Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 5

Caricato da

andrewkyler92Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 5

Caricato da

andrewkyler92Copyright:

Formati disponibili

CHAPTER 5:

IMPERFECTIONS IN SOLIDS

TOPICS

Types of imperfections-

Point: Vacancy, interstitial and substitution

Line defects: Dislocations

Area defects: External surfaces, grain boundaries,,

Volume defects: Cracks, pores

Estimation of no of defects, energy of formation of a defect

Edge dislocation, screw dislocation, Burger vectors

Tilt boundaries, Twin boundaries, other defects

Defects in ceramics and ionic crystals, defects in polymers

TYPES OF IMPERFECTIONS

Vacancies

Interstitial sites

Substitutional atoms

Dislocations

Grain Boundaries

External Surfaces

Point defects

Line defects

Area defects

Volume defects

Cracks, Pores,

other phases

POINT DEFECTS

Vacancies:

-vacant atomic sites in a structure.

Self-Interstitials:

-"extra" atoms positioned between atomic sites.

Vacancy

distortion

of planes

self-

interstitial

distortion

of planes

INTRODUCTION

Vacancies are equilibrium defects! i.e., they will

always be present in a crystal at finite temperature.

They are not created due to any shortcomings in

the process of crystal growth.

An amount of energy Q

d

is required to create a

single defect. Then why are there defects?

To increase the entropy (disorder) of the crystal!

Any system at equilibrium has the maximum

possible entropy.

The equilibrium configuration of a system (crystal)

is found by minimizing the Gibbs Free energy (G= H-

T

S

) of a crystal.

EQUIL. CONCENTRATION: POINT DEFECTS

Boltzmann's constant

(1.38 x 10

-23

J/atom K)

(8.62 x 10

-5

eV/atom K)

|

N

D

N

=

exp

Q

D

kT

|

\

|

.

|

No. of defects

No. of potential

defect sites.

Activation energy

Temperature

Each lattice site

is a potential

vacancy site

Activation Energy: Energy required

for the formation of a vacancy. kJ/mol

-1

, ev/point imperfection

Given:

ESTIMATING VACANCY CONCENTRATION

8.62 x 10

-5

eV/atom-K

0.9eV/atom

1273K

|

N

D

N

=

exp

Q

D

kT

|

\

|

.

|

For 1m

3

, N =

N

A

A

Cu

x

x 1m

3

= 8.0 x 10

28

sites

= 2.7 10

-4

Find the equil. # of vacancies in 1m

3

of Cu at

1000

o

C.

We can get Q

v

from experiments.

|

N

v

N

=

exp

Q

v

k T

|

\

|

.

|

MEASURING ACTIVATION ENERGY

Measure this...

N

v

N

T

exponential

dependence!

defect concentration

Re plot it...

1/T

N

N

v

ln

-

Q

v

/k

slope

5.1 Calculate the fraction of atom sites that are vacant for Cu

at its melting temp of 1048

o

C (1347 K) Assume an energy of

vacancy formation of 0.90 eV/atom

5.2 Calculate the number of vacancies per cubic meter in gold

at 900

o

C. The energy for formation of vacancy is 0.98

eV/atom. Density= 18.63 g/cm3 and at. Wt= 196.9 g/mol.

POINT DEFECTS IN ALLOYS

Two outcomes if impurity (B) added to host

Solid solution of B in A (i.e., random dist. of point defects)

Solid solution of B in A plus particles of a new phase (usually

for a larger amount of B)

OR

Substitutional solid soln.( Cu in Ni)

Interstitial solid soln.(e.g., C in Fe)

Second phase particle

--different composition

--often different structure.

An ordered alloy becomes disordered (random) at a higher

temperatures.

SOLID SOLUTION

A solid solution is a solid-state solution of one

or more solutes in a solvent.

Such a mixture is considered a solution rather

than a compound when the crystal structure of

the solvent remains unchanged by addition of

the solutes, and when the mixture remains in a

single homogeneous phase.

This often happens when the two elements

(generally metals) involved are close together

on the periodic table.

FACTORS AFFECTING SOLID SOLUTION

Atomic size factor: Appreciable solubility of a solute

when the difference between the two atom sizes are

within +/- 15%. Failing which lattice distortions and

new phases are formed.

Crystal Structure: For appreciable solubility the

crystal structures of solute and solvent should be

the same.

Electronegativity: Large electronegativity differences

can lead to an intermetallic compound rather than a

substitution solid solution.

Valences: More tendency to dissolve a higher

valency metal than a lower valency.

EXAMPLES

Substitutional solid solution: Cu & Ni

Same atomic radii (0.128 nm for Cu & 0.125 nm for

Ni)

Both have same crystal structure (FCC)

Same electronegativities (1.9 and 1.8)

Interstitial Solid Solution: (impurity atoms fill in voids

or interstices among the host atoms)

Maximum solubility is less than 10% if atom is

bigger than interstitial site.

Eg: Solubility limit of C in Fe is 2 %

Atomic radius of C = 0.071 nm and that of Fe =

0.124nm

Which of these elements would you expect to form the following

with Nickel.

a)A substitutional solid solution having complete solubility.

b) A substitutional solid solution having incomplete solubility.

c) An interstitial solution.

5.4

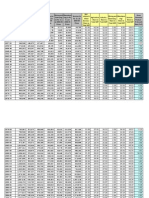

Element Atomic Crystal Electro- Valence

Radius Structure nega-

(nm) tivity

Cu 0.1278 FCC 1.9 +2

C 0.071

H 0.046

O 0.060

Ag 0.1445 FCC 1.9 +1

Al 0.1431 FCC 1.5 +3

Co 0.1253 HCP 1.8 +2

Cr 0.1249 BCC 1.6 +3

Fe 0.1241 BCC 1.8 +2

Ni 0.1246 FCC 1.8 +2

Pt 0.1376 FCC 2.2 +2

Zn 0.1332 HCP 1.6 +2

a) