Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CEC 105 Practical

Caricato da

VietHungCaoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CEC 105 Practical

Caricato da

VietHungCaoCopyright:

Formati disponibili

UNESCO-NIGERIA TECHNICAL & VOCATIONAL EDUCATION REVITALISATION PROJECTPHASE II

NATIONAL DIPLOMA IN CIVIL ENGINEERING TECHNOLOGY

CIVIL ENGINEERING CONSTRUCTION I

COURSE CODE: CEC105

YEAR I- SEMESTER I PRACTICAL

Table of Contents WEEK 1 PRACTICAL Set out a building

WEEK 2

PRACTICAL Set out building (3-4-5) method

WEEK 3

PRACTICAL Set up a moving profile for circular building PRACTICAL Building a brick wall PRACTICAL Making a precast lintel PRACTICAL Insitu concrete lintel PRACTICAL Laying bituminous felt PRACTICAL Applying asphalt finish PRACTICAL Fixing timber staircase on site PRACTICAL Making concrete staircase PRACTICAL SETTING OUT USING THEODOLITE METHOD

WEEK 4

WEEK 5

WEEK 6

WEEK 7

WEEK 8

WEEK 9

WEEK 10

WEEK 11

WEEK 12 EXCAVATING DRAIN POSITIONS

WEEK 13 TESTING DRAINS WEEK 14 CONSTRUCTION OF BATTENED DOORS WEEK 15 CONSTRUCTION OF FRAME AND BRACED DOORS

WEEK 1 PRACTICAL TITLE: AIM: SET OUT A BUILDING KNOW HOW TO SET OUT A BUILDING

EQUIPMENT: sharp pegs, a mallet, a hammer, a ball of string, a 30 metre steel tape PROCEDURES: 1. Assemble the equipment for setting out: sharp pegs, a mallet, a hammer, a ball of string, a 30 metre steel tape 2. Find out the distance from the site boundary to the building line on the working Drawing. Use the tape to measure the same distance from the site boundary to the location of the building line on the ground. Select a corner on the ground to be corner A. 3. Place a peg in the ground at corner A and hammer a nail into the top of the peg. 4. Repeat these steps to place a peg in the ground for corner B 5. Tie the string between pegs A and B. Check that the distance on the ground is the same measurement as the distance on the drawing. 6. Repeat these steps for corners C and D.

7. Measure the diagonals A-D and B-C (the two diagonal should be equal) 8. Use the builders square to check that the corners are at right angles.

WEEK 2 TITLE: SET OUT A BUILDING AIM: SET OUT A BUILDING USING 3-4-5 METHOD

PROCEDURES: 1. Nail three pieces of timber together which you cut to these lengths to make a frame 750mm 1000mm 1250mm A frame with a right angled corner is called a square. 2. Place the right angle of the square against the lines between the corners. If the corners are not at right angles then move the corner pegs until they make right angles. 3. Measure the diagonals to check that they are the same length.

WEEK 3 TITLE: SETTING OUT BUILDING AIM: SETTING UP A MOVING PROFILE FOR CIRCULAR

BUILDING. PROCEDURES: 1. Find out the radius of the building from the working drawings 2. Mark out the measurement on the ground. 3. Place a stake securely in the ground at the end of the radius in the centre of the building. 4. Drill a 12mm hole in the stake 5. Place a 12mm reinforcing bars in the hole in the stake 6. Check that the top of the bar is level. 7. Cement the stake in position 8. Loop a piece of rope which is the length of the radius of the building over the reinforcing bar 9. Measure the distance to the inner and outer sides of the foundation from the working drawing 10. Use the rope to measure the same distances on the ground 11. Mark the distances around the outline of the building

WEEK 4 TITLE: AIM: BUILDING A BRICK WALL KNOW HOW TO BUILD A BRICKWALL

PROCEDURES: 1. Use the profile lines to locate an external corner on the strip foundation 2. Use a builders level held vertically or a plumb-line to mark the position of the external corner with wet mortar. Repeat steps 1 and 2 for all four corners. 3. Stretch a line between the corners to provide a position for the first course of brick. Secure the line by wrapping it around a brick and putting another brick on top. Remove the line after the first course of bricks is laid 4. Lay the bricks in a row. Adjust their position by tapping the bricks back for 8 or 10 courses. Check that they are level horizontally and vertically with the builders level 5. Build up the corners by racking the brick back for 8 or 10 courses. Check your accuracy with builders level. Use a gauge rod to control the height. 6. Insert metal pegs in the mortar joint on the corners for each completed course of brickwork. Stretch a line between the pegs so that it is flush

with the surface of the brickwork to provide a guide for the next course of brickwork. 7. Continue checking horizontal and vertical levels. 8. From the joints while the mortar is soft.

