop ValvesRahul PatilNessuna valutazione finora

- Stop and Check ValvesDocumento24 pagineStop and Check ValvesRahul PatilNessuna valutazione finora

- Optyma CU Leaflet - 46CDocumento8 pagineOptyma CU Leaflet - 46CRahul PatilNessuna valutazione finora

- Evaporative Condenser Control in Industrial Refrigeration SystemsDocumento21 pagineEvaporative Condenser Control in Industrial Refrigeration SystemsMichael BasaNessuna valutazione finora

- PV000 A102 WhenitcomesDocumento1 paginaPV000 A102 WhenitcomesRahul PatilNessuna valutazione finora

- FRCC PV 002 A1 02 Poster ManeuropDocumento1 paginaFRCC PV 002 A1 02 Poster Maneuropamerican_guy10Nessuna valutazione finora

- Chapter - 07 Filter Driers & Sight GlassesDocumento10 pagineChapter - 07 Filter Driers & Sight Glasseskonislav2Nessuna valutazione finora

- Optyma-Plus Poster Pv800a102Documento1 paginaOptyma-Plus Poster Pv800a102Rahul PatilNessuna valutazione finora

- Chapter 05 Pressure RegulatorsDocumento10 pagineChapter 05 Pressure RegulatorsRahul PatilNessuna valutazione finora

- Chapter 10 Trouble ShootDocumento59 pagineChapter 10 Trouble ShootRahul PatilNessuna valutazione finora

- Chapter 06 Water ValvesDocumento6 pagineChapter 06 Water ValvesRahul PatilNessuna valutazione finora

- Chapter 02 Solenoid ValvesDocumento6 pagineChapter 02 Solenoid ValvesRahul PatilNessuna valutazione finora

- Chapter 09 Practical TipsDocumento20 pagineChapter 09 Practical TipsRahul PatilNessuna valutazione finora

- Chapter 04 ThermostatsDocumento8 pagineChapter 04 ThermostatsRahul PatilNessuna valutazione finora

- Chapter 03 Pressure ControlsDocumento8 pagineChapter 03 Pressure ControlsRahul PatilNessuna valutazione finora

- INS DS 0058 Buckling Pin Pressure Relief ValveDocumento12 pagineINS DS 0058 Buckling Pin Pressure Relief ValvelutzzNessuna valutazione finora

- Housekeeping ScheduleDocumento2 pagineHousekeeping ScheduleZeyya Nikka Cordova Pingad100% (1)

- Bluebox Tetris - 2 80-900Documento50 pagineBluebox Tetris - 2 80-900Montassar BouslamaNessuna valutazione finora

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocumento25 pagine26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- Peko Katalog EN 2016 PDFDocumento103 paginePeko Katalog EN 2016 PDFVanjaNessuna valutazione finora

- Slab WoodArmor Thesis PDFDocumento410 pagineSlab WoodArmor Thesis PDFshish0iitrNessuna valutazione finora

- Installation Manual: R410A Split SeriesDocumento14 pagineInstallation Manual: R410A Split Serieswarick mNessuna valutazione finora

- Building Envelope Thermal Bridging Guide: Analysis, Applications & InsightsDocumento81 pagineBuilding Envelope Thermal Bridging Guide: Analysis, Applications & InsightsArul Sankaran100% (1)

- Durco Mark 3: ASME (ANSI) Chemical Process PumpsDocumento36 pagineDurco Mark 3: ASME (ANSI) Chemical Process PumpsMohd Danial HNessuna valutazione finora

- Scrap Yard Mochia BOQDocumento8 pagineScrap Yard Mochia BOQSAMEERNessuna valutazione finora

- SFD N004 2013 PDFDocumento21 pagineSFD N004 2013 PDFMohamed Abo-ZaidNessuna valutazione finora

- 52 Week PPM Planner Template-15 Jul 14Documento26 pagine52 Week PPM Planner Template-15 Jul 14safetydellNessuna valutazione finora

- Fabrication and Processing of CeramicsDocumento14 pagineFabrication and Processing of CeramicsMinJing ParkNessuna valutazione finora

- BanbgroupDocumento59 pagineBanbgroupVenkata RajuNessuna valutazione finora

- Acoustic Emission Testing Method: Questions AnswersDocumento22 pagineAcoustic Emission Testing Method: Questions AnswersSadhasivam Velu100% (2)

