Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MTU and DSE Controllers Configuration Guide

Caricato da

ABOUDHTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MTU and DSE Controllers Configuration Guide

Caricato da

ABOUDHCopyright:

Formati disponibili

MTU and DSE Controllers

15 MTU

Engines in the MTU range are split into subgroups depending upon the type of engine governing are employed. These different systems are fully compatible with the DSE Controllers when configured correctly and can allow engine control and diagnostics via the J1939 link. We have collated the following data for the electronically governed engines.

57

MTU and DSE Controllers

15.1 ADEC

ADEC ECU Mounted on the engine

SAM module mounted in the customer panel

15.1.1 ECU FUNCTIONALITY

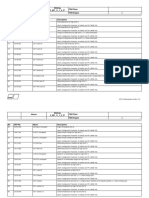

ADEC FUNCTIONALITY MODBUS Engine Hours MODBUS Oil Pressure MODBUS Coolant Temperature MODBUS Engine RPM MODBUS Charge Alt MODBUS Speed Feed Engine speed Oil Pressure Coolant Temperature Battery Voltage Charge Alternator Voltage Engine Hours Number of Starts Oil Temperature Coolant Pressure Inlet Temperature Exhaust Temperature Fuel Temperature Turbo Pressure Fuel Pressure Fuel Consumption Fuel Used Atmospheric Pressure Water in Fuel ADEC FUNCTIONALITY DM1 Conv. Method DM1 Ignored DM1 Amber DM1 Red DM1 Protect DM1 Malfunction Start Stop 1500/1800 switch Idle Mode Speed Control Source address ECU Power ECU Stop J1939 msg Proprietary msg Notes DTC Ignore 4

DSE DSE DSE

0x1 &delay OHECS, RQST, EBC1, CCVS, TSC1 mtu_LS, mtu_SDS, mtu_CONT ECU permanently powered.

LEGEND Function supported Not supported DSE controller measures/calculates the value

DSE

15.1.2 ECU WIRING

DSE TERMINAL DESCRIPTION Fuel Relay Output Start Relay Output CANbus common CANbus H CANbus L MTU ADEC TERMINAL X1 37 X1 43 1 (Hi) 2 (Lo) MTU SAM TERMINAL X23 3 X23 2 X23 1 NOTES Start input of ADEC (DI 7). Connect X1 22 to GND This terminal is optional. Start command is also sent by CAN message. Stop input of ADEC (DI 1). Connect X1 28 to GND Screen for the J1939 cable. Connect at one end only. J1939 + Use only screened 120 impedance cable approved specifically for use in CANbus applications. J1939 Use only screened 120 impedance cable approved specifically for use in CANbus applications.

NOTE:NOTE:- The ADEC ECU is designed to be permanently powered via the emergency emergency stop button on the control panel. NOTE:NOTE:- Cranking of the engine is managed by the ADEC controller following instruction from the DSE controller. NOTE:NOTE:-The ADEC ECU has to be used with in conjunction with the MTU SAM display module.

58

MTU and DSE Controllers

15.1.3 CAN CONFIGURATION

Information regarding these configuration parameters can be found in the products software manual, please refer to section entitled Bibliography for more details.

15.1.3.1 DSE CONFIGURATION SUITE SOFTWARE

These settings are only applicable to DSE controllers which use the DSE Configuration Suite Software. This comprises of the DSE31xx, DSE44xx, DSE6xxx, DSE71xx, DSE72xx, DSE73xx and DSE8xxx series of controllers. The DSE controller must be configured for the MTU ADEC CAN file.

15.1.3.2 DSE5XXX/75XX PC SOFTWARE

These settings are only applicable to DSE controllers which use the DSE5xxx and DSE75xx PC Software. This comprises the DSE5xxx and DSE75xx series of controllers. The DSE controller must be configured for the mtu-ADEC CAN file.

