Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tea Manufacture

Caricato da

amit huidromCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tea Manufacture

Caricato da

amit huidromCopyright:

Formati disponibili

Copyright: Alan and Iris Macfarlane 2002

MODERN METHODS OF TEA GROWING AND PROCESSING The following description of current tea manufacture methods was obtained from a Tea Manager in Assam in 2001. Film of the processes which he describes can be seen on the film section of this web-site. Pickers take the first two leaves with the bud. The first flush is in March when they pick for 2-3 weeks with a short dormant spell before the second flush in MayJune when they pick each of those months. There is also an autumn flush in November-December when they pick for a further 2-3 weeks. The rest of the time the bushes need to be weeded and pruned so they do not grow too long. In all, there is a ten month cycle and in the other two months the machines and factory are cleaned, repaired and painted. Orthodox (rolled) tea has a different production cycle. Lorries bring tea from the garden to the factory. The process of making the dried tea leaf starts with the fresh leaves being emptied into troughs where they are allowed to go flaccid and dry a little before being moved on by human labour. This starts the process of breaking down the cells after which there is a 6-14 hour withering period using a rolling table or rotor wain. Oxidisation occurs when the cells are disturbed so the process is to literally break down the leaf. Fine tea is invariably CTC (prepared by the cut, tear, curl method) which sums up the stages. The rollers used are based on those used in flour mills and consist of a series of cutting edges that have to be kept sharp. These were introduced in the late 1950s and 1960s. Cutting and tearing gives a higher concentration of tea by volume. Both orthodox (rolled tea) and Darjeeling have less processing as the leaf is not cut so much and makes a weaker tea. The CTC process takes 25-40 minutes and after that the marl, as it is now called, is allowed to cool so that the oxidisation process can continue. Temperature is crucial here for if it exceeds 35 degrees centigrade then the marl will be spoilt. So cold air is blown onto the marl while it moves along a conveyer belt. Marl used to be left on the floor to oxidise but it was difficult to check the speed of oxidisation when in heaps. There is no machine that can tell when fermentation has finished. It is left to the skill and experience of the manager and his staff to halt the process at the right time before drying. This can take 45 minutes to 2.5 hours. The dryers are used to arrest the oxidisation process. In the dryers, hot air blows through the marl and the chaff is separated from it by suction. Then it is run through rollers that are covered in plastic that creates static electricity to attract finer dust particles. The cleaned dried tea is sifted by size into different containers. Tea dust itself is wrongly assumed to be of very poor quality, but it can be better than others can as it dissolves faster in hot water and is much more concentrated. So it gives many more cups per leaf than ordinary tea. The tea piled in this factory was worth 105 crore rs. and would fetch about 100rs. per kg at auction [approximately 70 rupees to the ]. This garden is among the top 25 in Assam. From here, 37% is exported. The year 2001 has been a bad one for tea and the price had slumped at auction. Indian tea used to be sold in Pakistan and Afghanistan. Now the border was sealed and Pakistan was buying tea from Sri Lanka. Good tea production in India had slumped 10%, poor teas by 25-40%, due to competition from elsewhere.

Copyright: Alan and Iris Macfarlane 2002

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 03 066 01 0 02Documento89 pagine03 066 01 0 02amit huidromNessuna valutazione finora

- CISS Rural GodownsDocumento1 paginaCISS Rural Godownsamit huidromNessuna valutazione finora

- Note: RFQ Stands Modified To The Extent Required As Per These InstructionsDocumento5 pagineNote: RFQ Stands Modified To The Extent Required As Per These Instructionsamit huidromNessuna valutazione finora

- SAP Purchasing User Training ManualDocumento28 pagineSAP Purchasing User Training Manualamit huidrom100% (2)

- SapDocumento18 pagineSapRitu100% (3)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Curamik Design Rules DBC 20150901Documento8 pagineCuramik Design Rules DBC 20150901Ale VuNessuna valutazione finora

- White Button Mushroom Cultivation ManualDocumento8 pagineWhite Button Mushroom Cultivation ManualKhurram Ismail100% (4)

- UBITX V6 MainDocumento15 pagineUBITX V6 MainEngaf ProcurementNessuna valutazione finora

- Chapter 1: Investment Landscape: Financial GoalsDocumento8 pagineChapter 1: Investment Landscape: Financial GoalsshubhamNessuna valutazione finora

- Simavi - Project Officer PROPOPIDocumento4 pagineSimavi - Project Officer PROPOPIAgus NugrahaNessuna valutazione finora

