Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Calibration Methods-Low-Level Turbidimeter Measurement

Caricato da

megacobCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Calibration Methods-Low-Level Turbidimeter Measurement

Caricato da

megacobCopyright:

Formati disponibili

Application Note 128

Revised 12/15/09

Calibration Methods for Low-level Turbidimeter Measurement

Introduction

The process of calibrating and subsequently verifying the calibration of turbidimeters for low-level measurement is very sensitive to user technique and the surrounding environment. As measured turbidity levels drop below 1.0 NTU, interferences caused by bubbles, particulate contamination, and stray light become major factors. To minimize these errors, many approaches can be taken. Two of the most common approaches for low-level calibration are one-point and two-point calibrations. After identifying and addressing turbidity interferences, the calibration approach that is best suited for a specific low-level measurement can be identified. This article discusses possible errors and the resulting calibration approach Hach uses for its turbidimeters.

Interferences in Low Turbidity Measurement

Hach Companys approach to turbidimeter calibration has been very consistent over several generations of turbidimeters. In turbidity science it is well known that the correlation between turbidity and nephelometric light scatter (light scattered by particles at an angle of 90 degrees to the incident light source) is highly linear over the range of 0.012 to 40 NTU. Because of this relationship, an approach that reduces calibration error while extending measurement accuracy to the lowest turbidity levels can be taken. At very low turbidity levels, measurement errors become very significant. The major source of error is stray light. Stray light is defined as any light reaching the light scatter (90 degree) detector that is not scattered by the sample. Stray light is always a positive interference. Sources of stray light include dust contamination in the instrument optics, low quality or damaged sample cells and instrument electronics. The best way to reduce stray light is through the design of robust instruments with high quality optics combined with good laboratory and measurement technique. Hach leads the market in the production of instruments with extremely low stray light levels. Another significant error can be attributed to bubbles in the sample. Bubbles in most samples are easily eliminated by allowing the sample to stand for a short time period (2-5 minutes) before measurement. For process instruments, bubble removal is best accomplished through the use of bubble traps. At low turbidity levels, a wait of 25 minutes will not result in particulate settling. The third error source that must be considered is contributed through the preparation of the calibration standards. Calibration standards can be easily and accurately prepared at higher values (greater than 1 NTU) if close attention is paid to cleanliness, dilution water of high quality (low turbidity) is available, and good analytical technique is applied. By addressing these issues, an analyst can prepare standards to within 2 percent at turbidity levels down to 10 NTU and to within 3 percent at turbidity levels between 10 NTU and 1 NTU. Calibration standards below 1.0 NTU can be prepared if dilution water of the highest quality (ultra-filtered or reverse-osmosis) is used to prepare all standards and to clean sample chambers, cells, and glassware. Excellent laboratory technique is necessary to reduce any source of contamination. Unfortunately, high purity water is often difficult to obtain and even when all cleanliness issues are addressed, a 0.30 NTU standard typically has a 10 percent (best-case) error.

Hach designs its instruments for higher-level calibration because the accuracy of a prepared 20 NTU standard is typically better than 2 percent. Preparation of standards below 1 NTU will result in much greater error mostly due to residual turbidity in the dilution water. Filtration will greatly lower this interference. If possible, use either distilled or deionized water that has been passed through an ultra-filtration process such as reverse-osmosis.

The One-point Calibration Algorithm

The calibration of Hach turbidimeters was designed to reduce or eliminate the interferences presented previously. The calibration algorithm is very simple and is based on two readings; a calibration standard and a zero point, which requires no standard. The basis for this algorithm approach is discussed below. The nephelometric detector response to turbidity is highly linear in the range of 0.012 to 40 NTU. This linearity allows a calibration to be performed using a single standard at any point in this range. For Hach turbidimeters, the 20 NTU calibration point is preferred due to ease of preparation and high accuracy. Even if the dilution water has some turbidity (less than 0.5 NTU), the error contributed to the standard is low. In addition, errors due to instrument stray light are negligible at 20 NTU. Since a calibration performed at 20 NTU has a very low error, theoretically, measurement error will also be low when a turbidimeter is calibrated at this level. If the sum of the errors between the standard and the instrument equal 2 percent at 20 NTU, the same accuracy can be extrapolated to low-level measurements. The zero point is performed with the instrument light source turned off, but with all other measurement parameters in place. During this measurement, any residual light in the optics or environment that could result in interference is effectively removed from all subsequent measurements. This is often referred to as the blank or as dark values. Typically the zero point is determined when the instrument power is cycled. After the zero measurement and standard measurement have been taken, the instrument algorithm draws a straight line between these two points, constructing the linear calibration curve. The only remaining error is from stray light contributed by the instrument lamp. This error becomes a factor at the lowest measurements, typically below 0.05 NTU. Most Hach turbidimeters require the measurement of the dilution water (DW) so the turbidity contribution of the dilution water used to prepare the high-end calibration standard(s) can be compensated. Once measured, the value of the DW standard is stored in the software of the turbidimeter. The value is then subtracted from the measured value of the other calibration standards. By subtracting this value from the measured value of the calibration standards, the absolute value of each calibration standard is calculated and the accuracy of the high-end calibration points is maximized. The use of the one-point calibration algorithm deals with all the interferences noted above except for stray light observed when the instrument light source is on. This interference is mediated by designing the instrument to produce high collimated light and eliminate light exposure to all surfaces inside the instrument optics except the sample cell. This is exactly what Hach does. With high quality components coupled with strict design standards, Hach turbidimeters are able to bring incident lamp stray light to very low levels (<0.025 NTU). It is only at the lowest turbidity levels that a minute portion of stray light may be observed and it is always a positive interference.

