Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DIN 1055 6 2005silos - Parte2

Caricato da

Angel AlvarezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DIN 1055 6 2005silos - Parte2

Caricato da

Angel AlvarezCopyright:

Formati disponibili

DIN 1055-6:2005-03

REFERENCES TO OTHER STANDARDS

The documents mentioned below are required for using this standard. In case of dated references, only the edition mentioned is applicable. In case of undated references the latest edition of the document mentioned is applicable (inclusive of all revisions). DIN 1045-1 Plain concrete, reinforced and prestressed concrete structures - Part 1: design and construction DIN 1055-1 Actions on structures part 1: specific gravity and surface loads of building materials, building components and storage materials DIN 1055-3 Actions on structures part 3: self loads and superimposed loads for high buildings DIN 1055-4 DIN 1055-5 DIN 1055-7 DIN 1055-9 DIN 1055-10 Actions on structures part 4: wind loads Actions on structures part 5: snow and ice loads Actions on structures part 7: temperature actions Actions on structures part 9: unusual actions Actions on structures part 10: actions due to cranes and machines DIN 1055-100 Actions on structures part 100: bases of structural planning: security concepts and rules for design calculations

16

DIN 1055-6:2005-03 DIN EN 26184-1 Explosion protection systems part 1: determination of explosion indices of combustible dust in air DIN EN 1127-1 Explosive atmospheres explosion protection part 1: basic concepts and methodology DIN EN 50014 Electrical equipment for areas with explosion hazard general specifications ISO 3898:1997 VDI 2263 Bases for design of structures notations, general symbols Dust fires and dust explosions; dangers, evaluation and protective measures VDI 3673 Sheet 1 Pressure relief of dust explosions

DEFINITIONS AND SYMBOLS

3.1

Definitions

The definitions given below as well as those given in DIN 1055-100 are applicable to this standard.

3.1.1 Aerated silo bottom A silo bottom in which grooves (aeration channels) have been provided, through which air is injected in order to activate the bulk material flow in the area above the silo bottom (see figure 6b).

17

DIN 1055-6:2005-03

3.1.2 Internal diameter of a silo cross-section dc The diameter of the largest inscribed circle of the inner cross-section of a silo bin (see figure 1d).

3.1.3 Circular silo A silo whose ground plan or shaft cross-section shows a circular form (see figure 1 d)

3.1.4 Cohesion Shear strength of the bulk material when direct stress does not act in the plane of breach

3.1.5 Conical hopper A hopper in which the inclined side-surfaces converge at a point, which can as a rule ensure an axially symmetric flow of bulk material

3.1.6 Eccentric discharge A flow profile in the bulk material in which the distribution of the moving bulk material is unsymmetrical with relation to the vertical central axis. This is usually due to an eccentrically placed outlet opening (see figures 3c and 3d, 4b and 4c). It can, however, also happen due to other phenomena which lead to non-symmetry (see figure 5d).

18

DIN 1055-6:2005-03 3.1.7 Eccentric filling A situation during or after the filling of the silo, in which the peak of the banked-up bulk material surface (peak of the banked-up cone) is no longer centered in the vertical central axis of the silo (see figure 1b).

3.1.8 Equivalent bulk material surface Height of the envisaged leveled (horizontal) bulk material surface, which is the result of the volume balance between the envisaged and the actual pattern of the surface shape (see figure 1a)

3.1.9 Hopper for expanded flow A hopper in which the side surfaces in the lower part of the hopper are steep enough to create a mass flow, while the side surfaces in the upper part of the hopper have a more gradual inclination so that a core flow can be expected there (see figure 6d). This arrangement reduces the height of the hopper and at the same time ensures a reliable discharge.

3.1.10 Horizontal (silo) bottom The inner bottom surface of the silo with an inclination that is less than 5o

3.1.11 Flow profile The geometric form of the bulk material that is flowing out, when the flow is fully developed (see figures 2 to 5). The silo is in this case is almost completely filled-up (state of maximum fill).