WEEK 5 TITLE: CASTING A PRECAST LINTEL AIM: KNOW HOT TO PRCAST LINTEL IS MADE

PROCEDURES: 1. Make a timber box in an open top, which is the same size as the external dimensions of the finished lintel. 2. Paint the inside of the box with releasing oil. This stop the concrete sticking to the timber 3. Bend the end of the reinforcement bars to right angles (900). If the lintel contains more than one bar, then make short cross bars and wire the cross bar to the long bars 4. Insert spacers that holds the bars 25mm from the bottom of the formwork. Spacers are small cement block embedded with tie wires that you use to attach them to the bars 5. Place the reinforcement in the formwork and check that the bars are 50mm from each end of the box and supported by spacers. 6. Mix the require amount of concrete 7. Pour the concrete into the timber box and make sure that it flows down around and under the rods, then pack it down to remove any trapped air.

8. Make a smooth finish on the top of the concrete with a wood float and write the word top on the concrete. 9. Cover the box with wet sacking and leave to set for seven days.

WEEK 6 TITLE: AIM: PROCEDURES: 1. Erect the timber formwork across the opening and support it from the floor below. Use wedges to level the support and formwork. 2. Seal all the joint with building paper or mastic between the timber formwork and the brickwork to stop the cement and water leaking out. 3. Paint the inside of the formwork with releasing oil. 4. Place the reinforcement in the formwork using the same method describe in making precast lintel 5. Pour the concrete and cover it with wet sacking and leave it for seven days. INSITU CONCRETE LINTEL MAKING AN INSITU CONCRETE LINTEL

WEEK SEVEN TITLE: LAYING BITUMINOUS FELT

AIM: LAYING BITUMINOUS FELT ON ROOF PROCEDURES: 1. Roll out the first sheet of felt over the roof boarding and nail it with large head roofing nails. 2. Roll out the next sheet of felt so that it overlaps the first by 50mm and nail it down 3. Continue step 1 and 2 until the entire roof is covered in a layer of felt 4. Apply hot bitumen to the first layer of felt. Then roll out another layer, but do not nail it. The sheets in this layer should overlap the first layer by 50mm. 5. Repeat step 4 with the third layer 6. Spread a layer of white marble or limestone chips set in bitumen over the top layer to reflect heat.

WEEK 8 TITLE: AIM: APPLYING A MASTIC ASPHALT FINISH LAY MASTIC ASPHALT FINISH

PROCEDURES: 1. Melt the solid blocks of asphalt in a boiler. 2. Sweep the roof surface. 3. Lay an under felt cover over the roof surface that prevents the penetration of the asphalt into the roof surface. 4. Carry the hot melted asphalt in buckets to the roof. 5. Spread a 10mm thick layer of asphalt by hand with a wood float 6. Apply the second layer to the same thickness so that it melts into the first layer and weld the edges of the two layers together to a 20mm thickness. 7. Make a 450 wedge or fillet at the junction with vertical upstands that increase the thickness of the asphalt at week points. Vertical upstands should be at least 150 mm above the finished level of the asphalt. 8. Spread a 12 mm layer of white crushed stone over the surface or paint the surface with reflective paint.

WEEK 9 TITLE: AIM: FIXING A TIMBER STAIRCASE ON SITE HOW TO FIX TIMBER STAIRCASE ON SITE

PROCEDURES: 1. Fix the stair to the wall with plugs and crews. 2. Tightly fix against the staircase trimmer joist at the top and be cut and shaped to fit against the skirting beside it. 3. Make the lower end of the staircase rests on the floor. 4. Cut and match to the skirting as required 5. Insert the outer string in the newel posts at the top and bottom. The stair wall trimmer slots into the top newel post and they are screwed or nailed together. 6. Fix the lower newel post to the floor with brackets. 7. Finally, fit the handrail and balustrade to the string and newels to complete the staircase fixing on site.