59

MTU and DSE Controllers

15.2 MDEC

15.2.1 ECU FUNCTIONALITY

MDEC FUNCTIONALITY MODBUS Engine Hours MODBUS Oil Pressure MODBUS Coolant Temperature MODBUS Engine RPM MODBUS Charge Alt MODBUS Speed Feed Engine speed Oil Pressure Coolant Temperature Battery Voltage Charge Alternator Voltage Engine Hours Number of Starts Oil Temperature Coolant Pressure Inlet Temperature Exhaust Temperature Fuel Temperature Turbo Pressure Fuel Pressure Fuel Consumption Fuel Used Atmospheric Pressure Water in Fuel MDEC FUNCTIONALITY DM1 Conv. Method DM1 Ignored DM1 Amber DM1 Red DM1 Protect DM1 Malfunction Start Stop 1500/1800 switch Idle Mode Speed Control Source address ECU Power ECU Stop J1939 msg Proprietary msg Notes DTC Ignore N/A

(Not available when using MTU MDEC 303)

DSE

DSE

N/A &delay N/A N/A ECU permanently powered.

LEGEND Function supported Not supported DSE controller measures/calculates the value

DSE

15.2.2 ECU WIRING

DSE TERMINAL DESCRIPTION Fuel Relay Output Start Relay Output CANbus common CANbus H CANbus L MTU MDEC X1 CONNECTER TERMINAL BE9 BE1 E G F NOTES Start input of MDEC Run input of MDEC Screen for the J1939 cable. Connect at one end only. J1939 + Use only screened 120 impedance cable approved specifically for use in CANbus applications. J1939 Use only screened 120 impedance cable approved specifically for use in CANbus applications.

NOTE:NOTE:-The MDEC ECU is designed to be permanently powered however the DSE controller can be configured to switch the ECU power by configuring an Auxiliary output to be ECU power. This output should be used to control the ECU power relay and will turn off the MDEC ECU when the DSE controller is placed into STOP/RESET mode. Note that using this method, the MDEC mode.

ECU takes approximately 30 seconds to power up once the DSE controller is taken out of STOP/RESET

NOTE:NOTE:-Cranking of the engine is managed by the MDEC controller following instruction from the DSE controller. NOTE:NOTE:-The MTU engine can be used with or without the MTU PIM display module. Ensure that MTU are informed prior to the despatch of your engine whether or not you intend to fit fit the PIM module and also that you require CAN for connection to the DSE controller. This will ensure that you receive the engine with the relevant options enabled. Incorrectly set options for PIM and and secondary CAN controller may lead to CAN 1 NODE LOST 180 errors displayed by the DSE module (and MTU PIM module) NOTE:NOTE:-DSE55xx, DSE55xx, DSE75xx DSE75xx and DSE8xxx DSE8xxx can perform synchronising and loadsharing using CAN instructions to the engine ECU when using the MTUMTU-MDECMDEC-304 configuration file in conjunction with compatible compatible MDEC controllers. If in doubt about the MDEC version you have, you are referred to MTU. NOTE:NOTE:-MDEC Speed control is configurable. Ensure it is set to receive speed control signals via the CAN interface.

60

MTU and DSE Controllers

15.2.3 CAN CONFIGURATION

Information regarding these configuration parameters can be found in the products software manual, please refer to section entitled Bibliography for more details.

15.2.3.1 DSE CONFIGURATION SUITE SOFTWARE

These settings are only applicable to DSE controllers which use the DSE Configuration Suite Software. This comprises of the DSE31xx, DSE44xx, DSE6xxx, DSE71xx, DSE72xx, DSE73xx and DSE8xxx series of controllers. Using the MTU MDEC303 CAN file with a version 304 MDEC a warning error code SD CAN SPEED DEMAND 250 will be displayed on the DSE controller (and MTU PIM module). Speed control is not available using the MTU MDEC303 CAN file. If in doubt about the MDEC version you have, you are referred to MTU. When using the MTU MDEC304 CAN file, speed control is available. If in doubt about the MDEC version you have, you are referred to MTU.

When using the MTU MDEC504 CAN file, speed control is available. If in doubt about the MDEC version you have, you are referred to MTU.

Using the MTU MDEC304 CAN file and above will require a SW1 setting of 5.0 and an SW2 setting of 4.0. This setting is only applicable with DSE Load Share Controllers and will need fine tuning during the DSE Four Steps to Successful Synchronisation Commissioning steps.

15.2.3.2 DSE5XXX/75XX PC SOFTWARE

These settings are only applicable to DSE controllers which use the DSE5xxx and DSE75xx PC Software. This comprises the DSE5xxx and DSE75xx series of controllers. Using the mtu-MDEC-303 CAN file with a version 304 MDEC, a warning error code SD CAN SPEED DEMAND 250 will be displayed on the DSE controller (and MTU PIM module). Speed control is not available using the mtu-MDEC-303 CAN file When using the mtu-MDEC-304 CAN file, speed control is available.

NOTE:NOTE:- The mtumtu-MDECMDEC-506 CAN file is not currently available for the DSE5xxx and DSE75xxx range of modules. Please contact the DSE Technical Support Department for more information. Using the MTU MDEC304 CAN file and above will require a SW1 setting of 5.0 and an SW2 setting of 4.0. This setting is only applicable with DSE Load Share Controllers and will need fine tuning during the DSE Four Steps to Successful Synchronisation Commissioning steps. Ensure crank disconnect on Charge Alternator Voltage is disabled (not checked).

61

MTU and DSE Controllers

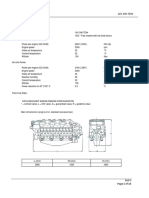

15.3 ECU8

ECU8 Mounted on the engine

Smart Connect module mounted in the customer panel

15.3.1 ECU FUNCTIONALITY

ECU8 FUNCTIONALITY MODBUS Engine Hours MODBUS Oil Pressure MODBUS Coolant Temperature MODBUS Engine RPM MODBUS Charge Alt MODBUS Speed Feed Engine speed Oil Pressure Coolant Temperature Battery Voltage Charge Alternator Voltage Engine Hours Number of Starts Oil Temperature Coolant Pressure Inlet Temperature Exhaust Temperature Fuel Temperature Turbo Pressure Fuel Pressure Fuel Consumption Fuel Used Atmospheric Pressure Water in Fuel ECU8 FUNCTIONALITY DM1 Conv. Method DM1 Ignored DM1 Amber DM1 Red DM1 Protect DM1 Malfunction Start Stop 1500/1800 switch Idle Mode Speed Control Source address ECU Power ECU Stop J1939 msg Proprietary msg Notes DTC Ignore N/A

DSE DSE DSE

0x01 &delay OHECS, RQST, EBC1, CCVS, TSC1 mtu_LS, mtu_SDS, mtu_CONT

LEGEND Function supported Not supported DSE controller measures/calculates the value

DSE

15.3.2 ECU WIRING

DSE TERMINAL DESCRIPTION ECU8 X1 CONNECTOR TERMINAL NOTES External relay used to close terminal 31 to terminal 32. NOTE:NOTE:- On applicable modules, configure the Fuel Relay Output to CAN ECU 31, 32

Fuel Relay Output

Power. Power.

CAUTION! CAUTION!: UTION!:- An external slave relay will be needed. Check Check the current consumption and specify relay accordingly. accordingly.

DSE TERMINAL DESCRIPTION CANbus common CANbus H CANbus L

SMART CONNECT X4 CONNECTOR TERMINAL 3 1 2

NOTES Screen for the J1939 cable. Connect at one end only. J1939 + Use only screened 120 impedance cable approved specifically for use in CANbus applications. J1939 Use only screened 120 impedance cable approved specifically for use in CANbus applications.