19

DIN 1055-6:2005-03 3.1.12 Fluidized bulk material That state of a stored powdery bulk material in which it contains a large proportion of air pockets with a pressure gradient which acts against the weight of the particles and counterbalances the same. The air can either be drawn in by means of specific ventilation or be introduced through the filling process. A bulk material is designated as fluidized even if only a part of the weight of the bulk material is counterbalanced by the air pockets.

3.1.13 Free-flowing granular material Granular bulk material in which the flow pattern is not noticeably influenced by cohesion

3.1.14 Fully filled state A silo is in the fully filled state when the surface of the bulk material has achieved the highest position that it can possibly acquire within the service life of the structure while the silo is in operation. NOTE:

This is taken as the ruling condition for design calculations of silos.

3.1.15 Core flow Flow profile, in which a flow channel develops in the bulk material above the outlet opening, while the bulk material remains undisturbed in the area between the flow channel and the silo wall (see figure 2) NOTE:

The flow channel can, in such case, come into contact with the vertical silo wall one

would then term it mixed flow or it can stretch right up to the surface without any point of contact whatsoever with the silo wall, in which case the term funnel flow or shaft flow is used to describe it.

20

DIN 1055-6:2005-03 3.1.16 Granular material Material which is composed of separate and individual grains of specific particles, with the particles having more or less equal dimensions and where the air between the individual grains plays only a marginal role in the determination of the loads and has only a marginal influence on the bulk material flow.

3.1.17 High fill speed That condition in a silo, in which the speed of the filling leads to an intake of air of such an order that it would affect the pressure ratios at the wall.

3.1.18 Homogenizing silos Silos in which the bulk material is homogenized with the help of fluidization, i.e. homogenized by means of mixing.

3.1.19 Hopper Silo bottom with inclined walls

3.1.20 Hopper load ratio value F A value which specifies the relationship between the normal load pn on the inclined hopper walls and the mean vertical load pv at this position in the bulk material. 3.1.21 Silo of medium slimness A silo whose ratio of height to diameter lies between 1.0 < hc / dc < 2.0 NOTE: 3.1.22

exceptions are defined in 5.3.

21

DIN 1055-6:2005-03 Internal funnel flow Flow profile with funnel flow in which the flow channel limit stretches up to the surface of the bulk material without the flow area coming into contact with the silo wall in the process (see figures 2 and 3).

3.1.23 Horizontal load ratio K A value which specifies the relationship between the mean horizontal load pn acting on the vertical silo walls, and the mean vertical load pv at this position in the bulk material. 3.1.24 Marginal cohesion A bulk material sample shows a marginal cohesion when the cohesion c is smaller than 4% of the pre-consolidation stress r NOTE

a process for the determination of cohesion is given in C.9

3.1.25 Mass flow Flow profile in which all the bulk material particles in the silo are simultaneously in motion during discharge (see figure 2a)

3.1.26 Mixed flow Core flow profile in which the flow channel, which is still beneath the bulk material surface, comes into contact with the vertical silo walls (see figures 2c and 4)

3.1.27 Non-circular silo A silo, wherein the cross-section is not a circle (see figure 1)

22

DIN 1055-6:2005-03 3.1.28 Bulk material A term used to describe a granular material ranging from a dust-like to a large-grained variety with and without cohesion, which contains pores in addition to and in-between the individual solid material particles that may be filled with air or moisture.

3.1.29 Reference surface load Local load perpendicular to the vertical silo wall to be placed at any chosen height in a specific portion of its surface.

3.1.30 Funnel flow Flow profile in which the bulk material is in motion above the outlet opening in a vertical or almost vertical flow channel, but is in a state of rest next to the flow channel (see figures 2 and 3). NOTE

If the outlet opening is placed eccentrically (see figures 3c and d) or if due to certain factors

the flow channel deviates from the vertical axis above the discharge (see figure 5), the flow of the bulk material can appear against the wall.