WEEK 10 TITLE: AIM: CONCRETE STAIRCASE MAKING A CONCRETE STAIRCASE

PROCEDURES: A concrete staircase is usually made on site. The construction procedure is the same as for other concrete slab. 1. Erect timber formwork 2. Oil the formwork to prevent the concrete sticking to the timber 3. Position the steel reinforcement 4. Mix concrete by hand or mixer 5. Pour concrete and compact 6. Cure concrete for seven days 7. Remove the formwork after seven days

WEEK11 TITLE:SETTINGOUTUSINGTHEODOLITEMETHOD AIM:KnowHowToSetoutBuildingUsingTheodolite PROCEDURES:

1. MountandsettheinstrumentatpointA,sightthetelescope,rangeandpeg outpointEandBtoestablishthebuildingline 2. turnthetheodolitescrews,setandadjustthedegreereadingto0to00turn thetelescopeoftheinstrumentonthetripodstandtowardstherightaxisuntil youcansight9000000usingtheinstrumentrangetoestablishandpegout pointFandC

3. transfertheinstrumenttopointC,andfollowingthesameprocedureatA, rangeAandF,settheangle0000000,turnforwardstherightaxistosight andobtain90000000andtoestablishpointGandD 4. pointHcouldbeestablishedbyusingameasuringtape. 5. checkthewholemeasurementagainbymountingtheinstrumentonpointsB andDandrepeatthewholeprocess

WEEK12 TITLE:EXCAVATINGDRAINPOSITIONS AIM:KnowHowToExcavateDrainPositions PROCEDURES: 1. Mark out the position of the drain runs on the ground and mark the manhole positions. 2. Calculatethedepthoftheinvertsatthemanholespositions. 3. Calculatethedepthoftheexcavationandadd100mmforbeddingifrequired. 4. measuretheheightoftheuppersightrailabovethedatum 5. set up sight rails on the first straight drain run and calculate the length of the traveler. 6. excavate the trench until you reach the correct level by lining up the traveler orboningrodwiththelinebetweenthesightrails 7. insert some pegs in the bottom of the trench that project 100mm off the bottom 8. fill the bottom of the trench with 100mm granular material until it covers the pegs.

9. attach a batten to the bottom of the rod so that it can sit drains on the bedding and keep checking the levels with the boning rod. Joint the pipes so thatsocketfacestheflow 10.testthedrainsandbackfill 11.repeatprocedureforthenextdrainrun

WEEK13 TITLE:TESTINGDRAINS AIM:KnowHowDrainsaretestedforleakageusingthehydraulictestmethod THEORY: Drains that carry sewage must not leak into surrounding ground. To ensure that the joints are secured, drains should be tested before they are covered. Theyarethreemethodoftestingdrains:

1. theballtest 2. thehydraulictest 3. themirrorandtorchtest PROCEDURE:Hydraulictest 1. plugthelowerendofadrainrun 2. insertatemporaryjointanda1.5meterlengthofpipeatthehigherend 3. pourwaterinthedrainuntiltheuprightpipeisfull. 4. leaveitfortwohours 5. checkthelevel 6. topthewaterlevelup

7. checkthelevelsagainafterhalfanhour thelevelshoulddroplessthan6.4mmpermetreof100mmpipeor4.5mmper 150mmpipe. Ifthedropinthewaterlevelisgreaterthan6.4mmor4.5mmthenthepipe

mustbeinspectedforleakandyourepairorreplaceit.

WEEK14 TITLE:DOORCONSTRUCTION AIM:Knowhowtomakealedged,bracedandbatteneddoor. THEORY: This is a very simple door for internal or external use and is cheap to make Itconsistofthefollowing:

1. Tongued,groovedandVjointbattensmeasuring10025mm 2. Diagonal piles pieces called braces that measure about 10025mm. braces shouldbefixedsothattheyslopeupawayfromthehinges PROCEDURES: 1. assemblebattensthataretherightsizeforthedoor 2. gluethetonguesandgroovestogether 3. screwornailthebattenstotheledges 4. cutoutandfitthebracesbetweentheledges 5. nailthebattenstothebraces. Thistypeofdoordoesnothaveanyspecialwoodworkingjoints.

