Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flange Gasket, Bolt, Wrench and Torque Reference Chart

Caricato da

rlk2806Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flange Gasket, Bolt, Wrench and Torque Reference Chart

Caricato da

rlk2806Copyright:

Formati disponibili

Page 1 of 12

Look to

as "The Source".

API SPEC 6A, 16A, 17D AND MSS FLANGE GASKET, BOLT AND TORQUE REFERENCE CHART

TRADEMARK

REG. U.S. PATENT OFFICE

2011 WWW.WOODCOUSA.COM

WOODCO USA provides Web Site Tools for identification, estimating, and reference only. Do not use this information for manufacturing or inspection. Users of these tools should not use them as a substitute for professional engineering advice. Anyone making use of the information presented does so at his own risk and assumes any and all liability resulting from such use. FOR FURTHER INFORMATION, OR TO LEARN MORE ABOUT WOODCO USA PRODUCTS AND SERVICES, CONTACT: WOODCO USA P.O. Box 1261 Houston, Texas 77251-1261 Phone: 713-672-9491 U.S. and Canada: 1-800-496-6326 Fax: 713-672-8768 www.woodcousa.com sales@woodcousa.com

Page 2 of 12

Look to

as "The Source".

Flange Reference Chart

Torque values shown on this page apply only to API Spec 6A designated integral flanges, for surface applications. For make-up torque for Fluoropolymer coated B7/L7 bolts and 2H nuts for surface applications, see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 1-13/16" 10M 1-13/16" 10M 6BX TO 17SV 1-13/16" 15M 1-13/16" 20M 2-1/16" 2M*** 2-1/16" 3M*** 2-1/16" 5M*** 2-1/16" 5M 17 SS TO SS 2-1/16" 5M 17 SS TO SV 2-1/16" 10M 2-1/16" 10M 6BX TO 17SV 2-1/16" 15M 2-1/16" 20M 2-9/16" 2M*** Ring Gasket BX-151 BX-151 SBX-151 BX-151 BX-151 R-23 or RX-23 R-24 or RX-24 R-24 or RX-24 BX-152 SBX-152 BX-152 SBX-152 BX-152 BX-152 SBX-152 BX-152 BX-152 R-26 or RX-26 Number of Bolts 8 8 8 8 8 8 8 8 Stud Bolt 3/4" x 5-1/2" 3/4" x 6-1/2" 7/8" x 6" 1" x 7-3/4" 5/8" x 5" 7/8" x 6-1/2" 7/8" x 6-1/2" 7/8" x 6" Tap End Stud 3/4 x 3-3/4" 3/4 x 4-3/4" 7/8" x 4-1/8" 1" x 5-1/8" 5/8" x 3-5/8" 7/8" x 4-5/8" 7/8" x 4-5/8" 7/8" x 4-1/4" Wrench Torque* Size Ft. Lbs. 1-1/4" 1-1/4" 1-7/16" 1-5/8" 1-1/16" 1-7/16" 1-7/16" 1-7/16" 200 See Page 11 319 474 115 319 319 See Page 11 See Page 11 200 See Page 11 319 686 200

8 8 8 8 8 8

7/8" x 7" 3/4" x 5-1/2" 3/4" x 6-1/2" 7/8" x 6-1/2" 1-1/8" x 8-1/2" 3/4" x 5-1/2"

7/8" x 5" 3/4" x 3-7/8" 3/4" x 4-3/4" 7/8" x 4-3/8" 1-1/8" x 5-3/4" 3/4" x 4"

1-7/16" 1-1/4" 1-1/4" 1-7/16" 1-13/16" 1-1/4"

