Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Valley Metro 2011 Stray Current Corrosion Control System Evaluation

Caricato da

Joe BlagTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Valley Metro 2011 Stray Current Corrosion Control System Evaluation

Caricato da

Joe BlagCopyright:

Formati disponibili

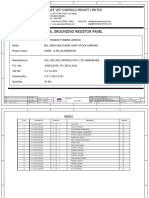

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

METRO LIGHT RAIL 605 S. 48TH STREET PHOENIX, ARIZONA 85034 Submitted by CORRPRO PROJECT No. : 340160354 DOC 1, REV 1

1 0

REV

03/21/2012 03/01/2012

DATE DD/MM/YY

Comments Incorporated Issued for Approval

REMARKS

E. Goldberg E. Goldberg

PREPARED BY

Sarvjit Singh Sarvjit Singh

REVIEWED BY

Designation/ Project

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 1 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

TABLE OF CONTENTS 1.0 2.0 3.0 EXECUTIVE SUMMARY .................................................................................. 3 INTRODUCTION .............................................................................................. 5 CONCLUSIONS ................................................................................................. 7

3.1 3.2 3.3 3.4 3.5 STRAY CURRENT EXCHANGE BETWEEN METRO TRACKS AND EARTH .............................. 7 METRO TRACK-TO-EARTH RESISTANCE ...................................................................................... 7 METRO TRACK-TO-EARTH POTENTIALS ..................................................................................... 8 METRO YARDMAINLINE AND YARD-SHOP ELECTRICAL SEPARATION ............................ 8 SECTION 5.6 OF THE INTERGOVERNMENTAL AGREEMENT ................................................... 9

4.0 RECOMMENDATIONS ................................................................................... 11 5.0 DISCUSSION .....................................................................................................12

5.1 5.2 5.3 6.1 6.2 6.3 TRACK-TO-EARTH RESISTANCE .................................................................................................... 12 TRACK-TO-EARTH POTENTIAL ..................................................................................................... 12 STRAY CURRENT ................................................................................................................................ 12 TRACK-TO-EARTH RESISTANCE TESTS ....................................................................................... 13 TRACK-TO-EARTH POTENTIAL MEASUREMENTS AT SUBSTATIONS .................................. 13 PIPELINE POTENTIAL MONITORING .......................................................................................... 14

6.0 TEST METHODS ..............................................................................................13

APPENDICES APPENDIX - A .......................................................... Track-to-Earth Resistance Test Data APPENDIX - B .............................................. Traction Power Substation Potential Graphs APPENDIX - C ........................................................ Pipeline Test Station Potential Graphs APPENDIX - D ....................................................... Aerial Imagery Maps of Test Locations APPENDIX - E ........................................ Section 5.6 of the Intergovernmental Agreement

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 2 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

1.0

EXECUTIVE SUMMARY

This report outlines the results of an evaluation of the in-service stray current corrosion control system associated with Valley Metros direct current (DC) powered light rail transit system. Consistent with Corrpros recommended scope of work, the field aspects of the evaluation were completed between December 5th, 2011 and December 9th, 2011. The field testing included: Track-to-earth resistance measurements for the entire mainline and for the yard tracks. Track-to-earth potential measurements at sub-stations. Utility structure-to-earth potential measurements at representative locations, principally the City of Phoenix ductile iron water pipelines and South West Gas pipelines. The measured, normalized track-to-earth resistance ranges from 103.70 Ohms-1,000 feet of single track (2 rails) to in excess of 1,000 Ohms-1,000 feet. The average normalized track-toearth resistance is approximately 306 Ohms-1,000 feet. The minimum acceptance resistance criterion for embedded track under test was 100 Ohms-1000 feet track. The comparison of test data between the previous years testing and the current testing indicates no decay in the track-to-earth resistance of the mainline tracks. Along the Metro Light Rail route, pipe-to-soil potential data was recorded for the following at randomly selected test points: ten (10) water pipeline test points, two (2) South West Gas test points, and one (1) reinforcing rebar test point. The pipeline test point data recorded do not indicate detrimental interference effects on these selected pipelines. The very low level effects measured are of the same scale as reported during the 2010 evaluation. It should be noted that the pipe-to-soil potential logging was carried out on different pipes (not on previously tested pipelines) along the entire route of the mainline tracks. This reinforces that there are no signs of degradation of the mainline track electrical isolation characteristics. The magnitude and time characteristics of the track-to-earth potentials are considered normal with no indication of anomalous conditions that could impact stray current control.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 3 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

The total stray current exchange between the Metro mainline tracks and earth is estimated to be less than 2 amperes. This level of stray current exchange is quite low, indicative of effective stray current control. It is comparable to a low-output impressed current cathodic protection system for a coated pipeline that is several miles long. The track-to-earth potential logging data collected at the randomly selected TPSSs (traction power substations) is normal. Present track-to-earth potential levels are considered typical with no anomalous conditions indicated. Recommendations derived from Corrpros evaluation include continued periodic surveillance. The next step in this regard would be to develop a standard operating procedure (SOP). A sufficiently detailed SOP is in order to establish a solid foundation for the stray current control program and to assure consistency in the future; the SOP was incorporated during the 2011 testing and is being issued as a separate document.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 4 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

2.0

INTRODUCTION

This report presents results of Corrpros annual evaluation of in-service stray current corrosion control for the Valley Metro light rail in Phoenix, Arizona. platforms. The stray current exchange between a direct current powered rail transit system and earth can pose a risk of accelerated corrosion to the buried utility infrastructure as well as Metro facilities. The Metro system includes state-of-the-art features that have been designed to effectively control the level of stray current to practicable minimums. The primary design measure is an electrically ungrounded traction power negative distribution system. This includes the use of an electrically insulating rail boot for embedded mainline track-work (predominant track type) and insulating rail fasteners for direct fixation track-work across two bridges. While the stray current control measures are expected to be low maintenance, they do require periodic monitoring to responsibly detect and correct anomalous conditions which will undoubtedly occur from time to time as the system ages. Prior to constructing the system, Metro entered into an intergovernmental agreement that included Section 5.6 on corrosion control (The Agreement Sec. 5.6 is in Appendix E of this report). The Agreement Sec. 5.6 stipulates that Metro will conduct stray current monitoring and track-to-earth resistance tests on an annual basis. Track-to-earth resistances below 100 Ohms-1,000 feet (2 rails) for embedded track and 250 ohms-1,000 feet for direct fixation track require corrective action based on the intergovernmental agreement page C-12. The field aspects of Corrpros evaluation included: Track-to-earth resistance measurements for the entire mainline and for the yard tracks. Track-to-earth potential measurements at sub-stations. Utility structure-to-earth potential measurements at representative locations, principally the City of Phoenix ductile iron water pipelines along with South West Gas pipelines. The system alignment is approximately 21.5 miles long with 14 traction power sub-stations and 35 passenger station

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 5 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

The entire testing was carried out with full support from the support by the Valley Metro light rail crew. All necessary work permits and access to various facilities was also provided and obtained by the Valley Metro. Track-to-earth resistance testing was performed during nonrevenue hours of the train.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 6 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

3.0

CONCLUSIONS

3.1 STRAY CURRENT EXCHANGE BETWEEN METRO TRACKS AND EARTH

a) The calculated normal stray current exchange between the Metro mainline tracks and earth is less than 2 amperes for the entire 21.5 miles. b) Determined by the magnitude of stray current voltage, the level of stray current exchange is quite low, indicative of effective stray current control. It is comparable to a low-output impressed current cathodic protection system for a coated pipeline that is several miles long. c) The low-level stray current exchange between the Metro mainline tracks and earth is considered consistent with design requirements. d) The maximum average voltage change recorded for the utility test points was 20mV and the minimum average voltage change recorded for the utility test points was 2.5mV; as depicted in Appendix C.