62

MTU and DSE Controllers

15.3.3 CAN CONFIGURATION

Information regarding these configuration parameters can be found in the products software manual, please refer to section entitled Bibliography for more details.

15.3.3.1 DSE CONFIGURATION SUITE SOFTWARE

These settings are only applicable to DSE controllers which use the DSE Configuration Suite Software. This comprises of the DSE31xx, DSE44xx, DSE6xxx, DSE71xx, DSE72xx, DSE73xx and DSE8xxx series of controllers. The DSE controller must be configured for the MTU ECU8 CAN file.

Using the MTU ECU8 CAN file will require a SW1 setting of 5.0 and an SW2 setting of 4.0. This setting is only applicable with DSE Load Share Controllers and will need fine tuning during the DSE Four Steps to Successful Synchronisation Commissioning steps.

15.3.3.2 DSE5XXX/75XX PC SOFTWARE

These settings are only applicable to DSE controllers which use the DSE5xxx and DSE75xx PC Software. This comprises the DSE5xxx and DSE75xx series of controllers.

NOTE:NOTE:- The MTU ECU8 CAN file is not currently available for the DSE5xxx and DSE75xxx range of modules. Please contact the DSE Technical Support Department for more information.

63

Potrebbero piacerti anche

- E532304 - 00E - ADEC and SAM Connection InterfaseDocumento202 pagineE532304 - 00E - ADEC and SAM Connection InterfaseAlex Robledo Olarte92% (12)

- Error Code ECU8Documento16 pagineError Code ECU8Giang DoNessuna valutazione finora

- ADEC Genset Functions and ParameterDocumento52 pagineADEC Genset Functions and ParameterRizki Heru Hermawan83% (23)

- ADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFDocumento246 pagineADEC™ - Electronics Documentation For Electronic Engine Control Unit ECU-7 - 2007 - MTU® PDFpevare90% (30)

- Mtu 16v2000g65 PDFDocumento144 pagineMtu 16v2000g65 PDFPhạm Hoài AnhNessuna valutazione finora

- Error Code MTU ADEC ECU 7Documento24 pagineError Code MTU ADEC ECU 7Sudiono Ajb92% (12)

- ADEC™ - Error List - 2006 - MTU® PDFDocumento33 pagineADEC™ - Error List - 2006 - MTU® PDFpevare100% (4)

- Dvigatel Mtu 12v2000g65eDocumento155 pagineDvigatel Mtu 12v2000g65eAziz Arrahal100% (1)

- 1600 Series Parts and OverviewDocumento94 pagine1600 Series Parts and OverviewJorge Eraldo Albarran PoleoNessuna valutazione finora

- Manual MTUDocumento134 pagineManual MTUjuan pablo zuniga100% (2)

- MtuDocumento464 pagineMtuDarin Hood100% (12)

- E531827 00E CAN FieldbusDocumento46 pagineE531827 00E CAN Fieldbusarcangel_picNessuna valutazione finora

- Adec Advanced Diesel Engine Controller For Genset Application 2007Documento11 pagineAdec Advanced Diesel Engine Controller For Genset Application 2007Mauro Miranda Couto100% (2)

- ADEC Error List: ECU7 - SoftwareDocumento33 pagineADEC Error List: ECU7 - SoftwareGiang Do100% (1)

- MDEC Stationary DieselDocumento5 pagineMDEC Stationary DieselAhmad Shahrul Mohamed100% (2)

- Engine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsDocumento62 pagineEngine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsGeorge Barsoum100% (3)

- XZ599001-200541 - Serie 2000 - ComapDocumento53 pagineXZ599001-200541 - Serie 2000 - ComapGiang Do100% (1)

- MTU 4000 With MIP v1.8Documento23 pagineMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- ADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFDocumento49 pagineADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFaup100% (3)

- System Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Documento198 pagineSystem Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Minh Le100% (1)

- ADEC Advanced Diesel Engine ControllerDocumento49 pagineADEC Advanced Diesel Engine Controllerpevare100% (12)

