Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UltraformN2320003UNCQ600 Astm

Caricato da

renebbDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UltraformN2320003UNCQ600 Astm

Caricato da

renebbCopyright:

Formati disponibili

Product Information Feb 2014

Ultraform N 2320 003 UNC Q600

Polyoxymethylene

Product Description Ultraform N 2320 003 UNC Q600 is a rapidly freezing general-purpose injection-molding POM grade. It contains a mold release agent. Applications Typical applications include spring elements, clips, gas filler caps, gear wheels, small motor parts, curtain hooks and release buttons for safety belts. PHYSICAL Specific Gravity Mold Shrinkage (1/8" bar, in/in) Moisture, % (50% RH) (Saturation) MECHANICAL Tensile Strength, Yield, MPa (psi) 23C (73F) Elongation, Yield, % 23C (73F) Flexural Modulus, MPa (psi) 23C (73F) IMPACT Notched Izod Impact, J/M (ft-lbs/in) -40C (-40F) 23C (73F) THERMAL Melting Point, C(F) Heat Deflection @ 264 psi (1.8 MPa) C(F) Heat Deflection @ 66 psi (.45 MPa) C(F) Coef. of Linear Thermal Expansion, mm/mm C (in/in F) ELECTRICAL Volume Resistivity, 1.5 mm Surface Resistivity, 1.5 mm Processing Guidelines Material Handling Max. Water content: 0.15% Product is supplied in polyethylene bags and drying prior to molding is not required. However, after relatively long storage or when handling material from previously opened containers, preliminary drying is recommended in order to remove any moisture which has been absorbed. If drying is required, a dehumidifying or desiccant dryer operating at 80 - 110 degC (176 - 230 degF) is recommended. Drying time is dependent on moisture level, but 2-4 hours is generally sufficient. Further information concerning safe handling procedures can be obtained from the Material Safety Data Sheet. Alternatively, please contact your BASF representative. ASTM Test Method D-792 D-570 0.2 0.8 Property Value 65 (9,430) D-638 9.4 D-790 ASTM Test Method D-256 2,470 (358,000) Property Value 59.8 (1.1) 69.4 (1.3) Property Value 167 (332) 99 (210) 154 (309) 0.6 X10-4 Property Value 1E13 1E13 Property Value 1.4 0.02

ASTM Test Method D-638

ASTM Test Method D-3418 D-648 D-648 E-831 ASTM Test Method D-257 D-257

BASF Corporation Engineering Plastics 1609 Biddle Avenue Wyandotte, MI 48192

General Information: 800-BC-RESIN Technical Assistance: 800-527-TECH (734-324-5150) Web address: http://www.plasticsportal.com/usa Page 1 of 2

Ultraform N 2320 003 UNC Q600

Typical Profile Melt Temperature 190-230 degC (375-446 degF) Mold Temperature 60-120 degC (140-248 degF) Injection and Packing Pressure 35-70 bar (500-1000psi)

Mold Temperatures A mold temperature of 80-90 degC (176-194 degF) is recommended, but temperatures of as low as 45 degC (113 degF) and as high as 105 degC (221 degF) can be used where applicable. Pressures Injection speed must be optimized. A filling rate which is too high results in anisotropic mechanical properties, while a filling rate which is too low yields parts with poor surface finish. The tool must be vented to avoid burn marks and prevent mold deposits. Injection pressure controls the filling of the part and should be applied for 90% of ram travel. Packing pressure affects the final part and can be used effectively in controlling sink marks and shrinkage. It should be applied and maintained until the gate area is completely frozen off. Back pressure can be utilized to provide uniform melt consistency and reduce trapped air and gas. Minimal back pressure should be utilized to prevent glass breakage. recommended. Fill Rate Injection speed must be optimized. A filling rate which is too high results in anisotropic mechanical properties, while a filling rate which is too low yields parts with poor surface finish. The tool must be vented to avoid burn marks and prevent mold deposits.

Note Although all statements and information in this publication are believed to be accurate and reliable, they are presented gratis and for guidance only, and risks and liability for results obtained by use of the products or application of the suggestions described are assumed by the user. NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or suggestions concerning possible use of the products are made without representation or warranty that any such use is free of patent infringement and are not recommendations to infringe any patent. The user should not assume that toxicity data and safety measures are indicated or that other measures may not be required.

