Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bt65 PCP Air Rifle Manual

Caricato da

shjefkeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bt65 PCP Air Rifle Manual

Caricato da

shjefkeCopyright:

Formati disponibili

HATSAN ARMS COMPANY

Serious. Solid. Impact.

BT65 SERIES PCP AIR RIFLE

INSTRUCTION MANUAL

PLEASE READ THIS MANUAL BEFORE USING YOUR AIR GUN

Thank you for choosing HATSAN BT65 PCP air rie. Always use caution when operating this rie. Learn and obey the laws of your state and/or country, and be responsible in your use of this air rie. Please read this manual completely before handling or shooting your air gun. Its the sole responsibility of the user to use this air gun properly and safely. Your air rie contains many features which gives greater handling, greater accuracy and enjoyment: Dovetail groove receiver for both 11mm and 22mm scope mounts. Overall blued nish Precision ried steel barrel for accuracy Manual Safety Synthetic or wooden stock all with elevation adjustable comb Stock length of pull and stock t adjustable rubber recoil pad Adjustable rear & front sight with ber optic. Quattro Trigger: 2-stage full adjustable match trigger for trigger travel and trigger load. Metal trigger Detachable air cylinder tube enabling to use spare air cylinders Built-in pressure gauge to monitor the cylinder pressure Standard quick-ll nozzle & air cylinder discharging cap 10 shot magazine (9 shot in .25 / 6.35mm caliber) Side bolt or rear bolt action

Warning!

1. Each HATSAN BT65 PCP air rie contains pressurized air and should only be dismantled by a competent gunsmith. Do not attempt to dismantle the rie if the rie is partially or fully charged, except for removal and replacement of the air cylinder. Serious injury and/or damage may result if this instruction is ignored. Never shoot the rie when the air cylinder is removed or empty. This may damage your rie. Never attempt to dismantle the air cylinder parts or air gauge when the air cylinder is fully or partially charged. Serious injury and/or damage may result if this instruction is ignored. 2. Dont use BB pellets with your rie and use only factory manufactured waisted pellets. 3. HATSAN BT65 PCP air rie is designed specically for use with dry compressed air. NO OTHER GAS OR GAS COMBINATION MUST BE USED. The rie may be lled from a divers bottle, a suitable compressor or by using a hand pump specically made to ll pre-charged air guns. MAXIMUM SAFE WORKING PRESSURE (SWP) : 200 BAR. RECOMMENDED FILL PRESSURE : 190 BAR

GENERAL INSTRUCTIONS

BT65 series may have rear & front sight assembled at factory. If not, you should mount Scopes and other alternate optic sights before use. Scopes and other alternate optic sights can also be mounted on BT65 having rear & front sight. Before using your new air rie check if it is fully charged and abide the below basic safety rules: Basic Safety Rules: 1. Treat every rie as if it is loaded. 2. Never point the rie at anyone, or allow anyone to point a rie at you, even if you know it is not loaded. 3. Always carry the rie so that the direction of the muzzle is under control, even if you stumble. 4. Always be sure of your target and what lies behind it before ring your rie. 5. Never leave a loaded rie unattended. 6. Beware of targets that tend to cause ricochets 7. It is recommended that eye & ear protection is worn when charging the cylinder and when shooting.

Section I. SPECIFICATIONS

BT65 is a 10 shot (9 shot in .25 / 6.35mm caliber), pre-charged, manual loading, pneumatic air rie with detachable air cylinder tube (255cc) It is available .177 (4.5mm), .22 (5.5mm) and .25 (6.35mm) caliber. Barrel Length Overall Length Weight Maximum cylinder ll pressure 585mm / 23 1085mm / 42.7 4.3kg / 9.4lbs 200 Bar

Maximum Muzzle Velocity/Energy: 1250fps (380m/s) in cal .177 (4.5mm), Energy 40Joules / 30ft.lbs 1180fps (360m/s) in cal.22 (5.5mm), Energy 61Joules / 45ft.lbs 1090fps (330m/s) in cal.25 (6.35mm), Energy 71Joules / 52ft.lbs

* Above maximum muzzle velocity gures may differ depending on the pellet weight & shape. * The energy restriction of a particular country can be achieved by the reduction in the muzzle velocity. The above maximum velocity gures are obtained when there is no energy restriction on the air rie and when measured at optimum pressure value in the air tube. As a nature of PCP air ries the velocity starts low at maximum pressure level in the air tube, then starts to increase and gets to the maximum at optimum pressure value in the air tube; and then it starts to decrease again as the pressure in the air cylinder gets too low.

