Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dow Corning

Caricato da

Kiran DuggarajuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dow Corning

Caricato da

Kiran DuggarajuCopyright:

Formati disponibili

Cleaners Remove Silicone Deposits from Industrial Equipment and Surfaces

Case Study: Dow Corning DS-2025 Silicone Cleaning Solvent and Dow Corning DS-1000 Aqueous Silicone Cleaner

PrOJecT

Demonstrate the removal of cured and uncured silicone from substrates.

PrOducTs

Dow Corning DS-2025 Silicone Cleaning Solvent Dow Corning DS-1000 Aqueous Silicone Cleaner

Silicones are widely used in various products and in manufacturing processes, and good cleaning practices can help you reduce the risk of microbial or chemical contamination in nished products, reduce the likelihood of buildup-related equipment failures, and contribute to good industrial hygiene and worker safety. Dow Corning offers two products for the easy removal of silicone deposits on tools, kettles, bottling lines, pipes, manufacturing equipment, oors and other surfaces: Dow Corning DS-2025 Silicone Cleaning Solvent for removing cured silicones and Dow Corning DS-1000 Aqueous Silicone Cleaner for removing uncured silicones.

Figure 1

Using Dow Corning DS-2025 Silicone Cleaning Solvent to remove cured silicone

To demonstrate the cleaning effect of Dow Corning DS-2025 Silicone Cleaning Solvent, a plastic pipe was coated with XIAMETER RSN-0749 Resin a curable silicone that, on evaporation of the cyclomethicone, forms a cured lm of highmolecular-weight silicone resin. The silicone was applied to the outside of the pipe rather than the inside (Figure 1) so the cleaning can be seen more effectively. The pipe was left to stand in Dow Corning DS-2025 Silicone Cleaning Solvent overnight at room temperature (Figure 2). It was then rinsed with water and dried to yield a clean pipe (Figure 3).

Figure 2

Recommended procedure for using Dow Corning DS-2025 Silicone Cleaning Solvent to remove cured silicone from industrial equipment: 1. Silicone digestion - Drain tanks and lines from a maximum of residue and water (0.5% maximum). - Fill tanks and lines with Dow Corning DS-2025 Silicone Cleaning Solvent. - Ventilation is required. A nitrogen blanket is not required but may be used as an additional safety measure if working at 60C.

Figure 3

- Recirculate Dow Corning DS-2025 Silicone Cleaning Solvent at room temperature (or up to 60C) until dissolution of residue is effective. Typically, this takes one to four hours. - Note that no impact of Dow Corning DS-2025 Silicone Cleaning Solvent on stainless steel 304 and 316 has been detected. Additionally, no impact has been detected on Teon, Viton, nitrile, polyethylene, polypropylene or EPDM gaskets, seals and joints, as well as ABS and PET. However, Dow Corning DS-2025 Silicone Cleaning Solvent will affect nylon, butyl rubber, polyurethane and silicone gaskets, seals and joints.

continued on back

2. Degreasing - Drain Dow Corning DS-2025 Silicone Cleaning Solvent from unit and rell container for next use. - Start CIP cleaning with 10% Dow Corning DS-1000 Aqueous Silicone Cleaner to solubilize and remove solvent residue. 3. Sanitization - Perform nal sanitization according to customer standard practice.

Further information

To request samples of Dow Corning DS-2025 Silicone Cleaning Solvent or Dow Corning DS-1000 Aqueous Silicone Cleaner or to obtain contact information for your local sales/technical representatives or distributor, visit dowcorning.com/SiliconeCleaning.

Using Dow Corning DS-1000 Aqueous Silicone Cleaner to remove uncured silicone

To demonstrate the cleaning effect of Dow Corning DS-1000 Aqueous Silicone Cleaner, some XIAMETER PMX-200 Silicone Fluid, 350 CS a typical uncured silicone was poured Figure 4 onto a oor (Figure 4). The bulk of the spill was cleaned up using paper tissue to leave a residue of silicone on the oor (Figure 5). The oor was then cleaned with a 10% aqueous solution of Dow Corning DS-1000 Aqueous Silicone Cleaner to give a clean surface (Figure 6). Recommended procedure for using Dow Corning DS-1000 Aqueous Silicone Cleaner to remove uncured silicone from industrial equipment: 1. Degreasing - Drain any residues from unit. - Fill unit with a 10% aqueous solution of Dow Corning DS-1000 Aqueous Silicone Cleaner. - Heat up to 80C and recirculate using the CIP cleaning procedure to solubilize and remove silicone residues. Recirculate through piping and spray nozzle-ball where relevant. 2. Sanitization - Drain off Dow Corning DS-1000 Aqueous Silicone Cleaner solution. - Perform nal sanitization according to customer standard practice.

Photos: Page 1 - AV19391, AV19396, AV19397; Page 2 - AV19389, AV19392, AV19394. HANDLING PRECAUTIONS PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND MATERIAL SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE MATERIAL SAFETY DATA SHEET IS AVAILABLE ON THE DOW CORNING WEBSITE AT DOWCORNING.COM, OR FROM YOUR DOW CORNING SALES APPLICATION ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CORNING CUSTOMER SERVICE. LIMITED WARRANTY INFORMATION PLEASE READ CAREFULLY The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customers tests to ensure that our products are safe, effective and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent. Dow Cornings sole warranty is that our products will meet the sales specications in effect at the time of shipment. Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted. DOW CORNING SPECIFICALLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY. DOW CORNING DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES. Dow Corning is a registered trademark of Dow Corning Corporation. XIAMETER is a registered trademark of Dow Corning Corporation. We help you invent the future is a trademark of Dow Corning Corporation. Teon and Viton are registered trademarks of E. I. du Pont de Nemours and Company. 2012 Dow Corning Corporation. All rights reserved. Printed in USA

AGP12376

Figure 5

Figure 6

Form No. 26-1881-01

Potrebbero piacerti anche

- Post-merger integration A Complete Guide - 2019 EditionDa EverandPost-merger integration A Complete Guide - 2019 EditionNessuna valutazione finora

- Managing in Organisation Syllabus PDFDocumento5 pagineManaging in Organisation Syllabus PDFArafath CholasseryNessuna valutazione finora

- Neuromarketing, From Novelty To MainstreamDocumento4 pagineNeuromarketing, From Novelty To MainstreamKarla Tristan0% (1)

- SI Report Case Study SuncorDocumento6 pagineSI Report Case Study SuncorNick AroraNessuna valutazione finora

- 02 2012 Frigo Laessoe Reduced PDFDocumento9 pagine02 2012 Frigo Laessoe Reduced PDFfaizthemeNessuna valutazione finora

- Competence Based DiversificationDocumento12 pagineCompetence Based DiversificationBayron FloresNessuna valutazione finora

- Research Paper: Bill Gates As Charismatic LeaderDocumento4 pagineResearch Paper: Bill Gates As Charismatic Leaderkhushiyadav630% (1)

- Session 1 - Introduction and Graphical Method To Solve LPPDocumento74 pagineSession 1 - Introduction and Graphical Method To Solve LPPChandra RoyNessuna valutazione finora

- The Product Life Cycle (PLC)Documento5 pagineThe Product Life Cycle (PLC)tejaNessuna valutazione finora

- Case of HyfluxDocumento6 pagineCase of HyfluxMai NganNessuna valutazione finora

- Ikea Marcomm and Control & MonitorDocumento4 pagineIkea Marcomm and Control & MonitorbabyzaaraNessuna valutazione finora

- Definition of A ConstraintDocumento9 pagineDefinition of A Constraintrajlaxmi_patilNessuna valutazione finora

- Strategic ManagentDocumento2 pagineStrategic Managentmurtaza259Nessuna valutazione finora

- Bus 162: Case Study 1 - Colgate's Distasteful ToothpasteDocumento1 paginaBus 162: Case Study 1 - Colgate's Distasteful ToothpasteFaizan Ahmed KiyaniNessuna valutazione finora

- Dell Case - Narmin MammadovaDocumento12 pagineDell Case - Narmin MammadovaNarmin J. Mamedova100% (1)

- AssignmentDocumento6 pagineAssignmentDave Erming Du100% (1)

- Jot Case Analysis:: The 2013 CIMA Global Business Challenge in Partnership With BarclaysDocumento25 pagineJot Case Analysis:: The 2013 CIMA Global Business Challenge in Partnership With BarclaysJo Anne V. GuevarraNessuna valutazione finora

- Case Blackberry 2016formatvDocumento30 pagineCase Blackberry 2016formatvSumalatha BNessuna valutazione finora

- Task EnvironmentDocumento2 pagineTask EnvironmentMohammad SarifudinNessuna valutazione finora

- Businees EthicsDocumento6 pagineBusinees Ethicsmigire kennedyNessuna valutazione finora

- Assignment: Marketing Mix Tactics For Achieving Christian Louboutin Shoes PositioningDocumento15 pagineAssignment: Marketing Mix Tactics For Achieving Christian Louboutin Shoes Positioningneeta pandeyNessuna valutazione finora