3.2 Metro Track-to-Earth Resistance

a) All other factors equal, the higher the track-to-earth resistance, the lower the level of stray current and resulting stray current corrosion impact on neighboring utilities and transit structures. b) The measured, normalized track-to-earth resistance ranges from 103.70 Ohms-1,000 feet of single track (2 rails) to in excess of 1,000 Ohms-1,000 feet. The average normalized track-to-earth resistance for the mainline track is approximately 306 Ohms1,000 feet. [From Appendix A: Mainline Track-to-Earth Resistance Average = (414.85 + 250.73 + 623.03 + 308.38 + 139.24 +103.70) 6 306 Ohms-1,000 feet.] c) The calculated composite resistance-to-earth for the entire mainline track is approximately on the order of 1.1419 Ohm. [From Appendix A: Mainline Measured Track-to-Earth Resistances in Parallel = 1 [(1/9.87) + (1/3.22) + (1/19.55) + (1/8.72) + (1/3.86) + (1/25.66)] 1.1419 Ohms.] d) The measured mainline track-to-earth resistances are generally consistent with prior data. They are in excess of the design and construction acceptance criterion of minimum 100 Ohms-1,000 feet for embedded track and minimum 250 Ohms-1,000 feet for ballasted and direct fixation track. e) The mainline track-to-earth resistance testing revealed no direct track to ground electrical contacts (shorts) or other anomalous conditions that could result in concentrated levels of high stray current exchange. Such conditions can occur, CORROSION CONTROL EVALUATION 340160354 DOC 01 Page 7 of 14 Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

particularly with signaling circuits, switch machines, and along the direct fixation track on the Tempe Town Lake Bridge and over Interstate 10 (I-10). Periodic surveillance of the track-to-earth resistance allows for early detection and resolution of any stray current problems. f) Corrpro carried out testing of the stray current control facilities between December 5 , 2011 and December 9th, 2011. Precipitation (rainfall) during 2011 was recorded approximately 1.41 inches based on the National Weather Service report. We did not observe any rain during the time period of testing. The impact of previous precipitation on track-to-earth resistance levels is not known. Based on statistics, the reported normal annual precipitation for Phoenix is approximately 0.99 inches. Stray current leakage levels typically increase during periods of precipitation and for some time thereafter.

th

g) Testing of the track-to-earth resistance is a straightforward process. It should be considered Metros first line of defense for effective stray current control. Manual testing on an annual basis is the minimum requirement to comply with the intergovernmental agreement.

3.3 Metro Track-to-Earth Potentials

a) The maximum track-to-earth potentials range from negative -4.95 volts (rails accumulating stray current from earth in vicinity of measurement) to positive +4.0 volts (rails discharging stray current to earth in vicinity of measurement) during peak transit operating periods. b) The magnitude and time characteristics of the track-to-earth potentials are considered normal with no indication of anomalous conditions that could impact stray current control.

3.4 Metro YardMainline and Yard-Shop Electrical Separation

a) By design, for stray current control, the yard traction power system is intended to be electrically separated from the mainline system under normal transit operations. Similarly, the yard traction power system is to be electrically separated from the shop system where the rails are grounded for electrical safety. The separation was found to be in place during Corrpros field evaluation. b) Transit and railed maintenance vehicles that are parked across the yard/mainline rail insulating joints and or parked across the yard/shop rail insulating joints can cause excessive, unacceptable stray current levels because they electrically connect the different traction power electrification circuits. When the insulating joints are bridged, they can lower the effective resistance-to-earth of the mainline rail system and increase stray currents over extended distances. c) The worst stray current corrosion conditions occur when the yard-shop insulating joints are shorted concurrent with the yard-mainline insulating joints. Procedures need to be maintained at all times to avoid these conditions.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 8 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

d) The track-to-earth resistance measured in the yard 329.66 -1,000 ft. e) Pipe-to-soil potentials were monitored at thirteen (13) representative locations along the Valley Metro light rail tracks. Ten (10) of the test points were on ductile iron water lines that included corrosion control test stations and galvanic current cathodic protection (magnesium anodes). Two (2) test points were on South West Gas pipelines, and the other test point was a rebar test station for the concrete pad below the rail. The locations were selected to determine typical and expected worse-case conditions based on analyses of the track-to-earth resistance and track-to-earth potential data obtained during Corrpros field evaluation. f) There are two predominant transit-influenced stray current effects influencing the water lines. The most prevalent is caused by transit operations along the mainline. There is also a sporadic spike-type effect, which is believed to be associated with transit vehicles entering or leaving the yard and shorting the yard-mainline rail insulating joints. The spike-type effects are typically greater than those caused by the mainline operations. This same condition was observed in our previous evaluation in 2010 and 2009.

g) Average maximum transit-influenced pipe-to-soil potential variations caused by mainline operations are typically less than 0.020 volt referenced to the quiescent potential that exists during non-revenue periods. The largest magnitude variation is 0.020 volt and occurs at the water line test point at 33.448073, 112.022441. h) Average maximum spike-type changes in pipe-to-soil potential are typically less than 0.050 volt referenced to the quiescent potential that exists during non-revenue periods. The largest spike-type change is 0.125 volt, occurring at the water line test point at 33.446312, -111.970915. i) While the pipe-to-soil potential data indicate Metro is having an electrical effect on the water lines, the effects are considered very low and do not present a corrosion threat. Pipe-to-soil potential variations caused by mainline transit operations that are consistently greater than 0.1 volt would typically warrant further evaluation relative to corrosion control significance. The measured effects are much lower than this threshold level. The low-level stray current effects detected at the structures tested is considered to have very little impact on the operational reliability and service life of the utilities, provided there is no substantial increase and the utility cathodic protection is maintained.

j)

3.5 Section 5.6 of the Intergovernmental Agreement

a) Corrpros evaluation of current conditions conforms to the breadth and intent of Section 5.6 of the intergovernmental agreement on corrosion control. b) A program consisting of periodic track-to-earth resistance testing for the entire Valley Metro light rail system coupled with measurements at a sampling of utility monitoring points is the most responsive and cost-effective method for complying with the

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 9 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

intergovernmental agreement. This proactive approach will also keep overall stray current levels to a practicable minimum.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 10 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

4.0

RECOMMENDATIONS

with the intergovernmental agreement. The information should also be conveyed to other interested parties as appropriate.

1. The information contained in this report should be conveyed to the City of Phoenix to comply

2. Adhere to the written guidelines (SOP) for Valley Metros light rail system stray current corrosion control maintenance and monitoring program as developed by Corrpro to assure consistency in the future. 3. Conduct annual track-to-earth resistance tests as stated in the Intergovernmental Agreement on Corrosion Control, Sec. 5.6. Track-to-earth resistances below 100 Ohms-1,000 feet (2 rails) for embedded track and 250 ohms-1,000 feet for direct fixation track require corrective action based on the agreement. Track-to-earth resistance testing should be considered Valley Metros first line of defense for effective stray current control.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 11 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

5.0

DISCUSSION

5.1 Track-to-Earth Resistance

For this project, Corrpro measured the track-to-earth resistance. From Ohms law, increasing track-to-earth resistance will decrease the amount of stray current exchange between the traction power system and the earth. Testing conducted during the 2011 survey indicates that the mainline track-to-earth resistances are sufficient to satisfy the intergovernmental agreement for the mainline tracks and effectively control stray current. The track-to-earth test data and calculation sheets are provided in Appendix A.

