Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chemical Separation of Industrial Dusts in Electrostatic Precipitators

Caricato da

Deniz TepeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chemical Separation of Industrial Dusts in Electrostatic Precipitators

Caricato da

Deniz TepeCopyright:

Formati disponibili

(

..

---_._. -- ......

CHEMICAL SEPARATION OF INDUSTRIAL DUSTS

IN ELECTROSTATIC PRECIPITATORS

by

Omar Feroze Ali, B.Eng.

A thesis submitted to the Faculty of Graddate and Researh

in partial fulfillment of the requirements for the degree'of

Master of Engineering_

McGill universirty,

/

DepartMent of Chemical Engineering,

.Montreal, Canada.

December, 1982.

...

..

)

,1

f

":.::; ..

........ " ....,.. .... .... - , .... .... "" ... ""' .... -

11

':::-

1

,

, --

-.

.'.

}

\...j

./

CHEl.fICAL SEPARATION OF INDUS TRIAL DUSTS lU ELECTROSTATIC PRECIPITATORS

"'

(.>

..

')

--------, ., ... --_ ...... ... _ ........ ...... *t ... q $ .tntt

1

f

1

;

1

...

(

ABSTRACT

This work the segregation of indus-

trial dusts in electrostatic precipita tors , The overall purpose was

to determine the minimum information needed on a dust and collection

, i

system to predici if segregation of components is possible and how

,

this could be enhanced, Bath laboratory nd industrial scale ESP's

were used.

,'f

The dusts studied were from a copper smelter, zinc smelter,

power plant and municipal incinerator, The dust was characterized using

an electron microscope withoanalysing capabilities, cascade impactor,

X-ray spectrometer and cyclone, Theoret1cal predictions of

component segregation were obta1ned with the Southern Research Institute

(SRI) computer model of ESP performance,

Sign1ficant se9regation was obtained only for the copper

smelter dust.

In aIl cases, however, the combined

wit:h the SRI predictions agreed weIl w1th the ESP results.

\

\

1

.

\

l'

t )

,

\,

1 /

.J

1

f'

.

,,.

...

. '

(

ii

RESUME

. ,

Ce travail porte sur la sparation chimique de

l'aide de prcipitateurs lectrostatiques. Le but

principal tait de dterminer minimale requise, sur la

poussire et le systme de collection, pour prdire si la sgrgation est

et comment elle peut tre amliore. Des lectro-

l'chelle de laboratoire et industrielle ont t utiliss.

Les poussires tudies provenaient du procd d'affinage

du cuivre et du zinc, d'une gnratrice de puissance et d'un incinrateur

Les poussires ont t caractrises l'aide d'un micros-

,cope lectronique, d'un contacteur en cascade, d'un spectromtre fluores-

cent rayon-x et d'un cyclone. Des prdictions thoriques sur la

sparation des composants ont t obtenues partir du modle SRI

(Southern Research Institute) pour l'valuation de la performance d'un

prcipitateur lectrostatique.

Une sparation significative a t 'obtenue, seule-

ment pour le cas de la poussire provenant de l'affinage du cuivre.

Cependant, dans tous les cas, la caractrisation des poussires combine

avec les prdictions du modle SRI , coincident avec les rsultats ob-

tenus pour les prcipitateurs lectrostatiques.

(

\

j

1

Hi

e author has the greatest pleasure to acknowledge his

sincere and to Ilthe following people.

Pr fessor R.J. Munz for his advice, guidance and finan-

[

q

cial support thro ghout this research. He was very helpful.

g

oin

9

\\

Dr R. Salcedo whose help and advice got this research

1

1

MI M. Ross, MI. M. Harrigan, Mrs. M. and

Mr. M. Leroux, of the .McGill Institutf of Occupational lIealth and Safety.

for their help.

MI. J. Dumont who, as usual, .,-Ias always very helpful.

Mrs P. Hyland for typing the

<fi

My P rents and famiIy for their love, support and con-

tinuous encouragerne t.

My wife, Rani, for her love, and support

..

1

\

\

,

1

\

(

(

ABSTRACT

RESUME

AClCNOWLEDGEMENTS

TABLE OF CONTENTS

LIST OF FIGURES

LIS T OF TABLES

CHAPTER

CHAPTER

..

1

l

II

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.4

2.4.1

2.4.2

2.4.3

2.5

2.5.1

2.5.2

III

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

\_ .. -

TABLE OF CONTENTS

" ..

INTRODUCTION AND BACKGROUND

FUNDAMENTALS OF ELECTROSTATIC PRECIPITATION

Corona Generation

Particle Charging

Field Charging

Diffusion Charging

combined Field and Diffusion Charging

Particle Collection

Introduction

Theoretical Migration Velocity

Efficiency Equation

The SRI Electrostatic Precipitator

Performance Computer Model

General Description

Experimental Verification

,

LITERATURE REVIEW

Introduction

Observed Solid-Solid in ESP's

Power Plants

zinc and'Lead Smelters

Iron and Steel Industry

Cement Industry

Aluminium Production

Municipal Incinerator

Co

iv

i

Hi

iv

viii

xiii

1

4

4

4

5

5

7

9

11

11

11

13

14

14

17

21

21

21

21

25

25

(l 2B

t9

29

"

1

CHAPTER

CHAPTER

(

3.2 .1

3.2.8

.

3.3

3.4"

3.5

IV

4.1

4.2

4.2.1

4.2.2

4.3

v

5.1

5.2

5.2.1

5.2.2

5.2.2.1

5.2.2.2

5.2.3

5.3

5.3.1

5.3.2

5.3.3

5.4

5.5

5.5.1

5.5.2

5.6

5.6.1

5.6.2

5.6.3

5.6.4

5.7

5.7.1

5.7.2

5.7.3

5.7.4

5.8

5.8.1

5.8.Q

5.8.3

5.8.4

1

Petroleum Industry

Copper Smelters

Pu1p and Paper Industry

Separation Efficiencies

Mechanisrns of Solid-Solid Segregation in ESP's

Conclusions

EXPERIMENTAL EQUIPMENT

General Description

Particle Feeding

Vibrating Screw Feeder

Wright Oust Feeder

Safety Precautions

EXPERIMENTAL TECHNIQUES

Introduction

Dust Sampling

General Considerations

Sampling Trains

Outlet Sarnpling Trains

Inlet Sampling Trains

Anderson Cascade Impacter

Chemical Analyses

Atomic Absorption Spectrephotometer

Sample Preparation

Instrument Conditions

Particle Collection Experiments

Procedure for Typical ESP Run

Treatment of Experimental Data

Electron Microscope: Hicro Analysis

Considerations

Energy Dispersive X-ray Analyser (EDAX 707A)

Specimen Preparation

Particle Analysis

X-ray Diffractometry

Principle of Operation of the X-ray

Diffractometer

Sample Preparation

Instrument Conditions

Identification of Chemical Compounds

X-ray Fluorescence Spectrometer

Principle of Operation of the X-ray

Fluorescence Spectrometer

Sample Preparation

Instrument Conditions

Identification of the Elements

\

\

\

\

1

\

v

Page

30

30

31

31

33

34

36

36

38

39

39

41

42

42

42

42

42

42

43

43

45

45

46

46

46

47

47

51

52

52

53

55

55

56

57

57

58

58

59

60

60

61

61

.' J

(

CHAPTER

(

,

CHAPTER

(

VI

6.1

6.2

6.3

6.3.1

6.3.2

6.3.3

6.3'.4

6.3.5

6.3.6

6.3.7

6.3.8

6.4

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

6.4.6

6.4.7

6.4.8

6.4.9

6.5

6.5.1

6.5.2

6.5.3

6.5.4

6.5.5

6.5.6

6.5.7

6.6

6.6.1

6.6.2

6.6.3

VII

7.1

7.2

OUST CHARACTERIZATION, LABORATORY SCALE

EXPERIMENTS AND SIMULATION

Introduction

Choice of OUst Used

Copper Smelter (Noranda) Dust

Introduction

Chemical Composition of the Bulk Sample

X-ray Diffraction

Precipitation of Noranda Oust:

Global Collection Efficiencies

Computer Simulations (SRI Model:

Lab Scale ESP)

Elemental Collection and Separation Effi-

ciency as a Function of ESP Length

Scanning Electron Microscope

Conclusions

lndustrial Zinc Smelter Dust

Chemical Analysis

X-ray Diffraction

Cyclone Analysis

Precipitation of the Overall OUst

Theoretical Prediction: SRI Model

Comparison of Theoretical and'Experimental

Collect!on Efficiencies .

Scanning Electron Microscopy

Conclusions

Hydro Power Plant Fly Ash

Cyclone Analysis

of the Overall Oust

X-ray F1uarascence

Scanning Microscope

with Values Reported by Curtis (1977)

Municipal Fly Ash

Introducti'on

X-ray Fluorescence

Conclusions

SRI MOOELLING OF THE NORANOA OUST

IN AN INDUSTRIAL ESP : COMPARISON

WITH EXPERIMENTAL DATA

Introduction

Simulation Resu1ts for Present Operating

Conditions

vi .1

,

62

62

62

64

64

65

65

67

69

74

79

86

90

90

91

91

93

95

103

107

112

114

118 .

118

119

119

122

, 127

129

130

132

132

132

135

136

136

139

.'

J

(:

....

CHAPTER

REFERENCES

APPENDIX

APPENDIX

..

7.3

7.4

7.5

VIII

8.1

8.2

A

B

"\;i.mulation Resu1 ts for Increased Dust Load-

ings: Loading Increases to 27.1 91m

3

and ~ 2 7 g/m

3

Effect of Varying Current on Collection

Efficiency

Comparison of Theoretical Predictions

and Industrial Data for the Noranda Dust

Conclusions

CONCLUSIONS AND RECOMMENDATIONS

Conclusions

Recommendations for Future Work

TABLES

COMPUTER OUTPUT

r

..

..

" .

vii

145

154

155

161

164

164

168

169

A-l

B-1

j'

1

"1

(

Figure

2.1

2.2

2.3

2.4

3.2

4.1

4.2

5.1

6.1

6.2

LIST OF FIGURES

field Unes for charged

particle in electnc field, McDonald et al

(1978)

Electrostatic tator system mode 1 ,

Nichols et 'al (1970)

flow diagram of tator nodel

computer program, Gooch et al (1977)

(a, b) measured and ldeal1y

.cula ted collecti on e ff

in the laboratory Goach et al

(1976 a, b)

size segregation of mataIs,

retort stack, Jacko et al (1975)

Inlet distnbution ta Baghouse from

arc furnace, Lee et al (1975)

diagram of facility,

Salcedo (1981)

Schematic of Wrlght dust

Salcedo (1981)

Schematic diagram of Minicyclone, Sa1ceda (1981)

OVerall size of Noranda dust at the

ESP inlet (Anderson Ml< III Cascade Impactor)

Elemental indi 'lJ'ldual size of the

Noranda dust at the ESP inlet (Anderson .MK III

Cascade Impactor)

viii

10

15

18

19

26

27

37

40

48

70

71

Figure

6.3

r

,

6.4

6.5

6.7.

6.S'

6.9

6.10

, 6.12

6.13

(

E1ementa1 individua1 size distribution of the

dust at the ESP inlet (Anderson MK III

Cascade Impactor) " Salcedo (1981)

')

Cumulative e1emental collection and separation

efficiency of the Noranda dust as a function of

ESP length

Cumulative elemental collection and separation ef-

of the Noranda dust as a of

ESP Length, Salcedo (1981)

Scanning electron micrograph of a group of small

part1cles (X 10,000): Noranda dust

Scanning electron micrograph of a large particle

by srnall particles (X 5,000):

N9randa

Scanning electron micrograph of the particle shcwn

in Figure 6.7 .with the rnapping for Cu super-

imposed: Noranda dust

Scanning electron micrograph of the

in Figure 6. 7 wi th the mapping for

imposed: Noranda dust

!3ackground mapping fO'r Cu

(

pal.ticIe shown

Pb super-

Scanning micrograph of a group of small

particles (X 50,000): Mapping for Pb: Noranda dust

scanning electron micr9graph of the sarne particles as

in Figure 6.11: for Cu: Noranda dust

Energy ve analysis of X-rays ('EDAX) of a large

particIe: Noranda dust

ix

72

76

77

80

80

81

81

1

82

85

85

1

88

Figure

6.14

6.15

6.16

6.17

6.18

6.20

e'

6.21

6.22'

6.23

, ,

,. ,

Overall size distribution of the zinc smelter dust

at the ESP inlet (Anderson MK III Cascade Impac-

tor) Runs No. 2 and No. 3

Elemental size distribution of the zinc smelter

dust at the ESP inlet <tnderson MK III ascade

Impactor) Run No. 2 (i

Elemental size distribution of the zinc smelter

dust at the ESP inlet (Anderson MK III Cascade

Impactor) Run No. 3

Theoretically predicted collection efficiencies

versus dimensionless length for Zn at various

values of di-electric constant: Zinc smelter dust

Theoretically predicted colleltion efficienfies

versus dimensionless length for Fe at various

values of di-e1ectric constant: Zinc smelter dust

OVerall collection efficiency of zinc smelter dust

versus dimensionless length: Runs No. 2 . and

No. 3

Cumulative elemental collection and separation ef-

ficiencies as a function of ESP, length: Run No. 2

Cumulative elemental collection and separation ef-

\

ficiencies as a function of ESP length: Run No. 3

Scanning electron micrograph of a group of partic1es:

Mapping for irone zinc smelter dust

Scanning electtqn micrograph of the same particle as

in,Figure 6.20: Mapping for zinc. Zinc smelter dust

/

\...

'X

97

100

101

106

108

109

ho

111

113

113

1. ,

-1" ~ ~ - - - - - - .

--_._( .,

..

,

. 1

, !

Figure

6.24

,I

6.25

6.26

6.27

6.28

7.1

7.2

7.3

7.4

7.5

7.6

-

J

o

Ertergy dispersive analysis of X-rays (EDAXi of a

bunch of particles: Zinc smelter dust

Ove raIl distribution of the power plant

fly ash at the ESP (Anderson MK III as-

cade Impactor)

,.,

. .

Overall collection efficiency of power plant fly

ash versus d1mens10nless length

Scanning electron micrograph of a group of particles

(X 10,000): Power plant fly ash

Energy dspers1ve analys1s of X-rays (EDAX) of' a

large .and a smal1 particle super1mposed

Plots of collection and separation efficiency versus

3

length in Section 1: ,20.9 g/m

(3.04 gr/acf) 53kV, 170 mA

Plots of collection and 'separation efficiency versus

lengt? in Section Il: 20.9 g/m

3

[3.04 gr/acf) 44kV, 290'mA

Plots of collectJ.on, and separation efficiency versus

3

length in Section Ill: 20.9 g/m

[3 . 04 gr/acf) 42 kV, 390 mA

Plots of and separation efficiency versus

length for aIl three sections: 20.9 g/m

3

[3.04 gr/acf)

Plots of collection and separation effic1ency versus

3 '

length for aIl three sections: 27.1 g/m

[3.94 gr/acf)

Plots of collection and separatin efficiency versus

1ength for aIl thre sections: 62.7 g/m

3

(9.12 gr/acfJ

xi

115

123

124

128

128

140

141

,142

143

147

148

"

\

1

1

/

l'

..

(

Figure

'"

7.7

7.8

7.9

7.10

"

0

, .

..

Plots'of separation efficiencies versus

length for all three sections at different dust

loadings

Plots of efficiency versus

length 1n Sect10n l

voltage of 53 kV

(3.04 gr/acf]

for different currents at a

3

toad1ng is 20.9 g/m

Position of sampling points along the industrial ESP

of Cu and (Pb + Zn + Cd) versus

length for the indus trial data pnd theoretical pre-

dictions: Noranda dust

.'

151

156

157

J

160

c.

-,-

(

r

Table

3.1 .

6.1

6.2

6.3

./

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

,

LIST OF TABLES

Comparison of the composition of some eLements in

samples of the precipitator and post-precipitator

fly ash: Ontario Hydro

Elemental composition of Noranda dust feed

Chemical forms of the elements: Noranda dust

Experimental conditions and global results for

Noranda dust

Size distribution of copper and (lead, zinc and cadmium):

% undersize

and SRI elemental collection efficiency

for Noranda dust

'Non-Cumulative collection efficiency for Noranda dust

Ratio of lead/copper concentration in large particles:

Noranda clust

Ratio of lead/copper concentration in smalt particles:

Norancla dust

Elemental composition of the zinc smelter dust

Chemical forms of the elements: zinc smelter dust

o

Results of cyclone analysis on zinc smelter dust

Experimental conditions and global results for

zinc smelter dust

Comparison of the elemental composition of the precipi-

tated zinc smelter along the plates of the ESP,

.with the feed composition

xiii

23

1

66

66

68

73

75

75

84

87

92

92

94

...