- Mtu Sam & Adec E532304 - 00eDocumento216 pagineMtu Sam & Adec E532304 - 00ecampioed85% (13)

- E532284 - Funcional Descrition MtuDocumento42 pagineE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- Adec 1600Documento84 pagineAdec 1600Sudiono Ajb50% (2)

- 4000 G OverhoolDocumento745 pagine4000 G Overhoolaup100% (2)

- Option H5, H7 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK, Rev. I PDFDocumento84 pagineOption H5, H7 and H13 MTU MDEC, ADEC, J1939 CANbus Engine Interface 4189340674 UK, Rev. I PDFoscarafonso100% (2)

- MTU Engine 4000-Series Functional DescriptionDocumento42 pagineMTU Engine 4000-Series Functional DescriptionAlex100% (1)

- ComAp Electronic Engines Support For Perkins 2Documento15 pagineComAp Electronic Engines Support For Perkins 2Bhuneshwar Prasad100% (1)

- 00a MTU Abreviation ListDocumento12 pagine00a MTU Abreviation ListJuan Rivera100% (2)

- Edoc - Pub E53173000eDocumento64 pagineEdoc - Pub E53173000eBayanaka TehnikNessuna valutazione finora

- Ecu - 7 Präsentation 11 07 - C&i - eDocumento40 pagineEcu - 7 Präsentation 11 07 - C&i - eRogelio Adolfo Leiva Barraza67% (3)

- Mtu4000 s2 Gen DescDocumento48 pagineMtu4000 s2 Gen Descgabriel100% (1)

- ADEC Genset Functions and ParameterDocumento52 pagineADEC Genset Functions and ParameterOunna PechNessuna valutazione finora

- 06-Mics Kerys - Navigation: Titre de La DiapositiveDocumento145 pagine06-Mics Kerys - Navigation: Titre de La DiapositiveMohammad HazbehzadNessuna valutazione finora

- ADEC™ - Advanced Diesel Engine Controller For Genset Application - 2007 - MTU® PDFDocumento11 pagineADEC™ - Advanced Diesel Engine Controller For Genset Application - 2007 - MTU® PDFpevare100% (5)

- Workshopman 03Documento33 pagineWorkshopman 03Mohand Oubélaid Ait HammouNessuna valutazione finora

- Adjustments Sam Via MinidialogDocumento4 pagineAdjustments Sam Via Minidialogarcangel_pic100% (1)

- Мануал L33 - new - MS50199 - 01EDocumento16 pagineМануал L33 - new - MS50199 - 01EAleksey100% (1)

- MTU 4000 Maintenance ScheduleDocumento35 pagineMTU 4000 Maintenance Schedulenereomad100% (8)

- 02ecu 8sameDocumento69 pagine02ecu 8sameSudiono Ajb80% (5)

- Mtu Diesel Engine MS150068 - 01eDocumento287 pagineMtu Diesel Engine MS150068 - 01eM Nuraga Lazuardy Ramadhan100% (1)

- Series 2000 For Power GenerationDocumento6 pagineSeries 2000 For Power GenerationBarham Gen BarhamNessuna valutazione finora

- Mtu Reach SVHC 2018-10-29 enDocumento75 pagineMtu Reach SVHC 2018-10-29 enalawi50% (2)

- MTUDocumento16 pagineMTUWira Karya Diesel40% (5)

- 8V 10V 12V1600 Operation & Maintenance MS150076 02EDocumento138 pagine8V 10V 12V1600 Operation & Maintenance MS150076 02EETGI100% (3)

- Field Automation Level Assembly CatalogDocumento254 pagineField Automation Level Assembly CatalogAbdul KhaliqNessuna valutazione finora

- APP. Installation Detroit Diesel S2000 7SA2000Documento233 pagineAPP. Installation Detroit Diesel S2000 7SA2000SonthiM100% (3)