Side Bolt Version

2

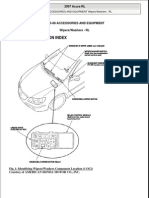

Section II. BASIC PARTS OF YOUR GUN

7 3 8 9 10 11 12 13 15

14 4

1. Butt Pad 2. Stock 3. Adjustable Comb 4. Grip

16

5. Trigger 6. Trigger Guard 7. Scope Rail 8. Side bolt Handle

9. Receiver 10. Magazine 11. Magazine Release Bolt 12. Rear Sight

13. Barrel 14. Air Cylinder Tube 15. Front Sight 16. Muzzle Cap

Rear Bolt Version

8 2 3 7 9 10 11 12 13 15

14 4

1. Butt Pad 2. Stock 3. Adjustable Comb 4. Grip

16

5. Trigger 6. Trigger Guard 7. Scope Rail 8. Rear bolt Handle

9. Receiver 10. Magazine 11. Magazine Release Bolt 12. Rear Sight

13. Barrel 14. Air Cylinder Tube 15. Front Sight 16. Muzzle Cap

Section III. MANUAL SAFETY

Safety button can be set to ON and OFF position manually. To set the safety to ON, pull safety button. In this position, the trigger cannot be pulled and the gun cannot be red. (Fig.1) To remove the safety to OFF, push safety button.In this position, the gun is ready to shoot. (Fig. 2)

SAFETY ON

SAFETY OFF

Fig. 1

Fig. 2

CAUTION: Until you are actually ready to shoot, keep the safety button in the ON position (Fig. 1).

Section V. QUATTRO TRIGGER

Your air rie is equipped with Quattro trigger, (Fig. 3), you can adjust trigger travel & trigger pull as follows: BOLT#1 is for trigger pull force adjustment. For less trigger pull force prior to discharge, rotate BOLT #1 clockwise; and vice versa. BOLT#2 is for trigger travel adjustment. For less trigger travel prior to discharge, rotate BOLT #2 clockwise; and vice versa. BOLT#3 is for adjusting the trigger force to pull the trigger till the end of 1st stage. When this is turned clockwise, this force increases; and vice versa.

BOLT#3 BOLT#2 BOLT#1

Fig. 3

Section VI. MICRO ADJUSTABLE REAR-SIGHT & ADJUSTABLE KNOB#2 FRONT SIGHT

Your air rie come with ber optic rear & front sight tted-except on models with xed noise-dampener whereas you should t a scope or other alternate optic sights.. The rear-sight is a sensitive device and can be adjusted both for elevation and windage. Windage adjustment If the shot is deected to the left of the target, turn the KNOB1 clockwise. (Fig. 4) If the shot is deected to the right of the target, turn the KNOB1 counter-clockwise. (Fig. 4) Elevation adjustment If the shot is too high, turn KNOB2 clockwise. (Fig. 4) If the shot is too low, turn KNOB2 screw counter-clockwise. (Fig. 4) Further elevation adjustment is possible by means of the adjustable front sight. If the shot is too high, turn KNOB3 clockwise. (Fig. 5) If the shot is too low, turn KNOB3 counter-clockwise. (Fig. 5) KNOB#1

Fig. 4

KNOB#3

Fig. 5

Section VI. OPERATING INSTRUCTIONS

Fit the ller nozzle to the air-line of the charging equipment, which must incorporate a pressure gauge. Ensure both ller nozzle and rie ller hole are clear from dirt and push the nozzle into the ller hole. Fill the rie to the cylinder pressure quoted previously in this manual. Do not exceed the maximum ll pressure as this will reduce the velocity of the rie and may damage rie components. When using the divers bottle, rell the rie slowly to prevent the heat created by the lling operation damaging the ries components. *Undo the bleeder valve on the hose before disconnecting the ll nozzle from the rie. You can assemble spare air cylinder to your rie. In order to do that, rst remove the air cylinder mounted on the rie by turning it counter-clockwise. Then assemble the spare air cylinder by aligning and rotating it clockwise.