5.2 Track-to-Earth Potential

Track-to-Earth Potential is used to estimate the amount of current exchange between the rail tracks and the earth. Corrpro measured track-to-earth potentials at ten (10) traction power substation locations along the alignment using Tinker & Rasor data loggers. Graphs of the potentials recorded by the data loggers are provided in Appendix B.

5.3 Stray Current

Stray current, is current that travels along an unintended path, like traction power current traveling through the earth to return to the substation via another route instead of along the rails. As stray current moves through the earth it can be collected on and discharged from buried metallic utilities. corrosion is increased. The electrical potential testing carried out by Corrpro indicates that the level of stray current is minimal and there is a low risk of accelerated damage of buried utilities due to the Valley Metros DC traction power systems. At locations of discharge from the metal structure, the electrical potential of the structure will be made more positive; at these locations the risk of accelerated

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 12 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

6.0

TEST METHODS

6.1 Track-to-Earth Resistance Tests

This is the primary field measurement used to gauge the in-service effectiveness of Metros stray current corrosion control measures. If the track-to-earth resistance is maintained at a relatively high level, the risk of the transit system causing stray current on nearby utilities can be kept to a minimum. a) For the survey, Corrpro measured track-to-earth resistances for the entire mainline system ( 21.5 miles) on a track section by track section basis, typically for dual track section lengths an average of 16,000 feet. b) The tests were performed during non-revenue service, roughly 12:30 AM to 4:00 AM. c) The tests were conducted while temporarily disconnecting impedance bond cables across certain rail insulating joints to sectionalize the rail network into approximate lengths of 16,000 feet. d) The data sheets include a sketch of each test set up with locations of potential measurements, connections for the applied current and locations of insulating joints. e) A direct current (DC) test voltage of approximately 12-volts was impressed between the track section under test and an earth ground connection. The current output and DC voltage shift due to the applied current was measured and recorded simultaneously. f) Cross-bonds, TPSS negative return and signal wire connections to the rails were left connected during the testing of the mainline.

6.2 Track-to-Earth Potential Measurements at Substations

Concurrent with the pipeline potential monitoring, Corrpro used the battery-powered data loggers to monitor track-to-earth potentials at ten (10) TPSSs. Using Ohms Law, the track-toearth potential data is used in conjunction with the track-to-earth resistance data to estimate the magnitude and polarities of stray current exchange between the system rails and earth. a) The data logger positive lead was connected to the track negative return and test common lead was connected to the building ground bus. Test connections were made safely with the traction power energized. b) The monitoring period per substation was in excess of 12 hours and includes at least one morning and or one afternoon rush-hour period.

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 13 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL SYSTEM EVALUATION

6.3 Pipeline Potential Monitoring

Corrpro used battery-powered data loggers to monitor pipe-to-soil potentials at ten (10) water pipeline test station locations and two (2) South West Gas pipeline test stations along the Valley Metro light rail alignment. This data helps evaluate the effects of the stray current from the rail on the nearby foreign structures. a) Monitoring was performed typically in excess of 12 hours to cover at least one period of peak rail operation. b) Measurements were also made at one power pole electrical ground rods. Experience shows data from the ground connections can often provide an overall indication of stray current effects in a given area. c) Corrpro recorded the GPS coordinates (3 meter accuracy) for each of the utility test points, traction power sub stations (TPSS), and catenary poles utilized during the potential monitoring and testing. The locations are shown on the satellite imagery sheets in Appendix - D.

END OF REPORT

CORROSION CONTROL EVALUATION

340160354 DOC 01

Page 14 of 14

Rev 1

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

APPENDIX A Track-to-Earth Resistance Test Data

Table A1 Figure A1 Summary Table - Track-to-Earth Resistance Track-to-Earth Resistance vs. Location Track-to-Earth Resistance Appendix A Reference Number Field Data, Calculation Sheets and Sketches Stn. 909+86 to 1119+93 Stn. 1119+93 to 1509+01 Stn. 1509+01 to 1668+34 Stn. 1668+34 to 1845+08 Stn. 1845+08 to 2025+10 Stn. 2025+10 to 2045+30 Stn. 4+00 to 28+00 (Yard Entrance) Yard Lines

1 2 3 4 5 6 7 8

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

Table A1

Appendix A Reference Number

Summary Table - Track-to-Earth Resistance

Number of Crossovers and other Special Trackwork Sections in Test Normalized Trackto-Earth Resistance (-1,000 Ft. of Single Track) Measured Resistance (Ohms) Estimated Track Length (including Special Track) System Length (Feet) Start Stn. No. End Stn. No. Date Tested

Notes

1 2 3 4 5 6 7

Dec. 08, 2011 Dec. 08, 2011 Dec. 07, 2011 Dec. 06, 2011 Dec. 05, 2011 Dec. 05, 2011 Dec. 09, 2011

909+86 1119+93 1509+01 1668+34 1845+08 2025+10 4+00

1119+93 1509+01 1668+34 1845+08 2025+10 2045+30 28+00

21,007 38,908 15,933 17,674 18,002 2,020 1,200

42,014 77,816 31,866 35,348 36,004 4,040 2,400

9.87 3.22 19.55 8.72 3.86 25.66 629.13

414.85 250.73 623.03 308.38 139.24 103.70 1,509.93

2 2 2 2 2 2 0

North end of Lines to Pierson St. Pierson St. to 27th St. 27th St. to 51st St. 51st St. to 6th St. 6th St. to Dobson Rd. Dobson Rd. to E. End of Tracks Main Line to Yard Entrance Tracks Yard Track Testing

Dec. 09, 2011

28+00

13,500

27,000

12.20

329.66

The yard includes combination of direct fixation and embedded tracks.

TOTAL Miles

113,544 21.5

211,126

All in parallel : 1.1419

Average Normalized Track-to-Earth Resistance for entire Mainline system:

306.65

(-1,000FT)

CORROSION CONTROL EVALUATION

340160354 DOC 01

APPENDIX

Rev 1

Figure A1 Track-to-Earth Resistance vs. Location

700 T# - Traction Power Sub-Station Approximate Locations Yard Entrance at Stn 1647+25 600

Normalized Track-to-Earth Resistance (ohm-1,000 Ft of Track, 2 Rails)

500

306 Ohm-1,000 FT Average for entire Mainline

100 ohm-1,000 FT Minimum for compliance with Intergovernmental Agreement

400

300

200

100

T1 T2 T3 T4 T5 T6 T7

Yard Entrance

T8 T9 T10 T11 T12 T13

0 900+00 1000+00 1100+00 1200+00 1300+00 1400+00 1500+00 1600+00 1700+00 1800+00 1900+00 2000+00 2100+00

Track Station Number

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location: Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/8/2011 Metro Light Rail - Pheonix, AZ 340160354 11:59 PM North End of Line 1119+93 Pierson St. 909+86 End of Track 2 42,014 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 45 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured 1119+93

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.741

Vdc

8.620 0.618 8.640 0.613 8.610 0.622 8.610 0.619

Vdc

1.346 0.288 1.263 0.282 1.379 0.292 1.343 0.287 1.364 1.362 1.360 1.360 -

Vdc

7.274 7.377 7.231 7.267 7.486 7.358 7.290 7.250 -

9.816

9.955

9.758

9.807

909+86 8.850 8.720 8.650 8.610 9.874 10.103 9.930 9.838 9.784 -

Test Location Starting Station

North End of Line 1119+93 Average Change (V) 7.317

Date:

Page 2 of 2 12/8/2011

Estimated Track Length (including Special Track) Start and End Station No. 1119+93 909+86 42,014

Current Applied (Amps.) 0.741

Measured Resistance ( ) 9.87398785

Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track) 414.85

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 1119+93

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/8/2011 Metro Light Rail - Pheonix, AZ 340160354 11:59 PM North End of Line 1119+93 Pierson St. th 1509+01 27 St. 2 77,816 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 45 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured 1119+93