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 3 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 2-9/16" 3M*** 2-9/16" 5M*** 2-9/16" 5M 17 SS TO SS 2-9/16" 5M 17 SS TO SV 2-9/16" 10M 2-9/16" 10M 6BX TO 17SV 2-9/16" 15M 2-9/16" 20M 3-1/8" 2M*** 3-1/8 3M*** 3-1/8" 5M*** 3-1/8" 5M 17 SS TO SS 3-1/8" 5M 17 SS TO SV Ring Gasket R-27 or RX-27 R-27 or RX-27 BX-153 SBX-153 BX-153 SBX-153 BX-153 BX-153 SBX-153 BX-153 BX-153 R-31 or RX-31 R-31 or RX-31 R-35 or RX-35 BX-154 SBX-154 BX-154 SBX-154 Number of Bolts 8 8 8 Stud Bolt 1" x 7" 1" x 7" 1" x 6-1/2" Tap End Stud 1" x 5-1/8" 1" x 5-1/8" 1" x 4-5/8" Wrench Torque* Size Ft. Lbs. 1-5/8" 1-5/8" 1-5/8" 474 474 See Page 11 See Page 11 319 See Page 11 474 953 200 319 686 See Page 11 See Page 11

8 8 8 8 8 8 8 8 8

1" x 7-1/4" 7/8" x 6-1/2" 7/8" x 7-1/4" 1" x 7-1/4" 1-1/4" x 9-1/2" 3/4" x 5-3/4" 7/8" x 6-1/2" 1-1/8" x 7-3/4" 1-1/8" x 7-1/4"

1" x 5-3/8" 7/8" x 4-3/8" 7/8" x 5" 1" x 4-7/8" 1-1/4" x 6-1/4" 3/4" x 4-1/8" 7/8" x 4-5/8" 1-1/8" x 5-5/8" 1-1/8" x 5-1/8"

1-5/8" 1-7/16" 1-7/16" 1-5/8" 2" 1-1/4" 1-7/16" 1-13/16" 1-13/16"

1-1/8" x 8"

1-1/8" x 5-3/4"

1-13/16"

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 4 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 3-1/16" 10M 3-1/16" 10M 6BX TO 17SV 3-1/16" 15M 3-1/16" 20M 4-1/16" 2M*** Ring Gasket BX-154 BX-154 SBX-154 BX-154 BX-154 R-37 or RX-37 R-37 or RX-37 R-39 or RX-39 BX-155 SBX-155 BX-155 SBX-155 BX-155 BX-155 SBX-155 BX-155 Number of Bolts 8 8 8 8 8 Stud Bolt 1" x 7-1/4" 1" x 8" 1-1/8" x 8" 1-3/8" x 10-1/4" 7/8" x 6-1/2" Tap End Stud 1" x 5" 1" x 5-3/4" 1-1/8" x 5-1/2" 1-3/8" x 6-3/4" 7/8" x 4-5/8" Wrench Torque* Size Ft. Lbs. 1-5/8" 1-5/8" 1-13/16" 2-3/16" 1-7/16" 474 See Page 11 686 1,281 319

4-1/16" 3M***

1-1/8" x 7-1/2"

1-1/8" x 5-1/2"

1-13/16"

686

4-1/16" 5M*** 4-1/16" 5M 17 SS TO SS 4-1/16" 5M 17 SS TO SV 4-1/16" 10M 4-1/16" 10M 6BX TO 17SV 4-1/16" 15M

1-1/4" x 8-1/2"

1-1/4" x 6-1/8"

2"

953 See Page 11 See Page 11 686 See Page 11 1,281

1-1/4" x 8"

1-1/4" x 5-5/8"

2"

8 8 8 8

1-1/4" x 8-3/4" 1-1/8" x 8-1/2" 1-1/8" x 9-1/2" 1-3/8" x 9-3/4"

1-1/4" x 6-1/4" 1-1/8" x 5-3/4" 1-1/8" x 6-5/8" 1-3/8" x 6-1/2"

2" 1-13/16" 1-13/16" 2-3/16"

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 5 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 4-1/16" 20M 5-1/8" 2M*** Ring Gasket BX-155 R-41 or RX-41 R-41 or RX-41 R-44 or RX-44 BX-169 SBX-169 BX-169 SBX-169 BX-169 BX-169 SBX-169 BX-169 R-45 or RX-45 R-45 or RX-45 R-46 or RX-46 Number of Bolts 8 8 Stud Bolt 1-3/4" x 12-1/2" 1" x 7-1/4" Tap End Stud 1-3/4" x 8-3/8" 1" x 5-1/4" Wrench Torque* Size Ft. Lbs. 2-3/4" 1-5/8" 2,696 474