Filler Nozzle

Loading the rie & shooting 1. The magazine comes in the box as not assembled on the air rie for safety purposes. It incorporates a raised boss on its rear face and can only be tted one way to the rie. It rotates clockwise when viewed from the rear of the rie. The groove on the side of the barrel housing allows you to observe whether the next magazine chamber about to rotate into alignment with the barrel is loaded with a pellet or empty. 2. To t the magazine on the air rie; lift the cocking bolt, pull it backwards and lock it in the rear. (Fig. 6, Fig. 7). THIS OPERATION COCKS THE TRIGGER MECHANISM/HAMMER ASSEMBLY. IF THE SAFETY IS SET TO OFF POSITION AND THE TRIGGER IS PULLED, THE RIFLE WILL DISCHARGE. Push forward the magazine release bolt and lock it upwards. Remove the magazine by pulling it to the right. (Fig. 8) 3. Load pellets through the rear of the magazine. (Fig.9). Push the pellet noses through the retaining O-ring until their skirts lie ush or below the bottom of the magazine face. 4. Place the loaded magazine in its place and unlock magazine release bolt by pulling it downwards so it locks back to its place under spring load. (Fig.10). If necessary rotate the magazine counter-clockwise until its movement is arrested by the magazine stop. DO NOT CLOSE THE COCKING BOLT / MAGAZINE RELEASE BOLT UNTIL YOU ARE READY TO FIRE. ENSURE THE COCKING BOLT IS FULLY CLOSED BEFORE FIRING THE RIFLE AS ITS PERFORMANCE WILL BE AFFECTED IF NOT FULLY CLOSE.

REAR BOLT VERSION

2 1

SIDE BOLT VERSION 1 2

Fig. 6

Fig. 7

5. Close cocking bolt and lock it in the rear position. 6. Sight-in either with sights or other optic sights; disengage safety and get ready for shooting. 7. Pull the trigger gently and the rie will re. 8. To reload rie, pull the cocking bolt fully and close so the next pellet is indexed with the barrel. Then repeat above items 6 & 7.

Fig. 8

Fig. 9

Fig. 10

Note: As the pellets are used and the magazine rotates, its empty chambers become visible above the barrel housing. These chambers may be relled as they are revealed without removing the magazine if desired. Note: You cannot cock the rie and index the next pellet in the magazine unless you shoot the previous pellet in the barrel. This is because of a feature which prevents more than one pellet being loaded in the barrel which may cause damage to the rie. Comb Adjustment: The comb is adjustable for elevation. Simply loosen the 2 screws located beneath the comb and adjust the comb elevation suitable to your aiming position. Then tighten the screws so the comb becomes solid. The screws can be adjusted with a suitable screw driver or with a coin. Stock Length of Pull Adjustment The butt pad is adjustable for stock length of pull. Simply loosen the 2 screws located on the left side of stock comb and adjust the comb elevation suitable to your aiming position. Then tighten the screws so the comb becomes solid. The screws can be adjusted with a suitable screw driver or with a coin. Butt Bad Adjustment: The butt pad is adjustable for height and it rotates slightly over stock providing you the perfect height and angle of the butt pad. In order to adjust the butt pad, simply loosen the bolt in the butt pad with a suitable allen wrench and heighten or lower it according to shooting conformance. Then tighten the bolt.