98

102

Table

6.14

6.15

6.16

6.17

6.18

\ 6.19

6.20

6.21

7.1

7.2

7.3

7.4

(

t

Size distributions of copper, zinc and iron: Zinc

smelter dust: Cumulative % undersize

Values of di-electric constants simulated in SRI

mode1: Zinc sme1ter dust

Comparison of the concentration of iron/zinc in a

group of partic1es: Zinc smelter dust

Results of cyclone analysis on Ontario Hydro Fly Ash

Experimental conditions and global results for the

power plant fly ash

Non-Cumulative collection efficiency for the power plant

Uy ash

Ratio of peak heights (in1et/outlet) for different ele-

ments in the two dust samples: Ontario Hypro Fly Ash

Ratio of peak heights (inlet/outlet) for different ele-

ments in the two dust smples from the Nunicipal

Incinerator Electrostanic precipitator

Input data for computer modelling in industrial ESP:

Noranda dust

..

Particle Siz distribution of copper and (lead, zinc and

cadmiUm) entering and leaving Section 1: Noranda Dust

Comparison of dust layer-thickness (mm/min) at dif-

ferent dust loadings

Ratio of current carried by ions to particles for the

dust 27.1 g/m

3

and 62.7 g/m

3

xiv

104

116

116

120

121

121

125

134

137

144

150

153

1

1

!

i

1

i

>

!

1

1

l

...

(

Table

7.5

7.6

A-l

A-2

A-3

A-4

)

A-5

Concentrations of copper at ~ h midpoints of the three

electrical sections! Noranda dust

Concentrations of lead, zinc and cadmium at the midpoints

of the three electrical sections: Noranda dust

Physical dimensions and operating conditions of the

laboratory and indus trial ESP needed for the SRI

computer simulation

Copper concentrations along length of the industrial ESP

Zinc concentrations along length of the indus trial ESP

Lead concentrations along length of the indus trial ESP

Cadmium concentrations along length of the indus trial ESP

..

..

xv

159

159

A-2

A-3

A-4

A-5

A-6

/

f

,

1

,

1

{.

l

(

(

CAAPTIR l

INTRODUCTION AND BACKGROUND

The control of partlculate emisslons from large-scale

indus trial processes has been an lncreasingly important ptbblem sinee

the latter part of thlS century. In many cases, these emissions may

contaln valuable component(s) which, if recovered, can have signlfieant

process values.

Electrostatlc preclpitators (ESP)J whlch are high effi-

ciency gas-solid separation devlces, have been used ta control emissl0ns

from power plants and many processing lndustries as weIl as in the re-

covery of valuable materials like gold and silver from ffilnts and of eopper,

lead and Zlnc from non-ferrous smelters (White, 1963).

In most cases, when the precipitated dust lS collected in

bulk, lt has ta be subJected ta further enrichment (hydro or pyrometallur-

gical technlques) before lt can be of any Slgnlflcant process value.

Several cases have been reported, however, ln WhlCh segregation of different

\

chemlcal specles has occurred along lndustrlal ESP's. If the ESP lS

divlded up lnta sectlons and the enrlched dust collected separately,

further processlng mlght be less expenslve Slnce the quantity of dust

treated wl11 be smaller.

It was only recently, however, that the segregatlon

mechanisms ln ESP's were fully lnvestigated by Salcedo (1981). He con-

cluded that the dust praperties that affect solid-solld segregatl0n are

partlcle Slze dlstrlbution, electrlcal reslstivlty, and dlelectric constant

;

,

~

~

,

,

~

i

l

,

~

1

~

&

~

~

t

~

~

~

R

l;

2

(

and the ESP operating variables are air velocity, applied voltage and

corona current.

The overall purpose of this study to determine the

minimum information must be available on a dust and collection

system in order to the degree of segregation and how might

be enhanced. The may be a characterization

of the dust the may include full scale

trial experiments supplemented by computer

The specifie objectives of work were as follows:

(1) To identify dusts where

of valuable elements

(2 ) To several promising dusts and de-

termine if further 1n a laboratory

scale ESP worthwhile. f'

1

'.

(3) To measure the and effi-

ciencies of the chosen dusts Along the length of

the precipitator at room temperature.

1

(4) To compare the results obtained w1th

those uS1ng the Southern Research

tute (SRI) computer model.

Il

(5) To carry out industr1al scale experiments and simu-

.,

lations where possible.

(

,

"

\

3

(.

(6) To compare the simulation$ obtained in objective

(5) to actual results obtained by

and mass measurements in precipitators

where p'ossible.

./

\

The ESP laboratory at McGil, is equipped with a laboratory

l

!

scale having a high voltage supply of 40 kV (maximum) and

i

1,

a air velocity through the of 5 rn/s.

,

was used to the segregation of the LndustrLal dusts

chosen.

Chapter II the fundamental theory of electro-

precLpitatLon and the Southern Research Institute (SRI) computer

... .)

!l'Odel. Chapter III is a literature review of solid-solid segregation in

ESP's. Chapter IV descrLbes the experimental and Chapter V

the experimental teqrniques used in this work. Chapter VI presents and

discusss experLmental results of dust characterLzation and laboratory

scale experiments and presents theoretical SRI predictions of collection

and separatLon effLciencLes of the dusts used, where applLcable

. Chapter VII the results by simulating the of

. ' the industrLal Noranda dust in an Lndustrial scale ESP, the SRI

model.

,

hapter VIII summarizes the conclusions of the work and

/ gives recommendations for future work.

t

1

1-

r

4

(

CHAPTER II

.

FUNDAMENTALS OF ELECTROSTATIC PRECIPITATION

2.1 Introduction

The process of electrostatic precipitation can be divided

into three main steps:

1. Generation of a corona and associated electric

field.

2. Particle charging.

t

1

,.

3. Particle collection.

;

In industrial precipitators, a fourth step, partic1e removal

is'also of major

These processes have recent1y been reviewed in great detai1

1

by Sa1cedo (1981) and only the most important concepts are repeated here.

2.2 Corona Generation

White (1963), defines corona as the 1oca1ised breakdown of a

gas which does not propagat; ta form a streamer; a streamer i5 a 1uminou5

filament of heavi1y ionized gas extending from the electrode sur-

,

face. The breakdown strength of air, at standard conditions, is about

(

(

. (

5

..

If a high enough voltage is applied to a pair of electrodes,

with one having a short radius yf curvature, very high fields can exist

in the immediate of that electrode resulting in the formation of

a corona. Bath positive and negative coronas are possible.

The negative corona is used more often industry because

of its greater and current values at lower voltages.

The ions gQnerated by the corona are responsib1e for charg-

."

ing the dust

2.3 Partic1e charging

The mechanisms or particle charging by ions in ,an electric

.fie1d are field and diffusion charging and were discussed in

detail by Crawford (1976), Oglesby et al (1970, 1975,1978), Robinson (1971),

(1951,1963) and Sa1cedo (1981). Both field and diffusion charging

ac> simultaneously w1th field being dom1nant for part1cles with a

mean mass diameter (MMD) above about 1-2 and diffusion charging pre-

for MMD below 0.2 ; both mechanisms are important in the

..

intermediate range.

2.3.1 Field Charging

A brif review of the mechanism of field fo1lows

1

1

!

l

(

Where

(1. 602

" Q

[N eb. Q /4 E J [1 - Q/Q J2

o l. sos

(N) is free ion density, (e) is the elementary charge

o

-19

x 10 (Q) is parti91e charge after charging time

and (Qs) is saturation charge given by

=

3TI[K/K + 2] c E D

2

o avg

Where (E ) is the average field in,the interelectrode spacing.

av

7

(2.1)

(t)

(2.2)

For an initia11y uncharged particle, the above equation

/>'

integrates to

Q = Q t!(t+T)

s

(2.3)

Where 1 is the charging tlme constant, i.e., the time ta achieve 50%

saturation charge, given by

2.3 .2

4 E IN eb,

a 0 l

Diffuslon Charging

1

(2.4)

Oiffusl.on charging (MMD partl.c1es < 0.2 um) exists wlthout

the applicatlon of an electrl.c'fl.eld. are two mal.n theories re1ating

.

ta the chargl.ng of the partic1es by dl.ffusl.on: Liu et al (1977, 1978)

,

8

suggest that the charging occurs by a diffusion process, in which the ions

move continuously towards the particle along a concentration gradient.