5-1/8" 3M***

1-1/4" x 8-1/4"

1-1/4" x 6"

2"

953

5-1/8" 5M*** 5-1/8" 5M 17 SS TO SS 5-1/8" 5M 17 SS TO SV 5-1/8" 10M 5-1/8" 10M 6BX TO 17SV 5-1/8" 15M 7-1/16" 2M***

1-1/2" x 10-1/2"

1-1/2" x 7-3/8"

2-3/8"

1,677 See Page 11 See Page 11 686 See Page 11 1,677 474

1-1/2" x 10"

1-1/2" x 6-7/8"

2-3/8"

8 12 12 12 12

1-1/2" x 11" 1-1/8" x 9-1/4" 1-1/8" x 10-1/4" 1-1/2" x 11-1/2" 1" x 7-1/2"

1-1/2" x 7-3/4" 1-1/8" x 6" 1-1/8" x 7" 1-1/2" x 7-5/8" 1" x 5-3/8"

2-3/8" 1-13/16" 1-13/16" 2-3/8" 1-5/8"

7-1/16" 3M***

12

1-1/8" x 8-1/2"

1-1/8" x 5-7/8"

1-13/16"

686

7-1/16" 5M***

12

1-3/8" x 11-1/4"

1-3/8" x 7-1/2"

2-3/16"

1,281

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 6 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 7-1/16" 5M 17 SS TO SS 7-1/16" 5M 17 SS TO SV 7-1/16" 10M 7-1/16" 10M 6BX TO 17SV 7-1/16" 15M 7-1/16" 20M 9" 2M*** Ring Gasket BX-156 SBX-156 BX-156 SBX-156 BX-156 BX-156 SBX-156 BX-156 BX-156 R-49 or RX-49 R-49 or RX-49 R-50 or RX-50 BX-157 SBX-157 BX-157 SBX-157 BX-157 Number of Bolts 12 Stud Bolt 1-3/8" x 10-3/4" Tap End Stud 1-3/8" x 7" Wrench Torque* Size Ft. Lbs. 2-3/16" See Page 11 See Page 11 1,677 See Page 11 1,677 4,061 686

12 12 12 16 16 12

1-3/8" x 11-3/4" 1-1/2" x 11-3/4" 1-1/2" x 13" 1-1/2" x 13" 2" x 17-3/4" 1-1/8" x 8-1/2"

1-3/8" x 8-1/8" 1-1/2" x 7-3/4" 1-1/2" x 9" 1-1/2" x 8-3/8" 2" x 11-1/8" 1-1/8" x 5-7/8"

2-3/16" 2-3/8" 2-3/8" 2-3/8" 3-1/8" 1-13/16"

9" 3M***

12

1-3/8" x 9-1/2"

1-3/8" x 6-3/4"

2-3/16"

1,281

9" 5M*** 9" 5M 17 SS TO SS 9" 5M 17 SS TO SV 9" 10M

12

1-5/8" x 12-1/2"

1-5/8" x 8-1/2"

2-9/16"

2,146 See Page 11 See Page 11 1,677

12

1-5/8" x 12"

1-5/8" x 8"

2-9/16"

12 16

1-5/8" x 13-1/4" 1-1/2" x 13-1/2"

1-5/8" x 9-1/8" 1-1/2" x 8-1/2"

2-9/16" 2-3/8"

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 7 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 9" 10M 6BX TO 17SV 9" 15M 9" 20M 11" 2M*** Ring Gasket BX-157 SBX-157 BX-157 BX-157 R-53 or RX-53 R-53 or RX-53 R-54 or RX-54 BX-158 SBX-158 BX-158 SBX-158 BX-158 BX-158 SBX-158 BX-158 BX-158 Number of Bolts 16 16 16 16 Stud Bolt 1-1/2" x 15" 1-7/8" x 16" 2-1/2" x 21-3/4 1-1/4" x 9-1/4" Tap End Stud 1-1/2" x 10-1/8" 1-7/8" x 10-1/8" 2-1/2" x 13-3/4" 1-1/4" x 6-1/2" Wrench Torque* Size Ft. Lbs. 2-3/8" 2-15/16" 3-7/8" 2" See Page 11 3,332 8,030 953