Section VII. MAINTENANCE

Never attempt to disassemble this rie when it is charged, except for removal and replacement of the air cylinder. Never re the rie when the air cylinder is removed or empty. Failure to obey this instruction could result in damage to your rie. Never lubricate inside the barrel as this will affect the accuracy & grouping of the rie in negative manner. Occasionally apply proper mineral based oils sparingly to the following parts: The trigger mechanism The pellet probe The cocking lever sliding surface The stern of the magazine pin and the magazine release. The magazine axis hole and the outer O-ring. DO NOT OVER-LUBRICATE THE RIFLE! It is recommended to clean the barrel with a cleaning rod every 500 shots. Never lubricate inside the barrel. 7

Warning!

Before you begin oiling or cleaning your air gun, always check to make sure it is unloaded. Always be sure your gun barrel is clean and not blocked. After cleaning ensure that no cleaning patch or other obstruction remains in the barrel. Annually, take your air gun to a gunsmith even if it seems to be working well, since some issues in your gun may not be apparent from external examination. Take your air gun to a gunsmith if water, sand, etc. enters the internal mechanism of the air gun, for complete cleaning. Dangerous conditions may occur if you do not keep your air gun clean and working properly. Quick Fill Nozzle O-Rings Replacement After a period of time, the O-rings on the ll nozzle will need to be replaced. The need for this will become noticeable if air is heard leaking from the nozzle or the nozzle ejected from the rie while charging the rie. Always ensure to replace both O-rings. Magazine O-rings Replacement The O-ring which retains the pellets in the magazine will need to be replaced after many hundreds of shots have been red. Its replacement becomes apparent when the ries cocking lever becomes stiff to operate. Repositioning the O-ring in its groove may also overcome the stiffness. Lightly oil the replacement O-ring before tting. Safety Measures & Warnings This air gun will re if cocked, loaded, safety disengaged and trigger pulled. Air guns are not toys. Never let young children use an air gun unsupervised. Adult supervision is strictly required during use. Misuse or careless use may cause serious injury or death. Learn how your air gun operates and safe gun handling procedures before loading and using it. ALWAYS USE EYE & HEARING PROTECTION AND MAKE BYSTANDERS USE THE SAME. Failure to do so may result in eye injuries and permanent hearing loss. Do not point at anything you do not intend to shoot even though the gun is unloaded. Always keep the gun pointed in a safe direction. Never pull a gun toward you by the muzzle. Always aim at a safe target, taking care that it does not conceal any other object. Before you re, consider where the pellet will travel should you miss your intended target, thus ensuring no damage or harm could result. Be sure of your target before you pull the trigger. Never shoot at sounds. When shooting, always have a safe shooting range, that is; have a safe area for shooting, a safe distance between you and the target, and a safe backstop to trap the pellets and hold the target. Do not re at a target, which allows ricochets or deections. Do not re into or at water. Do not re at or near power lines or insulators. Be especially careful in wooded areas where power lines may not be as visible. Do not load the gun until you are ready to shoot. Always keep your ngers away from the trigger & muzzle during cocking and handling. Do not walk, run or jump when carrying a loaded or cocked air gun. A loaded or a cocked gun should never be carried inside a vehicle, house, camp or public place. Never climb a tree or fence or jump a ditch with a loaded gun. In such a case, rst unload it and hand the gun to a friend or place it on the ground on the other side of the obstacle before crossing yourself. When transporting the gun, keep it unloaded and on safe. Always keep the gun on safe until you are ready to shoot even if the gun is unloaded. Do not put the gun away loaded and unattended. Always check to see if the gun is on safe and unloaded when getting it from another person or from storage. Always keep the air gun and/or pellets out of the reach of children. Keep the air gun and pellets in separate places, better if under lock and key. Do not attempt to disassemble or tamper with your gun. Use a competent gunsmith. Many air guns contain powerful springs or high pressure air cylinders which can cause serious injury if released in an uncontrolled manner. Always handle and treat your gun as though it were loaded. Improper use or handling of air guns is not the responsibility of the manufacturer or distributor, under any circumstances. The user is responsible for any harm, which may be caused. Think rst, re second. Dont rely on any mechanical safety. Half safe is not safe. Air guns should never be used under the inuences of alcohol or drugs. 8

facebook.com/hatsan.com.tr twitter.com/hatsan_arms youtube.com/hatsanarms

Izmir - Ankara Karayolu 28. km. No. 289 35170, Kemalpasa Izmir - TURKEY Tel: +90 (232) 878 91 00 Fax: +90 (232) 878 91 02 www.hatsan.com.tr info@hatsan.com.tr

BT65 MANUAL - AUGUST 2011

HATSAN ARMS COMPANY

Potrebbero piacerti anche

- Beeman Gs 1000 ManualDocumento4 pagineBeeman Gs 1000 Manualanbsc2100% (1)

- Sales Representative A Complete Guide - 2020 EditionDa EverandSales Representative A Complete Guide - 2020 EditionNessuna valutazione finora

- Car Maintainer, Group B: Passbooks Study GuideDa EverandCar Maintainer, Group B: Passbooks Study GuideNessuna valutazione finora

- Draftsman/Drafter: Passbooks Study GuideDa EverandDraftsman/Drafter: Passbooks Study GuideNessuna valutazione finora

- Chapter 11 Thread FastenerDocumento54 pagineChapter 11 Thread FasteneriwtolivNessuna valutazione finora

- CZ 200 PCP Air Rifle Manual PDFDocumento18 pagineCZ 200 PCP Air Rifle Manual PDFErikNessuna valutazione finora

- Manual cz630 631 - enDocumento16 pagineManual cz630 631 - enPeter SakeNessuna valutazione finora

- 0101 08InstallingA2SightsDocumento2 pagine0101 08InstallingA2SightsmaxrexNessuna valutazione finora

- Smallbore Target Shooting GuideDocumento8 pagineSmallbore Target Shooting GuidetmflintNessuna valutazione finora

- Milling Machine Report DelyDocumento10 pagineMilling Machine Report DelyFazdly Azilan0% (2)

- 06 Browning Archery ManualDocumento12 pagine06 Browning Archery ManualEduardo De la CruzNessuna valutazione finora

- HSS Drill Speeds and FeedsDocumento1 paginaHSS Drill Speeds and FeedsfinndusNessuna valutazione finora

- JERICHO Manual 08 011 08 15 00 PDFDocumento74 pagineJERICHO Manual 08 011 08 15 00 PDFAlberto AmbiNessuna valutazione finora

- Ruger Precision Rifle 5.56/223 Spec SheetDocumento1 paginaRuger Precision Rifle 5.56/223 Spec SheetAmmoLand Shooting Sports NewsNessuna valutazione finora

- Soup To Nuts 2Documento10 pagineSoup To Nuts 2mtang45Nessuna valutazione finora

- Atm-1022 Mechanical Workshop Module 3 PDFDocumento19 pagineAtm-1022 Mechanical Workshop Module 3 PDFMohamed Sayed Abdel GaffarNessuna valutazione finora

- The Jewell Trigger ManualDocumento7 pagineThe Jewell Trigger ManualFrederik LavoieNessuna valutazione finora

- ATF Explosive Magazine Construction RequirementsDocumento2 pagineATF Explosive Magazine Construction Requirements@sssNessuna valutazione finora

- First-In-First-Out (FIFO)Documento4 pagineFirst-In-First-Out (FIFO)hazlanNessuna valutazione finora

- Barrett M82A1 Trigger ModificationsDocumento9 pagineBarrett M82A1 Trigger ModificationsAnthony Lyons50% (2)

- AR Module Trigger System: JARD, IncDocumento4 pagineAR Module Trigger System: JARD, IncJames McEwenNessuna valutazione finora

- Begin The Journey!: Travel Trailer Owner's ManualDocumento56 pagineBegin The Journey!: Travel Trailer Owner's Manualdeadlydecor tattoosNessuna valutazione finora

- Metal Forming ProcessesDocumento120 pagineMetal Forming ProcessesAditya KoutharapuNessuna valutazione finora

- M17a3 PDFDocumento14 pagineM17a3 PDFErika Lorena Gonzalez PeñaNessuna valutazione finora

