Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CMC

Caricato da

Chuma KhanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CMC

Caricato da

Chuma KhanCopyright:

Formati disponibili

CMC - Microcontroller

CMC

microcontroller

Control. The key to smooth, reliable, efficient operation. And to peace of mind. The CMC microcontroller for your centrifugal compressor provides that control and more. Using state-ofthe-art software and electronics, it is the most advanced microcontroller for centrifugals available today. And with its built-in flexibility, the CMC can adapt to your future needs, so it will be there for you tomorrow, too.

User-Friendly

Operation

The CMC uses a large graphical screen, which is available in 24 different languages, to display the operating parameters of the compressor. This allows the user to quickly view large amounts of data at one time, making the interface more user-friendly.

Acknowledge Key Graphic Display Contrast Key Navigation Keys Reset Key Start Key Stop Key Load/Unload Keys

Flexibility and

Efficiency

Designed to accommodate any equipment or system upgrades you may consider, the CMC is the most dependable, reliable and energy efficient microcontroller that can be installed on a centrifugal air compressor. The key to obtaining maximum energy efficiency from a centrifugal is running it as close to the natural surge line as possible without fluctuation or instability. With its advanced software and leading edge electronics, the CMC accomplishes this far better than any other microcontroller. For example, the CMC offers Ambient Control plus Parallel Valve control logic which combines air density compensation with the best valve logic algorithms in the industry, resulting in the most efficient and reliable control system. It is in a class all its own.

CMC Control Logic CMC Controller

Surge Line Discharge Pressure (PSIG)

Other Controllers

The closer to surge line you get...

Compressor Flow

...the less power you consume more reliably!

Power, kW

4-18% Energy Savings

Control Modes Available: Limit Amp or KW Control Amient Control plus Parallel Valve Control Logic Mass Flow Control Turbine or Engine Drive Control

SYSTEM

INFO

SETTINGS

400.0 100.0

High Load Limit (HLL) Throttle Limit (TL) Surge Indexing Enabled

The CMCs advanced electronics will provide you with all essential information and settings to automatically obtain maximum efficiency from your compressor. Selectable surge indexing and reload allows your compressor to reset and reload without manual intervention. This removes the need to manually reload a compressor due to sudden system changes, thus eliminating operation interruptions. The CMC offers two modes of operation to optimize your compressed air system. Modulate (constant pressure) control is available if you require tight pressure control. However, if your system is cyclical, Auto Dual may be the best mode of operation to save you money on energy costs. The CMC makes maintenance simple. Your compressors operating parameters are displayed in a way that is quick and easy to read. It will even provide you with the complete operators manual for your compressor right on screen, along with parts lists, maintenance schedules and toll-free telephone numbers to call for assistance, should the need arise. The event log screen simplifies troubleshooting and analysis of your compressor. Over two hundred (200) events can be logged, which includes any alarm, trip, and operational function changes.

Surge Indexing TL Increment Surge Indexing TL

1.0

3 Surge Reload Enabled

Surge Sensitivity 9

Ready

Trip Remote

2/6

SYSTEM

Control Mode Manual Modulate Autodual

INFO

SETTINGS

Reload Percent Unload Point (BV % Open) Unload Delay Time 1 1

Ready

Trip Remote

4/6

SYSTEM

Stage # 1 2 O i l water

INFO

Pressure 30 106 18

SETTINGS

Temperature 95 93 115 80 Vibration 0.25 0.22

Ready

Trip Remote

2/4

SYSTEM

INFO

SETTINGS

SYSTEM

Event Name 1 2 3 4 5 6 7

INFO

SETTINGS

Date 970720 970720 970720 970720 970720 970720 970720 Time 09:18:44 09:18:43 09:18:34 09:08:43 08:58:23 08:24:01 08:18:33

ROUTINE START/STOP Prior to starting, the operator should become familiar with the operation of the main driver. Refer to the driver manufacturer's instructions in the Operation Manual. The operator should also be familiar with all the accessory and optional equipment contained on the unit. Personnel who are unfamiliar with the compressor

Low Oil Pressure Trip Reset key pressed Low Oil Pressure Trip Acknowledge key pressed Low Oil Pressure Alarm Load key pressed Start key pressed