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

1.311

Vdc

5.913 1.329 5.886 1.355 5.863 1.357 5.879 1.385

Vdc

1.450 2.160 1.446 2.187 1.485 2.412 1.495 2.258 1.900 0.450 1.901 0.465 1.390 0.726 1.280 0.780

Vdc

4.463 4.440 4.378 4.384 3.732 3.748 4.268 4.380 -

3.404

3.387

3.339

3.344

1509+01 5.632 0.500 5.649 0.480 5.658 0.476 5.660 0.801 3.222 2.847 2.859 3.256 3.341 -

Test Location Starting Station

North End of Line 1119+93 Average Change (V) 4.224 Current Applied (Amps.) 1.311 Measured Resistance ( ) 3.22206331

Date:

Page 2 of 2 12/8/2011

Estimated Track Length (including Special Track) Start and End Station No. 1119+93 1509+01 77,816

Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track) 250.73

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 1119+93

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/7/2011 Metro Light Rail - Pheonix, AZ 340160354 11:59 PM

th 1509+01 27 St. st 1668+34 51 St. 2 31,866 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 46 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured 1509+01

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.374

Vdc

7.850 0.656 8.040 0.650 8.030 0.646 8.030 0.646

Vdc

0.420 0.555 0.412 0.552 0.350 0.556 0.366 0.556 0.883 0.823 0.754 0.826 0.692 0.843 0.660 0.812

Vdc

7.430 7.628 7.680 7.664 6.907 7.016 7.083 7.090 -

19.866

20.396

20.535

20.492

1668+34 7.790 0.751 7.770 0.778 7.775 0.760 7.750 0.757 19.552 18.468 18.759 18.939 18.957 -

Test Location Starting Station

1509+01

Date:

Page 2 of 2 12/7/2011

Estimated Track Length Average (including Special Track) Change (V) Start and End Station No. 1509+01 1668+34 31,866 7.312

Current Applied (Amps.) 0.374

Measured Normalized Track-to-Earth Resistance Resistance (-1,000 Ft. of ( ) Single Track) 19.5515374 623.03

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 1509+01

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/6/2011 Metro Light Rail - Pheonix, AZ 340160354 11:59 PM

st 1668+34 51 St. th 1845+08 E. 6 St. 2 35,348 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 44 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured 1668+34

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.460

Vdc

4.970 0.495 4.971 0.510 4.960 0.510 4.900 0.500

Vdc

0.825 0.350 0.825 0.360 0.836 0.357 0.824 0.370 1.256 0.109 1.217 0.101 1.145 0.996 1.140 0.980

Vdc

4.145 4.146 4.124 4.076 3.845 3.863 3.956 3.950 -

9.011

9.013

8.965

8.861

1845+08 5.101 0.872 5.080 0.869 5.101 0.837 5.090 0.847 8.724 8.359 8.398 8.600 8.587 -

Test Location Starting Station

1668+34

Date:

Page 2 of 2 12/6/2011

Estimated Track Length Average (including Special Track) Change (V) Start and End Station No. 1668+34 1845+08 35,348 4.013

Current Applied (Amps.) 0.460

Measured Normalized Track-to-Earth Resistance Resistance (-1,000 Ft. of ( ) Single Track) 8.72418478 308.38

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 1668+34

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/5/2011 Metro Light Rail - Pheonix, AZ 340160354 11:59 PM East End of Line 2025+10 Dobson Rd. th 1845+08 E. 6 St. 2 36,004 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 40 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured 2025+10

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.971

Vdc

-2.287 0.437 -2.305 0.444 -2.289 0.440 -2.310 0.440

Vdc

1.413 0.570 1.416 0.568 1.415 0.565 1.419 0.573 1.201 0.623 1.189 0.619 1.195 0.621 1.199 0.622

Vdc

3.700 3.721 3.704 3.729 3.802 3.787 3.800 3.798 -

3.811

3.832

3.815

3.840

1845+08 -2.601 0.512 -2.598 0.512 -2.605 0.509 -2.599 0.512 3.867 3.916 3.900 3.913 3.911 -

Test Location Starting Station

East End of Line 2025+10

Date:

Page 2 of 2 12/5/2011

Estimated Track Length Average Change (including Special Track) (V) Start and End Station No. 2025+10 1845+08 36,004 3.755

Current Applied (Amps.) 0.971

Measured Resistance ( ) 3.867276

Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track) 139.24

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 2025+10

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/5/2011 Metro Light Rail - Pheonix, AZ 340160354 11:59 PM East End of Line 2025+10 Dobson Rd. 2045+30 E. End of Tracks 2 4,040 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 40 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured 2025+10

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.268

Vdc

9.520 0.502 9.531 0.516 9.610 0.512 9.621 0.532

Vdc

2.380 0.609 2.400 0.600 2.460 0.613 2.462 0.589 3.250 3.125 3.117 3.175

Vdc

7.140 7.131 7.150 7.159 6.490 6.655 6.693 6.615 -

26.642

26.608

26.679

26.713

2045+30 9.740 9.780 9.810 9.790 25.668 24.216 24.832 24.974 24.683 -

Test Location Starting Station

East End of Line 2025+10

Date:

Page 2 of 2 12/5/2011

Estimated Track Length Average Change (including Special Track) (V) Start and End Station No. 2025+10 2045+30 4,040 6.879

Current Applied (Amps.) 0.268

Measured Normalized Track-to-Earth Resistance Resistance (-1,000 Ft. of ( ) Single Track) 25.6683769 103.70

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 2025+10

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/9/2011 Metro Light Rail - Pheonix, AZ 340160354 8:00 AM Yard Testing 4+00 Main Line Entrance 28+00 Yard Entrance 2 2,400 -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 55 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. 4+00 Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. 28+00 Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6a) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8a) Potential w.r.t. GRD for Catentary Pole Average resistance measured

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.020

Vdc

13.150

Vdc

0.490

Vdc

12.660 -

633.000

13.150

0.556

12.594 -

629.700

13.130

0.450

12.680 -

634.000

13.150

0.420

12.730 -

636.500

12.510 12.510 12.530 12.530 629.138

0.020 0.019 0.024 0.019

12.490 12.491 12.506 12.511 -

624.500 624.550 625.300 625.550 -

Test Location Starting Station

Yard Testing 004+00

Date:

Page 2 of 2 12/9/2011

Estimated Track Length (including Special Track) Start and End Station No. 4+00 28+00 2,400

Average Change (V) 12.583

Current Applied (Amps.) 0.020

Measured Resistance ( ) 629.1375

Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track) 1509.93

Sketch/Calculations: Notes:

1a

5a

2a

6a WB track

3a

7a

4a

8a

EB track

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 28+00

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

Track-to-Earth Resistance Tests Track Section Using Current Drop Method

Engineer: Technician: Date: Client: Job #: Time: Test Location Starting Station Ending Station Test 1 or 2 track directions Track Length (FT) Adder for Special Track (FT) Ed Goldberg Mike Beebe 12/9/2011 Metro Light Rail - Pheonix, AZ 340160354 8:00 AM Yard Testing 28+00 Yard Entrance 2 27,000 Total Estimated -

Page 1 of 2 Project Desc.: Track-to-Earth Resistance Testing Weather/Notes: Clear 55 F Voltmeter S/N: Fluke 187V S/N 12850307 Ammeter S/N: Fluke with 0.01 ohm wire shunt S/N 12850307 Other S/N

Test Location

Quantity Units, V, mV, Ohms Track-to-Earth @ (1) Stn No. 28+00 Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (1a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (2a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (3a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (4a) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (5) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (6) Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (7) Stn No. Potential w.r.t. GRD for Catentary Pole Track-to-Earth @ (8) Potential w.r.t. GRD for Catentary Pole Average resistance measured Test Location Starting Station

Current

Voltage On Voltage Off

Voltage Delta

Calculated Resistance

Amps.