WEEK15 TITLE:DOORCONSTRUCTION AIM:Knowhowtomakeframed,bracedandbatteneddoor. THEORY: This door is strong then the ledged, braced and battened door because thebattensaresetinsideatimberframe Theframed,bracedandbatteneddoorconsistofthefollowingpieces:

1. Battensthatformthesurfaceofthedoor 2. Aframewithaheadrail,bottomrailandtwostiles 3. Aledge 4. Braces PROCEDURE: 1. cutandassemblethepiecesoftheframetofitthedoorsize 2. inserttheheadandbottomrailintorecessesinthestiles 3. fitthebraces 4. nailthebattensonthebracesandstile.

Potrebbero piacerti anche

- Cec 110pDocumento20 pagineCec 110pLucia Luciaa100% (8)

- Civil Engineering Construction CEC 105 Practical-1 PDFDocumento25 pagineCivil Engineering Construction CEC 105 Practical-1 PDFAhmad Abubakar88% (8)

- Cec 107 Practical - Introduction To Fluid MechanicsDocumento28 pagineCec 107 Practical - Introduction To Fluid MechanicsVietHungCao100% (1)

- Cec 102 Practical - Introductory HydrologyDocumento25 pagineCec 102 Practical - Introductory HydrologyVietHungCao100% (2)

- Cec 103. - Workshop Technology 1Documento128 pagineCec 103. - Workshop Technology 1VietHungCao92% (13)

- Cec 242-Construction ManagementDocumento132 pagineCec 242-Construction ManagementVietHungCao50% (4)

- Cec 103 PDFDocumento128 pagineCec 103 PDFAhmad AbubakarNessuna valutazione finora

- Cec 108 Prac-Geology - Soil MechnicsDocumento36 pagineCec 108 Prac-Geology - Soil MechnicsVietHungCao89% (9)

- Cec 204 PracticalDocumento35 pagineCec 204 PracticalPratibha Singh50% (2)

- Cec 104 Prac-Material Properties ofDocumento42 pagineCec 104 Prac-Material Properties ofVietHungCao67% (6)

- Sug 102 P - Basic Principles in Surveying IIDocumento14 pagineSug 102 P - Basic Principles in Surveying IIVietHungCao80% (5)

- Cec 242 PDFDocumento132 pagineCec 242 PDFGodsfavour Egbodi80% (5)

- Cec 212 NotesDocumento39 pagineCec 212 NotesMuniru Qudus100% (1)

- Cec 203 ScheduleDocumento5 pagineCec 203 ScheduleSky Kush67% (6)

- Cec 207 Theory-1-1 PDFDocumento76 pagineCec 207 Theory-1-1 PDFBare CooperNessuna valutazione finora

- BLD 102 PracticalBookDocumento29 pagineBLD 102 PracticalBookdkaviti50% (2)

- Cec 107 Theory - Introduction To Fluid MechanicsDocumento56 pagineCec 107 Theory - Introduction To Fluid MechanicsVietHungCao69% (13)

- CEC110 TheoryDocumento100 pagineCEC110 TheoryAbdulrahMan muhammmed65% (17)

- Cec 214Documento5 pagineCec 214ABDULRAHAMAN MUHAMMED75% (12)

- Git 201 P-2Documento21 pagineGit 201 P-2ishaq kazeemNessuna valutazione finora

- Engineering Measurement and Evaluation Cec214Documento12 pagineEngineering Measurement and Evaluation Cec214Hussaini bobo65% (17)

- Cec 102 Theory - Introductory HydrologyDocumento73 pagineCec 102 Theory - Introductory HydrologyVietHungCao80% (10)

- Cec 203 Workshop Technology IiDocumento8 pagineCec 203 Workshop Technology IiAbubakar Lukman100% (5)

- CEC 106 PracticalDocumento44 pagineCEC 106 PracticalSimon Watila67% (3)

- Cec 208 TheoryDocumento87 pagineCec 208 TheorySolomon Tamuno Iyango95% (20)

- Guide in Assessing Information 1. Who The Users Will BeDocumento3 pagineGuide in Assessing Information 1. Who The Users Will BeCHINGCHONG SLAYERNessuna valutazione finora