Ready

Trip Remote

Not Ready

6/6

Trip Remote

2/4

Universal

Communications

The optional Universal Communications Module (UCM) provides additional flexibility to the CMC. The UCM allows the CMC to communicate with other industrial systems MODBUS & MODBUS Plus Protocol The UCM supports MODBUS protocol a widely used industry standard method of message structuring created by Modicon. This feature allows the CMC to communicate with any MODBUS-compliant product using the RTU transmission mode. In addition, through the use of a converter, the UCM is capable of communicating via MODBUS Plus. This is a benefit when you want to standardize your compressed air system controls and communicate with other products. AB DF1 Protocol Ingersoll-Rand understands the importance of being able to integrate with other systems and the latest technology on the market. The UCM supports Allen-Bradley DF1 protocol as well as Data Highway Plus with the use of an Allen-Bradley 1770-KF2 network adapter. Modem Awareness For additional flexibility and functionality, the UCM module is also capable of communicating through a modem to accept modem commands.

CMC

Universal Communication Module

DCS MODEM

6

ASM/ASC

Additional Control Relay (Opt)

Ingersoll-Rand provides you with the ability to control additional auxiliary equipment (ie. water solenoid valve).

Universal Communications Module (Opt)

The UCM allows the CMC to communicate with other industrial systems.

Microcontroller Board

Simple microcontroller board for control, monitoring and protection of your compressor.

Start (Run) Relay

Main relay (CR1) for compressor start circuit.

Test Connection

Provided for testing purposes.

Control Transformer (Opt)

Converts incoming power to 120V. Can be installed by Ingersoll-Rand for simple installation and start-up.

Customer Connection

Three simple connections for your incoming power.

Prelube Pump Starter & Lube Oil Heater Contactor (Opt)

By Ingersoll-Rand installing these components installation and start-up of your compressor is simplified.

Terminal Blocks

Easily accessible and simple to understand connections.

Vibration Transmitters

Vibration is monitored on all stages to ensure compressor reliability and performance.

Seal Air Switch

Protective functions such as this are incorporated into control panel to maintain compressor integrity.

Seal Air Regulator

Provides adequate seal air to maintain 100% oil free air at all times.

System Pressure

This transducer provides a system discharge pressure signal for easy monitoring of compressed air system.

Simplified

Installation and Start-up

Stage Data (Opt)

Interstage temperature and pressure is monitored to ensure proper compressor operation.

D S R E G IS

TE

R QUALIT

AS

SURANC

LL

OY

I S O 9 0 01

More Than Air. Solutions.

Online solutions: www.air.ingersoll-rand.com

Ingersoll-Rand air compressors are not designed, intended or approved for breathing applications. Ingersoll-Rand does not approve specialized equipment for breathing air applications and assumes no responsibility or liability for compressors used for breathing air service. Nothing contained in this brochure is intended to extend any warranty or representation, expressed or implied, regarding the products described herein. Any such warranties or other terms and conditions of sale shall be in accordance with Ingersoll-Rand's standard terms and conditions of sale for such products which are available upon request. Product improvement is a continuing goal at Ingersoll-Rand. Designs and specifications are subject to change without notice or obligation.

Ingersoll-Rand Company 800-B Beaty Street Davidson, NC 28036 (800) 247-8640 Ingersoll-Rand Italiana S.p.A. Strada Provinciale Cassanese 20060 Vignate, Milano, Italy (02) 950561

2003 Ingersoll-Rand Company Form 8519 Printed in USA

CMC - Microcontroller

Potrebbero piacerti anche

- Screw Compressors: Model: VD55-10DGDocumento20 pagineScrew Compressors: Model: VD55-10DGVoştinar IoanNessuna valutazione finora

- CRITICAL EVALUATION OF KOHLBERG's THEORYDocumento3 pagineCRITICAL EVALUATION OF KOHLBERG's THEORYChuma Khan100% (1)

- Na NO2Documento10 pagineNa NO2Trần Thùy LinhNessuna valutazione finora

- Csa Rotordryer PDFDocumento8 pagineCsa Rotordryer PDFpeterpunk75Nessuna valutazione finora

- Field Performance Testing For Centrifugal CompressorsDocumento7 pagineField Performance Testing For Centrifugal CompressorsRicardo BecNessuna valutazione finora

- CPVR60 Industrial Air CompressorsDocumento17 pagineCPVR60 Industrial Air CompressorsIpenu Sujarwo100% (1)

- Project Management, Tools, Process, Plans and Project Planning TipsDocumento16 pagineProject Management, Tools, Process, Plans and Project Planning TipsChuma Khan100% (1)

- 0574 8231 35Documento2 pagine0574 8231 35UbanAirlangga100% (1)

- b25d b30d Mkiii HydraulicsDocumento28 pagineb25d b30d Mkiii HydraulicsErmias100% (3)

- Screw Compressors: Model: VE22-10BDocumento30 pagineScrew Compressors: Model: VE22-10BVoştinar IoanNessuna valutazione finora

- Schneider Air Compressor-Katalog 2011 enDocumento291 pagineSchneider Air Compressor-Katalog 2011 envirgil guimanNessuna valutazione finora

- Revision Module 1,2,3Documento129 pagineRevision Module 1,2,3jitamitra88Nessuna valutazione finora

- Shell and Tube Heat Exchanger DesignDocumento41 pagineShell and Tube Heat Exchanger DesignAhmad Budiman100% (2)

- Air 4 Bar PlantDocumento7 pagineAir 4 Bar PlantAbu ZakaNessuna valutazione finora

- Capacitor BanksDocumento49 pagineCapacitor BanksAmal P RaviNessuna valutazione finora

- The Machine-Room-Less Elevator: Kone E MonospaceDocumento8 pagineThe Machine-Room-Less Elevator: Kone E MonospaceAbdelmuneimNessuna valutazione finora

- Leonova Condmaster ManualDocumento172 pagineLeonova Condmaster ManualThomas BembeNessuna valutazione finora

- List of Electronics Manufacturing Companies in Noida - ElectronicsmediaDocumento2 pagineList of Electronics Manufacturing Companies in Noida - ElectronicsmediaBlue Oceon50% (4)

- GARDNER DENVER - ELECTRAâ "SAVER - Compressor ManualDocumento58 pagineGARDNER DENVER - ELECTRAâ "SAVER - Compressor ManualJair Aguirre RamirezNessuna valutazione finora

- Installation Operating Manual SewatecDocumento82 pagineInstallation Operating Manual SewatecMouayed Zeadan100% (1)

- 8602 BookDocumento240 pagine8602 BookSohail100% (2)

- Tabel Bunga Untuk Ekonomi TeknikDocumento32 pagineTabel Bunga Untuk Ekonomi TeknikElvina Noviarni Chandra78% (9)

- High Efficiency Compressed Air Dryers: Adsorption Dryers Classical SystemDocumento8 pagineHigh Efficiency Compressed Air Dryers: Adsorption Dryers Classical Systemneversig100% (1)

- PSA Oxymat Servicio de MantenimientoDocumento28 paginePSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezNessuna valutazione finora

- Rotina de Inspeção em ManutençãoDocumento11 pagineRotina de Inspeção em ManutençãoBrender VictorNessuna valutazione finora

- Learning From AiChEDocumento74 pagineLearning From AiChEChuma Khan100% (1)

- Instruction book maintenance scheduleDocumento4 pagineInstruction book maintenance scheduleTolias EgwNessuna valutazione finora

- C950 Planning & Installation Manual: CentacDocumento41 pagineC950 Planning & Installation Manual: CentacBrender Victor100% (1)

- Atlas Copco Stationary Air Compressors: GA5, GA7, GA11C With Elektronikon I or Elektronikon II RegulatorDocumento78 pagineAtlas Copco Stationary Air Compressors: GA5, GA7, GA11C With Elektronikon I or Elektronikon II RegulatorKrzysiek PodsiadłoNessuna valutazione finora

- Che-481 - Fuel and Combustion - Group 09Documento24 pagineChe-481 - Fuel and Combustion - Group 09Osama HasanNessuna valutazione finora

- Che-481 - Fuel and Combustion - Group 09Documento24 pagineChe-481 - Fuel and Combustion - Group 09Osama HasanNessuna valutazione finora

- Academic Transition To Senior High SchoolDocumento30 pagineAcademic Transition To Senior High SchoolGabriel ExalaNessuna valutazione finora

- Hydro Turbine Speed Governing SystemDocumento12 pagineHydro Turbine Speed Governing SystemNaveen Kumar100% (1)

