Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Typical Installation of Springhangers

Caricato da

kaiju85Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Typical Installation of Springhangers

Caricato da

kaiju85Copyright:

Formati disponibili

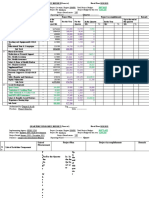

Installation Instruction for Spring Hanger

Each size of isolator is identified by the colour coded spring or colour coded identification spot. Y Hanger sizes must be selected in accordance with the rated load capacities detailed on our appropriate leaflets. Y Pipes should be supported on either side of changes of direction and additional hangers used to support heavy fittings and vertical droppers

For larger pipe sizes two hangers can be used at each support position. See Figure 1.

VERTICAL DROPPERS

HEAVY PIPEWORK

SUPPORTING HEAVY VALVES

FIGURE 1

Installation Instruction for Spring Hanger

Y Pipework or equipment must be supported using a solid scaffolding arrangement or hung using wires, ropes or chains in its final position. See Figure 2. Y Spring or rubber hanger brackets should then be securely fixed to upper ceiling or steel gantry at correct spacing to suit hanger load capability.

SOLID SCAFFOLDING

SUPPORTING ROPES, CHAINS OR WIRES

FIGURE 2

Installation Instruction for Spring Hanger

Y Drop rods should then be cut to size and screwed home into connector coupling on spring hangers or through underside of mount on rubber hangers. See Figure 3. Y Once the pipe/equipment end of the drop rod has been secured, the solid scaffolding or supporting wires can be removed, allowing the weight of pipe work/equipment to be taken by the hangers.

SPRING HANGER

RUBBER HANGER

Locknut by others Bracket fixing by others

Drop rod by others Pipe bracket by others

FIGURE 3

Y Depending on the amount of hanger element deflection, either by design or as required by specification, (see our appropriate leaflets) drop rods will require adjustment. This should be done on spring hangers by slackening top locknuts on drop rod inside hanger and then adjusting lower nut until correct height of pipe work requirement is achieved. It is important that on the spring type hangers a gap of 2 to 3 mm is maintained between the lower washer and underside of frame. See Figure 4.

SPRING HANGER

Top locknut Adjustment Adjustment nut Adjustment 2 to 3mm gap min Drop rod Drop rod

RUBBER HANGER

Locknut

FIGURE 4

Installation Instruction for Spring Hanger

Adjustment on rubber hangers should be done by slackening locknut on drop rod inside hanger and then releasing load on element by lifting pipe or equipment and then screwing drop rod further through element. Y If adjustment of spring mounts after installation is not desired or possible, pre compression of springs can be made prior to installation by slackening top locknut and adjusting lower nut until spring is compressed by required amount (max. 25 mm). See Figure 5 Y Hangers can also be fitted into drop rod length as per Figure 6, but care must be taken to ensure misalignment of hanger does not occur.

Precompression 25mm max

FIGURE 5

FIGURE 6

Y Ensure hangers are not over loaded when installed. Check springs are not coil bound or elements deflected more than limits allowed in our leaflets. Make sure drop rods are centrally positioned within hanger brackets and are not misaligned. See Figure 7.

FIGURE 7

Note: Surface corrosion is likely without additional protection for external applications.

Potrebbero piacerti anche

- Theory of Constraints in Supply Chain ManagementDocumento2 pagineTheory of Constraints in Supply Chain Managementkaiju85Nessuna valutazione finora

- Pipe Hangers, Pipe Supports, Variable and Constant Spring HangersDocumento2 paginePipe Hangers, Pipe Supports, Variable and Constant Spring Hangerskaiju85Nessuna valutazione finora

- Electrical Engineering DesignDocumento14 pagineElectrical Engineering Designkaiju85Nessuna valutazione finora

- A Guide To The Selection, Application & Function of Pipe HangersDocumento44 pagineA Guide To The Selection, Application & Function of Pipe Hangerskaiju85Nessuna valutazione finora

- Cable Tray ManualDocumento53 pagineCable Tray Manualkaiju85100% (1)

- Deluge System General PDFDocumento2 pagineDeluge System General PDFkaiju85100% (3)

- In ToolsDocumento21 pagineIn ToolsPanagiotis KatsirisNessuna valutazione finora

- TANK Design DetailingDocumento17 pagineTANK Design DetailingTiffany Vabiola100% (8)

- Deluge Valve PDFDocumento11 pagineDeluge Valve PDFkaiju85Nessuna valutazione finora

- Assembly DrawingDocumento19 pagineAssembly Drawingkaiju85Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- FINALE Final Chapter1 PhoebeKatesMDelicanaPR-IIeditedphoebe 1Documento67 pagineFINALE Final Chapter1 PhoebeKatesMDelicanaPR-IIeditedphoebe 1Jane ParkNessuna valutazione finora

- UM-1D User ManualDocumento30 pagineUM-1D User ManualAhmedBalaoutaNessuna valutazione finora

- Human Rights Law - Yasin vs. Hon. Judge Sharia CourtDocumento7 pagineHuman Rights Law - Yasin vs. Hon. Judge Sharia CourtElixirLanganlanganNessuna valutazione finora

- W2 - Fundementals of SepDocumento36 pagineW2 - Fundementals of Sephairen jegerNessuna valutazione finora

- Post Traumatic Stress DisorderDocumento2 paginePost Traumatic Stress Disorderapi-188978784100% (1)

- Api 579-2 - 4.4Documento22 pagineApi 579-2 - 4.4Robiansah Tri AchbarNessuna valutazione finora

- Biology 2 Chapter 4Documento61 pagineBiology 2 Chapter 4Malas Nak TaipNessuna valutazione finora

- Rahu Yantra Kal Sarp Yantra: Our RecommendationsDocumento2 pagineRahu Yantra Kal Sarp Yantra: Our RecommendationsAbhijeet DeshmukkhNessuna valutazione finora

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDocumento29 pagineUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemNessuna valutazione finora

- 51 - Methemoglobin ProducersDocumento20 pagine51 - Methemoglobin ProducersCabinet VeterinarNessuna valutazione finora

- Generic 5S ChecklistDocumento2 pagineGeneric 5S Checklistswamireddy100% (1)

- FRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012Documento19 pagineFRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012BeastNessuna valutazione finora

- CampingDocumento25 pagineCampingChristine May SusanaNessuna valutazione finora

- E3sconf 2F20187307002Documento4 pagineE3sconf 2F20187307002Nguyễn Thành VinhNessuna valutazione finora

- PaintballDocumento44 paginePaintballGmsnm Usp MpNessuna valutazione finora

- Sports MedicineDocumento2 pagineSports MedicineShelby HooklynNessuna valutazione finora

- 45096Documento12 pagine45096Halusan MaybeNessuna valutazione finora

- Vicat Apparatus PrimoDocumento10 pagineVicat Apparatus PrimoMoreno, Leanne B.Nessuna valutazione finora

- Imagine Unit 1 P 10 11Documento1 paginaImagine Unit 1 P 10 11נויה לבדובNessuna valutazione finora

- KhanIzh - FGI Life - Offer Letter - V1 - Signed - 20220113154558Documento6 pagineKhanIzh - FGI Life - Offer Letter - V1 - Signed - 20220113154558Izharul HaqueNessuna valutazione finora

- Laughter, It Is Good For YouDocumento2 pagineLaughter, It Is Good For YouClaire B.L.Nessuna valutazione finora

- Lead Avr PDFDocumento9 pagineLead Avr PDFsiddharthNessuna valutazione finora

- Quarterly Progress Report FormatDocumento7 pagineQuarterly Progress Report FormatDegnesh AssefaNessuna valutazione finora

- How To Create Your Cosmetic Product Information FileDocumento12 pagineHow To Create Your Cosmetic Product Information Filewill100% (3)

- AppendicitisDocumento7 pagineAppendicitisTim LuoNessuna valutazione finora

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDocumento356 pagineThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNessuna valutazione finora

- 4th Summative Science 6Documento2 pagine4th Summative Science 6brian blase dumosdosNessuna valutazione finora

- This Unit Group Contains The Following Occupations Included On The 2012 Skilled Occupation List (SOL)Documento4 pagineThis Unit Group Contains The Following Occupations Included On The 2012 Skilled Occupation List (SOL)Abdul Rahim QhurramNessuna valutazione finora

- Bulk-Fill Composite RestorationsDocumento9 pagineBulk-Fill Composite RestorationssusethNessuna valutazione finora