- SUG 102 Theory PDFDocumento80 pagineSUG 102 Theory PDFBurlyNessuna valutazione finora

- Cec 201 TheoryDocumento98 pagineCec 201 Theoryishaq kazeem50% (4)

- SUG 102 TheoryDocumento80 pagineSUG 102 TheoryVietHungCao80% (10)

- Sug 208-Enginering Surveying IDocumento65 pagineSug 208-Enginering Surveying IVietHungCao100% (13)

- CEC 108 Theory PDFDocumento87 pagineCEC 108 Theory PDFSky Kush95% (21)

- BLD 105 Merged PDFDocumento59 pagineBLD 105 Merged PDFdkaviti100% (2)

- Sug 208Documento65 pagineSug 208fate oreavbiere100% (2)

- Cec 210-Civil Engineering Drawing IIDocumento34 pagineCec 210-Civil Engineering Drawing IIVietHungCao76% (21)

- QUS 104 Building ScienceDocumento70 pagineQUS 104 Building ScienceOlagoke Habeeb Ademola100% (3)

- SUG 102 Lecture NoteDocumento36 pagineSUG 102 Lecture Notehassan sodick100% (3)

- Cec 205-Theory of StructuresDocumento61 pagineCec 205-Theory of StructuresVietHungCao85% (27)

- SUG 208 Manuals PDFDocumento21 pagineSUG 208 Manuals PDFArinze samuel100% (1)

- BLD 103 Building Construction I CombinedDocumento56 pagineBLD 103 Building Construction I Combinedshaybaby1657% (7)

- Civil Engineering Technology: Higher National Diploma (HND)Documento172 pagineCivil Engineering Technology: Higher National Diploma (HND)Harshit Raj Gupta0% (1)

- QUS 102 Measurement of Building WorksDocumento120 pagineQUS 102 Measurement of Building Worksyes i can86% (7)

- Science & Properties of MaterialsDocumento91 pagineScience & Properties of MaterialsAbdulrahMan muhammmed100% (1)

- Cec 208 Lecture Notes 1Documento9 pagineCec 208 Lecture Notes 1Zaid Habibu100% (1)

- Cec 207 Theory - HydrogeologyDocumento76 pagineCec 207 Theory - HydrogeologyVietHungCao78% (18)

- Cec 204 Theory PDFDocumento64 pagineCec 204 Theory PDFGodsfavour Egbodi100% (1)

- BLD 204 PDFDocumento20 pagineBLD 204 PDFOluwaseyi Toheeb Arc.Azeez50% (2)

- BLD 206 MergedDocumento54 pagineBLD 206 MergedVietHungCao100% (1)

- Cec 209 - Civil Engineering Drawing IDocumento44 pagineCec 209 - Civil Engineering Drawing IVietHungCao89% (9)

- BLD 207 Building Services Final CombinedDocumento169 pagineBLD 207 Building Services Final CombinedVietHungCao100% (7)

- Engineering Surveying: Theory and Examination Problems for StudentsDa EverandEngineering Surveying: Theory and Examination Problems for StudentsValutazione: 4.5 su 5 stelle4.5/5 (8)

- Cec 110p PDFDocumento20 pagineCec 110p PDFJoifry DonnaNessuna valutazione finora

- BrickDocumento13 pagineBrickniravhirparaNessuna valutazione finora

- Report of CTBMMSMT 1Documento15 pagineReport of CTBMMSMT 1api-291031287Nessuna valutazione finora

- Tehnology of ConstructionDocumento11 pagineTehnology of ConstructionZenaida VoiculetNessuna valutazione finora

- Fredy InglesDocumento3 pagineFredy InglesandreaNessuna valutazione finora

- How To Lay Cement Brick in ConstructionDocumento2 pagineHow To Lay Cement Brick in ConstructionRoNessuna valutazione finora

- Bahasa InggrisDocumento12 pagineBahasa InggrisRahayu RifkaNessuna valutazione finora

- Objectives of On The Job Training ProgramDocumento17 pagineObjectives of On The Job Training ProgramArjun Kumar YadavNessuna valutazione finora