- Workholding MethodDocumento37 pagineWorkholding MethodAinii KunNessuna valutazione finora

- Nist Technical Note 1297 SDocumento25 pagineNist Technical Note 1297 SRonny Andalas100% (1)

- MBD Annular SectionDocumento4 pagineMBD Annular SectionCompra Venta De Maquinaria IndustrialNessuna valutazione finora

- VSE120Documento2 pagineVSE120ABYASARIDER AgunNessuna valutazione finora

- Sti 2011Documento34 pagineSti 2011preceptiveinquirerNessuna valutazione finora

- Steel Challenge Rules 2013Documento36 pagineSteel Challenge Rules 2013jasonsivertsenNessuna valutazione finora

- Tool Joints Dimensions 2Documento2 pagineTool Joints Dimensions 2Carlos Alberto Rodriguez MendezNessuna valutazione finora

- Design Criteria For Shooting RangesDocumento8 pagineDesign Criteria For Shooting Rangesrickoshea160Nessuna valutazione finora

- Wiper WasherDocumento26 pagineWiper Washermkisa70100% (1)

- Grizzly Mill With DRODocumento70 pagineGrizzly Mill With DRONO2NWONessuna valutazione finora

- Hand Tools: An Educational Guide ForDocumento20 pagineHand Tools: An Educational Guide Forsaeedbhatti100% (2)

- MEM09002 - Interpret Technical DrawingDocumento4 pagineMEM09002 - Interpret Technical DrawingedNessuna valutazione finora

- Counterweight Rigging ManualDocumento34 pagineCounterweight Rigging ManualGustavo ArancibiaNessuna valutazione finora

- User ManualDocumento22 pagineUser Manualliwei0% (1)

- Various Fixing MethodsDocumento5 pagineVarious Fixing Methodssheepyy100% (1)

- Armscor 1911Documento16 pagineArmscor 1911Richard DimondaNessuna valutazione finora

- Various Types of Mill CuttersDocumento6 pagineVarious Types of Mill CuttersKarthiNessuna valutazione finora

- Floating Reamer InstructionsDocumento1 paginaFloating Reamer InstructionsAndrew DeutschmanNessuna valutazione finora

- Turbocharged Engines PDFDocumento72 pagineTurbocharged Engines PDFVeler VelericNessuna valutazione finora

- Small Arms Ammunition 2009Documento16 pagineSmall Arms Ammunition 2009zex0130% (2)

- Armor Piercing Bullets With Sintered Carbide Cores PDFDocumento137 pagineArmor Piercing Bullets With Sintered Carbide Cores PDFfogdartNessuna valutazione finora

- Dbs22 enDocumento14 pagineDbs22 enmilivoj11Nessuna valutazione finora

- Vernier CaliperDocumento7 pagineVernier CaliperNaiphil Mae Canque100% (1)

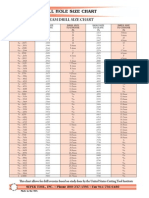

- Drill Hole Size ChartDocumento1 paginaDrill Hole Size ChartWilliam James Abercrombie100% (1)

- GPS System 1200: RTK Quick Guide July, 2005Documento241 pagineGPS System 1200: RTK Quick Guide July, 2005Horatiu PetreaNessuna valutazione finora

- Rotek 84pgcat FINAL ViewOnly Swing Bearning1Documento82 pagineRotek 84pgcat FINAL ViewOnly Swing Bearning1dsnsarmaNessuna valutazione finora

- Billy Bob's Golf 2017Documento116 pagineBilly Bob's Golf 2017cs2k2000Nessuna valutazione finora

- Chapter 11 - Technical DrawingDocumento46 pagineChapter 11 - Technical DrawingΘωμάς ΠολύζοςNessuna valutazione finora

- Savage Lewis MachinegunDocumento61 pagineSavage Lewis Machinegunvideo951Nessuna valutazione finora

- Hatsan AirMax PCP Air Rifle ManualDocumento8 pagineHatsan AirMax PCP Air Rifle ManualСињор Кнежевић100% (1)