BASF Corporation Engineering Plastics 1609 Biddle Avenue Wyandotte, MI 48192

General Information: 800-BC-RESIN Technical Assistance: 800-527-TECH (734-324-5150) Web address: http://www.plasticsportal.com/usa Page 2 of 2

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ASME Section VIII Rules For Construction of Pressure Vessels Division 1Documento820 pagineASME Section VIII Rules For Construction of Pressure Vessels Division 1renebb100% (1)

- Liste Produits PMUC 2010 Rév CDocumento22 pagineListe Produits PMUC 2010 Rév CSéverine et Renaud AnnavalNessuna valutazione finora

- Product Literature AHUDocumento20 pagineProduct Literature AHUmichaelmangaa100% (1)

- ISOStandardDocumento3 pagineISOStandardlady soto chNessuna valutazione finora

- Concrete Mix Design Aci 211 - 1ijaDocumento49 pagineConcrete Mix Design Aci 211 - 1ijaKhayrun HadullaNessuna valutazione finora

- 7-Method Statement For Gypsum PartitionDocumento9 pagine7-Method Statement For Gypsum Partitionozyoclown100% (5)

- Mat Chem Comp GB en PDFDocumento48 pagineMat Chem Comp GB en PDFvzimak2355Nessuna valutazione finora

- Design and Testing of Unbalanced Mass Mechanical Vibration ExciterDocumento7 pagineDesign and Testing of Unbalanced Mass Mechanical Vibration ExciterrenebbNessuna valutazione finora

- Snap Fit CalculationsDocumento7 pagineSnap Fit CalculationsKok MunNessuna valutazione finora

- PVAR Catalog PDFDocumento16 paginePVAR Catalog PDFrenebbNessuna valutazione finora

- 20140308011Documento7 pagine20140308011renebbNessuna valutazione finora

- Ultramid B3WG6 NYLON PDFDocumento3 pagineUltramid B3WG6 NYLON PDFrenebbNessuna valutazione finora

- 50 - 3 446 40309 4 - Leseprobe02Documento12 pagine50 - 3 446 40309 4 - Leseprobe02renebbNessuna valutazione finora

- NGT Thread Series: Total Solution For Thread GaugingDocumento2 pagineNGT Thread Series: Total Solution For Thread Gaugingrenebb100% (1)

- In-Line Check Valves CV-3+ - WebDocumento15 pagineIn-Line Check Valves CV-3+ - WebrenebbNessuna valutazione finora

- Snap Fit CalculationsDocumento7 pagineSnap Fit CalculationsKok MunNessuna valutazione finora

- Alloys SpecialtyDocumento1 paginaAlloys SpecialtyrenebbNessuna valutazione finora

- Chapter 16 Compressible Flow: 16.1 Speed of SoundDocumento42 pagineChapter 16 Compressible Flow: 16.1 Speed of SoundrenebbNessuna valutazione finora

- Calculate Mass Flow or Volumetric Flow For Any GasDocumento2 pagineCalculate Mass Flow or Volumetric Flow For Any Gasvicbalt07Nessuna valutazione finora

- Snap-Fit Design ManualDocumento24 pagineSnap-Fit Design ManualrenebbNessuna valutazione finora

- Placas Circulares Con RibsDocumento150 paginePlacas Circulares Con RibsrenebbNessuna valutazione finora

- Bending of Circular Plates Under A Unifrom Load On A Concentric CircleDocumento45 pagineBending of Circular Plates Under A Unifrom Load On A Concentric CirclerenebbNessuna valutazione finora

- Contentfile 1825Documento29 pagineContentfile 1825Shanmugam BalasubramaniamNessuna valutazione finora

- Curved BeamDocumento85 pagineCurved Beampoojasmita14100% (3)

- Ultramid B3WG6Documento3 pagineUltramid B3WG6renebbNessuna valutazione finora

- N GT, SGT : TABLE IX.6. - Dtmensions of Plug (External Q P P H XDocumento1 paginaN GT, SGT : TABLE IX.6. - Dtmensions of Plug (External Q P P H XrenebbNessuna valutazione finora

- FastRite2012 FittingsCatalogDocumento425 pagineFastRite2012 FittingsCatalogrenebbNessuna valutazione finora