11" 3M***

16

1-3/8" x 10"

1-3/8" x 7"

2-3/16"

1,281

11" 5M*** 11" 5M 17 SS TO SS 11" 5M 17 SS TO SV 11" 10M 11" 10M 6BX TO 17SV 11" 15M 11" 20M

12

1-7/8" x 14-1/4"

1-7/8" x 9-5/8"

2-15/16"

3,332 See Page 11 See Page 11 2,696 See Page 11 4,061 9,712

12

1-7/8" x 13-3/4"

1-7/8" x 9-1/8"

2-15/16"

12 16 16 20 16

1-7/8" x 15-1/4" 1-3/4" x 15-1/4" 1-3/4" x 17" 2" x 19-1/2" 2-3/4" x 23-3/4"

1-7/8" x 10-1/2" 1-3/4" x 9-3/4" 1-3/4" x 11-1/2" 2" x 12" 2-3/4" x 15"

2-15/16" 2-3/4" 2-3/4" 3-1/8" 4-1/4"

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 8 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 13-5/8" 2M*** 13-5/8 3M*** 13-5/8" 5M 13-5/8" 10M 13-5/8" 10M 6BX TO 17SV 13-5/8" 15M 13-5/8" 20M 16-3/4" 2M*** Ring Gasket R-57 or RX-57 R-57 or RX-57 BX-160 BX-159 BX-159 SBX-159 BX-159 BX-159 R-65 or RX-65 R-66 or RX-66 BX-162 BX-162 BX-163 BX-164 BX-164 Number of Bolts 20 20 16 20 20 20 20 20 Stud Bolt 1-1/4" x 9-1/2" 1-3/8" x 10-3/4" 1-5/8" x 12-3/4" 1-7/8" x 17-3/4" 1-7/8" x 19-3/4" 2-1/4" x 21-1/4" 3" x 29-3/4" 1-1/2" x 10-3/4" Tap End Stud 1-1/4" x 6-5/8" 1-3/8" x 7-3/8" 1-5/8" x 8-3/8" 1-7/8" x 11" 1-7/8" x 13-1/8" 2-1/4" x 13-1/4" 3" x 18-1/8" 1-1/2" x 7-1/2" Wrench Torque* Size Ft. Lbs. 2" 2-3/16" 2-9/16" 2-15/16" 2-15/16" 3-1/2" 4-5/8" 2-3/8" 726** 976** 2,146 3,332 See Page 11 5,822 12,654 1,278**

16-3/4" 3M*** 16-3/4" 5M 16-3/4" 10M 18-3/4" 5M 18-3/4" 10M 18-3/4" 15M

20 16 24 20 24 20

1-5/8" x 12-1/4" 1-7/8" x 14-3/4" 1-7/8" x 17-3/4" 2" x 17-3/4" 2-1/4" x 22-3/4" 3" x 26-3/4"

1-5/8" x 8-3/8" 1-7/8" x 9-1/2" 1-7/8" x 11" 2" x 11-1/4" 2-1/4" x 14" 3" x 16-3/4"

2-9/16" 2-15/16" 2-15/16" 3-1/8" 3-1/2" 4-5/8"

2,146 3,332 3,332 4,061 5,822 12,654

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

** These API Spec. 6A flanges have stress limits that necessitate lower than normal torque values

for bolts used in these flanges.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

2011 WWW.WOODCOUSA.COM

Page 9 of 12

Look to

as "The Source".

Flange Reference Chart

These torque values apply only to current API 6A, 16A, and 17D integral connectors. For make-up torque for fluoropolymer coated B7/L7 bolts and 2H nuts see page 10 of this document. Refer to 17D Torque Chart on page 11 when using 6BX Flanges for Subsea Applications See page 12 of this document for important notes. Flange Size 20-3/4" 3M*** Ring Gasket R-74 or RX-74 R-73 or RX-73 BX-165 BX-166 BX-167 BX-168 Number of Bolts 20 Stud Bolt 2" x 15" Tap End Stud 2" x 10-1/8" Wrench Torque* Size Ft. Lbs. 3-1/8" 4,061