- Air Miser System Benefits MS129Documento4 pagineAir Miser System Benefits MS129Diego PareschiNessuna valutazione finora

- Tri Sen Controle Surge Compressores TS160Documento6 pagineTri Sen Controle Surge Compressores TS160Jimmy RumlusNessuna valutazione finora

- AC Oil-Free Air - ZH+ & ZH 355-900 - 2013 - 0625 - LRDocumento16 pagineAC Oil-Free Air - ZH+ & ZH 355-900 - 2013 - 0625 - LRmasrooor100% (1)

- Filter Solutions English Feb 2019 HR-páginas-1,8-9,25-26Documento5 pagineFilter Solutions English Feb 2019 HR-páginas-1,8-9,25-26samuelNessuna valutazione finora

- Curtis Compressor Challenge Air PDFDocumento44 pagineCurtis Compressor Challenge Air PDFSamy SamyNessuna valutazione finora

- SB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFDocumento3 pagineSB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFNoufou DarankoumNessuna valutazione finora

- Operator Manual for Champion Screw CompressorDocumento90 pagineOperator Manual for Champion Screw CompressorPrince NeroNessuna valutazione finora

- SA英文使用手册NEWDocumento49 pagineSA英文使用手册NEWBernad Orlando0% (1)

- Samson PRV Mounting and Operating InstructionDocumento20 pagineSamson PRV Mounting and Operating InstructionRick CalaguiNessuna valutazione finora

- Minimum Pressure Valve MPVL65FH and MPVL65FHSDocumento2 pagineMinimum Pressure Valve MPVL65FH and MPVL65FHSСергей КолесниковNessuna valutazione finora

- FD CatalogueDocumento16 pagineFD Cataloguevirtech1Nessuna valutazione finora

- Ingersoll Rand X-IRI Communications Gateway Operators ManualDocumento81 pagineIngersoll Rand X-IRI Communications Gateway Operators ManualWilliam PachecoNessuna valutazione finora

- Camcs L PlantairDocumento20 pagineCamcs L PlantairSergio MoncadaNessuna valutazione finora

- EVO Screw-Air-manual 2020 enDocumento36 pagineEVO Screw-Air-manual 2020 enRoman ChubaNessuna valutazione finora

- Hes 1250 2015Documento74 pagineHes 1250 2015SAUL OSPINONessuna valutazione finora

- Almig Flex GB Web 1 2Documento8 pagineAlmig Flex GB Web 1 2sebastianNessuna valutazione finora

- Senator LSV Series With Mam-660 ControllerDocumento64 pagineSenator LSV Series With Mam-660 ControllerRomanCHubaNessuna valutazione finora

- C13579-80-Bill of MaterialsDocumento19 pagineC13579-80-Bill of MaterialsBrender Victor100% (1)

- PT Cemindo Gemilang Rev 1Documento11 paginePT Cemindo Gemilang Rev 1ShahNessuna valutazione finora

- Ficha Ig Compresoresdetornillo R37IE en 0Documento1 paginaFicha Ig Compresoresdetornillo R37IE en 0death666darkNessuna valutazione finora

- 2935 0751 31 - Large Compressors Product Grouping ChartDocumento1 pagina2935 0751 31 - Large Compressors Product Grouping ChartNicholas MurondaNessuna valutazione finora

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Documento12 pagineP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariNessuna valutazione finora

- F 0077 e 55Documento6 pagineF 0077 e 55Bùi Cảnh TrungNessuna valutazione finora

- Manual OMIDocumento13 pagineManual OMIMatias CzarnotaNessuna valutazione finora

- User'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerDocumento67 pagineUser'S, Maintenance and Spare Parts Manual: Refrigerating Air DryerValentin Bogdan100% (1)

- V780M WNDocumento2 pagineV780M WNTriệu Tử Long100% (1)

- ALM Refrigeration Air DryerDocumento34 pagineALM Refrigeration Air DryerJunaid AhmedNessuna valutazione finora

- TR ProductDataSheetAllSeriesDocumento2 pagineTR ProductDataSheetAllSeriesAndry Setiawan100% (1)

- Ingersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 enDocumento12 pagineIngersoll Rand Oil Free CompressedAirTechnologyIAS 0701015 envkees1987Nessuna valutazione finora

- Adsorption Dryer Operating InstructionsDocumento63 pagineAdsorption Dryer Operating InstructionsTina ManousiNessuna valutazione finora

- Bill Of Material For AG Equipment Air Compressor SystemDocumento8 pagineBill Of Material For AG Equipment Air Compressor SystemHashemAliHashemNessuna valutazione finora

- Hpa1000 Part List Rev01Documento29 pagineHpa1000 Part List Rev01Jorge100% (1)

- Copeland Compresor 2019 ECT2014DS78 PDFDocumento166 pagineCopeland Compresor 2019 ECT2014DS78 PDFFrancisco Sanchez RNessuna valutazione finora

- ARCA Evolution160 240 enDocumento2 pagineARCA Evolution160 240 enadyturNessuna valutazione finora

- DENAIR Oil-Free Air Compressor PDFDocumento8 pagineDENAIR Oil-Free Air Compressor PDFagasmekatron100% (1)

- Specification ARX120HK EnglishDocumento5 pagineSpecification ARX120HK Englishheruono sitorusNessuna valutazione finora

- 360 CDE Atlas Copco Air Dryers ManualDocumento38 pagine360 CDE Atlas Copco Air Dryers Manualshamil130798100% (1)

- KBD Manual Rev J 01-11Documento44 pagineKBD Manual Rev J 01-11Ismael Cano ParejoNessuna valutazione finora

- Regulus Control SystemDocumento6 pagineRegulus Control Systemdennis_packiaraj3063Nessuna valutazione finora

- FDbrochureDocumento13 pagineFDbrochureAyman Mohammed Ibrahim AbdouNessuna valutazione finora

- Almig Combi GB WebDocumento8 pagineAlmig Combi GB WebRomanCHubaNessuna valutazione finora

- D Woodward Integrated Compressor Control Afjfkjfj FJFJFJFDocumento5 pagineD Woodward Integrated Compressor Control Afjfkjfj FJFJFJFDiego PareschiNessuna valutazione finora

- Modeling & Simulation of Secondary ReformerDocumento8 pagineModeling & Simulation of Secondary ReformerChuma KhanNessuna valutazione finora

- Inspection For High Temperature H2 AttackDocumento29 pagineInspection For High Temperature H2 AttackChuma KhanNessuna valutazione finora

- Catalyst Performance Assessment MethodsDocumento3 pagineCatalyst Performance Assessment MethodsMuthu KumarNessuna valutazione finora

- ImprovementofstrippingindexofcatacarbsystemDocumento15 pagineImprovementofstrippingindexofcatacarbsystemChuma KhanNessuna valutazione finora

- State Point ArticleDocumento15 pagineState Point Articlealfredmbewe6308Nessuna valutazione finora

- FIORDA Case Study Corrosion Attack On Primary Reformer TubesDocumento7 pagineFIORDA Case Study Corrosion Attack On Primary Reformer TubesChuma Khan100% (1)

- Catalyst Performance Assessment MethodsDocumento3 pagineCatalyst Performance Assessment MethodsMuthu KumarNessuna valutazione finora

- Catalyst Performance Assessment MethodsDocumento3 pagineCatalyst Performance Assessment MethodsMuthu KumarNessuna valutazione finora

- Activated Sludge Treatment Lecture NotesDocumento22 pagineActivated Sludge Treatment Lecture NotesChuma KhanNessuna valutazione finora

- Energy Efficiency of ChillersDocumento5 pagineEnergy Efficiency of ChillersChuma KhanNessuna valutazione finora

- Economics Sample QuizDocumento5 pagineEconomics Sample QuizChuma KhanNessuna valutazione finora

- OrificeDocumento5 pagineOrificeyuvionfireNessuna valutazione finora

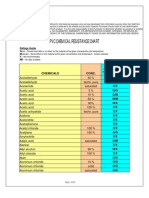

- PVC Chemical ResistanceDocumento20 paginePVC Chemical ResistanceYamin MohdNessuna valutazione finora

- JSSW Vessel Design CriteriaDocumento38 pagineJSSW Vessel Design CriterialafondejsNessuna valutazione finora

- Easy-Line 05 EDocumento2 pagineEasy-Line 05 EChuma KhanNessuna valutazione finora

- The Control of PHDocumento6 pagineThe Control of PHRoman MangalindanNessuna valutazione finora

- Appl. Environ. Microbiol. 1983 Bancroft 683 8Documento7 pagineAppl. Environ. Microbiol. 1983 Bancroft 683 8Chuma KhanNessuna valutazione finora

- How To Excel at Project ManagementDocumento27 pagineHow To Excel at Project ManagementChuma KhanNessuna valutazione finora

- Preparing An Effective Case AnalysisDocumento4 paginePreparing An Effective Case AnalysisMuhammad MujahidNessuna valutazione finora

- Chem 361 Separation Methods IntroDocumento8 pagineChem 361 Separation Methods IntroTwum SomoahNessuna valutazione finora

- Kevin Chiu - Solving Procrastination v1.1Documento2 pagineKevin Chiu - Solving Procrastination v1.1TêteHauteNessuna valutazione finora

- IIT BOMBAY RESUME by SathyamoorthyDocumento1 paginaIIT BOMBAY RESUME by SathyamoorthySathyamoorthy VenkateshNessuna valutazione finora

- FMBXXX Quick Manual v3.5Documento18 pagineFMBXXX Quick Manual v3.5AMNessuna valutazione finora

- Carl Rogers, Otto Rank, and "The BeyondDocumento58 pagineCarl Rogers, Otto Rank, and "The BeyondAnca ElenaNessuna valutazione finora

- Soft Computing Techniques Assignment1 PDFDocumento14 pagineSoft Computing Techniques Assignment1 PDFshadan alamNessuna valutazione finora

- Chapter 1 Optical Fiber Transmission Media PDFDocumento46 pagineChapter 1 Optical Fiber Transmission Media PDFGilang AnandaNessuna valutazione finora

- +GF+ Pressure Retaining Valve Type 586Documento4 pagine+GF+ Pressure Retaining Valve Type 586ROMNANessuna valutazione finora

- Curriculum Vitae: Name: Mobile: EmailDocumento3 pagineCurriculum Vitae: Name: Mobile: EmailRākesh RakhiNessuna valutazione finora

- 13 Nilufer-CaliskanDocumento7 pagine13 Nilufer-Caliskanab theproNessuna valutazione finora

- Proposal BP3IP FinalDocumento3 pagineProposal BP3IP FinalGiant SeptiantoNessuna valutazione finora

- Catering Reserving and Ordering System with MongoDB, Express, Node.js (39Documento5 pagineCatering Reserving and Ordering System with MongoDB, Express, Node.js (39radha krishnaNessuna valutazione finora

- Halo Outdoor slmt1000 - slmt1000wDocumento1 paginaHalo Outdoor slmt1000 - slmt1000wFrank MoyaNessuna valutazione finora

- CA Ashish Dewani - Resume-1Documento2 pagineCA Ashish Dewani - Resume-1Payal JainNessuna valutazione finora

- Advance Distributed ComputingDocumento2 pagineAdvance Distributed ComputingValia Centre of ExcellenceNessuna valutazione finora

- CM Group Marketing To Gen Z ReportDocumento20 pagineCM Group Marketing To Gen Z Reportroni21Nessuna valutazione finora

- Get Started On Creating Your Event Budget:: If You Decide To Build Your Own Start by Creating A Few ColumnsDocumento4 pagineGet Started On Creating Your Event Budget:: If You Decide To Build Your Own Start by Creating A Few ColumnsGeomarkPaalaMortelNessuna valutazione finora

- Application-Form MRP-INFORMCC 2021 VFFDocumento5 pagineApplication-Form MRP-INFORMCC 2021 VFFBouramaNessuna valutazione finora

- DMS 48 NormesDocumento11 pagineDMS 48 NormesSonia WittmannNessuna valutazione finora

- Finimpianti Power EngDocumento2 pagineFinimpianti Power EngJosip GrlicaNessuna valutazione finora

- Mini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler ModulesDocumento2 pagineMini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler Moduleslejlas77Nessuna valutazione finora

- Air Cooled Screw Chiller Performance SpecificationDocumento2 pagineAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- Schippers and Bendrup - Ethnomusicology Ecology and SustainabilityDocumento12 pagineSchippers and Bendrup - Ethnomusicology Ecology and SustainabilityLuca GambirasioNessuna valutazione finora