- E Nose IoTDocumento8 pagineE Nose IoTarun rajaNessuna valutazione finora

- Analisa RAB Dan INCOME Videotron TrenggalekDocumento2 pagineAnalisa RAB Dan INCOME Videotron TrenggalekMohammad Bagus SaputroNessuna valutazione finora

- KV Tripple Eccentric Butterfly Valve-LinDocumento12 pagineKV Tripple Eccentric Butterfly Valve-LinWelma JohnsonNessuna valutazione finora

- RCC Design of Toe-Slab: Input DataDocumento2 pagineRCC Design of Toe-Slab: Input DataAnkitaNessuna valutazione finora

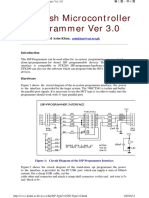

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocumento4 pagineISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNessuna valutazione finora

- Unit 5 Andhra Pradesh.Documento18 pagineUnit 5 Andhra Pradesh.Charu ModiNessuna valutazione finora

- Prevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaDocumento10 paginePrevalence of Peptic Ulcer in Patients Attending Kampala International University Teaching Hospital in Ishaka Bushenyi Municipality, UgandaKIU PUBLICATION AND EXTENSIONNessuna valutazione finora

- Bba Colleges in IndiaDocumento7 pagineBba Colleges in IndiaSumit GuptaNessuna valutazione finora

- August 2015Documento96 pagineAugust 2015Cleaner MagazineNessuna valutazione finora

- YeetDocumento8 pagineYeetBeLoopersNessuna valutazione finora

- NIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksDocumento15 pagineNIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksChristopher HerringNessuna valutazione finora

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Documento3 pagineAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNessuna valutazione finora

- Tindara Addabbo, Edoardo Ales, Ylenia Curzi, Tommaso Fabbri, Olga Rymkevich, Iacopo Senatori - Performance Appraisal in Modern Employment Relations_ An Interdisciplinary Approach-Springer Internationa.pdfDocumento278 pagineTindara Addabbo, Edoardo Ales, Ylenia Curzi, Tommaso Fabbri, Olga Rymkevich, Iacopo Senatori - Performance Appraisal in Modern Employment Relations_ An Interdisciplinary Approach-Springer Internationa.pdfMario ChristopherNessuna valutazione finora

- Matrix of Consumer Agencies and Areas of Concern: Specific Concern Agency ConcernedDocumento4 pagineMatrix of Consumer Agencies and Areas of Concern: Specific Concern Agency ConcernedAJ SantosNessuna valutazione finora

- ABB Price Book 524Documento1 paginaABB Price Book 524EliasNessuna valutazione finora

- Belimo Fire & Smoke Damper ActuatorsDocumento16 pagineBelimo Fire & Smoke Damper ActuatorsSrikanth TagoreNessuna valutazione finora

- tdr100 - DeviceDocumento4 paginetdr100 - DeviceSrđan PavićNessuna valutazione finora

- DR-2100P Manual EspDocumento86 pagineDR-2100P Manual EspGustavo HolikNessuna valutazione finora

- Human Resource Management by John Ivancevich PDFDocumento656 pagineHuman Resource Management by John Ivancevich PDFHaroldM.MagallanesNessuna valutazione finora

- 87 - Case Study On Multicomponent Distillation and Distillation Column SequencingDocumento15 pagine87 - Case Study On Multicomponent Distillation and Distillation Column SequencingFranklin Santiago Suclla Podesta50% (2)

- Powerpoint Presentation R.A 7877 - Anti Sexual Harassment ActDocumento14 paginePowerpoint Presentation R.A 7877 - Anti Sexual Harassment ActApple100% (1)

- 0063 - Proforma Accompanying The Application For Leave WITHOUT ALLOWANCE Is FORWARDED To GOVERNMEDocumento4 pagine0063 - Proforma Accompanying The Application For Leave WITHOUT ALLOWANCE Is FORWARDED To GOVERNMESreedharanPN100% (4)

- PartitionDocumento5 paginePartitionKotagiri AravindNessuna valutazione finora

- Writing Task The Strategy of Regional Economic DevelopementDocumento4 pagineWriting Task The Strategy of Regional Economic DevelopementyosiNessuna valutazione finora

- ArpitResumeISM PDFDocumento1 paginaArpitResumeISM PDFchethan rNessuna valutazione finora