Using a high-level standard for calibration adequately addresses the interferences that would result from the use of a low-level standard. The accuracy of the instrument remains consistent with the value of the standard through the range of linearity (0.012 to 40 NTU). This means that if a 2 percent error is made at 20 NTU, the measurement error will be 2 percent anywhere in the range of linearity. However, if a low-level standard was used, and the accuracy was 10 percent (which is typical), the accuracy of the measurement over the range of linearity would also be 10 percent. The use of a high-level standard that can be prepared accurately will result in the highest accuracy for low-level measurements.

The Two-point Calibration Algorithm

The two-point calibration algorithm is a common approach to calibration of turbidimeters. This method uses two calibration standards that are typically set at the extreme ends of the measurement range. Both standards must be defined, one with a high turbidity value and one with a low (non-zero) turbidity value. The algorithm draws a straight line through the two calibration points and then extrapolates the resultant slope of this line over the entire linear range of 0.012 to 40 NTU. In theory, this approach should address the low-level interferences mentioned above and compensate for stray light, regardless of the level. The need for extremely high quality instrument components and design are less important because stray light is accounted for in the calibration. Calibration standard preparation is the key to accuracy because the errors introduced with poorly prepared standards can be substantial. The difficulty in preparing and properly measuring the low-level calibration standard is the major concern with the two-point calibration method. As was mentioned in the one-point calibration, it is nearly impossible to prepare a low turbidity standard accurately because of the issues discussed earlier. Hach turbidimeters do not typically use the two-point calibration method because of the high risk of creating false negative measurement error. False negative error means that a measurement reading is lower than the true value of the sample. In turbidity measurement, a false negative could leave water treatment plant personnel thinking they are producing low turbidity water, when in reality, the turbidity value of the water they are producing is higher than is being reported. It is very easy to create a false negative condition if a calibration standard value is actually higher than its reported value. When calibrating with a low-level standard at the low end of the two-point calibration, the preparation error is usually positive (i.e, the actual value of the standard is higher than the reported value). This positive error can be attributed to not accounting for the turbidity of the dilution water used in the standard preparation. When such a standard is used for calibration, the resulting measurement condition typically has a false negative bias, creating the false negative measurement condition. Many instrument manufacturers attempt to use lower quality components as a cost-saving measure. Doing so increases the importance of accurately prepared standards that account for all turbidity introduced during preparation.

The Use of StablCal for Calibrations

As mentioned above, when formazin standards are prepared, the turbidity of the standard is the sum of both the turbidity of the dilution water and the turbidity associated with the formazin polymer. Since the turbidity of the dilution water may not be known, it must be measured on the turbidimeter so it can be then subtracted from the net turbidity of the prepared standard. Performing this subtraction of the dilution water turbidity will then yield a highly accurate standard that is used in the calibration. However, when StablCal standards are prepared at the factory, the dilution water value is accounted for and the standard is adjusted to the theoretical value prior to packaging. Thus, there is no need for the instrument to measure the value of the dilution water when StablCal standards are being used for calibration. Newer Hach instrumentation has modified calibration

curves that do not require the measurement of the dilution water during the calibration. These include any process instruments that are on the SC platform and the 2100Q and 2100Qis turbidimeters. These instruments have eliminated the steps associated with this measurement when a calibration curve that references StablCal is selected. StablCal calibration kits for Hach laboratory turbidimeter models 2100AN, 2100AN IS, 2100N, 2100N IS and the 2100P and 2100P IS portable turbidimeters have been modified to accommodate the existing algorithms of these models of turbidimeters. These instruments have existing calibration software that still requires the measurement of the dilution water as part of the calibration procedure. To accommodate this step, these kits include a <0.1 NTU stablcal solution that is to be used in the dilution water measurement step. The <0.1 introduces a very small error to the calibration curve that is less than 0.2%, which still allows for the instrument to perform within its published specifications.