- CQC Online ManualDocumento14 pagineCQC Online Manualnabeelmerchant01Nessuna valutazione finora

- Installation Guide FX GEN 3 Rev 25-10-2022Documento10 pagineInstallation Guide FX GEN 3 Rev 25-10-2022chapixNessuna valutazione finora

- Gladius - Bullboss - en User ManualDocumento8 pagineGladius - Bullboss - en User Manualdavid wilsonNessuna valutazione finora

- Artemis Data SpecDocumento8 pagineArtemis Data SpecDenny AriantoNessuna valutazione finora

- BSA Scorpion & T10Documento2 pagineBSA Scorpion & T10Pera DjetlicNessuna valutazione finora

- Manual Matador r5m English PDFDocumento14 pagineManual Matador r5m English PDFwachu73100% (1)

- 10-20 Series: Parts Manual 45-8010ENDocumento12 pagine10-20 Series: Parts Manual 45-8010ENshjefkeNessuna valutazione finora

- Kunststof Kabelbinders 2-LOCK ElematicDocumento3 pagineKunststof Kabelbinders 2-LOCK ElematicshjefkeNessuna valutazione finora

- 42,0426,0001, enDocumento212 pagine42,0426,0001, enJavier MiramontesNessuna valutazione finora

- Minarc: EN FI SV NO DA DE NL FR ES PL RU PT ITDocumento18 pagineMinarc: EN FI SV NO DA DE NL FR ES PL RU PT ITshjefkeNessuna valutazione finora

- 10-22 Series: Parts Manual 45-8013Documento8 pagine10-22 Series: Parts Manual 45-8013shjefkeNessuna valutazione finora

- A 299001Documento2 pagineA 299001shjefkeNessuna valutazione finora

- Crosman TR77 Manual en ES-minDocumento2 pagineCrosman TR77 Manual en ES-minshjefkeNessuna valutazione finora

- Duramax Retrofit Torch: Powermax Powermax PowermaxDocumento64 pagineDuramax Retrofit Torch: Powermax Powermax PowermaxshjefkeNessuna valutazione finora

- A 299001Documento2 pagineA 299001shjefkeNessuna valutazione finora

- Mill4 11Documento12 pagineMill4 11shjefkeNessuna valutazione finora

- Technical Data: RTD Chlorine-Free LiquidDocumento1 paginaTechnical Data: RTD Chlorine-Free LiquidshjefkeNessuna valutazione finora

- Edsyn GMBH Europa: Zentrum Für Löt-Und EntlötsystemeDocumento6 pagineEdsyn GMBH Europa: Zentrum Für Löt-Und EntlötsystemeshjefkeNessuna valutazione finora

- Schaublin 150 Catalogue 1989Documento39 pagineSchaublin 150 Catalogue 1989shjefke100% (2)

- Avon Isi Viking Z Seven 60 MinDocumento2 pagineAvon Isi Viking Z Seven 60 MinshjefkeNessuna valutazione finora

- 175 CacDocumento5 pagine175 CacshjefkeNessuna valutazione finora

- Datasheet BlueSolar Monocrystalline Panels enDocumento1 paginaDatasheet BlueSolar Monocrystalline Panels enshjefkeNessuna valutazione finora

- Webasto Dbw2010 2020 300 RepairDocumento72 pagineWebasto Dbw2010 2020 300 RepairshjefkeNessuna valutazione finora

- Drug War FactbookDocumento288 pagineDrug War FactbookIvan PojomovskyNessuna valutazione finora

- 09 Recurve ManualDocumento20 pagine09 Recurve ManualOmar MuñozNessuna valutazione finora

- Mars Climate Orbiter ReportDocumento27 pagineMars Climate Orbiter Reportbiguelo100% (1)

- List of ItemsDocumento5 pagineList of ItemsMoiNessuna valutazione finora

- Welding SymbolDocumento8 pagineWelding SymbolMuhammad Cahya Adi PNessuna valutazione finora