3.1.31 Level flow Flow profile in a silo with a rectangular or a quadratic cross-section and a slit-shaped outlet opening. The discharge slit runs parallel to two silo walls. Its length corresponds to the length of both these silo walls.

3.1.32 Powdery bulk material A bulk material whose mean particle size is smaller than 0.05 mm

23

DIN 1055-6:2005-03 3.1.33 Silo with braced wall Silo with a horizontal bottom and and a height to diameter ratio of hc / dc < 0.4 3.1.34 Flat hopper A hopper in which the full amount of wall friction is not mobilized

3.1.35 Silo A structure for storage of bulk material

3.1.36 Slim silo A silo with a height-diameter ratio of hc / dc > 2.0, or one which fulfills the additional conditions given in 5.3

3.1.37 Slimness Ratio of the height to diameter hc / dc of the vertical portion of the silo 3.1.38 Low silo A silo with a height-diameter ratio of 0.4 < hc / dc < 1.0 or one in which the additional conditions as per 5.3 are fulfilled. NOTE

silo category. In case of a height-diameter ratio of hc / dc < 0.4, and if the silo contains a hopper, the silo

will fall into the category of a low silo. Otherwise in case of a flat silo bottom it falls into the braced-wall

24

DIN 1055-6:2005-03 3.1.39 Steep hopper A hopper in which the full wall friction is mobilized after the filling 3.1.40 Stress in the bulk material Force per unit area within the stored bulk material

3.1.41 Tank A structure for storage of fluids

3.1.42 A thick-walled silo A silo with a diameter-to-wall thickness ratio which is less than dc /t = 200 3.1.43 A thin-walled silo A silo with a diameter-to-wall thickness ratio which is greater than dc /t = 200 3.1.44 Wall friction Force per unit area along the silo wall (vertical or inclined) on account of friction between the bulk material and the silo wall.

3.1.45 Hopper junction The section between the hopper and the vertical silo wall, i.e. the transition from the vertical part of the silo into the hopper

25

DIN 1055-6:2005-03 3.1.46 Vertical Silo shaft The part of the silo which comprises of the vertical walls

3.1.47 Wedge-shaped hopper A hopper in which the surfaces converge at a slit for ensuring an even flow of the bulk material; the walls of each of the other two hoppers run vertically

3.2

Symbols

3.2.1 General A list of basic symbols (letter symbols) is given in DIN 1055-100. The additional letter symbols for this part of the standard are given below. The symbols used are based on the conventions of ISO 3898:1997.

3.2.2 Latin letters, capital A Ac cross-section of the vertical shaft cross-section of the flow channel in case of eccentric discharge (large

eccentricities) B C Co Cop depth parameter in case of eccentrically filled low silos load augmentation factor discharge factor (load augmentation factor during discharge) for the bulk material bulk material parameter for the reference surface load (load augmentation factor)

26

DIN 1055-6:2005-03 Cb Ch Cpe Cpf CS CT load augmentation factor for the bottom loads load augmentation factor for the horizontal discharge loads load augmentation factor for the reference surface loads during discharge load augmentation factor for the reference surface loads in case of fill loads correction value for slimness in a silo with medium slimness load augmentation factor for making allowance for temperature differences or changes Cw E Es Ew F correction value for discharge for the wall friction loads (load augmentation factor) ratio of eccentricity (during fill and discharge) to silo radius effective elasticity modulus of the stored bulk material at the relevant stress level elasticity modulus of the silo wall relationship between the vertical loads on the silo wall and the mean vertical load in the bulk material at this point Fe load ratio in the hopper during the discharge (relationship between loads perpendicular to the silo wall and mean vertical loads in the bulk material) Ff load ratio in the hopper after the filling (relationship between loads perpendicular to the silo wall and mean vertical loads in the bulk material)