- Brick ReportDocumento15 pagineBrick ReportEffaNessuna valutazione finora

- Comment On List of Material Equipment PDFDocumento20 pagineComment On List of Material Equipment PDFVietHungCaoNessuna valutazione finora

- Geoslope ManualDocumento523 pagineGeoslope Manualwiwiz2000100% (4)

- Clubhouse-ID Works-Addendum No 2 To Tender PDFDocumento33 pagineClubhouse-ID Works-Addendum No 2 To Tender PDFVietHungCao100% (1)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- GXD - VN Cost Estimating Guide For Road Construction PDFDocumento118 pagineGXD - VN Cost Estimating Guide For Road Construction PDFVietHungCaoNessuna valutazione finora

- 02 150416-Clubhouse-Schedule of Finishes Rev.1 PDFDocumento3 pagine02 150416-Clubhouse-Schedule of Finishes Rev.1 PDFVietHungCaoNessuna valutazione finora

- Cost-Handbook-Vietnam-2014-Langdon & Seah Vietnam Co LTD PDFDocumento146 pagineCost-Handbook-Vietnam-2014-Langdon & Seah Vietnam Co LTD PDFVietHungCaoNessuna valutazione finora

- BLD 104 Building Construction CombinedDocumento59 pagineBLD 104 Building Construction Combineddkaviti83% (6)

- Construction Tender1 Benh Vien QT Viet My PDFDocumento98 pagineConstruction Tender1 Benh Vien QT Viet My PDFVietHungCaoNessuna valutazione finora

- BLD 206 MergedDocumento54 pagineBLD 206 MergedVietHungCao100% (1)

- BLD 206 MergedDocumento54 pagineBLD 206 MergedVietHungCao100% (1)

- Sug 208-Enginering Surveying IDocumento65 pagineSug 208-Enginering Surveying IVietHungCao100% (13)

- Sug 102 P - Basic Principles in Surveying IIDocumento14 pagineSug 102 P - Basic Principles in Surveying IIVietHungCao80% (5)

- SUG 102 TheoryDocumento80 pagineSUG 102 TheoryVietHungCao80% (10)

- Cec 209 - Civil Engineering Drawing IDocumento44 pagineCec 209 - Civil Engineering Drawing IVietHungCao89% (9)

- QUS 103 - Basic Engineering Science (Practicals)Documento31 pagineQUS 103 - Basic Engineering Science (Practicals)VietHungCaoNessuna valutazione finora

- BLD 208 Building Maitenance Final CombinedDocumento65 pagineBLD 208 Building Maitenance Final CombinedVietHungCao100% (5)

- QUS 201 - Building Measurement & Specification (Theory-Practical)Documento122 pagineQUS 201 - Building Measurement & Specification (Theory-Practical)VietHungCao93% (14)

- Cec 106 Theory - Strength of MaterialsDocumento77 pagineCec 106 Theory - Strength of MaterialsVietHungCao79% (14)

- QUS 103 - Basic Engineering Science (Theory)Documento58 pagineQUS 103 - Basic Engineering Science (Theory)Thapa Gorkha100% (10)

- EEC 129 TheoryDocumento55 pagineEEC 129 TheoryVietHungCao100% (6)

- Cec 107 Theory - Introduction To Fluid MechanicsDocumento56 pagineCec 107 Theory - Introduction To Fluid MechanicsVietHungCao69% (13)

- Cec 207 Theory - HydrogeologyDocumento76 pagineCec 207 Theory - HydrogeologyVietHungCao78% (18)

- EEC 129 PracticalDocumento48 pagineEEC 129 PracticalVietHungCao100% (6)

- Cec 106 Theory - Strength of MaterialsDocumento77 pagineCec 106 Theory - Strength of MaterialsVietHungCao79% (14)

- EEC 123 Electrical Machine I TheoryDocumento90 pagineEEC 123 Electrical Machine I TheoryVietHungCao86% (7)

- Cec 205-Theory of StructuresDocumento61 pagineCec 205-Theory of StructuresVietHungCao85% (27)

- Vernacular Modernism: Hassan FathyDocumento32 pagineVernacular Modernism: Hassan FathyThabisNessuna valutazione finora

- Comparative Analysis of Building LawsDocumento2 pagineComparative Analysis of Building LawsJasper John RiveroNessuna valutazione finora