- 12V Mtu 4000Documento248 pagine12V Mtu 4000Mig Vazq100% (5)

- Installation and Commissioning Instructions: Electronic Control System Engine Interface (EIM) Application: MarineDocumento114 pagineInstallation and Commissioning Instructions: Electronic Control System Engine Interface (EIM) Application: MarineWilliam PeeleNessuna valutazione finora

- SensorsDocumento9 pagineSensorsGiang DoNessuna valutazione finora

- Mtu 1600 Operating InstructionsDocumento134 pagineMtu 1600 Operating InstructionsGerman O.Nessuna valutazione finora

- CanbuswiringforDSEcontrollers (Motores Eletrônicos)Documento34 pagineCanbuswiringforDSEcontrollers (Motores Eletrônicos)Gustavo PereiraNessuna valutazione finora

- Smart Connect: 1 © MTU TC FN / Actual State: 07/2009 Geno - Basics - MechDocumento20 pagineSmart Connect: 1 © MTU TC FN / Actual State: 07/2009 Geno - Basics - MechAnonymous uEt1sNhU7l71% (14)

- Operating Instructions: Diesel Engine 12 V 4000 T94, T94LDocumento197 pagineOperating Instructions: Diesel Engine 12 V 4000 T94, T94LCristian A.Nessuna valutazione finora

- ADEC Advanced Diesel Engine Controller For Genset Application 2007 MTU PDFDocumento11 pagineADEC Advanced Diesel Engine Controller For Genset Application 2007 MTU PDFthanhhai3150% (2)

- Description of Option H6 (Serial Communication - Cummins GCS)Documento15 pagineDescription of Option H6 (Serial Communication - Cummins GCS)farhan rajib100% (1)

- User Manual Thomson Mec 310#genset Controller Option J Canbus j1939 eDocumento14 pagineUser Manual Thomson Mec 310#genset Controller Option J Canbus j1939 eJapraAnugrahNessuna valutazione finora

- BMW Hints and TipsDocumento3 pagineBMW Hints and Tipsnorfitri100% (5)

- Gencomm Control KeysDocumento4 pagineGencomm Control Keyskazishah100% (1)

- Waukesha 7101 SpecDocumento4 pagineWaukesha 7101 SpecDennis Daniel100% (1)

- M. Honda GCV 160Documento48 pagineM. Honda GCV 160DEBRIX100% (2)

- Amfandmains Parallel Controller Deepseaelectronics: DescriptionDocumento2 pagineAmfandmains Parallel Controller Deepseaelectronics: DescriptionSandro MunizNessuna valutazione finora

- Engine Dataplate: Automotive and IndustrialDocumento8 pagineEngine Dataplate: Automotive and IndustrialABOUDHNessuna valutazione finora

- UT-2505 Converter ManualDocumento21 pagineUT-2505 Converter ManualABOUDHNessuna valutazione finora

- DSE556datasheetDocumento2 pagineDSE556datasheettonwalaNessuna valutazione finora

- ABB Tmax Circuit BreakersDocumento32 pagineABB Tmax Circuit BreakersABOUDHNessuna valutazione finora

- Monicon: Generator Control ModuleDocumento2 pagineMonicon: Generator Control ModuleABOUDHNessuna valutazione finora

- User Guide: Outdoor Security Wi-Fi Camera Tapo C310Documento29 pagineUser Guide: Outdoor Security Wi-Fi Camera Tapo C310ran_tomNessuna valutazione finora

- Track Mounted Socket: R Ordering InformationDocumento2 pagineTrack Mounted Socket: R Ordering InformationABOUDHNessuna valutazione finora

- ABB Tmax Circuit BreakersDocumento63 pagineABB Tmax Circuit BreakersXander LeeNessuna valutazione finora

- Caterpillar Connection Diagrams Sr4 and Sr4bDocumento65 pagineCaterpillar Connection Diagrams Sr4 and Sr4bMinggoy S Palabra67% (3)