0.264

Vdc

3.350 0.518 3.347 0.518 3.352 0.515 3.345 0.512

Vdc

0.121 0.647 0.128 0.652 0.125 0.632 0.120 0.648 0.132 0.127 0.128 0.130

Vdc

3.229 3.219 3.227 3.225 3.217 3.225 3.223 3.219

12.231

12.193

12.223

12.216

Inside Yard 3.349 Inside Yard 3.352 Inside Yard 3.351 Inside Yard 3.349 12.210 Yard Testing 028+00 Estimated Track Length (including Special Track) 27,000 12.208 12.186

Date:

Page 2 of 2 12/9/2011

Average Change (V) 3.223

Start and End Station No. 28+00

Current Applied (Amps.) 0.264

Measured Resistance ( ) 12.209596

Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track) 329.66

Sketch/Calculations: Notes:

Voltage Applied with a timed interupter switch. The current measured using calibrated Shunt. Located at Station: 28+00

*Calculation Note: [Average Voltage Change (V) Current Applied (Amps.)] (Estimated Track Length 1,000) = Normalized Track-to-Earth Resistance (-1,000 Ft. of Single Track)

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

APPENDIX B Traction Power Substation Potential Graphs

Table B1: Table B2: Figure B1: Figure B2: Figure B3: Summary Table - Track-to-Earth Potential Datalogs Summary Table - Estimated Current Exchange between Track and Earth Data Logger Locations and Structure Type versus Location Track-to-Earth Potential Stray Current Exchange

Track-to-Earth Potential Traces Appendix B Reference Location ID Stn. No. Number 1 2 3 4 5 6 7 8 9 10 TPSS#1 TPSS#2 TPSS#5 TPSS#7 TPSS#8 TPSS#9 TPSS#10 TPSS#12 TPSS#13 TPSS#14 1003+50 1051+25 1301+50 1496+25 1578+20 1693+50 1787+15 1925+00 1996+90 2037+50

Note: All measurements made using utility bond bus connection and substation grounding connection inside the traction power sub-station buildings for above locations.

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

Figure B1 - Data Logger Locations and Structure Type versus Location

South West Gas-to-Earth Potential

3

Waterline-to-Earth Potential

2

Track-to-Earth Potential

1

Yard Entrance T5 T6 T7 T8 T9 T10 T11 T12 T13 T14

T1

T2

T4

0 900+00 1000+00 1100+00 1200+00 1300+00 1400+00 1500+00 1600+00 1700+00 1800+00 1900+00 2000+00 2100+00

Track Location Station Number TPSS

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

Table B1 - Summary Table - Track-to-Earth Potential Datalogs

Quiescent Magnitude: NonRevenue Hours (Volts) Average Maximum Potential (Volt w.r.t. Ground Bus) Positive (Rails Discharging Stray Current) Negative (Rails Accumulating Stray Current)

Location ID

Stn. No.

TPSS#1 TPSS#2 TPSS#5 TPSS#7 TPSS#8 TPSS#9 TPSS#10 TPSS#12 TPSS#13 TPSS#14

1003+50 1051+25 1301+50 1496+25 1578+20 1693+50 1787+15 1925+00 1996+90 2037+50

-1.50 -0.50 -0.50 -1.00 -1.00 -1.50 -1.00 -1.50 -1.50 -1.00

2.25 1.50 2.40 1.95 4.00 0.95 2.25 2.00 3.00 2.00

-4 -4.85 -0.45 -3 -4.25 -3.5 -4.75 -4.75 -4.75 -4.95

*No testing was done at TPSS: 3, 4, 6, and 11 *Potentials are all with respect to electrical ground

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

Figure B2 - Track-to-Earth Potential

6

2 Track-to-Earth Potential (Volts)

-2

-4

-6

RED line: Average Maximum Positive Track-to-Earth Potential (Rails Discharging Stray Current)

-8

Black line: Average Maximum Negative Track-to-Earth Potential (Rails Accumulating Stray Current)

Yard Entrance T7 T8 T9 T10 T11 T12 T13

T1

T2

T3

T4

T5

T6

-10 900+00 1000+00 1100+00 1200+00 1300+00 1400+00 1500+00 1600+00 1700+00 1800+00 1900+00 2000+00 2100+00

Track Station Number

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

Table B2 - Summary Table Calculated Current Exchange Between Track and Earth

Average Maximum Stray Current Exchange (mA per 1000 ft of track system) Location ID Stn. No. From Track to Earth From Earth to Track

TPSS#1 TPSS#2 TPSS#5 TPSS#7 TPSS#8 TPSS#9 TPSS#10 TPSS#12 TPSS#13 TPSS#14

1003+50 1051+25 1301+50 1496+25 1578+20 1693+50 1787+15 1925+00 1996+90 2037+50

10.8 12.0 19.1 15.5 12.8 6.2 14.6 28.8 43.2 38.5

-19.3 -38.6 -3.6 -23.9 -13.6 -22.7 -30.8 -68.3 -68.3 -95.2

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

Figure B3 - Stray Current Exchange

60 Stray Current Exchange Between Tracks and Earth (milliampere per 1,000 FT of Track System - Four Rails)

RED line: Average Maximum Stray Current From Track to Earth Black line: Average Maximum Stray Current From Earth to Track