- Transco Summary Gudinace For Work Method Statements R 0 300912Documento12 pagineTransco Summary Gudinace For Work Method Statements R 0 300912kla_alk100% (2)

- Abu Khader Group ProposalDocumento5 pagineAbu Khader Group ProposalChristine AghabiNessuna valutazione finora

- CreditCardStatement3665658 - 2087 - 02-Mar-21Documento2 pagineCreditCardStatement3665658 - 2087 - 02-Mar-21Aamir MushtaqNessuna valutazione finora

- Summative Test 3.1 Math 10Documento2 pagineSummative Test 3.1 Math 10Christian DecenaNessuna valutazione finora

- Assessment Center GuideDocumento4 pagineAssessment Center GuidebilloobuttNessuna valutazione finora

- Vocabulary Placement TestDocumento3 pagineVocabulary Placement TestMonica Vergara MejiaNessuna valutazione finora

- Thi Thu TNTHPT - Tieng Anh 12 - 136Documento5 pagineThi Thu TNTHPT - Tieng Anh 12 - 136Yến LinhNessuna valutazione finora

- Legend 1028KDocumento2 pagineLegend 1028KAndres Fdo Mora DNessuna valutazione finora

- 3.Space-Activity BookDocumento21 pagine3.Space-Activity BookRania FarranNessuna valutazione finora

- Current Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Documento11 pagineCurrent Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Manoj Digi Loans100% (1)

- Ee - Lab ReportDocumento36 pagineEe - Lab ReportNoshaba Noreen75% (4)

- Spectatorship Affect and Liveness in Contemporary British Performance PDFDocumento358 pagineSpectatorship Affect and Liveness in Contemporary British Performance PDFShivansh Tuli100% (1)

- Appendix in Research PaperDocumento6 pagineAppendix in Research Papergvzfmq91100% (1)

- 843-Artificial Intelligence-Xi XiiDocumento11 pagine843-Artificial Intelligence-Xi XiiPɾαƙԋყαƚ PαɳԃҽყNessuna valutazione finora

- Tankless Vs TankDocumento2 pagineTankless Vs TankClick's PlumbingNessuna valutazione finora

- EPAL TRW EPAL2 2edition Section2 Part2 GBDocumento45 pagineEPAL TRW EPAL2 2edition Section2 Part2 GBGabriele AsnaghiNessuna valutazione finora

- Respons 910 Analyzer: Operator's ManualDocumento246 pagineRespons 910 Analyzer: Operator's ManualUmashankar LoganathanNessuna valutazione finora

- Section A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentDocumento22 pagineSection A - Listening (15 PTS) I. Listen To The Dialogue and Fill in Each Blank With ONE Suitable Word or Number. The House For RentThanh PhongNessuna valutazione finora

- Exercise Workbook For Student 31: SAP B1 On Cloud - BASICDocumento40 pagineExercise Workbook For Student 31: SAP B1 On Cloud - BASICDan Andrei BongoNessuna valutazione finora

- A4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Documento25 pagineA4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Alonso TabordaNessuna valutazione finora

- What Is A RubricDocumento2 pagineWhat Is A Rubricjasmina2869Nessuna valutazione finora

- Semiconductor Application Library ManualDocumento494 pagineSemiconductor Application Library ManualValerioApicellaNessuna valutazione finora

- 6 The Relationship Between Job Satisfaction and Intention To Stay in Taiwanese Nurse PractitionersDocumento1 pagina6 The Relationship Between Job Satisfaction and Intention To Stay in Taiwanese Nurse Practitionersroselle portudoNessuna valutazione finora

- Defense MechanismsDocumento4 pagineDefense MechanismsTillu TilluNessuna valutazione finora

- Giáo Trình LabviewDocumento54 pagineGiáo Trình LabviewXuan Chiem0% (1)

- Altium Rigid Flex GuidebookDocumento40 pagineAltium Rigid Flex GuidebookKiran Jot Singh100% (1)

- Close Up b1 AnswersDocumento6 pagineClose Up b1 Answersmega dragos100% (1)