Liu et al (1967, 1968), Murphy et al (1959), Smith et al (1975,1976) and

White (1951, 1963) consider charging as a probabi1istic process governed

by the kinetic theory of gases.

In the derivation of the c1assical diffusion charging

.

equation, the assumptions were made:

The particles are spherical,

the ions which reach the surface are re-

tained by induced charges with 100\ attachment

efficiency,

the externa1 field i8 only considered as a source of

ions and does not influence the charging process.

Whi te (1963) de ved the following quation uslng the above

assumptions:

.

dt

2 ...

[e rr D V N /4J Exp{-Q /2rr E D kT)

o e 0

(2.S)

For an initia11y uncharged particle, equation (2.5) integrates into the

fo1lowing

Q

2

p2n E D kT/e] tn(l + D V N e t/8 E kT)

o 0 0

(2.6)

l'

1

1

1

1 .

1

(}

..

!

j

'"

.

f

..

,

(

..

....

;

"'

9

where k is the Boltzmann constant (1.38 x 10-

23

JK-l)

.;.tA'

(8 kT)1TM)1/2 V is the ion mean thermal velocity given by V ..

e-

where M is 'the mass of a singte ion,

e' ls the electronic charge ('1.602

x 10-

19

Coul)

olt'

D is the parti cIe diameter,

:

-

N ls the free ion dens:i!ty,

0

E is the permittivity of vacuum (8.85 x

10-

12

Fm-

l

)

.0

.. .

2.3.3 Combined Field and Diffusion Chtr9ing

In the intermediate range of particle sizes both charging

mechanisms contribute significant charges. The c1assical diffusion

charging shown above the charges acquired by the

,

fine particles (D < 1 - 2 by a factor of or three (Hewitt (1957),

Liu et al 1978), Penny et al (1957), Smith et al (1978) and Van

Bush et al (19BO,and it holds particles down to about 0.1 diameter.

Liu et al (1968) postulatd that the particle surface is

4ivided into two separate regions with charging regimes1 field

oceurs when the angle of approach of the incoming ions relative to

the undisturbed electric field (8) is less than a eritical value e

o

(Figure 2.J.).

,.

.

Saturation by field charging occurs when the external field

the presence of the di-electric partiele) equals the self .

. .

1

:

l

.1

t

i

j

J

d

f

,

...

"

10

(

/

..

:-

-

NEGATIVE IONS

9

0

..

0

,

..

"

f

e

,

1

f

NEGATIVEL y CHARGED PARTICLE

=

..

Figure 2.1. ,Electric field lines for partially h ~ g e ~ particle

in e1ectric field, McDonald et al (1978)

1

..

i'

,

,

(

, .

-

Il

field from the particle. In the particle surface defined beyond this

critical angle 8

o

diffusion charging allowed at a rate defined by

the classical diffusion charging equation.

2.4 Particle Collection

\

2.4.1 Introduction

1

The basic step that oocurs after particle charqing ia the

movement to and collection of the dust particles on the passive

electrdes. 1 These steps were reviewed in detail by Salcedo (1981)

\.

industrial precipitators are single stage units wher

the field for charging is the sarne as the collection field.

2.4.2 Theoretical Migration Velocitx'

If the charged particles are subjected to an eleotric fielp,

they migrate ta the collection plates;' the terminal velocity attained ls

....

referred to s the migration velocity.

To derive a theoretical expression for this velocity, the

following assumptions were made:

The fluid is quiescent,

the particle charge d,.oes not.

..

... 'i' .. --,".---.

"

!

1

1

t

i

1

1

1

1,

... )

12

negligible added mass, rotation and history

effects,

negligib1e gravit y and buoyancy effects,

the Reynolds number of the is very small

0.5) ,

the parti1es are spherical

\

..

Oglesby et al (1970, 1978) and (1963) derived the

fo11owing equation based on the above assumptions

where

M dw '" Q E - (3n )..1 0 w / c)

dt

M is the ma5S of the particle,

..

w is the particle ve1ocity' relative to the sta-

tiona:ry fluid,

E is the' e1ectric field strength,'

o is the partiele diameter,

C i5 the Cunningham correction factor and i5 given by

McDonald (1978a) and Theodore et al (1976) as

C - l + 2>"/D [-1.26 + 0.4 Exp(- 0.55 0/),,)]

r

where i8 the mo1ecu1ar mean free path in air given by Smith et al

(1977) as

(2.8)

(2.9)

. :

1

..

13

/

1

.2-.4.3 Collection Efficiency Equation

A collection effieiency equatlon, based on the followlng

assumptions', was derived by White (1963) and oglesby et al (1970, 1975,

1978):

'.

Turbulence causes the particles to be uniformly dis-

tributed in any cross-section (in industrial ESP's,

the gas flow is always

the gas velocity i5 uniform, except for a boundary

layer near the wall,

particle motion in the boundary layer at the

collection plates is governed by stokesian flow,

there are no multiparticle effects,

the particles are mono-disperse spheres,

the of partiele-gas and partie le-ion collisions

..

'\

can be ignored,

there are no disturbing effects sueh as erosion, re-

entrainment, uneven gas flow or baek-corona.

The following equation, which 15 the Deutsch-Anderson

(

collection equation, 15 then obtained.

14

fi .. 1 - Exp [- W L' 1 v SJ

o avg

(2.10)

where n i5 the collectlon efficiency of the ESP,

L i5 the length of the ESP,

V i5 the average gas velocity,

avg

S lS the Wlre to plate spacing,

,

"

'W saturation migration velocity.

0

2.5 The SRI Electrostatic Precipitator Performance Computer o d ~ l

2.5.1 General Description

A brief overview of the SRI computer model will be given

here. More details are given by Salcedo (1981).

The electrostatic precipitator 15 a complex system, in which

the various sub-systems (corona generation, electric field, particle charg-

ing and collectlon, dust properties and non-ideal effects) are closely lnter-

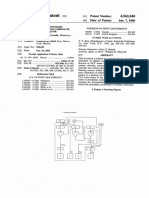

related. The systern's analysls of ESP's were first worked out by NichaIs

et al (1970) and Oglesby et al (1970) at the Southern Research Instltute

(SRI), Alabill1la; (Figure 2.2) At that tlme, a rellable theory of electrlc

fields ln parallel type ESP ,s with the presence of space charge was not yet,

available, and the model included the theoretlcal relatlonships derlved for

cylindrlcal (tubular) ESP's. No corrections were included in the original

model to acco,unt for non-ideal effects, which may either increase or decrease

,.

,

J

1

1

i

J

!

t

1

l,

1-

.........

..

IlIRE RADIUS

COlLECTOR RADlUS

III RE ROIJ6HHESS

SECOIIllARY ElII SS1 OH

AVAlAIICHE COfFFI C 1

RADIATIOH

ElECTIOEGA TI VE GAS

GAS VElOCITY

VElOCITY OISTRIBUTlOH

COLLECTION AREA

VOlIJ'{ FLOW

APPLIED VOlTAGE

GAS DEHSITY

10/1 lIlB lU TY

WHdJUmmOH

(Oum 1 011 ARa

VIRE RADIUS

COllECTOR RAD1 US

PARTICLE SIZE

DIELECTRIC COICSTAHT

TIl'{

TEIftRATURE

OUST LOO

GAS AND OOST

1011 VELOC ITY

-

-""

-

CORONA

6EHERATIClII

NEGATIVE

IOH

FORl'oATlOH

ELECTRI(

FIELD

PARTICLE

CHAR6ING

2.2

---" ........................ .. ..

. ....

RES 1 STlVIll

1-- VAl! 10 IIMlS. IQ.ECIUI

ElfCTIIC

GASVE OCITY

AIID ClIAf 1 CAl.

FIELD IN

DEPOSIT PARTICLE

IDAIRII;

FORCE

ELECTRI(

III ND

PARTlClf

COlLECTlOH

"

t

1--

PARTICLE

REENTRAIIt'EHT

OOST

1

l

1--

ROlIVAl

1-- SPACE CHARGE

:

GAS AND IJICOLLECTED IlUST

COllECTED DUST

OOST LOAD

1

1--

PlATE [{S16ft PARTlClf SIZE

HOPPER SIGN OUST PROPERTl[!

GAS VELOC III TEIl'ERA TURE

GAS DISTRIMUJ!

RAPl'IIKi FoRCE

RAPP1116 INTERYAl

E1ctrostatic precipitator system model, Nichols et al (1970)

;-..

"1

1-'

VI

\

(

the collection and charging was the only charging mechanism con-

r

sidered. The model was updated in 1978 to correct the above short-

comings.