40

20

-20

-40

-60

-80

Yard Entrance

-100

T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13

-120 900+00

1000+00

1100+00

1200+00

1300+00

1400+00

1500+00

1600+00

1700+00

1800+00

1900+00

2000+00

Track Station Number

2100+00

-2

-2

-4

-4

-6

-6

AC/DC Unfiltered DC Voltage

-8

-8

-10

-10

-12

-12

-14

-14

Time (Minutes) 12/7/2011 4:23:03 Substation 1 AM

Unit: Tinker & Rasor

s/n: 03138-E20

File: Config.dlg

Latitude, Longitude: 33.517680, -112.098807

Dates Data was Recorded: 12/07/11 to 12/09/12

10

10

-5

-5

AC/DC Unfiltered DC Voltage

-10

-10

-15

-15

Time (Minutes) File: Config.dlg 12/7/2011 Substation 24:17:17 AM

Unit: Tinker & Rasor

s/n: 02244-05102-E20

Latitude, Longitude: 33.510018, -112.093846

Dates Data was Recorded: 12/07/11 to 12/09/12

15

15

10

10

-5

-5

AC/DC Unfiltered DC Voltage

-10

-10

-15

-15

-20

-20

Time (Minutes) 12/7/2011 4:59:20 Substation 5 AM

Unit: Tinker & Rasor

s/n: 03173-E20

File: Config.dlg

Latitude, Longitude: 33.458872, -112.074098

Dates Data was Recorded: 12/07/11 to 12/09/12

-2

-2

-4

-4

AC/DC Unfiltered DC Voltage

-6

-6

-8

-8

-10

-10

-12

-12

Time (Minutes) 12/6/2011 5:26:05 Substation 7 PM

Unit: Tinker & Rasor

s/n: 03138-E20

File: Config.dlg

Latitude, Longitude: 33.448083, -112.026494

Dates Data was Recorded: 12/06/11 to 12/07/12

20

20

15

15

10

10

-5

-5

AC/DC Unfiltered DC Voltage

-10

-10

-15

-15

-20

-20

-25

-25

Time (Minutes) File: Config(1).dlg 12/6/2011 6:16:59 Substation 8 PM

Unit: Tinker & Rasor

s/n: 03173-E20

Latitude, Longitude: 33.447857, -112.000766

Dates Data was Recorded: 12/06/11 to 12/07/12

-2

-2

-4

-4

AC/DC Unfiltered DC Voltage

-6

-6

-8

-8

-10

-10

-12

-12

Time (Minutes) File: Config(1).dlg 12/6/2011 Substation 9 5:05:00 PM

Unit: Tinker & Rasor

s/n: 02244-05102-E20

Latitude, Longitude: 33.445430, -111.963359

Dates Data was Recorded: 12/06/11 to 12/07/12

15

15

10

10

-5

-5

AC/DC Unfiltered DC Voltage

-10

-10

-15

-15

-20

-20

Time (Minutes) 12/6/2011 5:46:09 Substation 10PM

Unit: Data Logger

s/n: 02811-E20

File: Config(1).dlg

Latitude, Longitude: 33.429684, -111.943314

Dates Data was Recorded: 12/06/11 to 12/07/12

15

15

10

10

AC/DC Unfiltered DC Voltage

-5

-5

-10

-10

-15

-15

Time (Minutes) File: Sub Substation Station 12 12-5-11 to 12-6-11.dlg 12

Unit: Tinker & Rasor

s/n: 02244-05102-E20

12/5/2011 11:01:34 PM

Latitude, Longitude: 33.414292, -111.907126

Dates Data was Recorded: 12/05/11 to 12/06/12

15

15

10

10

AC/DC Unfiltered DC Voltage

-5

-5

-10

-10

-15

-15

Time (Minutes) 12/6/2011 12:16:06 Substation 13 AM

Unit: Tinker & Rasor

s/n: 03173-E20

File: Config.dlg

Latitude, Longitude: 33.415035, -111.883953

Dates Data was Recorded: 12/05/11 to 12/06/12

10

10

-5

-5

-10

-10

AC/DC Unfiltered DC Voltage

-15

-15

-20

-20

-25

-25

Time (Minutes) 12/6/2011 12:36:16 AM Substation 14

Unit: Data Logger

s/n: 02811-E20

File: Config.dlg

Latitude, Longitude: 33.415109, -111.870665 Dates Data was Recorded: 12/05/11 to 12/06/12

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

APPENDIX C Utility Potential Traces and Other Utility Data

Thirteen Datalog Traces of Utility Potential Versus Time Appendix C Reference Number 1 2 3 4 5 6 7 8 9 10 11 12 13 Reference Appendix D Page 6 9 9 6 2 4 2 2 4 4 4 2 2

Structure

Latitude

Longitude 111.970915 111.946918 111.950642 111.970724 112.073652 112.024303 112.073641 112.073664 112.023642 112.024780 112.022441 112.073666 112.073619

Fire Hydrant South West Gas Rebar South West Gas Fire Hydrant Waterline Fire Hydrant Fire Hydrant Waterline Fire Hydrant Fire Hydrant Fire Hydrant Fire Hydrant

33.446312 33.438035 33.439816 33.446290 33.483312 33.448094 33.482397 33.483758 33.448075 33.448079 33.448073 33.483218 33.481940

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

DC Voltage

Time

WashingtonStreetFireHydrantTestStation (Latitude,Longitude:33.446312,111.970915)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

WashingtonStreetSouthWestGasTestStation (Latitude,Longitude:33.438035,111.946918)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

DataLoggerinMedianatParksideDriveRebarTestStation (Latitude,Longitude:33.439816,111.950642)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

WashingtonStreetSouthWestGasTestStation (Latitude,Longitude:33.446290,111.970724)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

N.CentralAve.FireHydrantTestStation (Latitude,Longitude:33.483312,112.073652)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

E.WashingtonStreetWaterTestStation (Latitude,Longitude:33.448094,112.024303)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

N.CentralAve.FireHydrantTestStation (Latitude,Longitude:33.482397,112.073641)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

N.CentralAve.FireHydrantTestStation (Latitude,Longitude:33.483758,112.073664)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

E.WashingtonStreetWaterTestStation (Latitude,Longitude:33.448075,112.023642)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

E.WashingtonStreetFireHydrantTestStation (Latitude,Longitude:33.448079,112.024780)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

E.WashingtonStreetFireHydrantTestStation (Latitude,Longitude:33.448073,112.022441)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

N.CentralAve.FireHydrantTestStation (Latitude,Longitude:33.483218,112.073666)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

DC Voltage

Time

N.CentralAve.&E.CatalinaDr.FireHydrantTestStation (Latitude,Longitude:33.481940,112.073619)

*Dateformatofdatalogging:Year/Month/Day *Timeformatofdatalogging:24hrClock

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

APPENDIX D Aerial Imagery Maps of Test Locations

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

Appendix - D Page # 1

Appendix - D Page # 2

Appendix - D Page # 3

Appendix - D Page # 4

Appendix - D Page # 5

Appendix - D Page # 6

Appendix - D Page # 7

Appendix - D Page # 8

Appendix - D Page # 9

Appendix - D Page # 10

2011 STRAY CURRENT CORROSION CONTROL EVALUATION

APPENDIX E Section 5.6 of the Intergovernmental Agreement

340160354 DOC 01 APPENDIX Rev 1

CORROSION CONTROL EVALUATION

Potrebbero piacerti anche

- Relevant Characteristics of Power Lines Passing through Urban AreasDa EverandRelevant Characteristics of Power Lines Passing through Urban AreasNessuna valutazione finora

- Energetic Processes in Follow-Up Electrical Control Systems: International Series of Monographs on Electronics and InstrumentationDa EverandEnergetic Processes in Follow-Up Electrical Control Systems: International Series of Monographs on Electronics and InstrumentationNessuna valutazione finora

- Water Line Stray Current ControlDocumento18 pagineWater Line Stray Current ControlVinzoKeiNessuna valutazione finora

- Emi 2Documento11 pagineEmi 2Rafi MuhammedNessuna valutazione finora

- Stray Currents Mitigation, Control and Monitoring in Bangalore Metro DC Transit SystemDocumento7 pagineStray Currents Mitigation, Control and Monitoring in Bangalore Metro DC Transit SystemAnil Yadav100% (1)

- Environmental Characteristics of HVDC Overhead TransmissionDocumento10 pagineEnvironmental Characteristics of HVDC Overhead TransmissionPrazetyo Adi NugrohoNessuna valutazione finora

- Environmental Characteristics of HVDC Overhead Transmission LinesDocumento5 pagineEnvironmental Characteristics of HVDC Overhead Transmission LinesRavi K NNessuna valutazione finora

- High-Speed Inspection of RailsDocumento8 pagineHigh-Speed Inspection of RailsEryk RyzkoNessuna valutazione finora

- 2012 ProjectDocumento66 pagine2012 ProjectYash BhattiproluNessuna valutazione finora

- Remote Monitoring-Cathodic Protection-Specification 2Documento5 pagineRemote Monitoring-Cathodic Protection-Specification 2Mohamed RafihNessuna valutazione finora

- Final Earthing V3Documento22 pagineFinal Earthing V3RewanEsamNessuna valutazione finora

- Costs Study of 69-To 345-Kv Overhead Power-Transmission SystemsDocumento17 pagineCosts Study of 69-To 345-Kv Overhead Power-Transmission SystemsKevin ChangNessuna valutazione finora

- Locating Leaks in Sewer Pipes Using Electro-Scan - The Variation of Electric Current Flow Through The Pipe WallDocumento7 pagineLocating Leaks in Sewer Pipes Using Electro-Scan - The Variation of Electric Current Flow Through The Pipe WallAhmad Zubair RasulyNessuna valutazione finora

- Partial DischargeDocumento12 paginePartial DischargetarsudinNessuna valutazione finora