21-1/4" 2M*** 21-1/4" 5M 21-1/4" 10M 26-3/4" 2M 26-3/4" 3M 30" 300 MSS1

24 24 24 20 24 28 28 20 32 32

1-5/8" x 12-1/4" 2" x 19" 2-1/2" x 24-3/4" 1-3/4" x 14-1/4" 2" x 17-1/2" 1-3/4" x 13-1/2" 2" x 15-3/4" 3" x 14" 1-5/8" x 14-1/2" 1-7/8" x 17-3/4"

1-5/8" x 8-3/8" 2" x 11-3/4" 2-1/2" x 15-1/8" 1-3/4" x 9-1/8" 2" x 11" 1-3/4" x 9-1/8" 2" x 10-1/2" 3" x 20-1/2" 1-5/8" x 9-1/4" 1-7/8" x 11"

2-9/16" 3-1/8" 3-7/8" 2-3/4" 3-1/8" 2-3/4" 3-1/8" 4-5/8" 2-9/16" 2-15/16"

1,635** 4,061 8,030 2,696 4,061 2,696 4,061 7,400** 2,146 3,332

R-95 or RXR-95 or 30" 600 MSS1,2 RX-95 R-102 or 30" 900 MSS1,2 RX-102 30" 2M 30" 3M BX-303 BX-303

* Make-up torque for "black" or "plated" B7/L7 bolts and 2H nuts using API BUL 5A3 / ISO 13678 thread compound. These torque values assume undamaged bolts, clean conditions and smooth bearing surfaces with generous lubrication of threads and bearing faces on nuts.

** These flanges have stress limits that necessitate lower than normal torque values for bolts used

in these flanges.

***

These current flanges previously had old API size and series designations. See Flange Cross Reference Chart on the WOODCO USA website.

1 Not API, See MSS SP-44 published by the Manufacturers Standardization Society. 2 This MSS flange requires longer bolts for connections between full bore flanges and blind

flanges.

2011 WWW.WOODCOUSA.COM

Page 10 of 12

Look to

as "The Source".

Flange Reference Chart

Torque Values for API Spec 6A Integral Flanges Using Fluoropolymer Coated Bolts For Surface Applications These torques assume undamaged bolts, clean conditions and smooth bearing surfaces. The torque values shown in this table will apply 50% yield tension in the bolts. Stud 5/8" 3/4" 7/8" 1" 1-1/8" 1-1/4" * 1-3/8" * 1-1/2" * 1-5/8" * 1-3/4" Diameter Torque 68 118 188 279 401 553 739 962 1,226 1,534 Ft. Lbs.

1-7/8" 1,890

Stud 2" 2-1/4" 2-1/2" 2-5/8" 2-3/4" 3" 3-1/4" 3-3/4" 3-7/8" 4" Diameter Torque 2.297 3,276 4,500 4,716 5,424 7,047 8,965 13,782 15,208 16,730 Ft. Lbs. * Certain API Spec. 6A flanges have stress limits that necessitate lower than normal torque values for bolts used in these flanges. Use the chart below for these flanges. The torque values shown in this table will apply 40,000 psi stress in the bolts. Flange 13-5/8" 2M 13-5/8" 3M 16-3/4" 2M 21-1/4" 2M Size Stud 1-1/4" 1-3/8" 1-1/2" 1-5/8" Diameter Torque 421 563 733 934 Ft. Lbs.

2011 WWW.WOODCOUSA.COM

Page 11 of 12

Look to

as "The Source".

Flange Reference Chart Torque Values for 17D and 6BX Flange Bolts for Subsea Applications

For Flange Bolts and Nuts Having Fluoropolymer Coating

See Caution Below

Maximum 70% Minimum 67% Hex Nut * Yield Stress * Yield Stress Size Bolt Make up Bolt Make up Across Tension Torque Tension Torque Flats lbf ft lbs lbf ft lbs 1-1/4 1-7/16 1-5/8 1-13/16 2 2-3/16 2-3/8 2-9/16 2-3/4 2-15/16 3-1/8 3-1/2 3-7/8 4-1/4 4-5/8 5 23,530 32,483 42,614 55,608 70,330 86,777 104,951 124,852 146,480 169,833 194,914 250,256 312,504 345,310 414,127 489,194 160 253 376 539 744 994 1,294 1,649 2,063 2,541 3,087 4,402 6,044 7,284 9,443 12,013 24,538 33,937 44,522 58,098 73,478 90,662 109,650 130,442 153,038 177,438 203,642 261,461 326,497 360,772 432,670 511,098 167 264 393 564 777 1,038 1,352 1,723 2,155 2,654 3,225 4,599 6,315 7,611 9,866 12,551