- Tube Chart CharacteristicsDocumento3 pagineTube Chart CharacteristicsHussain FakhruddinNessuna valutazione finora

- Screw 1942Documento254 pagineScrew 1942renebbNessuna valutazione finora

- 17-Surface Roughness and Machining Symbols FullDocumento17 pagine17-Surface Roughness and Machining Symbols FullrenebbNessuna valutazione finora

- Finkle AndrewDocumento176 pagineFinkle AndrewrenebbNessuna valutazione finora

- Inclined StressDocumento28 pagineInclined StressAli El-Gazzar100% (1)

- Stress AnalysisDocumento24 pagineStress AnalysisrenebbNessuna valutazione finora

- Eng FormulasDocumento21 pagineEng FormulaszingalalaNessuna valutazione finora

- CH 9 WeldingDocumento18 pagineCH 9 WeldingHazim KhalilNessuna valutazione finora

- Degree SYLABUSDocumento25 pagineDegree SYLABUStom meeteiNessuna valutazione finora

- B.V. Doshi:Institute of Indology, AhmedabadDocumento9 pagineB.V. Doshi:Institute of Indology, Ahmedabadbharath PPNessuna valutazione finora

- A Study To Determine The Home-Buyer's Preferences Through Voice of CustomerDocumento7 pagineA Study To Determine The Home-Buyer's Preferences Through Voice of CustomerIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Valve Catalogue General Imsubs Pvt. Ltd.Documento20 pagineValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechNessuna valutazione finora

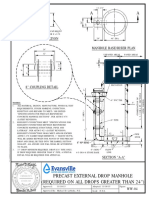

- Drop ManholeDocumento1 paginaDrop ManholeorganicspolybondNessuna valutazione finora

- Soda Can DesignDocumento11 pagineSoda Can DesignHector L Colon SandovalNessuna valutazione finora

- BehrensDocumento9 pagineBehrensTony ChanNessuna valutazione finora

- Structures Data SheetDocumento1 paginaStructures Data Sheetkrimchand1825Nessuna valutazione finora

- CMM Hybrid Columns: Brochure 38-01 EDocumento4 pagineCMM Hybrid Columns: Brochure 38-01 EGurpreet Singh BhatiaNessuna valutazione finora

- Environmental Protection Guidelines For Transmission Lines PDFDocumento5 pagineEnvironmental Protection Guidelines For Transmission Lines PDFTTaanNessuna valutazione finora

- Technical ManualDocumento375 pagineTechnical ManualmmediboyinaNessuna valutazione finora

- Gujarat Technological University Civil EngineeringDocumento3 pagineGujarat Technological University Civil EngineeringSheezan KhanNessuna valutazione finora

- International Center For Business SectorDocumento59 pagineInternational Center For Business SectornikhilNessuna valutazione finora

- Electrical Symbols Legend Abbreviations Legend: P U o R GDocumento5 pagineElectrical Symbols Legend Abbreviations Legend: P U o R GjorgeNessuna valutazione finora

- Seismic Design of Bridges ICE IStructE Part1Documento21 pagineSeismic Design of Bridges ICE IStructE Part1fethi42Nessuna valutazione finora

- Subjective QuestionsDocumento6 pagineSubjective QuestionsPRINCE VISHALNessuna valutazione finora

- Sans 10400 DisabledDocumento51 pagineSans 10400 Disabledsjoubert_törökNessuna valutazione finora

- IMG - 0083 PSME Code 2008 74Documento1 paginaIMG - 0083 PSME Code 2008 74Bugoy2023Nessuna valutazione finora

- Pipelaying and InstallationDocumento31 paginePipelaying and InstallationDaniel Inemugha100% (6)

- Project Report: Plan of A Residential ApartmentDocumento24 pagineProject Report: Plan of A Residential ApartmentAnush SNessuna valutazione finora

- Failure Theory For Piping MaterialDocumento29 pagineFailure Theory For Piping MaterialsaadvikhasNessuna valutazione finora

- Steel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Documento1 paginaSteel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Kuya Fabio VidalNessuna valutazione finora

- 45e PPB 246Documento16 pagine45e PPB 246HOMERO NOGUEDANessuna valutazione finora

- Step by Step Companion GuideDocumento4 pagineStep by Step Companion Guidebcap-oceanNessuna valutazione finora