- Esg Analysis of Companies in Poland PDFDocumento80 pagineEsg Analysis of Companies in Poland PDFAriel GarcíaNessuna valutazione finora

- Harley DavidsonDocumento8 pagineHarley DavidsonQuyen Tran ThaoNessuna valutazione finora

- Coca-Cola Case AnalysisDocumento13 pagineCoca-Cola Case AnalysisRen FangzhouNessuna valutazione finora

- Volkswagen AssignmentDocumento1 paginaVolkswagen AssignmentVishal MalhiNessuna valutazione finora

- Competitive Strategy in Fragmented IndustriesDocumento2 pagineCompetitive Strategy in Fragmented IndustriesJahnab GogoiNessuna valutazione finora

- Business Ethic Assignment-Ariq Wynalda-29118031-YP59CDocumento5 pagineBusiness Ethic Assignment-Ariq Wynalda-29118031-YP59CMoe EcchiNessuna valutazione finora

- International Negotiations PlanDocumento49 pagineInternational Negotiations PlanMariia KuchynskaNessuna valutazione finora

- Van Leer Packaging Worldwide - The TOTAL AccountDocumento15 pagineVan Leer Packaging Worldwide - The TOTAL AccountAgarwala Ashesh100% (1)

- E Bay Acquisition of Skype: Group 2Documento24 pagineE Bay Acquisition of Skype: Group 207anshuman0% (1)

- Lego MainDocumento18 pagineLego MainhellyNessuna valutazione finora

- An Evaluation of The Market Entry Strategies Adopted by McdonaldDocumento9 pagineAn Evaluation of The Market Entry Strategies Adopted by McdonaldSai Kishore NelloreNessuna valutazione finora

- Volkswagen - An Offshore CompanyDocumento10 pagineVolkswagen - An Offshore CompanyIoana ȚecuNessuna valutazione finora

- PGBM156 (SEGi) - Individual Assignment - 2021Documento5 paginePGBM156 (SEGi) - Individual Assignment - 2021anne anziyaNessuna valutazione finora

- OLI ParadigmDocumento12 pagineOLI Paradigmankushkumar2000Nessuna valutazione finora

- Specialisation and TradeDocumento11 pagineSpecialisation and Trade陳希程50% (2)

- Importance and Uses of Weighted Average Cost of Capital (WACC)Documento2 pagineImportance and Uses of Weighted Average Cost of Capital (WACC)Lyanna MormontNessuna valutazione finora

- MQM 385 Group ProjectDocumento31 pagineMQM 385 Group Projectapi-580843559Nessuna valutazione finora

- Fundamentalist Xian Belief EnvironmentDocumento82 pagineFundamentalist Xian Belief EnvironmentJoEllyn AndersonNessuna valutazione finora

- Akamai CaseStudy AudiDocumento2 pagineAkamai CaseStudy AuditrinityneoNessuna valutazione finora

- Modes of Global Market EntryDocumento25 pagineModes of Global Market EntryMathew VargheseNessuna valutazione finora

- Unit 5: Project Control: Essential ReadingDocumento27 pagineUnit 5: Project Control: Essential Readingtechnicalvijay100% (1)

- Diversification Strategy AssignmentDocumento6 pagineDiversification Strategy Assignmentisra robinsonNessuna valutazione finora

- Stock Market ParticipationDocumento45 pagineStock Market ParticipationRohitNessuna valutazione finora

- Summary Scandal: Know/index - HTMLDocumento3 pagineSummary Scandal: Know/index - HTMLHendrikNessuna valutazione finora

- Closing The Gender Pay GapDocumento4 pagineClosing The Gender Pay Gapapi-530290964Nessuna valutazione finora

- Dell's Marketing Strategy - 2006Documento58 pagineDell's Marketing Strategy - 2006Preeti IyerNessuna valutazione finora

- STM Ques PaperDocumento9 pagineSTM Ques PaperAnonymous 8SNpyXNessuna valutazione finora

- Dell Globalization ReportDocumento15 pagineDell Globalization ReportPramod VarmaNessuna valutazione finora

- MGMT4900 Spring 2021 Ryen SyllabusDocumento12 pagineMGMT4900 Spring 2021 Ryen SyllabusVKNessuna valutazione finora

- Samsung Corporate GovernanceDocumento26 pagineSamsung Corporate Governancezabi ullah MohammadiNessuna valutazione finora

- Digikala-Ramin Shabanpour (2016)Documento19 pagineDigikala-Ramin Shabanpour (2016)Ramin ShabNessuna valutazione finora