Bolt Size

3/4 - 10 UNC 7/8 - 9 UNC 1 - 8 UN 1-1/8 - 8 UN 1-1/4 - 8 UN 1-3/8 - 8 UN 1-1/2 - 8 UN 1-5/8 - 8 UN 1-3/4 - 8 UN 1-7/8 - 8 UN 2 - 8 UN 2-1/4 - 8 UN 2-1/2 - 8 UN 2-3/4 - 8 UN** 3 - 8 UN** 3-1/4 - 8 UN**

Torque ft lbs calculated to give % of yield tension stress for ASTM A193 B7 or ASTM A320 L7 bolts using ASTM A194 GR. 2H nuts with Fluoropolymer coating (Coefficient of Friction = 0.07).

**Torque calculated same as above based on reduced yield strength of 95,000 psi.

CAUTION: API Spec 17D requires flange connection bolt tightness (tension stress in the bolt) equal to 67% to 70% of the specified minimum yield strength of L7/B7 bolts. Operators should limit these higher tensions to only subsea flange connections that use BX or SBX ring gaskets and have designs that will allow face to face makeup. When using some lubricants and/or anti-corrosion coatings on bolts, tightening bolts consistent with the torque table shown above may in fact produce tension closer to the actual yield strength of the bolts. Operators should use an alternate method to measure tension in the bolts to confirm the applicability of this table.

2011 WWW.WOODCOUSA.COM

Page 12 of 12

Look to

as "The Source".

Flange Reference Chart Important Notes

Obsolete, Discontinued or Withdrawn flanges not included in this chart also use B7/L7 connecting bolts. For bolt sizes and torque values for these flanges, see individual flange pages in the Flange Slide Rule Program on the www.woodcousa.com web site. For bolt tightening sequence for API flanges, see individual flange pages in the Bolt Tightening Sequence index on the www.woodcousa.com web site. Flanges with "R" ring grooves can connect and seal with either R or RX ring gaskets. RX gaskets increase the stand-off between flanges, and studs shown on this chart have sufficient length to accommodate RX gaskets in these connections. In some cases equipment design may restrict clearance and shorter studs will increase convenience. For information on these shorter stud lengths, see AWHEM document TR9501 at www.awhem.org/docs.htm. To compare the difference in stand-off see http://www.woodcousa.com/standoff.htm#Select Caution: The difference in stand-off between R and RX gaskets can cause alignment problems on close coupled manifolding or pressure controlling loops. Assembly designers specify component dimensions which allow for the difference in stand-off between flanges when choosing either R or RX gaskets. When operators perform maintenance that involves disassembly, trouble free reassembly requires using gaskets the same as the gaskets originally chosen. Ring gaskets marked SRX or SBX have identical measurements to RX and BX ring gaskets with the the same number designation, and they will fit the same corresponding connectors. API Spec 17D intends SBX gaskets to seal all 17D SS and SV flanges and all 6BX flanges used for subsea applications. API Spec 17D intends SRX gaskets to seal only 5000 psi segmented flanges, not listed above. The "S" indicates these gaskets have vent holes to allow reliable connector makeup underwater (subsea). API Spec 17D requires that manufacturers use only corrosion resistant alloy as the material for these gaskets. For more information about ring gaskets, see Web Site Tools, and click on Ring Gasket Handling and Inspection Before Assembly. For more information about ring gasket sealing, see Web Site Tools, and click on Field Appraisal of Ring Grooves. For more information about flange connection make-up, see Web Site Tools, and click on Flange Make-up, Stand-off and Drift.