The main characteristics of the model are as follows:

"

.'

The electric field at the plate, which influences the

migration veloclty of the charged particles, is esti-

mated by two methods: lf the current voltage charac-

terlstlcs are known, the numerical technlque of Leutert

et al (1972) lS usedi if t,he current voltage characteris-

tics are unknown, th en the numerical technique of Mc-

Donald et al (1977) is used.

The partlcle charges are either by the theory

of Smith et al (1975, 1976) or by summing the charges

acquired by field and diffusion charging (see Salcedo

(1981

The collection efflciency is estimated by using the

Deutscr equation. Since thls'equatlon is only valid

for single sized particles of cons tant charge, this

problem is overcome by applying the Deutsch equation to

small lncrements and to representative mean sizes

of Slze classes in the partlcle size distrlbution histo-

gram. The global efficiency is then calculated by

weight averaging the fractional efficiency over the en-

/

tire size distributions.

,

1.

1

t

\

1

..

,

1

i

f

(

(

17

Provisions are included in the model ta correct for

non-ideal effects such as gas sneakage, non-uniform

velocity distribution, re-entrainment and particle

near corona wires or particle concentration

gradients.

Figure 2.3 from Gooch et al (1977) shows a simplified flow

J

diagram of the computer program, which is given in by McDonald

(1978a) Baslcally the program is structured inta three major lOOpSi

the outermost converging on the global efficiency, the next loop runs over

each length increment while the inner loop runs over'each particle size.

Also shown in Figure 2.3 is the part of the program which introduces theore-

tical and empirical corrections for non-ide al effects but which was not

used in this work.

2.5.2 Experimental Verification

In order tp compare the theoretica1 predictions of their model

to actual data, SRI conducted a series of tests in a

laboratory-scale parallel plate ESP similar to the one used thlS work.

Non-ideal effects, such as re-entrainment, were absent although a small

amount of gas sneakage could not have been prevented.

theoretical

et

al (1976a, b), Figures 2.4 a, b reported that the

and experimental data show goOO agreement for a wire

,

i

l

.

{

(

Figure 2.3.

1

i

1 Read d.Ua J

t

no of part .n eaeh l'l! bandl

-'

1Ci""1C. no. 01 len!!th IOClements and 'la/inclement from est.mate r---

ICalc. spa,e chaIlle due to palt.culat! based on 'Ioest.m.te f--

. rcilc. reduced flJ! on d!ns.ty for pirt.cle challZlnli calc 1

+

ICompute average f.eld for charg.n!l

t

1 Cau E f.eld. compute field at olate 1

t

lOlIi chlrlll!. clile charllll! on uch s.le part. f--

for uell S'le f,om W fOI !.ch uzel

t

1 Clic. no 01 part remO'/ed .n uch s.ze]

t

1 Som _.ghl or pan.cles removed 1

t

sile dIstribution to s!!Ct.on l

r for nch part Slll

(Cale. MMC and _."hl coile<:ted lor th., Ineremenil

1 Repe.t for eaeh .ncrement

(Check overall compuled "0 Wlth "0 estolNte. repea! .f reQu.red 1

1 Repe,! t.1I conve,!!eS :!: 0 05$

LCalc cffe.:t.ve 'Ne for each S'le l

t

1 .lc:. rate parameter 1

,..- - - - 'f - - - --

l (;li:.: facter 'vr ias velccltv

t

IClIC. correct.on fllctor 101 reentlalOment-snelluge]

+

IJ,;!lc r.ducea effect.ve We

t

1 ClItc. r,,(juced eHIC.eiCYl

T Repea! fOI each part. Slze

; / 1 Clic reduced eff.c.eiiCYl

1 ___ _

non-fal Prin! resulls

effects

-,

f

1

1

1

_01

Simplifi.ed flow diagram of precipi tatar model

computer program, Gooch et al (1977)

la

..

f

!

1

1

_____ : l

-----

,,-

.......

"

"

( a)

99 9. i i i l '1 l 1 JI i i i

998

;1.99

)0-

u

Z

w

Q98

1::

w

z

0

u

w 950

J

J

0

U

900

800

100

600

01

o e 26 9 nQ/cm2 ,_ ;ll7 m/r.ec

1 1 1

(b)

l ' 8 M/cm2 ,_ 'll7m/$ec

a J' . 'mm'.K /

99.9 1 1

.

. 1 A . 1

S=6.35 cm ore

,

NEGA TIVE CORONA

, J 1/

99.8

GAS VElOCITY - 1 46 mlsle 1 -428.0

o EXPERIMENTAL.

1 - 107.5fJAlm

2

"<Il.

OEXPERIMENTAl. 24.0

1- 268.BpAlm

2

>-

.t t etteal

u

99

AEXPERIMENTAl..,

z

j - 4Jo,.tA1m

2

w 200

a'{fo

H

- THEORETICAl

D / u..

S=9.5 cm

. /

u..

.1 I;e

w 16.0

Z

0

95

././ 1 e 0

12.0 ./ 1 U

.!

w

90 ..J

..J

.-y 0

8.0

e'"

U

80

4

.-......

6Ot-

-14.0

30

-'\

100

PARTICLE OIAt.lETER. Ml,omtll,.

il.1 1.0 10.0

GEOMETRie MEAN DIAMETER, J,lm

2.4 (a, b)

Experirnentally rneasured and.ideally calculated fractional

collection efficiencies in the laboratory precipitator,

Gooch et al (1976 a, b)

-E

u

>-

....

u

0

..J

w

>

Z

0

....

a::

C!)

... '."1 ri ... ....... "' .. ....... -...

"-"l

...

J

r;.

20

to plate spacing of 6.35 cm at a current density around

-4 -2

5.4 x 10 Am

For both higher and 10wer current densities and higher wire to plate

spacing (9.5 cm), the agreement worsens, with the experimental efficiencies

being higher thar the theoret1cal predictions except ae the low current

density of

-4 1""2

1.1 x 10 AIn

McDonald (1978b) reported resu1ts with trends similar to

Figures 2.4 a, b; the conditions reported were a wire to plate spacing

of 12.7 cm, an average air velocity of

-1

0.976 ms and an average current

density of

-4 -2

2.58 x 10 Am'.

Salcedo (1981) also used the SRI model to predict the

collection and separation efficiencies of

(a) mixtures of pure compounds,

(b) an industrial copper smelter dust,

in a laboratory scale ESP. Good qualitat1ve agreement and fair to good

quantitative agreement was reported between the SRI predictions and the

experimental separat10n efficiencies, in the absence of re-entrainment,

for mixtures of pure compounds. For the industrial copper smelter dust he

reported that the model underpredicts the collection of the large particles

and overpredicts the collection of the small particles. However, if there

is no re-entrainment, the prediations are good.

On the basis of the above tliscussions, it may be said that

the model is useful for predict1ng collection and separation efficiencies in

the absence of re-entrainment and other non-idea1 effects.

1

1

t

1

21

(

CHAPTER III

LITERATURE REVIEW

3.1 Introduction

The segregation of in ESP's is the enrichment of

sorne component(s) (relative ta the other component(s) in the flue gas)

in the dust collected by the precipitator. Sorne major instances of

ESP's are examined. A more detailed review is given

by Salcedo (1981)

n

3.2 Observed SaUd-SaUd Segregation in ESP' s

3.2.1 Power Plants

The fly ash produced from coal and ail fired industrial

boilers accounts for about 60% of total ESP installed capacity (Petter-

sen, (1980 Typical major elements found in the fly ash fram, the mOFe

cotmnOn, coal flied plants are Al, Fe and Si while typical minor elements

are Ti, Mg, Mn, S, Ni, Cu, Na, K and unburned C.

..

The alumina in the fly asn (15 - 30% Al

2

03) is

,

by Eisele et al (1979) as a possible source for metallurgical grade alumina

and by Mehrotra et al (1974) as a source of aluminum and titanium. The

vanadium content of the fly ash, although SInall in most cases, can he of

major importance ta Canada steel industry if enriched.

,

22

(

The six generating stations at Ontari'o Hydro bum coal

for the production of power. Table 3.1 below compares the composition

of sorne elements in the precipitator and post-precipitator fly ash when

U.S. 'bit1.1rrUnillUS coal is burnt. The enriclunent ratio, defined as the

ratio of the composition of an element in the precipitator and post-

precipitator ash, i5 also shown.

lt is apparent from Table 3.1 that a little elemental segre-

gation occur within the ESP sinee the enrichment ratio is different fran

unit Y in all of the cases; calcium has the highest enrichment ratio and as ,

such segregates more than the other elements. Vanadium also shows seme

segregation the post-precipitator a5h having more vanadium.