- Capm AnalysisDocumento18 pagineCapm Analysisnadun sanjeewaNessuna valutazione finora

- BlackstoneJTH Credit Suisse Presentation Final WEB PDFDocumento31 pagineBlackstoneJTH Credit Suisse Presentation Final WEB PDFMikeNessuna valutazione finora

- Case Brief: True Religion Jeans: Flash in The Pants or Enduring Brand?Documento2 pagineCase Brief: True Religion Jeans: Flash in The Pants or Enduring Brand?Евгения Романенко100% (1)

- Mock Interview 11jan16Documento1 paginaMock Interview 11jan16Chen ZhenxiongNessuna valutazione finora

- Hyundai Strategic Management AnalysisDocumento18 pagineHyundai Strategic Management AnalysisSiddhartha MishraNessuna valutazione finora

- ECO701 Economics and The Business Environment CourseworkDocumento19 pagineECO701 Economics and The Business Environment CourseworkSrijita SahaNessuna valutazione finora

- Quality Policy Metro Cash Carry - en PDFDocumento2 pagineQuality Policy Metro Cash Carry - en PDFSrikanth GuruNessuna valutazione finora

- Introduction To UML: Background What Is UML For? Building Blocks of UML AppendixDocumento59 pagineIntroduction To UML: Background What Is UML For? Building Blocks of UML AppendixKiran DuggarajuNessuna valutazione finora

- MCTS in KarnatakaDocumento22 pagineMCTS in KarnatakaKiran Duggaraju100% (1)

- Saurabh Et Al TIMReview June2012Documento7 pagineSaurabh Et Al TIMReview June2012Kiran DuggarajuNessuna valutazione finora

- Tele MedicineDocumento34 pagineTele MedicineKiran DuggarajuNessuna valutazione finora

- EU STEM Coalition - Brochure 2016Documento28 pagineEU STEM Coalition - Brochure 2016Kiran DuggarajuNessuna valutazione finora

- GIM India 2012 Telemedicine in Rural India Challenges OpportunitiesDocumento36 pagineGIM India 2012 Telemedicine in Rural India Challenges OpportunitiesKiran DuggarajuNessuna valutazione finora

- Etiquette - Do's & Don'ts: Presented By: D Vaishnavi Kalyani Class: 5, Section: ADocumento13 pagineEtiquette - Do's & Don'ts: Presented By: D Vaishnavi Kalyani Class: 5, Section: AKiran DuggarajuNessuna valutazione finora

- Industrial Maintenance Mechanics 1Documento7 pagineIndustrial Maintenance Mechanics 1Kiran DuggarajuNessuna valutazione finora

- N Vitalari A Prospective Analysis of The Healthcare IndustryDocumento47 pagineN Vitalari A Prospective Analysis of The Healthcare IndustryKiran DuggarajuNessuna valutazione finora

- Cover Letter For A Cost QuotationDocumento1 paginaCover Letter For A Cost QuotationKiran DuggarajuNessuna valutazione finora

- Industrial Cleaning ServicesDocumento4 pagineIndustrial Cleaning ServicesKiran DuggarajuNessuna valutazione finora

- Automobile Industry in IndiaDocumento37 pagineAutomobile Industry in IndiaKiran DuggarajuNessuna valutazione finora

- Industriereiniger EngDocumento6 pagineIndustriereiniger EngKiran DuggarajuNessuna valutazione finora

- Role of Phosphates in CleanersDocumento2 pagineRole of Phosphates in CleanersKiran DuggarajuNessuna valutazione finora

- CRC Interactive Industrial Catalog 08Documento80 pagineCRC Interactive Industrial Catalog 08Kiran DuggarajuNessuna valutazione finora

- Metal Products Industry: Sector Specific Technology Transfer GuideDocumento6 pagineMetal Products Industry: Sector Specific Technology Transfer GuideKiran DuggarajuNessuna valutazione finora

- Contact Cleaners: M.G. ChemicalsDocumento10 pagineContact Cleaners: M.G. ChemicalsKiran DuggarajuNessuna valutazione finora

- 3.B.1 Degreasing GB2009Documento14 pagine3.B.1 Degreasing GB2009Andi DaudNessuna valutazione finora

- ScaleBreak PTDocumento2 pagineScaleBreak PTKiran DuggarajuNessuna valutazione finora

- Experimental Study of Manufacturing of Chemical De-Scaling MaterialsDocumento6 pagineExperimental Study of Manufacturing of Chemical De-Scaling MaterialsKiran DuggarajuNessuna valutazione finora

- Water Treatment For Cooling TowersDocumento57 pagineWater Treatment For Cooling TowersKiran Duggaraju100% (3)

- Non Chemical DescalingDocumento32 pagineNon Chemical DescalingKiran DuggarajuNessuna valutazione finora

- Field Study 1-Act 5.1Documento5 pagineField Study 1-Act 5.1Mariya QuedzNessuna valutazione finora

- Cupping TherapyDocumento6 pagineCupping TherapymsbunnileeNessuna valutazione finora

- Inverter ProjectDocumento19 pagineInverter ProjectRavi Sharma100% (1)

- Reticular AbscessDocumento4 pagineReticular AbscessSasikala KaliapanNessuna valutazione finora

- Applications Shaft SealDocumento23 pagineApplications Shaft SealMandisa Sinenhlanhla NduliNessuna valutazione finora

- GST15!16!17-Bad Debt Relief RecoverDocumento10 pagineGST15!16!17-Bad Debt Relief RecoverDaud Farook IINessuna valutazione finora

- Pre Commissioning Check List of GeneratorDocumento26 paginePre Commissioning Check List of GeneratorSUROHMAN ROHMANNessuna valutazione finora

- 2018 Haar Wavelet For Solving The Inverse Point Kinetics EquationsDocumento8 pagine2018 Haar Wavelet For Solving The Inverse Point Kinetics EquationsGeraldinNessuna valutazione finora

- The Theory of Motivation in Dog Training: By: Ed FrawleyDocumento30 pagineThe Theory of Motivation in Dog Training: By: Ed Frawleyrodrigue angbohNessuna valutazione finora

- Case StudyDocumento3 pagineCase StudyMarlon MagtibayNessuna valutazione finora

- @9negros Occidental Vs BezoreDocumento3 pagine@9negros Occidental Vs BezoreSimeon SuanNessuna valutazione finora

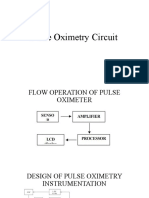

- Pulse Oximetry CircuitDocumento19 paginePulse Oximetry Circuitنواف الجهنيNessuna valutazione finora

- KorfundDocumento68 pagineKorfundnhy.mail2709100% (1)

- Antibacterial Effects of Essential OilsDocumento5 pagineAntibacterial Effects of Essential Oilsnightshade.lorna100% (1)

- Lecture 5 - Elements of Plasticity TheoryDocumento13 pagineLecture 5 - Elements of Plasticity TheoryNeeraj KumarNessuna valutazione finora

- X-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteDocumento2 pagineX-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteAmr RagabNessuna valutazione finora

- D 7752Documento6 pagineD 7752Asep TheaNessuna valutazione finora

- Blockchain Deck PDFDocumento65 pagineBlockchain Deck PDFsankhaNessuna valutazione finora

- 21-Ent, 45 Notes To PGDocumento12 pagine21-Ent, 45 Notes To PGAshish SinghNessuna valutazione finora

- Finding Clara: Establishing The Biographical Details of Clara Peeters (Ca. 1587-After 1636)Documento15 pagineFinding Clara: Establishing The Biographical Details of Clara Peeters (Ca. 1587-After 1636)victoriagalapedroNessuna valutazione finora

- BETP - Exp Clientele Dir 2012 - 03may2012Documento187 pagineBETP - Exp Clientele Dir 2012 - 03may2012Fernando EndayaNessuna valutazione finora

- Tests Conducted On Under Water Battery - YaduDocumento15 pagineTests Conducted On Under Water Battery - YadushuklahouseNessuna valutazione finora

- Y. C. Fung - Biomechanics - Motion, Flow, Stress, and Growth-Springer-Verlag New York (1990)Documento582 pagineY. C. Fung - Biomechanics - Motion, Flow, Stress, and Growth-Springer-Verlag New York (1990)saurabh kumar gupta100% (2)

- Chrono Biology SeminarDocumento39 pagineChrono Biology SeminarSurabhi VishnoiNessuna valutazione finora

- Fire CodeDocumento1 paginaFire CodeShainette VillarazaNessuna valutazione finora

- CHN REVIEWER LESSON 1 and 2Documento9 pagineCHN REVIEWER LESSON 1 and 2Imogen MasumiNessuna valutazione finora

- Problem Set in Power System 2Documento3 pagineProblem Set in Power System 2Andrew AlterNessuna valutazione finora

- Bakery Business PlanDocumento15 pagineBakery Business PlanGayu AishuNessuna valutazione finora

- Bar Exam Questions Week 1Documento30 pagineBar Exam Questions Week 1Mark Bantigue100% (1)