Conclusion

The best calibration approach should minimize all errors that contribute to low-level turbidity measurement. The prominent instrument error at low levels is stray light and is best minimized though instrument design. Other errors associated with calibration standards can be reduced through the use of accurately prepared higher-level standards. Hach turbidimeters successfully use the one-point calibration method by combining high-quality instrumentation with highly accurate standards. Interferences are minimized and low-level measurements can be made accurately and consistently for optimal turbidity measurement. Regardless of which calibration method is used, the instruments performance must be verified after calibration using an independent verification standard. The best source of verification standards must be accurately assayed with error tolerances defined. Examples of available standards that meet these criteria include StablCal Stabilized Formazin Certified Standards and dry verification standards also with defined accuracy tolerances. It is through verification that the end-user can obtain confidence that their instruments are optimized for performance.

HACH COMPANY WORLD HEADQUARTERS Telephone: (970) 669-3050 FAX: (970) 669-2932 FOR TECHNICAL ASSISTANCE, PRICE INFORMATION AND ORDERING: Call 800-227-4224 Contact the HACH office or distributor serving you. www.hach.com techhelp@hach.com

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Dacell DN-10W, DN-20W, DN-25W, DN-30W, DN-50W Digital Indicator ManualDocumento39 pagineDacell DN-10W, DN-20W, DN-25W, DN-30W, DN-50W Digital Indicator ManualmegacobNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hitachi U-4100 Brochure Optical PartsDocumento11 pagineHitachi U-4100 Brochure Optical PartsmegacobNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hitachi U-4100 BrochureDocumento7 pagineHitachi U-4100 BrochuremegacobNessuna valutazione finora

- HG ASTM ThermometersDocumento4 pagineHG ASTM ThermometersmegacobNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Matest Catalogues PDFDocumento528 pagineMatest Catalogues PDFmegacobNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Brookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416Documento25 pagineBrookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416megacobNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Dacell Dn-10w, Dn-15w, Dn-20w SpecDocumento1 paginaDacell Dn-10w, Dn-15w, Dn-20w SpecmegacobNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Brookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416Documento25 pagineBrookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416megacobNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Matest Catalogue 4 Bitumen AsphaltDocumento82 pagineMatest Catalogue 4 Bitumen AsphaltmegacobNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Cannon CT-1000 Installation and Operation ManualDocumento30 pagineCannon CT-1000 Installation and Operation ManualmegacobNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Chemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600Documento1 paginaChemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600megacobNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Digital PenetrometerDocumento1 paginaDigital PenetrometermegacobNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Gardco ASTM ThermometersDocumento15 pagineGardco ASTM ThermometersmegacobNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Instruction & Operation Manual: Digital Vacuum RegulatorDocumento38 pagineInstruction & Operation Manual: Digital Vacuum RegulatormegacobNessuna valutazione finora

- Guide To ATP For Road Hauliers and Manufacturers: March 2017Documento17 pagineGuide To ATP For Road Hauliers and Manufacturers: March 2017megacobNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sci Guide To ATP Monitoring 2Documento35 pagineSci Guide To ATP Monitoring 2megacobNessuna valutazione finora

- TCGRX ATP2 SellSheetDocumento2 pagineTCGRX ATP2 SellSheetmegacobNessuna valutazione finora

- Dust Analyzer Meters: Product code: HHPC - 2 (0.5 μm)Documento1 paginaDust Analyzer Meters: Product code: HHPC - 2 (0.5 μm)megacobNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Kyoritsu 2431 - IM - 92-1470A - E - LDocumento2 pagineKyoritsu 2431 - IM - 92-1470A - E - LmegacobNessuna valutazione finora

- Direct Reading Particulate Monitor and Air Station: Contact UsDocumento2 pagineDirect Reading Particulate Monitor and Air Station: Contact UsmegacobNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Sound Level Meter: IEC 61672 Class 2Documento2 pagineSound Level Meter: IEC 61672 Class 2megacobNessuna valutazione finora

- Safety Data Sheet: HI 93733B-0 Ammonia ReagentDocumento3 pagineSafety Data Sheet: HI 93733B-0 Ammonia ReagentmegacobNessuna valutazione finora

- Sound Level Meter: Model: SL-4022Documento2 pagineSound Level Meter: Model: SL-4022megacobNessuna valutazione finora

- Safety Data Sheet: HI 93733A-0 Nessler ReagentDocumento5 pagineSafety Data Sheet: HI 93733A-0 Nessler ReagentmegacobNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- HI 96733C Ammonia High Range ISM: Instruction ManualDocumento13 pagineHI 96733C Ammonia High Range ISM: Instruction ManualmegacobNessuna valutazione finora

- Sound Level Meter: Model: SL-4010Documento2 pagineSound Level Meter: Model: SL-4010megacobNessuna valutazione finora