The elemental weight percentages, uq,ed in the calculation

,

of the enrichment were obtained by analysing the tion of the

individual element in the bulk preeip1tated dust. Much higher values of

enrichment ratios are possible, if the dust is collected in sections, since

preferent1al precip1tation of elements can occur along the length of the

ESP No data on the segregation of elements wi th1n the ESP was ob-

tained from Ontario Hydro.

Ontario Hydro 1S now burning coal from other geographical

locations and appreciable quantities of two Western Canadian coals, Luscar

and Byron Creek, are now being mixed U.S. bituminous coal before be1ng

burnt. This could alter the compositions. No reports on the

combustion of thes'e coals were obtained from Ontario Hydro.

(

__ .J._,, __ _

1 1

------,-

1

,

1 Ci

1 \ "

!

1

l

, .

( ..

~

\

, ,

.

, .

\

TABLE 3.1

COMPARISON OF THE COMPOSITION OF SOME ELEMENTS IN SAMPLES OF THE

PRECIPLTATQR AND POST-PRECIPITATOR FLY ASH: ONTARIO HYDRO

/

. .

1

,

" {

"

-.----_._---_ .. -

23

,

1

1.,

1

1

,

1

1

1

.'

24 .

Mills tl966}' .report.ed that the fly ash produced' ftom the

combustion of coke (obtained from processing Venezuelan crude contaminated

with 130 ppm of V) at Petrofi'na in Montreal contained about 15\ by

This' vanadium rich fly ash was recovered by an electro-

static precipitator and the ash treated in bulk (method developed by

Petrofina) to vanadium pentoxide, of 99\ purity, at a rate of

455 to 545 kg/day (182.5 ta 219 tons/year). The capacity of the tret-

ment plant was 1354 kg/day (547.5 tans/year). No studies on segregation "

of vanad.iUIfl within the precipitator were reported.

At that time, the estimated Canadian need for vanadium was

135 tons/year of contaminated vanadium and which was weIl in reach of

Petrofinai Venezuelan crude is no longer being processed by Petrafina and

the process has been abandoned.

An alternative fuel for indus trial boilers is the bitumen

-residue of the Athabasca tar sands. Sirianni et al (1972), Stemerowicz et

al (1975) and Vezina et al (1965) showed that the ash produced after the

combust-ior of the bitumen fraction is rich in Ni('" 0.66%) and V('" 1.4\).

J

Petro1eurn coke, a by-product of the Suncor refinery at Fort

McMurray, fuels the coke-fired steam generator at the complexe Prokopuk

et al (1981) showed that the fly ash produced after the combustion of coke

contains 5i0

2

(14.3\), A1

2

0

3

(8.4\l, 1;'e

2

0

3

(2.7\), Ti0

2

(0.8\), P

2

0

5

(0.1\),

CaO (2.6%), MgO (0.7%), 50

3

(0.1\), Na

2

0 (0.5\), K

2

D (0.5\), NiD (0.4\) and

the are in weight percent at a 1imestone/fuel ratio

.

r'--'

"

1

.

, .

j

,

) ,

\.

"

,- f

25

: J

Qf 0.1. The most valuable element in the f1y ashiis is

produced at a rate of 2100 kg/day.

tion of the elements within the ESP

...

3.2.2 Zinc and Lead Smelters

No data are reported on the segrega-

.

"

'1

1

J,

Eatough et al (1974), jacko et al (1975) et al

(1970) reprt:!ed that the emissions are rich. ,in Zn and Pb with minor

"

>

'J

elernents being . Fe, Cd, Cu, Au and Ag A typical trace metal segrga-

tion by size is given by Jacko et al (197?) for particulate emissions from

a zinc facility and in F1gure '3.1; the more volatile

e1ements Pb, Zn and Cd are concentrated in the smaller particles and

the more refractory copper is evenly distributed with,particle'size. No

on elemerttal segregation has been reported.

3.2.3 Iron and Steel Industry

The gaseous effluents produeed from the 1ron and steel in-

dus tries are very rich in particulate iron oxides and account for about

10\ of the total

ESP instal1ed capacity (Pettersen (1980; other

meta11ic elements are Al, Zn, Pb, Mg and Mn.

-,

. '

" ,

r '

The size composition dependence ... fr.j,Jou,mL1l-.... a.un _______ _

electric arc furnace is given in Figure 3.2, Lee et al (1975) Only

Ni, Cu and Sb exhibit widely differing partiele size

,

1

, "

1

, j

1

r

!

J!

\

1

1

r

1

1

"

"

-:

'"

(

..

Figure 3.1

(

u1

1000

500

r"

200

Ir

100

!O

20

--\

.

..;

10

-

5.0

.;

2.0

J

1.0

/ .

0.5

CMlmlum \

D.2

-

0.1

0.05

"'<Coppet

--_.r'

0.2 0.4 0.6

l ' 2

"

6 10 20

diIIMw, mlCl'onl

Particle size segregation of metq1s, vertical

retort combUstion stack, jacko et al (1975)

<)

26

l

.1

,f

"

'.

1

J

1

1

l'

-.....-1It'"'''''T .. ....

, \

, ... _ ...... ...

-

'"

..

1 - Fe

- - - - - estmated

:2 - V

3 - Cr

4 - NI

.,nL-_ \...-

Il - Ml

Il - Cu

7 - Pb

--

- -

- Sb

Il:: 1 """-

-1. __

- -

l! 1

\.

--

-

-

- -..!..

\ - '\.'\"- 4

--

-

--

'\

"'

-

1

2

1

6.01 1 il sb 10 l '4I"S lia . =')l99

8

Figure 3.2. - Inlet distribution to baghouse from arc furnace,

Lee et al (1975t

--s:.

- ...__ ...--, ..............

...... .." ... c- ............ ___ ..

{"l

'" --..J

Ir

.-

\

28

Ni and Cu being smaller and Sb being larger. Since the size dis tri-

butions of Sb and were only estimates, it is unlikely that good

separation due to size i5 this dust.

Maczek et al (1980) report the recovery of Zn and Pb

(as oxides) by an ESP, downstream of baghouses, in

steel making fumaces. An enrichment of 2.5) in the concentration of

lead and zinc the precipitated dust that in the dust leaving the

electric furnaces was obtained.

3.2.4 Cement Industry

The atmospheric emissions from cement kilns account for

about 10% the total ESP installed capacity (1980. Re-

covery of the dust is important since its chemical composition is the same

as the kiln feed; 41% CaO, 19% Si0

2

, 10% Fe

2

0

3

, 10% (K

2

0 + MgO + Na

2

0)

with the balance being volatiles or combustiles (Oglesby et al (1970.

The are the most volatile components and concentrate

downstream from the other cement components, Oglesby et al (1970). A

possible for this dust collection size dif-

ferencesj the alkalis are the most volatile components and

of these followed by condensation results the formation of very fine

particles.

1

1

29

3.2.5 Aluminum Product10n

The alumina, used as feed in the reduction cells, is com-

posed of two S1ze fractions w1th the finer fractions contaminated with

Fe, T1, P, V, Zn and Ga, andDthe coarser useful fractlons rich in alumina.

Selective precipitation by the ESP (Bohm et al (1976)) a110ws the finer

fract10ns to be collected dmmstream of the COarser fractions; the finer

fractions, which a're enriched in the contaminants, may then be dlsposed of

without affecting the contaminant level in the reduction cells.

A similar segregation, due ta S1ze, was a1so reported by

Hanna et al (1972) who showed that the emissions from Soderberg reduction

cells show a segregation of par\iculate fLuqrides which are concentrated

in the larger particles.

'3.2.6 Municipal Incineratir

The effluents from a municipal incinerator plant can be rich

in Cu, Al, and Zn and even possibly V, Ag, and Au as reported by

GabIer (1979). In the Unlted States, approx1mately 9.3 million dry tons

of municlpal sewage sludge are generated annually of wh1ch 35% is inc1nerated.

ESP's are used ta control emisslons from munlclpal lncinerators. No

data are currently avallable in the literature on observed segregation in

this application.

\

\

,

1

1

l

1

l

1

30

3.2.7 Petroleum Industry

ESP's are widely used to recover catalysts dust from

discharge streams of catalyst regenerators; these dusts are produced by

the attrition of the catalyst (Oglesby et al (1979. No data are avail-

able in the literature on observed segregation in thlS application.