- Impact and Management of Stray Current On DC Rail SystemsDocumento8 pagineImpact and Management of Stray Current On DC Rail Systems曾乙申100% (1)

- Revailing Corrosion Mechanisms On Large Pipeline NetworksDocumento7 pagineRevailing Corrosion Mechanisms On Large Pipeline NetworksOwais Manzoor MalikNessuna valutazione finora

- ElectricalDocumento78 pagineElectricalsangeetaraiNessuna valutazione finora

- Subsea Pipeline StabilityDocumento9 pagineSubsea Pipeline StabilityJhy MhaNessuna valutazione finora

- LIDAR For IpipelineDocumento8 pagineLIDAR For Ipipelinewiwiz2000Nessuna valutazione finora

- Corrosion ProbeDocumento19 pagineCorrosion ProbeHaslizan HarunNessuna valutazione finora

- Analysis of Distribution Transformer Performance Under Non-Linear Balanced Load Conditions and Its Remedial MeasuresDocumento10 pagineAnalysis of Distribution Transformer Performance Under Non-Linear Balanced Load Conditions and Its Remedial MeasuresGaurang PatelNessuna valutazione finora

- Condition Assessment and Rehabilitation of Large Sewers: WWW - Nrc.ca/irc/ircpubsDocumento10 pagineCondition Assessment and Rehabilitation of Large Sewers: WWW - Nrc.ca/irc/ircpubsSyazwan MohdNessuna valutazione finora

- An Analysis of Mechanical EffectsDocumento9 pagineAn Analysis of Mechanical EffectsrenzomcuevaNessuna valutazione finora

- Overhead To Underground Transmission Line Coupling - Technical Recommendations To Brazilian UtilitiesDocumento9 pagineOverhead To Underground Transmission Line Coupling - Technical Recommendations To Brazilian UtilitiesRoberto Diniz Thomaz JúniorNessuna valutazione finora

- Telluric Currents-Paper No. 00741Documento7 pagineTelluric Currents-Paper No. 00741Juan David Benitez MonroyNessuna valutazione finora

- Fault Detection and Diagnostics For Non-Intrusive Monitoring Using Motor HarmonicsDocumento9 pagineFault Detection and Diagnostics For Non-Intrusive Monitoring Using Motor HarmonicsSumon DharaNessuna valutazione finora

- Notes - Power Transmission PlanningDocumento2 pagineNotes - Power Transmission PlanningKashaf ShahidNessuna valutazione finora

- Detection and Mitigation of Ac Interference On 200Km PipelineDocumento5 pagineDetection and Mitigation of Ac Interference On 200Km PipelineMarcelo Varejão CasarinNessuna valutazione finora

- Ground Fault Current Distribution When A Ground Fault Occurs in HV Substations Located in An Urban AreaDocumento13 pagineGround Fault Current Distribution When A Ground Fault Occurs in HV Substations Located in An Urban AreaRajendra Prasad ShuklaNessuna valutazione finora

- SPE Mexico Corrosion 06Documento9 pagineSPE Mexico Corrosion 06henbauNessuna valutazione finora

- 7-7 Bridge HydraulicsDocumento7 pagine7-7 Bridge Hydraulicscovos labNessuna valutazione finora

- Maintenance and Testing of Earthing SystemDocumento6 pagineMaintenance and Testing of Earthing SystemMuhammad Laiq Ahmed100% (1)

- Cathodic Protection PDFDocumento5 pagineCathodic Protection PDFpanmahiNessuna valutazione finora

- Instrumentation in TunnelsDocumento14 pagineInstrumentation in Tunnelssravan_ruby100% (2)

- Prelab ReportDocumento1 paginaPrelab ReportNtsika SokasiNessuna valutazione finora

- Hydraulic Transients in Service LinesDocumento6 pagineHydraulic Transients in Service Linestsegabirhan haileslassieNessuna valutazione finora

- Lessons Learned Document Library-LL20130701 Current Transformer Ground RelayDocumento3 pagineLessons Learned Document Library-LL20130701 Current Transformer Ground Relayjaackson10Nessuna valutazione finora

- 7 Energies 16Documento16 pagine7 Energies 16Lingesh K VNessuna valutazione finora

- Assessment of Grounding Schemes On Rail Potential and Stray Currents in A DC Transit System - 01705553Documento7 pagineAssessment of Grounding Schemes On Rail Potential and Stray Currents in A DC Transit System - 01705553npfhNessuna valutazione finora

- Cable-Climbing Robots For Power Transmission Lines InspectionDocumento25 pagineCable-Climbing Robots For Power Transmission Lines InspectionAdam BagaribNessuna valutazione finora

- Grounding Potential RaiseDocumento10 pagineGrounding Potential RaiseINAMULLAH MASAL KHANNessuna valutazione finora

- Pipelines On The Right of WayDocumento49 paginePipelines On The Right of WayDadi AzizNessuna valutazione finora

- The Effects of Earthing Strategies On Rail Potentlal and Stray Currents in D.C. Transit RailwaysDocumento7 pagineThe Effects of Earthing Strategies On Rail Potentlal and Stray Currents in D.C. Transit RailwaysUmesh Yadav100% (1)

- Utilisation of The Modern Off-Line Diagnosis Methods For The Medium and High Voltage BreakersDocumento5 pagineUtilisation of The Modern Off-Line Diagnosis Methods For The Medium and High Voltage BreakersIrinabucurestiNessuna valutazione finora

- Measurements For Testing Earthing System IntegrityDocumento9 pagineMeasurements For Testing Earthing System IntegrityMehdi_Mashayekhi_172Nessuna valutazione finora

- Structural Health Monitoring in The Mainland of China: Review and Future TrendsDocumento13 pagineStructural Health Monitoring in The Mainland of China: Review and Future TrendsVinhNguyenThanhNessuna valutazione finora

- Continuous Automated Flux Monitoring For Turbine Generator Rotor Condition Assessment - Epri 2004 PDFDocumento15 pagineContinuous Automated Flux Monitoring For Turbine Generator Rotor Condition Assessment - Epri 2004 PDFabdul2wajidNessuna valutazione finora

- Earth Potential Rise ManualDocumento25 pagineEarth Potential Rise Manualparas99Nessuna valutazione finora

- 401Documento14 pagine401giohaNessuna valutazione finora

- The Present Research Situation and Earthquake Damage Defensive Measures of The Transmission LinesDocumento8 pagineThe Present Research Situation and Earthquake Damage Defensive Measures of The Transmission LinesangelomarinilliNessuna valutazione finora

- Vibroacoustics Analysis of Punching Machine Hydraulic PipingDocumento10 pagineVibroacoustics Analysis of Punching Machine Hydraulic PipingFrancesca CoattiNessuna valutazione finora

- Ultrasonic Pulse VelocityDocumento16 pagineUltrasonic Pulse VelocityShivamBose100% (1)

- Cidra Sonartrac Flow Meters: An Alternative Flow Measurement TechnologyDocumento15 pagineCidra Sonartrac Flow Meters: An Alternative Flow Measurement TechnologyMarcoNessuna valutazione finora

- Analysis of Electrical Interference From Power Lines To Gas Pipelines Part 11: Parametric AnalysisDocumento7 pagineAnalysis of Electrical Interference From Power Lines To Gas Pipelines Part 11: Parametric AnalysisjgkrishnanNessuna valutazione finora

- 2010 An Advanced Method of Condition Assessment For Large Diameter Mortar Lined Steel PipelinesDocumento8 pagine2010 An Advanced Method of Condition Assessment For Large Diameter Mortar Lined Steel PipelinesHashfi HamdaniNessuna valutazione finora

- Pipe SurgeDocumento9 paginePipe SurgeMark Raphael KipkiruiNessuna valutazione finora