- Selection Guide of Clamp Meters: 2200 2200R 2002PA 2002R 2204R 2210R AC Clamp Meters ModelDocumento3 pagineSelection Guide of Clamp Meters: 2200 2200R 2002PA 2002R 2204R 2210R AC Clamp Meters ModelmegacobNessuna valutazione finora

- Sound Level Meter With Auto-Range and Rs-232C: Lutron SL-4012Documento2 pagineSound Level Meter With Auto-Range and Rs-232C: Lutron SL-4012megacobNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Project ManagementDocumento11 pagineProject ManagementBonaventure NzeyimanaNessuna valutazione finora

- PR KehumasanDocumento14 paginePR KehumasanImamNessuna valutazione finora

- AntibioticsDocumento36 pagineAntibioticsBen Paolo Cecilia RabaraNessuna valutazione finora

- II 2022 06 Baena-Rojas CanoDocumento11 pagineII 2022 06 Baena-Rojas CanoSebastian GaonaNessuna valutazione finora

- Traveling Salesman ProblemDocumento11 pagineTraveling Salesman ProblemdeardestinyNessuna valutazione finora

- ReadmeDocumento3 pagineReadmedhgdhdjhsNessuna valutazione finora

- Comparitive Study ICICI & HDFCDocumento22 pagineComparitive Study ICICI & HDFCshah faisal100% (1)

- Android Developer PDFDocumento2 pagineAndroid Developer PDFDarshan ChakrasaliNessuna valutazione finora

- OZO Player SDK User Guide 1.2.1Documento16 pagineOZO Player SDK User Guide 1.2.1aryan9411Nessuna valutazione finora

- Emea 119948060Documento31 pagineEmea 119948060ASHUTOSH MISHRANessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 04 - Fetch Decode Execute Cycle PDFDocumento3 pagine04 - Fetch Decode Execute Cycle PDFShaun HaxaelNessuna valutazione finora

- Essay Rough Draft 19Documento9 pagineEssay Rough Draft 19api-549246767Nessuna valutazione finora

- DQ Vibro SifterDocumento13 pagineDQ Vibro SifterDhaval Chapla67% (3)

- Anatomy Anal CanalDocumento14 pagineAnatomy Anal CanalBela Ronaldoe100% (1)

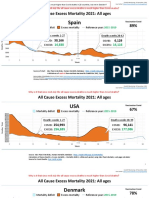

- Countries EXCESS DEATHS All Ages - 15nov2021Documento21 pagineCountries EXCESS DEATHS All Ages - 15nov2021robaksNessuna valutazione finora

- 05 x05 Standard Costing & Variance AnalysisDocumento27 pagine05 x05 Standard Costing & Variance AnalysisMary April MasbangNessuna valutazione finora

- Law of EvidenceDocumento14 pagineLaw of EvidenceIsha ChavanNessuna valutazione finora

- PSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterDocumento3 paginePSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterBabitha DhanaNessuna valutazione finora

- Origami Oso HormigueroDocumento9 pagineOrigami Oso HormigueroRogelio CerdaNessuna valutazione finora

- 3 ALCE Insulators 12R03.1Documento12 pagine3 ALCE Insulators 12R03.1Amílcar Duarte100% (1)

- Mark Garside Resume May 2014Documento3 pagineMark Garside Resume May 2014api-199955558Nessuna valutazione finora

- Parliament of India: Rajya SabhaDocumento64 pagineParliament of India: Rajya SabhaSivapothuraju KonathalaNessuna valutazione finora

- Pt3 English Module 2018Documento63 paginePt3 English Module 2018Annie Abdul Rahman50% (4)

- Snapdragon 435 Processor Product Brief PDFDocumento2 pagineSnapdragon 435 Processor Product Brief PDFrichardtao89Nessuna valutazione finora

- An Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesDocumento7 pagineAn Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesleecubongNessuna valutazione finora

- My Personal Code of Ethics1Documento1 paginaMy Personal Code of Ethics1Princess Angel LucanasNessuna valutazione finora

- Problem Set-02Documento2 pagineProblem Set-02linn.pa.pa.khaing.2020.2021.fbNessuna valutazione finora

- FDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaDocumento3 pagineFDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaGiorgi PopiashviliNessuna valutazione finora

- IEC ShipsDocumento6 pagineIEC ShipsdimitaringNessuna valutazione finora

- The Person Environment Occupation (PEO) Model of Occupational TherapyDocumento15 pagineThe Person Environment Occupation (PEO) Model of Occupational TherapyAlice GiffordNessuna valutazione finora

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDa EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNessuna valutazione finora

- A Practical Handbook for Drilling Fluids ProcessingDa EverandA Practical Handbook for Drilling Fluids ProcessingNessuna valutazione finora

- Casing and Liners for Drilling and Completion: Design and ApplicationDa EverandCasing and Liners for Drilling and Completion: Design and ApplicationValutazione: 5 su 5 stelle5/5 (3)