2011 WWW.WOODCOUSA.COM

Terms of Use Welcome to www.woodcousa.com, the official website of WOODCO USA (WOODCO). www.woodcousa.com provides services to you subject to the following conditions. If you visit www.woodcousa.com, you accept these conditions. Please read them carefully. In addition, when you use any current or future woodcousa.com service or download WOODCO USA software, you also agree to comply with any of these conditions that may apply to such service or software use. 1. WOODCO USA may change, add, or remove portions of its website at any time. WOODCO USA also may impose limits on certain features and services or restrict access to all or any part of its website without notice or liability. 2. WOODCO USA intends its website (the Content) for your personal use only. 3. All materials published on the WOODCO USA website have copyright protection pursuant to U.S. and international copyright laws. You may not modify, publish, transmit, participate in the transfer or sale of, reproduce (except as provided in Paragraph 4 below), create new works from, distribute, perform, display, or in any way exploit any of the Content in whole or in part. You shall abide by all additional copyright notices, information, and other restrictions associated with any of the Content. 4. You may download or copy the Content and other downloadable items forming parts of the Content for personal use only, provided that you maintain all copyright and other notices contained therein. You may not copy or store any Content for other than personal use without prior written permission from an officer of WOODCO USA. 5. WOODCO USA does not assume liability for any errors or omissions in the Content, or in the transmission or delivery of all or any part thereof, or for any damages arising there from. You acknowledge sole responsibility (sole risk) for any reliance you may have in the Content or actions you may take relying upon any of the Content. WOODCO USA makes every effort to assure the accuracy of the Content, but, WOODCO USA MAKES THE CONTENT AVAILABLE TO YOU ON AN "AS IT APPEARS" BASIS, WITHOUT WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY WARRANTIES OF TITLE OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. YOU HEREBY ACKNOWLEDGE THAT YOU USE THE CONTENT AT YOUR SOLE RISK. 6. You shall have no rights to any of the proprietary rights associated with any of the Content. 7. WOODCO USA may, in its sole discretion, terminate or suspend access to all or part of the Content for any reason, including without limitation, breach or assignment of this Agreement. 8. This Agreement originates in Houston, Texas and any interpretation and/or enforcement shall comply with Texas law. Any action to enforce this agreement shall occur in, and only in, the federal or state courts located in Harris County, Texas. 9. Privacy - Please review our Privacy Policy, which also governs your visit to woodcousa.com, to understand our practices. 10. Please direct all questions to: sitemaster@woodcousa.com Copyright Notice 1999 - 2012, WOODCO USA. WOODCO USA will enforce all rights under copyright law, regarding all photographs, graphics, written materials or other content appearing on this website, the legally protected property of WOODCO USA. WOODCO USA prohibits reproduction or re-use of any kind, other than that described in Terms of Use above, without written permission from an officer of WOODCO USA. Submit all requests for re-use of copyrighted materials in writing to: sitemaster@woodcousa.com

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grant Prideco Rotary Shoulder HandbookDocumento112 pagineGrant Prideco Rotary Shoulder Handbookrlk2806Nessuna valutazione finora

- 2-3-8 HT Pac Info PDFDocumento7 pagine2-3-8 HT Pac Info PDFrlk2806100% (1)

- Halliburton Packer Information PDFDocumento76 pagineHalliburton Packer Information PDFrlk2806100% (4)

- Wild Well Control - 2007Documento76 pagineWild Well Control - 2007ginozkyNessuna valutazione finora

- SWACO 90-90-080 (Rev. A)Documento125 pagineSWACO 90-90-080 (Rev. A)rlk2806Nessuna valutazione finora

- Bauer Junior II Operator's ManualDocumento70 pagineBauer Junior II Operator's ManualKjell KvitvikNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Lordk Edid 6507-Case Study Assignment 1 2 3Documento34 pagineLordk Edid 6507-Case Study Assignment 1 2 3api-310042469Nessuna valutazione finora

- Especificaciones Tecnicas Motor 4g54 2.6ltsDocumento20 pagineEspecificaciones Tecnicas Motor 4g54 2.6ltsjr50% (2)

- ID 2051814.1 Oracle Support Sample SetupDocumento9 pagineID 2051814.1 Oracle Support Sample SetupFerasHamdanNessuna valutazione finora