27

DIN 1055-6:2005-03 Fpe integral of the horizontal reference surface load for thin walled circular silos in the case of discharge loads Fpf integral of the horizontal reference surface load for thin walled circular silos in the case of filling loads G ratio of the radius of the flow channel to the radius of the internal cross-section of a circular silo K Km Ko characteristic value of the horizontal load ratio mean value of the horizontal load ratio value of K when horizontal elongation as well as principal stresses that run or are aligned horizontally and vertically are ruled out Pwe characteristic value of the sum total of the wall friction loads for each running meter in the circumferential direction of the vertical silo wall in the case of discharge loads Pwf characteristic value of the sum total of the wall friction loads for each running meter in the circumferential direction of the vertical silo wall in the case of fill loads PzSk characteristic value of the wall loads for each running meter in the circumferential direction of the vertical silo wall for low silos and large filling eccentricities S geometry factors for the hopper loads (= 2 in the case of cone shaped hoppers, =1 in the case of wedge shaped hoppers)

inner circumference of the cross-section of the vertical silo shaft

28

DIN 1055-6:2005-03

Usc

(inner) circumferential length of the flow channel in the contact zone up till the non flow zone of the bulk material during discharge with large eccentricities

Uwc

(inner) circumferential length of the flow channel in the contact area with the silo wall during discharge with large eccentricities

depth variation function: function for the description of the increase in load with increasing depth in the silo

YJ YR

depth variation function of the theory acc. to Janssen depth variation function for small silos

3.2.3 Latin letters, small a ax side length of a silo with a rectangular or a hexagonal cross-section (see figure 1d) divergence-coefficient (-factor) or conversion factor for calculating the upper and lower characteristic bulk material parameters from the mean values aK a a a divergence-coefficient or conversion factor for the horizontal load ratio divergence-coefficient or conversion factor for the bulk material specific gravity divergence-coefficient or conversion factor for the angle of the internal friction divergence-coefficient (-factor) or conversion factor for the coefficients of wall friction

29

DIN 1055-6:2005-03 b b c dc e ec width of a rectangular silo (see figure 1d) empirical coefficient for the hopper loads cohesion of the bulk material characteristic dimensions for the inner cross-section of the silo (see diagram 1d) the larger value of the eccentricities ef and eo eccentricities of the central axis of the flow channel during discharge with large eccentricities (see figure 11) ef largest eccentricity of the bulk cone at the bulk material surface during filling (see figure 1b) ef,cr largest fill eccentricity for which the simplified rules for the allowance for marginal eccentricities can be used (ef,cr = 0.25dc ) eo eo,cr eccentricities of the centre point of the outlet opening (see figure 1b) largest eccentricity of the outlet opening for which the simplified rules for the allowance for eccentricities can be used (eo,cr = 0.25dc ) et eccentricities of the peak of the fill-up cone at the bulk material surface when the silo is filled up (see figure 1b) et,,cr largest eccentricity of the fill-up cone at the bulk material surface for which the simplified rules for the allowance for eccentricities can be used (et,,cr = 0.25dc )

30

Potrebbero piacerti anche

- Errata 1 ASCE 7-10 Table 4-11Documento4 pagineErrata 1 ASCE 7-10 Table 4-11Ali AlomyNessuna valutazione finora

- The Boundary Element Method for Plate AnalysisDa EverandThe Boundary Element Method for Plate AnalysisNessuna valutazione finora

- Relating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaDocumento13 pagineRelating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaAniket DubeNessuna valutazione finora

- What Is Meant by Striking Formwork - Removal of Formwork - Minimum Period - CivilDigitalDocumento7 pagineWhat Is Meant by Striking Formwork - Removal of Formwork - Minimum Period - CivilDigitalAnonymous DlVrxSbVk9Nessuna valutazione finora