3.2.8 Copper Smelters

Emisslons fram copper smelters are rich in Fe, CU, Zn,

Pb ffild Cd with various other minor like As, Bi, Ag and

Au (Davis et al (1979), Eatough et al (1980), Tayler (1976) and Oglesby

et al (1970

Tayler (1976) showed that the dusts from bath a copper re-

verberatory fumace and copper converter consist of two size

"the coarser fractions (> 1 consist of the more refractory elements

while the more volatile elements 1 were concentrated in the finer

fractlons. Tayler attributed the existence of these two Slze r.anges ta

different mechanlsms of particle formatloni the coarser fractlon was most

probably formed by the dlsruptlOn of the melt by gas bubbles or mechanical

stirring while the finer fractlon was probably formed by volatilization

and subsequent condensation in the gas stream.

Salcedo (1981) conducted experiments on samples of a copper

reactor (Noranda) dust in a laboratory scale ESP. He also showed that

...

5

i[

1

"

C

,

(

"'

r

.'

(

i

j

31

there are two size distributions: the coarser particles were rich in

copper and the finer patticles were rich in lead, zinc and cadmium.

Selective precipitation was reported with the finer particles collect-

ing downstream of the coarser particles; a maximum separation efficiency

(difference in collection efficiencies) of about 30% was reported between

Cu apd (Pb + Zn + Cd) with the concentration of Cu in the collected

dust being higher than in the feed.

3.2.9 Pulp and Paper Industry

Emissions from this industry account for about 7% of, the

total ESP installed capacity (Pettersen (1980. The dust collected

downstream of the recovery boiler (Kraft process) is recycled to the pro-

cess without any (Oglesby et al (1970. Since the entire

dust stream is recycled, enrichment will have no process advantage.

Separation Efficiencies

Ta quantify the segregation of elements in industrial dusts,

an efficiency equation has to be developed. Schulz (1970) proposed that

a suitable efficiency equation should:

(1) be a function of feed and products amounts and

composition,

j

j

i

1

,

1

,

1

-

(

32

(2 ) be applicable to any physical separation

of one material from another and be adaptable

to multi-component systems,

(3) be, zero for mere sampling operations and 100%

for a perfect separation,

(4) . he independent of the means used to accomplish

the separation,

(5) be independent of economic considerations,

(6) be the same for tne separation of the first con-

stituent fram the second as for the separatiort of

the second from the first when a two compone nt

feed is treated in one operation,

(7) be physically

vay

that can he

visualized.

Schulz (1970) reviewed about 25 different commonly used

J

concentration and separation eff1ciency equations and concluded that the

separation efficiency (E) equation, defined by

s

E

s ..

1J

R.

1

R.

J

(3.1)

where R. and R. are collection efficiencies of components i and j ,

1 J

best obey aIl of the above criteria. This was used by Salcedo

(

i.

1

i

l

33

(1981J and was also used in this work to quantify the segregation of the

elements in the industrial dusts studied. It should be pointed out that

many other separat10n efficiencies could be calculated fram the raw data;

e.g., relative volatility defined as the ratio of the concentrat1on of

element X in the post-precipitator dust to its concentration in the pre-

cipitated dust.

3.4 Mechanisms of Solid-Solid Segregation in ESP's

Salcedo (19Bl), investigated the separation of of

pure compounds (CuO, MgO, Ti0

2

,AI

2

0

3

) in a laboratory scale ESP. The

following conclusions were reported:

(1) The dust properties that affect separation are

particle size distribution, di-electric constant

and resistiv1ty with parti cIe size being

most important.

(2) The ESP operating variables that affect component

segregation are air velocity, applied voltage and

corona current.

(3) The separation of mixtures of pure compounds can be

predicted fram the behaviour of the individual species,

when fed separately to the ESP only in the absence

of appreciable re-entrainment.

j

\

\

,

J

l'

1

1

1

(

34

3.5 Conclusions

The discussion on the solid-solid segregation of indus-

trial dusts can be into three categories:- (i) observed

segregation in ESP's, (li) Lndustrial dusts where segregation is

likely, and (111) industrLal dusts where segregation is unllkely.

(1) Observed in ESP's

Component segregation of the effluent dusts

cesslng industries has been observed in lndustrial ESP's.

of

Oglesby

al (1970) report the segregation of the alkalis from other cement consti-

1 tuents the dust fram the cements kilns and Bohm et al

(1976) report the collection of the finer contaminated particles down-

stream of the coarser alumina rich particles the aluminum reduction in-

dustry.

Salcedo (1981) reported the segregation af the coarser (Cu)

rith particles from the fLner (Pb + Zn + Cd) rich in the

Noranda copper srnelter dust with a laboratory scale ESP.

"

(ii) Industrial Dust where Segregation is likely

The emissions from a smelter are rich in (fine

particles) sorne other elements beLng iron, copper and cadmium. An

enrichment of zinc in the precipltated dust rnay have considerable process

value.

(

1

l'

,

35

The chemical compositions of the fly ash produced from

municipal incinerators depend on the nature of the materials burnti

recovery of valuable components i5 possible.

The fly ash from power plants has Al, Fe and Si as

major elements, with vanadium as a minor element. Upgrading the vanadium

cohtent may be of major importance.

(iii) Industrial Dust where Segregation 1s unlikely

The particle size distributions of the emissions from the

t

iron and steel industry indicate that component segregation due ta size

1s unlikely.

\;

,

..

v

\

,

1

1

}

1

.f

1

..

..

\

36

CHAPT ER IV

EXPERIMENTAL EQUIPMENT

4.1 General Description

K single stage, wire and plate type laboratory scale ESP,

designed and bui1t by Salcedo (1981) was used in this study.

A scnematic diagram of the ESP is shown in Figure 4.1

A blower (Canada Fans size 6Cl, SS wheel) with a 3 HP, 1750 rmp mator

and operating at 3590 rpm de1ivers 0.32 Nm

3 s-l

of air against

1950.9 N/m

2

(20 cm w.g.) The air then flows through the venturi meter,

a flexlble hose (to the propagation of vibration to the ESP)

and adjustab1e guiding vanes (to straighten the flow) before entering the

_.

ESP ,.

A plexiglass section, 36 cm long and housing a series of

sampling ports, is located in the ESP before the dis charge electrodes.

The plexiglass the ESP from the ductwork and allows

visual observation. Sampling was done from the central port, with a cas-

s

cade impactor, for particle'size distribution analysis.

The ESP itself consists of two stainless steel plates,

(1.25 m and 1.28 m long) in series and on each side, giving a total ESP

,

length of 2.53 mi the plate ta plate spacing is 16.2 cm. The fifteen

corona wires are straight and cylindrical with a'diameter of 1.57 mm.

The wires and collection plates are 38.5 cm high giving a total collec-

,/

1

\ .

'l

----,-- , --- ~ - - - - - - - - - - -

"

=: FLEXiBlE

?-HOSE

"

r

~

~

,.

SAMPLING

,PORTS \

PLEI\Uv1

CHAM3ER

o

o

o

o

o

MAI'OI.1ETERS

VENTURI

8>

, HV PONER

r---

..

COfO>JA

WIRES

r-------I

'

0 C0

HV DISTRIBUTION BAR

VALVE

...

OMPRESSOR

VACWM

PLMP

~

Figure 4.1. Schematic diagram of experimental facility, Salcedo (1981)

~ . _ - - . . . . . . . . . . . . . . .

r1

y

...

MAf\Ov1ETER

"

lN

--J

,

~ I

1

1

, .

,

1

1

\

1

1

. -.

'1

(.

(

1 1

)

38

(

2

.

.

tion area of ]",,95 m and a total "discharge wire length of 5.78 m

The power supply to the ESP 15 a single OC source

(Del Electronics Corporation, Model 40 TC 5-1, Vernon, N.Y.) with

continuously variable output secondary voltage from 0 - 40 kV and a

#

. maximum rated secondary current at 5 mA The power supply is protected

from current transients with a fixed overload relay of 120\ of its rated

...

current. Two meters, with precisions of + 0.8 kV and + 0.1 mA indi-

, cate the values of the secondary voltage-current.

,

\

The ESP plates are fastened to the supporting tables by

hingesi this eliminates dust collection hoppers and the associated non-

ideal effects such as gas sneakage and dust re-entrainment fram the hoppers.

The plates are closed with 12 "c" clamps,' evenly spaced, on each side and

sealed with aluminum tape ta prevent air leakage.