- Raft FoundationDocumento28 pagineRaft FoundationAashi Gupta100% (1)

- History Assignment 2Documento1 paginaHistory Assignment 2Mudit DuaNessuna valutazione finora

- Nishas Play School, GoaDocumento6 pagineNishas Play School, Goasuhana80% (10)

- River Song Apartment: Muhammed Aslem NazarDocumento51 pagineRiver Song Apartment: Muhammed Aslem NazarSunidhi VermaNessuna valutazione finora

- PVC Walls Panels Traders, Wholesalers and Buyers in DelhiDocumento5 paginePVC Walls Panels Traders, Wholesalers and Buyers in DelhisaaNessuna valutazione finora

- Technical Calculation E1 UAL TowerDocumento48 pagineTechnical Calculation E1 UAL TowermcbluedNessuna valutazione finora

- STR BnderDocumento6 pagineSTR Bnderhemanthkumar67008Nessuna valutazione finora

- W-L-1054 Pipe Through Gyp Board AssemblyDocumento2 pagineW-L-1054 Pipe Through Gyp Board AssemblyJason StelleNessuna valutazione finora

- Dry Construction PDFDocumento20 pagineDry Construction PDFANSLEM ALBERTNessuna valutazione finora

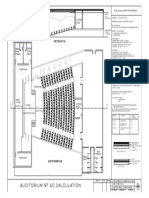

- Auditorium RT60 CalculationDocumento1 paginaAuditorium RT60 CalculationAniket WayalNessuna valutazione finora

- Mmc-Gamuda Conquas Road ShowDocumento86 pagineMmc-Gamuda Conquas Road ShowAlsonChinNessuna valutazione finora

- Tropical DesignDocumento8 pagineTropical DesigndellcyberNessuna valutazione finora

- Gant ChartDocumento18 pagineGant ChartNeal Cristian PerlasNessuna valutazione finora

- Eca Rumah Teres 2 TingkatDocumento5 pagineEca Rumah Teres 2 TingkatHazim Zakaria100% (1)

- Claudine Arendt's Lecture Following The Van Hove Prize Award CeremonyDocumento2 pagineClaudine Arendt's Lecture Following The Van Hove Prize Award CeremonyconstatbpuNessuna valutazione finora

- Wickes Calculating Building Materials Good Practice Leaflet 13Documento6 pagineWickes Calculating Building Materials Good Practice Leaflet 13scode990% (1)

- Tarmac Beam & Block FlooringDocumento8 pagineTarmac Beam & Block FlooringabcNessuna valutazione finora

- A3 Ticket Booth PDFDocumento3 pagineA3 Ticket Booth PDFBhisshmen RavindranNessuna valutazione finora

- Sandwich Panel - BONDOR INDONESIA PDFDocumento27 pagineSandwich Panel - BONDOR INDONESIA PDFSaor PakpahanNessuna valutazione finora

- 2 Solid and Hollow Block MSDocumento7 pagine2 Solid and Hollow Block MSGaneshNessuna valutazione finora

- Unit - 4 Vernacular Architecture of South IndiaDocumento40 pagineUnit - 4 Vernacular Architecture of South IndiaVinoth KumarNessuna valutazione finora

- Statesman Homes 2011 Price ListDocumento2 pagineStatesman Homes 2011 Price ListmrpoppyNessuna valutazione finora

- Understanding Architectural Details 3 Sample PDFDocumento23 pagineUnderstanding Architectural Details 3 Sample PDFolu67% (9)

- Concept: Case Study Dressing Table: RefrencesDocumento2 pagineConcept: Case Study Dressing Table: RefrencesNisha LamixaneNessuna valutazione finora

- Support Details For ASHRAE Heat Load Calculation SheetDocumento8 pagineSupport Details For ASHRAE Heat Load Calculation SheetShravanNessuna valutazione finora

- Pattern Language ContentsDocumento8 paginePattern Language ContentsSakina HuzaifaNessuna valutazione finora

- BCM Report 222Documento4 pagineBCM Report 222Shipra AnandNessuna valutazione finora

- Indian Architecture FinalDocumento6 pagineIndian Architecture FinalDimcy GuptaNessuna valutazione finora