- Chapter 1Documento33 pagineChapter 1Divya V SNessuna valutazione finora

- Mba Summer 2019Documento2 pagineMba Summer 2019Deepak SolankiNessuna valutazione finora

- Seismic Response Control Using Base Isolation Strategy, PDFDocumento5 pagineSeismic Response Control Using Base Isolation Strategy, PDFAashiq MohammedNessuna valutazione finora

- Ac I DiaphragmDocumento10 pagineAc I DiaphragmBintaZoelviaNessuna valutazione finora

- 2375 (1) .PDF (Elevator)Documento13 pagine2375 (1) .PDF (Elevator)matthew02012010Nessuna valutazione finora

- StandardiDocumento4 pagineStandardinikolicjelenaNessuna valutazione finora

- Accelerated Brideg Construction in Washington StateDocumento16 pagineAccelerated Brideg Construction in Washington StatesyedabdulhannanNessuna valutazione finora

- Topic 3 (Fema) SdofDocumento217 pagineTopic 3 (Fema) SdofBenedictus CaturNessuna valutazione finora

- Masonary Design Working StressDocumento21 pagineMasonary Design Working Stresstaz_taz3Nessuna valutazione finora

- Load CombinationsDocumento3 pagineLoad CombinationsKutty MansoorNessuna valutazione finora

- 17 Structural Seismic and Geotechnical EngineeringDocumento2 pagine17 Structural Seismic and Geotechnical EngineeringBipul PoudelNessuna valutazione finora

- CIVL 331 - Loads On StructuresDocumento27 pagineCIVL 331 - Loads On Structuresকাফী ওয়াহিদNessuna valutazione finora

- Seismic Analysis of A Liquid Storage Tan PDFDocumento5 pagineSeismic Analysis of A Liquid Storage Tan PDFMesfinNessuna valutazione finora

- SP 17M (14) Student PreviewDocumento12 pagineSP 17M (14) Student PreviewPrasanth B0% (1)

- Sharma Et Al-2017-Structural Concrete As PublishedDocumento9 pagineSharma Et Al-2017-Structural Concrete As PublisheddebiNessuna valutazione finora

- Slim Floor: Long Carbon Europe Sections and Merchant BarsDocumento36 pagineSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongNessuna valutazione finora

- Duct Runs Through Open Web JoistDocumento11 pagineDuct Runs Through Open Web JoistWilliam GrecoNessuna valutazione finora

- CH 17Documento21 pagineCH 17Emil Santos100% (1)

- Study On High-Rise Structure With Oblique Columns Etabs, Gen, SapDocumento7 pagineStudy On High-Rise Structure With Oblique Columns Etabs, Gen, SapMaad Ahmed Al-MaroofNessuna valutazione finora

- İsrail Deprem Yönetmeliği EkiDocumento18 pagineİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanNessuna valutazione finora

- Repeat Load Case For StaadDocumento1 paginaRepeat Load Case For StaadvodasanketNessuna valutazione finora

- Introductory Tutorial - PDF ETABS 2013 PDFDocumento116 pagineIntroductory Tutorial - PDF ETABS 2013 PDFlumilodi100% (1)

- Pca Circular Concrete Tanks PDFDocumento32 paginePca Circular Concrete Tanks PDFEugenio DurbanNessuna valutazione finora

- AISC-360-10 Example 003 PDFDocumento4 pagineAISC-360-10 Example 003 PDFwillowdo100% (1)

- WRC 297 RWE NODE 6340 25febDocumento4 pagineWRC 297 RWE NODE 6340 25febnamasralNessuna valutazione finora

- Different Types of Braced FrameDocumento3 pagineDifferent Types of Braced FrameAJAY KUMAR T.M100% (1)

- (1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesDocumento15 pagine(1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesEdison GuzmanNessuna valutazione finora

- Fan Foundation Frequency CheckDocumento4 pagineFan Foundation Frequency CheckdantevariasNessuna valutazione finora