- Revised Runway Length Discussion (20171206) - 201712211212022318Documento3 pagineRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiNessuna valutazione finora

- PC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFDocumento363 paginePC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFCarlos Israel Gomez100% (10)

- Theory: Figure 1: The Exit Age Distribution Curve E For Fluid Flowing Through A Vessel Also Called The Residence TimeDocumento5 pagineTheory: Figure 1: The Exit Age Distribution Curve E For Fluid Flowing Through A Vessel Also Called The Residence Timeiko856Nessuna valutazione finora

- Implementing The IBM Storwize V7000 V6.3: Front CoverDocumento630 pagineImplementing The IBM Storwize V7000 V6.3: Front CoverMimiLakicNessuna valutazione finora

- How To Use MySQL With ErlangDocumento2 pagineHow To Use MySQL With ErlangarthurbulivaNessuna valutazione finora

- WEdu Abroad - Study Abroad E-GuidebookDocumento111 pagineWEdu Abroad - Study Abroad E-GuidebookRithyKhouyNessuna valutazione finora

- Structural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementDocumento15 pagineStructural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementGSA publishNessuna valutazione finora

- Lec 1 - SuperelevationDocumento24 pagineLec 1 - SuperelevationMohamedNessuna valutazione finora

- Ch2 Snapshot 20 LightingDocumento4 pagineCh2 Snapshot 20 Lightinggarych72Nessuna valutazione finora

- InfoWorks ICM Overview 60 Mins PDFDocumento31 pagineInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- Etap - Relay CoordinationDocumento311 pagineEtap - Relay CoordinationManohar Potnuru100% (1)

- Water Tank Seat Slab DesignDocumento2 pagineWater Tank Seat Slab DesignMesfin Derbew100% (2)

- LAB 1 HandoutDocumento2 pagineLAB 1 HandoutManuGearNessuna valutazione finora

- 2 Combined Dci Standards 6 13 13Documento7 pagine2 Combined Dci Standards 6 13 13api-32776059Nessuna valutazione finora

- Sanjay ProjectDocumento41 pagineSanjay ProjectPrynka RawatNessuna valutazione finora

- Eco ProductsDocumento3 pagineEco Productssreekutty A SNessuna valutazione finora

- REERTRDocumento4 pagineREERTRvgteeNessuna valutazione finora

- Sensibo Sky User ManualDocumento34 pagineSensibo Sky User ManualMauMadie FuntanarNessuna valutazione finora

- Yuli's PPT FloralDocumento28 pagineYuli's PPT FloralYuli MyeshaNessuna valutazione finora

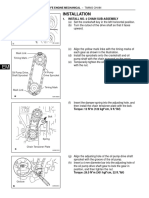

- Sincronizacion de Motor Toyota 2az-FeDocumento12 pagineSincronizacion de Motor Toyota 2az-FeWilliams NavasNessuna valutazione finora

- EmpanelHospList HelpFAQDocumento13 pagineEmpanelHospList HelpFAQaditi001Nessuna valutazione finora

- GEK 116403 Ge File. Performance TestsDocumento54 pagineGEK 116403 Ge File. Performance TestsSulaiman JafferyNessuna valutazione finora

- ANEP-25 (Environmental Factors For Surface Ships)Documento81 pagineANEP-25 (Environmental Factors For Surface Ships)Bahadır HarmancıNessuna valutazione finora

- Case Study Analysis of Apex Corporation PDFDocumento2 pagineCase Study Analysis of Apex Corporation PDFAJNessuna valutazione finora

- Cakewalk CA-2A T-Type Leveling Amp For FreeDocumento2 pagineCakewalk CA-2A T-Type Leveling Amp For FreeM. NngwenyaNessuna valutazione finora

- Acquisition (Pagtamo) Meaning-Making (Pag-Unawa) Transfer (Paglilipat)Documento2 pagineAcquisition (Pagtamo) Meaning-Making (Pag-Unawa) Transfer (Paglilipat)MAY BEVERLY MORALES100% (8)

- Subsea Pipeline Engineering (Indonesia) - ElisaDocumento5 pagineSubsea Pipeline Engineering (Indonesia) - ElisaMheErdiantoNessuna valutazione finora