The plates are cleaned by brushing the precipitated dust

into an appropriate receiver after each rune

The effluent air then passes into an aluminum converging

section, 31 cm long, .before aluminum piping 15.4 cm (1.0.) which

exi ts i t into the atmosphere.

4.2 Particle Feeding

The vibrating screw and the Wright dust used

in this work are described below.

1

______ __ ___________ __

c

-

!

(

..

1

J

39

4.2.1 Vibrating Screw Feeder

This feeder is used for feeding non-free frowing dust

,

with partic1e sizes larger than 5 in diameter.

The basic components of the screw feider are a brass dust

reservoir, a screw connected to a variable speed mator and a

!ine.

The dust flowrates fram the screw feeder can be varied by

controlling the screw rotational speed or by changing the screw itself

..

A small vibrator at the base of the dust reservoir prevents bridging of the

dust and al10ws for a more uniform feedrate. Dry compressed air i5 used

as the medium and static" charge build-up were reduced by grounding

the feeder and using copper conveying 1ines. The dust was fed to the

venturi throat to provide good dispersion.

4.2.2 Wright OUst Feeder

()

A Wright dust feeder (L. Adams, Minerva Road, London, England)

used t feed the industrial Noranda dust and the indus trial zinc smelter

dst the venturi throat.

3

The dust is packed carefully into a (40 cm of

effective volume) and scraped off by a blade at a rate controlled e

by a constant speeq and a variable gearing mechanism as shown in Figure

i

. 1

i

1

1

1

,

\

l ,

. 40

~

head

wheel

ln

constnctlon

Impact Ion plate

.ar + dust out

Figure 4.2. Schematic diagram of Wright dust feeder, Salcedo (19811

('

; .

~

l

:-

, ,

. '

,

1

1

,

1

1

, '

l-

i

"

!

!

1

i

1

<

t=-

"

l' . ,

41

4.2 Careful p'acking of the dust is necessary sfnce tao loose a pack:

ing will produce non-uniform feed rates while tao tight a packing will

prevent the scraping blade fram operating correctly causing the feeder

ta stop. The dust feed rate ls controlled by changing the gearing

ratio, the packed plug surface area or bulk density.

The operating instructions of the feeder (Adams (1964

...

were carefully followed.

4.3 Safety Precautions

Due ta the hign voltages of the power supply that energizes

the ESP, special attention had ta be taken (Salcedo (1981 ta ensure

proper and safe operation of the equipment. The ESP and power supply

shared a common ground with the building transformer which supplied the

primary current to the high-voltage power supply. AlI ground connections

, made v:i,a eight gauge stranded copper wire ta a conunon copper bus bar,

1

was the n' connected ta the ground at the building transformer. The

high voltage aluminum distribution bar was covered with a plxiglass shield,

which was in turn covered with grounded sheet metal. AlI sampling probes

were grounded.

During each experiment, the current measured at the ESP

plates was compared to that rneasured at the power supply.

,...

Any differences

between the two indicated an uncontrolled current leak through faulty in-

sulation and the experiment was discontinued until the was corrected.

i

1

f

,

,

1

, .

!.

1

(

1

Q

42

CHAPTER V

EXPERIMENTAL, TECHNIQUES

5.1 Introduction

This chapter discusses the equipment and procedures used to

the industrial dusts studied in this work. A review of a

typical run using the ESP is also outlined.

5.2

5.2.1

Dust Sampling

General Considerations

Sampling of the dust was performed at both the inlet and

" out let of the ESP to provide information on partiele size distributions

and chemieal compositions from whieh the elemental and fractional efficien-

cies could be calcula ted.

5.2. 2 Sampling Trains

5.2. Outlet Samphng Train

..

The bas1e components of the outlet sampling train are a

6.35 cm (1.0.) samp11ng nozzle (Nutech Corporation, Durham, N.C.), a filter

holder and appropr1ate f11ters, a mercury manometer rotameter for pres-

and flow measurements and a vacuum pump prov1ded w1th a bleed valve

for flow control. Flow ontrol 1S 1mportant to ma1ntain isokinetic

sampling at the samp11ng po1nts.

1

,

1

,

,

.

The sarnpling nozzles are tapered for minimum flow distur-

banee and have a single 90

0

long radius bend; the probes were kept

as short as possible ta minirnize dust in the lines. The

filter holder has a domed inlet for un1form dust distribut10n and accom-

43

modates 47 mm d1ameter filters. Dur1ng the exper1mental runs, sorne dust

collects on the walls and it is essential that this dust

be brushed onto the filter paper to avoid serious errors sinee very small

mas,ses' ("1. mg) are measured.

5.2.2.2 InIet, Sampling Train

The basic eomponents of the in let sampling train are a

7.49 mm (I.D.) nozzle made of stainless steel with a tapered inlet and a

single 90

0

long radius bend, an Anderson MK III inertial cascade impactor

(Anderson 2000 Ine., Atlanta, Georgia), a manometer and rotameter for

pressure and {low measurements and a vacuum pump provided with a bleed

valve for flow control.

5.2.3 Anderson Cascade Impactor

An Anderson MK III cascade impactor was used ta rneasure

the size distribution of the particles entering the ESP.

This is a size fractionating device, Working on the principle

of inertial impaction described by Marple et al (1976), Newton et al (1977)

1

1

1

1

44

Ci

and Ranz et al (1952). It is cornposed of a series of nine perforated

stainless steel plates (stages) rnounted on a frarne. The stages are

arranged order of geornetrieally deereasing hole sizes, with the holes

in adjacent stages arranged off center. A sample of the airborne dust

is at a known flow rate and the particles report to different

stages aecording to their aerodynarnic size.

The first stage is only a jet stage and the la st stage only

a collection stage. Glass fiber collection substrates were used to reduce

taring weights and the probability of dust bounee-off and re-entrainrnent .

The glass fiber substrates and were dessicated overnight under

vacuum, prior ta weighing bath before and after an experirnental rune This

eliminates any error caused by differences in humidity.

o

The cascade impactor eut-points were calculated by the follow-

lng equation:

(5.1 )

Where (D, P, C, V) are respectively the values of impactor

cut point, partie le density, Cunningham correction factor and jet velocity

-.at_standard (1) andactual (2) Since the

__ fator_involves the particle diarneter, the above relation has to be solved

by trial and error. of the dust was rneasured by a

Pynorneter.

1

45

c

5.3 Chemical Analyses

Chemical analyses of the dusts collected in the ESP and.

in the sampling trains at bath the inlet and out let of the ESP were

performed bYe Atomic Absorption Spectroscopy (AAS) ,

5.3.1 Atomic Absorption Spectrophotometer

The basic components of the AAS are:

a li9ht source wh1ch emits the spectrum of the e1e-

ment of interest, usually a hollow cathode lamp.

An absorption ce Il in which the atoms of the sample

to be n l y ~ e d are formed by thermal dissociation,

usual1y in a flame.

A.monochromator with exit slit to select the appropriate

absorption 1ine.

A detector ta measure the intensity of radiation,

an amplifier with display instruments for the readout,

of the absorption values',

t

1

The AAS used was a Perkin-Elmer 403 dual beam AA

Spectrophotometer.

,

(

,

(

<:

1

r

1

1

"

f

J

,

t

-r

l

,-

1

!

1

1

1

(

1

\

,.

46

Sample Preparation

Small amounts of the dust mg) were first dissolved

"'-

in a acid medium and then diluted to the approprlate concentra-

I

tions: . The analyses were always dane at dllutlon levels at whlch Beer's

law is appliCable; above thlS level, absorbance becomes a non-llnear func-

tion of concentration. The maximum recommended concentrations for the

various elements at WhlCh Beer's law was valid were obtained from the AA

Spectrophotometer application manual. Precise welghings and dilutions are

very important since very small concentrations are used.

5.3.3 Instrument Conditions

The AA Spectrophotometer was operated with both air - C

2

H

2

.

flarne and N

2

0 - C

2

H

2

flame, depending the elements to be analysed.

The air-acetylene flame was much more convenient than the N

2

0 - C

2

H

2

flame since the latter can easiIy forrn explosive mixtures and cause build-

up of carbon at the burner tip. Selection of the approprlate flarne as

weIl as slit setting and wavelength for each element analysed wa9 obtained

from the lnstruction manuai.

..,.

5.4 Minicyclone

.This device was used to separa te bulk samples of dust

two Slze components due to differences in size and/or density.

'!.

J

,

j

1

L

c

..

47

Figure 5.1" shows a schematic diagrarn of the minicyclone.