- Cement SiloDocumento7 pagineCement Silowidad alamriNessuna valutazione finora

- Structural Retrofitting of A Reinforced Concrete ChimneyDocumento6 pagineStructural Retrofitting of A Reinforced Concrete ChimneyIJAERS JOURNALNessuna valutazione finora

- Delhi Metro TEMPERATURE LOADDocumento3 pagineDelhi Metro TEMPERATURE LOADHarikrishnaNessuna valutazione finora

- Simplified Buckling-Strength Determination of Pultruded FRP Structural BeamsDocumento17 pagineSimplified Buckling-Strength Determination of Pultruded FRP Structural BeamswalaywanNessuna valutazione finora

- Special FoundationsDocumento26 pagineSpecial FoundationsCharlotte Tilbury100% (2)

- Xypex Test SummaryDocumento18 pagineXypex Test SummarySamrerng KriengprathanaNessuna valutazione finora

- Cracking in Post-Tensioned Slabs KBondyCrackingSlabsDocumento6 pagineCracking in Post-Tensioned Slabs KBondyCrackingSlabsMark RamnarineNessuna valutazione finora

- Structural Analysis 1: Statically Determinate StructuresDa EverandStructural Analysis 1: Statically Determinate StructuresNessuna valutazione finora

- Class 01 (Ntroduction and Overview of BNBC 2020)Documento23 pagineClass 01 (Ntroduction and Overview of BNBC 2020)Shantonu DeyNessuna valutazione finora

- Concrete 17 - Autogenous Shrinkage 1Documento8 pagineConcrete 17 - Autogenous Shrinkage 1Robert CoelhoNessuna valutazione finora

- Cold Formed Steel Members and SheetingDocumento14 pagineCold Formed Steel Members and SheetingMihai MariusNessuna valutazione finora

- Types of Columns in Building ConstructionDocumento8 pagineTypes of Columns in Building ConstructiongattaiahNessuna valutazione finora

- Tutorial PPT Sap1Documento34 pagineTutorial PPT Sap1Sukhwinder Singh GillNessuna valutazione finora

- Structural LoadsDocumento1 paginaStructural LoadsRamil A. Dela CruzNessuna valutazione finora

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDocumento51 pagineResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamNessuna valutazione finora

- Modal Mass, Stiffness and DampingDocumento5 pagineModal Mass, Stiffness and Dampingkudrilya100% (1)

- Static Structural Analysis Using Sap2000 For Truss and Frame (Beginner Level)Documento35 pagineStatic Structural Analysis Using Sap2000 For Truss and Frame (Beginner Level)Việt Vớ Vẩn100% (1)

- What's New in ASCE 7-16?: The Big ChangesDocumento17 pagineWhat's New in ASCE 7-16?: The Big ChangesTran - VHT - PEB Steel HCMC - DesignNessuna valutazione finora

- Earthquake Resisting System Class NotesDocumento17 pagineEarthquake Resisting System Class NotesatulNessuna valutazione finora

- CR17 2 PDFDocumento0 pagineCR17 2 PDFDiego OrozcoNessuna valutazione finora

- Rebar - Wikipedia, The Free EncyclopediaDocumento7 pagineRebar - Wikipedia, The Free EncyclopediajnmanivannanNessuna valutazione finora

- Report On Code Usage Exercise For DEEPSOIL V2.5 (Installed On An XP Home Edition System)Documento12 pagineReport On Code Usage Exercise For DEEPSOIL V2.5 (Installed On An XP Home Edition System)hricha_20Nessuna valutazione finora

- Treatment of Shear WallsDocumento8 pagineTreatment of Shear Wallsakash kumarNessuna valutazione finora

- Dimeco Catalogo Tecnico Parte1Documento20 pagineDimeco Catalogo Tecnico Parte1Angel AlvarezNessuna valutazione finora