- Pipeline Stress Analysis With Caesar IIDocumento16 paginePipeline Stress Analysis With Caesar IISathish KumarNessuna valutazione finora

- Air Duct CalculatorDocumento6 pagineAir Duct CalculatorrakeshamechNessuna valutazione finora

- Division 16 - Electrical Section 16720 - Fire Alarm SystemsDocumento3 pagineDivision 16 - Electrical Section 16720 - Fire Alarm SystemsMd. Mominul IslamNessuna valutazione finora

- Astm A560Documento5 pagineAstm A560MAX ALBERTO JUAREZ AVALOSNessuna valutazione finora

- Poor Concrete Construction Methods and Workmanship Are Responsible For The Failure of Buildings and StructureDocumento4 paginePoor Concrete Construction Methods and Workmanship Are Responsible For The Failure of Buildings and StructurepengniumNessuna valutazione finora

- Structural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersDocumento3 pagineStructural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersBoby CuliusNessuna valutazione finora

- p17 Tempra ProDocumento24 paginep17 Tempra ProKaja YusufNessuna valutazione finora

- Steel Racking Solutions, Inc.: 136 Production Court, Louisville Ky 40299Documento11 pagineSteel Racking Solutions, Inc.: 136 Production Court, Louisville Ky 40299Clyde FairbanksNessuna valutazione finora

- SR20715152848 - Very ImportantDocumento6 pagineSR20715152848 - Very Importantlogan firemanNessuna valutazione finora

- Almansoori Inspection Services: Travelling Block AssemblyDocumento2 pagineAlmansoori Inspection Services: Travelling Block AssemblyRanjithNessuna valutazione finora

- Deflections Due To Loading As Per ACIDocumento8 pagineDeflections Due To Loading As Per ACIRishabh LalaNessuna valutazione finora

- Equipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating SystemsDocumento100 pagineEquipment, Design, and Installation of Closed-Circuit Ammonia Mechanical Refrigerating Systemsᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Nessuna valutazione finora

- Surface Vehicle Recommended Practice: Issued OCT1999Documento19 pagineSurface Vehicle Recommended Practice: Issued OCT1999Paco LMNessuna valutazione finora

- ADM Specs GRP Enclosures and KiosksDocumento3 pagineADM Specs GRP Enclosures and KiosksMahiBoumNessuna valutazione finora

- Detailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Documento1 paginaDetailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Richard LeongNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDa EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNessuna valutazione finora

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDa EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Safety Fundamentals and Best Practices in Construction IndustryDa EverandSafety Fundamentals and Best Practices in Construction IndustryNessuna valutazione finora

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- Guidelines for Implementing Process Safety ManagementDa EverandGuidelines for Implementing Process Safety ManagementNessuna valutazione finora

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for Auditing Process Safety Management SystemsDa EverandGuidelines for Auditing Process Safety Management SystemsNessuna valutazione finora

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Advanced Process Control: Beyond Single Loop ControlDa EverandAdvanced Process Control: Beyond Single Loop ControlNessuna valutazione finora

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeDa EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNessuna valutazione finora

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersDa EverandRules of Thumb for Maintenance and Reliability EngineersValutazione: 4.5 su 5 stelle4.5/5 (12)

- Guidelines for Siting and Layout of FacilitiesDa EverandGuidelines for Siting and Layout of FacilitiesNessuna valutazione finora

- An Applied Guide to Water and Effluent Treatment Plant DesignDa EverandAn Applied Guide to Water and Effluent Treatment Plant DesignValutazione: 5 su 5 stelle5/5 (4)

- LNG Risk Based Safety: Modeling and Consequence AnalysisDa EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNessuna valutazione finora

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDa EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesDa EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNessuna valutazione finora

- Inherently Safer Chemical Processes: A Life Cycle ApproachDa EverandInherently Safer Chemical Processes: A Life Cycle ApproachValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for the Management of Change for Process SafetyDa EverandGuidelines for the Management of Change for Process SafetyNessuna valutazione finora

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisDa EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNessuna valutazione finora

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDa EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsValutazione: 4 su 5 stelle4/5 (11)