- 550 BrochureDocumento4 pagine550 BrochureABOUDHNessuna valutazione finora

- Deep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionsDocumento2 pagineDeep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionssdmelNessuna valutazione finora

- Emcp3 FinalDocumento169 pagineEmcp3 FinalĐoàn Ngọc Đại100% (5)

- ABB RelaysDocumento18 pagineABB RelaysABOUDHNessuna valutazione finora

- AutomaticCircuitRecloser SF6GasDocumento8 pagineAutomaticCircuitRecloser SF6GasABOUDHNessuna valutazione finora

- Pmi Rda-Rdat Series Batterycharger Userbook - enDocumento44 paginePmi Rda-Rdat Series Batterycharger Userbook - enABOUDH100% (1)

- Can and Dse ControllersDocumento88 pagineCan and Dse ControllersABOUDH100% (1)

- Note Alt R250EN 06-07Documento4 pagineNote Alt R250EN 06-07ABOUDHNessuna valutazione finora

- 70 1Documento7 pagine70 1ABOUDHNessuna valutazione finora

- AP Clutch Surplus Parts List 3-3-2011Documento2 pagineAP Clutch Surplus Parts List 3-3-2011ABOUDHNessuna valutazione finora

- Open Top HC Container SpecsDocumento1 paginaOpen Top HC Container SpecsABOUDHNessuna valutazione finora

- Selecting A ChargerDocumento4 pagineSelecting A ChargerABOUDHNessuna valutazione finora

- R 220 AvrDocumento8 pagineR 220 AvrABOUDHNessuna valutazione finora

- MCS2Documento3 pagineMCS2ABOUDHNessuna valutazione finora

- Dse 5210-5220Documento3 pagineDse 5210-5220ABOUDHNessuna valutazione finora

- 86 Catalogue Cre 2013 04 V8Documento94 pagine86 Catalogue Cre 2013 04 V8ABOUDHNessuna valutazione finora

- DSE 6010 DatasheetDocumento2 pagineDSE 6010 DatasheetRabih MradNessuna valutazione finora

- 4420Documento2 pagine4420ABOUDHNessuna valutazione finora

- DSE 6010 DatasheetDocumento2 pagineDSE 6010 DatasheetRabih MradNessuna valutazione finora

- Assignment - 3 (17MAT41)Documento2 pagineAssignment - 3 (17MAT41)Mayank Saini0% (1)

- Newton's Law of Cooling ExplainedDocumento7 pagineNewton's Law of Cooling ExplainedReggie DuenasNessuna valutazione finora

- Handbook of Magnetic PDFDocumento572 pagineHandbook of Magnetic PDFQassem MohaidatNessuna valutazione finora

- Significant Figures WorksheetDocumento2 pagineSignificant Figures WorksheetKevin BakerNessuna valutazione finora

- Stopping Sight DistanceDocumento28 pagineStopping Sight DistanceEman MousaNessuna valutazione finora

- GC Methode Development RestekDocumento71 pagineGC Methode Development RestekbenyNessuna valutazione finora

- Vulkollan: The Ultimate ElastomerDocumento24 pagineVulkollan: The Ultimate ElastomerMS Mechanic HSM 2Nessuna valutazione finora

- June 2014 QP - M2 EdexcelDocumento28 pagineJune 2014 QP - M2 EdexcelAmmar KarimiNessuna valutazione finora

- Joint Probability Distributions and Random SamplesDocumento22 pagineJoint Probability Distributions and Random SamplesChandrahasa Reddy Thatimakula100% (1)

- Bachelor of Science in Agricultural and Biosystems EngineeringDocumento4 pagineBachelor of Science in Agricultural and Biosystems Engineeringsheil.cogayNessuna valutazione finora

- L&T Project ReportDocumento48 pagineL&T Project Reportdeepakarora201188Nessuna valutazione finora

- 3 Basic Electrical EngineeringDocumento4 pagine3 Basic Electrical EngineeringJyothsna VayyalaNessuna valutazione finora