- ArccostsDocumento5 pagineArccostsAngel AlvarezNessuna valutazione finora

- ArccostsDocumento5 pagineArccostsAngel AlvarezNessuna valutazione finora

- ArccostsDocumento5 pagineArccostsAngel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte10Documento1 paginaCalculation CEMA 5 - Parte10Angel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte10Documento1 paginaCalculation CEMA 5 - Parte10Angel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte9Documento5 pagineCalculation CEMA 5 - Parte9Angel AlvarezNessuna valutazione finora

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte4Documento3 pagineCEMA B105.1 Welded Steel Conveyor Pulleys - Parte4Angel AlvarezNessuna valutazione finora

- Ba 1 3Documento16 pagineBa 1 3Angel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte3Documento5 pagineCalculation CEMA 5 - Parte3Angel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte2Documento5 pagineCalculation CEMA 5 - Parte2Angel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte3Documento5 pagineCalculation CEMA 5 - Parte3Angel AlvarezNessuna valutazione finora

- Calculation CEMA 5 - Parte4Documento5 pagineCalculation CEMA 5 - Parte4Angel AlvarezNessuna valutazione finora

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte5Documento3 pagineCEMA B105.1 Welded Steel Conveyor Pulleys - Parte5Angel Alvarez0% (1)

- Calculation CEMA 5 - Parte1Documento5 pagineCalculation CEMA 5 - Parte1Angel AlvarezNessuna valutazione finora

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte2Documento3 pagineCEMA B105.1 Welded Steel Conveyor Pulleys - Parte2Angel AlvarezNessuna valutazione finora

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte3Documento3 pagineCEMA B105.1 Welded Steel Conveyor Pulleys - Parte3Angel AlvarezNessuna valutazione finora

- Manufactura Ingenieria y Tecnologia-KalpakjianDocumento596 pagineManufactura Ingenieria y Tecnologia-Kalpakjiandgeio1988Nessuna valutazione finora

- CEMA B105.1 Welded Steel Conveyor Pulleys - Parte1Documento3 pagineCEMA B105.1 Welded Steel Conveyor Pulleys - Parte1Angel AlvarezNessuna valutazione finora

- Rotolok UK Rotary Valves AirlocksDocumento6 pagineRotolok UK Rotary Valves AirlocksAngel AlvarezNessuna valutazione finora

- Ba 1 3Documento16 pagineBa 1 3Angel AlvarezNessuna valutazione finora

- This Book Is The Milk OkDocumento121 pagineThis Book Is The Milk OkAngel Alvarez100% (1)

- VentilaciónDocumento11 pagineVentilaciónAngel AlvarezNessuna valutazione finora

- Prolite - Wet ScrubberDocumento6 pagineProlite - Wet ScrubberAngel AlvarezNessuna valutazione finora

- 2013 Motor Catalog Toshiba PDFDocumento228 pagine2013 Motor Catalog Toshiba PDFrelicario25Nessuna valutazione finora

- Idler EngrDimDocumento64 pagineIdler EngrDimOrlando MelipillanNessuna valutazione finora

- Basics of Dust Control - enDocumento48 pagineBasics of Dust Control - enMuhammad RafiNessuna valutazione finora

- Simbolos Hidraulicos Din Iso 1219Documento15 pagineSimbolos Hidraulicos Din Iso 1219Angel AlvarezNessuna valutazione finora

- Sulphuric Acid Storage TankDocumento143 pagineSulphuric Acid Storage TankAngel Alvarez100% (6)

- Vibrator Catalog Complete 003 T UpDocumento48 pagineVibrator Catalog Complete 003 T UpAngel AlvarezNessuna valutazione finora

- Supriya 113418799Documento4 pagineSupriya 113418799Kewl JstNessuna valutazione finora

- Highway Engineering B 1Documento8 pagineHighway Engineering B 1Angelica TolentinoNessuna valutazione finora

- Resistor DatasheetDocumento10 pagineResistor DatasheetEndradno KurniaNessuna valutazione finora