- Icst 1008Documento4 pagineIcst 1008International Jpurnal Of Technical Research And ApplicationsNessuna valutazione finora

- Detection of Buckling in Steelpipeline and Column by Distributed Brillouin SensorDocumento7 pagineDetection of Buckling in Steelpipeline and Column by Distributed Brillouin SensormanachemiaaNessuna valutazione finora

- WM2014 Conference, March 2 - 6, 2014, Phoenix, Arizona, USADocumento7 pagineWM2014 Conference, March 2 - 6, 2014, Phoenix, Arizona, USARoland Rawlins IgaborNessuna valutazione finora

- Measurement of Leakage Current For Monitoring The Performance of Outdoor Insulators 2012Documento7 pagineMeasurement of Leakage Current For Monitoring The Performance of Outdoor Insulators 2012Muhammad Usama MalikNessuna valutazione finora

- Effectively Addressing New Damage Mechanism Requirements With An Integrated PHA PDFDocumento20 pagineEffectively Addressing New Damage Mechanism Requirements With An Integrated PHA PDFSarmiento FerNessuna valutazione finora

- MBOT MegazineDocumento24 pagineMBOT MegazineJoe BlagNessuna valutazione finora

- One Corrosion Engineer's Lessons Learned - 1979-2010Documento24 pagineOne Corrosion Engineer's Lessons Learned - 1979-2010Joe BlagNessuna valutazione finora

- rr129 SCC From Ukhse PDFDocumento25 paginerr129 SCC From Ukhse PDFJoe BlagNessuna valutazione finora

- AC Mit PowerTool Quick Guide PrciDocumento23 pagineAC Mit PowerTool Quick Guide PrciJoe BlagNessuna valutazione finora

- Saudi Aramco NDT Methods Application On Heat ExchangersDocumento30 pagineSaudi Aramco NDT Methods Application On Heat Exchangersaasatti100% (1)

- Barlo - and - Zdunek-1995-Stray Current Corrosion in Electrified Rail SystemsDocumento47 pagineBarlo - and - Zdunek-1995-Stray Current Corrosion in Electrified Rail SystemsJoe BlagNessuna valutazione finora

- Th0800Coll Corrosive TechnologiesDocumento35 pagineTh0800Coll Corrosive TechnologiesJoe BlagNessuna valutazione finora

- Paul Vinik State Structural Material Systems EngineerDocumento7 paginePaul Vinik State Structural Material Systems EngineerJoe BlagNessuna valutazione finora

- 00039Documento8 pagine00039Joe BlagNessuna valutazione finora

- Asset IntegrityDocumento74 pagineAsset IntegrityAhmed Hazem100% (2)

- Corrosion in Cargo TanksDocumento21 pagineCorrosion in Cargo Tankssergiytitov100% (1)

- LahDocumento3 pagineLahJoe BlagNessuna valutazione finora

- Understanding Earth Ground Resistance by AEMCDocumento39 pagineUnderstanding Earth Ground Resistance by AEMCJawaid IqbalNessuna valutazione finora

- Calm Buoy Patent US6558215Documento11 pagineCalm Buoy Patent US6558215Joe BlagNessuna valutazione finora

- Sleeve LengthDocumento1 paginaSleeve LengthJoe BlagNessuna valutazione finora

- Standard SizeDocumento1 paginaStandard SizeJoe BlagNessuna valutazione finora

- Calm Buoy Patent US6558215Documento11 pagineCalm Buoy Patent US6558215Joe BlagNessuna valutazione finora

- Calm Buoy Patent US6558215Documento11 pagineCalm Buoy Patent US6558215Joe BlagNessuna valutazione finora

- Calm Buoy Patent US6558215Documento11 pagineCalm Buoy Patent US6558215Joe BlagNessuna valutazione finora

- Vappro703 DesludgeCANDocumento2 pagineVappro703 DesludgeCANJoe BlagNessuna valutazione finora

- 2007 7 Palmer JonesDocumento13 pagine2007 7 Palmer JonesGRANRICKYNessuna valutazione finora

- Sample ReportDocumento1 paginaSample ReportJoe BlagNessuna valutazione finora

- Digital Control System Paper PDFDocumento2 pagineDigital Control System Paper PDFdeepaksaini14Nessuna valutazione finora

- Letter by Letter Abu Taubah S Arabic Alphabet WorkbookDocumento2 pagineLetter by Letter Abu Taubah S Arabic Alphabet WorkbookSharief SkNessuna valutazione finora

- Manual SL7000Documento101 pagineManual SL7000Juan Carlos Camacho SilesNessuna valutazione finora

- Casio EDIFICE EQW-T620DC - qw5423 PDFDocumento8 pagineCasio EDIFICE EQW-T620DC - qw5423 PDFAlexander TeplyakovNessuna valutazione finora

- Electricity ExamDocumento4 pagineElectricity Examjorolan.annabelleNessuna valutazione finora

- Ttp223-Ba6 C80757Documento8 pagineTtp223-Ba6 C80757Sahar ShahidNessuna valutazione finora

- SolderDocumento13 pagineSolderBalaji N MuthuramanNessuna valutazione finora

- New Cost-Effective Silicon Carbide High Voltage Switch CreatedDocumento2 pagineNew Cost-Effective Silicon Carbide High Voltage Switch CreatedMatejŠarlijaNessuna valutazione finora

- (TUTORIAL) Unlock Sim Network On Samsung Galaxy Mini S5570, Ace S5830, Gio S5660, Pop I559, Fit S5670Documento30 pagine(TUTORIAL) Unlock Sim Network On Samsung Galaxy Mini S5570, Ace S5830, Gio S5660, Pop I559, Fit S5670edwartcano50% (2)

- Stock Statement AUG-18.Documento38 pagineStock Statement AUG-18.Atul TiwariNessuna valutazione finora

- Infineon Board Assembly Recommendations WaferLevelBGA Package v05 00 enDocumento21 pagineInfineon Board Assembly Recommendations WaferLevelBGA Package v05 00 enDiego SantosNessuna valutazione finora

- CM2880 Wiring Diagram enDocumento1 paginaCM2880 Wiring Diagram enAung Mh62% (21)

- NGR - Ninh Hoa - R#0Documento18 pagineNGR - Ninh Hoa - R#0trungtruc nguyenNessuna valutazione finora

- Mixed-Signal-Electronics: PD Dr.-Ing. Stephan HenzlerDocumento33 pagineMixed-Signal-Electronics: PD Dr.-Ing. Stephan HenzlerAhmed HamoudaNessuna valutazione finora

- Floor Box Brochure Q-1270BDocumento8 pagineFloor Box Brochure Q-1270BEDGAR HUGO CANO HURTADONessuna valutazione finora

- 12 Ict-X PDFDocumento176 pagine12 Ict-X PDFAditya KumarNessuna valutazione finora

- List Android New Application and Tools 2012Documento58 pagineList Android New Application and Tools 2012Muhammad RizwanNessuna valutazione finora

- Datasheet: SE-B1, B2, B3, B4Documento4 pagineDatasheet: SE-B1, B2, B3, B4Juan GuzmanNessuna valutazione finora

- ARM Case StudyDocumento4 pagineARM Case StudyUSystems LimitedNessuna valutazione finora

- Pages From Washer Dryer MeralcoDocumento1 paginaPages From Washer Dryer MeralcoLEON SOTNASNessuna valutazione finora

- 3va1225 5ef42 0aa0Documento5 pagine3va1225 5ef42 0aa0Alexander Urriola JimenezNessuna valutazione finora

- 2000-05 The Computer Paper - Ontario EditionDocumento143 pagine2000-05 The Computer Paper - Ontario Editionthecomputerpaper0% (1)