- TP PDFDocumento1 paginaTP PDFRîkèñ PâtélNessuna valutazione finora

- Research Paper in MicrowavesDocumento10 pagineResearch Paper in MicrowavesManoling PanopioNessuna valutazione finora

- Tehnički List Praha 9005 Epoxid-Poliester, Sitna Struktura, MatDocumento2 pagineTehnički List Praha 9005 Epoxid-Poliester, Sitna Struktura, Matjoki_loNessuna valutazione finora

- Presenting The PolyGame: Playing Seriously With Mitigation Strategies For Climate ChangeDocumento32 paginePresenting The PolyGame: Playing Seriously With Mitigation Strategies For Climate Changem_trNessuna valutazione finora

- Polarization Index TestDocumento3 paginePolarization Index TestShahriar AhmedNessuna valutazione finora

- The Effect of Vehicle Noise On Automatic Speech Recognition SystemsDocumento4 pagineThe Effect of Vehicle Noise On Automatic Speech Recognition SystemsadityaNessuna valutazione finora

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Documento6 pagineHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseNessuna valutazione finora

- MARK SCHEME For The June 2005 Question PaperDocumento6 pagineMARK SCHEME For The June 2005 Question PaperUmer AbbasNessuna valutazione finora

- Kepler's Three Laws of Planetary MotionDocumento12 pagineKepler's Three Laws of Planetary MotionAlyssa Rose RamosNessuna valutazione finora

- Gothic cathedral structural analysisDocumento43 pagineGothic cathedral structural analysisManuelPérezNessuna valutazione finora

- Factors Affecting The Velocity of Sound in A GasDocumento2 pagineFactors Affecting The Velocity of Sound in A GasShuvam ShahNessuna valutazione finora

- Aits 2223 FT Vi Jeem OfflineDocumento15 pagineAits 2223 FT Vi Jeem OfflineSuvrajyoti TaraphdarNessuna valutazione finora

- GE6251 Basic Civil and Mechanical Engineering Regulation 2013 Lecture NotesDocumento112 pagineGE6251 Basic Civil and Mechanical Engineering Regulation 2013 Lecture NotesSasi Dharan100% (1)

- Column C section and tie detailsDocumento1 paginaColumn C section and tie detailsبه شدار ازاد عبدالرحمن عليNessuna valutazione finora

- Electric Field and Coulomb's LawDocumento19 pagineElectric Field and Coulomb's LawYukiko HachiNessuna valutazione finora

- ME304 HOMEWORK 3Documento3 pagineME304 HOMEWORK 3Steve KrodaNessuna valutazione finora

- Wind Loading of Industrial, Mining and Petrochemical StructuresDocumento16 pagineWind Loading of Industrial, Mining and Petrochemical StructuresapirakqNessuna valutazione finora

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDa EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Pipeline Integrity: Management and Risk EvaluationDa EverandPipeline Integrity: Management and Risk EvaluationValutazione: 4.5 su 5 stelle4.5/5 (6)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesDa EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNessuna valutazione finora

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilDa EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNessuna valutazione finora

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationDa EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationValutazione: 4.5 su 5 stelle4.5/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisDa EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNessuna valutazione finora

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsDa EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsValutazione: 5 su 5 stelle5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDa EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesValutazione: 4 su 5 stelle4/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsDa EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNessuna valutazione finora

- Subsea Valves and Actuators for the Oil and Gas IndustryDa EverandSubsea Valves and Actuators for the Oil and Gas IndustryValutazione: 5 su 5 stelle5/5 (1)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- Petroleum Rock Mechanics: Drilling Operations and Well DesignDa EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignValutazione: 5 su 5 stelle5/5 (1)

- Compression Machinery for Oil and GasDa EverandCompression Machinery for Oil and GasKlaus BrunValutazione: 4 su 5 stelle4/5 (4)