- Brain Controlled Car For Disabled Using Artificial IntelligenceDocumento17 pagineBrain Controlled Car For Disabled Using Artificial IntelligenceMdkhanzNessuna valutazione finora

- Liebert PDX PCW Thermal Management System User ManualDocumento184 pagineLiebert PDX PCW Thermal Management System User ManualJeffNessuna valutazione finora

- SQL Server Connectivity Roadmap.: Preliminary TroubleshootingDocumento7 pagineSQL Server Connectivity Roadmap.: Preliminary Troubleshootingapi-3748582Nessuna valutazione finora

- Nupack User Guide 3.2Documento44 pagineNupack User Guide 3.2Dicastelgandolfo VchNessuna valutazione finora

- Batteries and Primitive Survival Ebook 2008+ PDFDocumento333 pagineBatteries and Primitive Survival Ebook 2008+ PDFOceanNessuna valutazione finora

- Fatwa Darul Uloom Deoband - Vol 1Documento276 pagineFatwa Darul Uloom Deoband - Vol 1Ahlehaq100% (3)

- Muhammad Akif Naeem Open Ended Lab Signals and SystemDocumento20 pagineMuhammad Akif Naeem Open Ended Lab Signals and SystemMuhammad Akif NaeemNessuna valutazione finora

- Chapter 6 SlidesDocumento28 pagineChapter 6 Slidesshinde_jayesh2005Nessuna valutazione finora

- BoyapatyDocumento5 pagineBoyapatylalalallalalaaluuuNessuna valutazione finora

- Is 1786Documento5 pagineIs 1786Jeevan ShendreNessuna valutazione finora

- Polylux WebkatalogDocumento96 paginePolylux WebkatalogNesil Abiera50% (2)

- WaterproofingDocumento29 pagineWaterproofingAakansha DNessuna valutazione finora

- Final ProjectDocumento4 pagineFinal Projectsajad soleymanzadeNessuna valutazione finora

- Bearing Detail PDFDocumento1.152 pagineBearing Detail PDFJayesh MachhiNessuna valutazione finora

- 13 Ijee2962nsDocumento15 pagine13 Ijee2962nspurvakul10Nessuna valutazione finora

- Cryogenics Handbook PDFDocumento227 pagineCryogenics Handbook PDFmangyanNessuna valutazione finora

- Depth of InvestigationDocumento8 pagineDepth of InvestigationGogot Pantja ParijogoNessuna valutazione finora

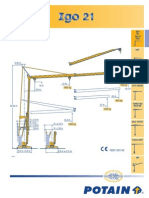

- Potain Igo 21 PDFDocumento4 paginePotain Igo 21 PDFMarco CruzNessuna valutazione finora

- Yousif Alotaibi 01 CVDocumento3 pagineYousif Alotaibi 01 CVyousefx20Nessuna valutazione finora

- Handling An Maintenance of Construction Machineries, Equipments and InstrumentsDocumento13 pagineHandling An Maintenance of Construction Machineries, Equipments and InstrumentsVelmurugan BalasubramanianNessuna valutazione finora

- Bomet CountyDocumento1 paginaBomet CountyPrince AliNessuna valutazione finora

- RISC Vs CISCDocumento13 pagineRISC Vs CISCBehin SamNessuna valutazione finora

- American University of Beirut Aub Thesis TemplateDocumento12 pagineAmerican University of Beirut Aub Thesis TemplateHassane EzzeddineNessuna valutazione finora

- 010 Zircoat MDocumento3 pagine010 Zircoat MvsdeepakchandraNessuna valutazione finora

- Explosion WeldingDocumento22 pagineExplosion WeldingLesther Alexander CorreaNessuna valutazione finora

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocumento15 pagine000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- V7.0 Function ListDocumento48 pagineV7.0 Function ListInyectronix VyhNessuna valutazione finora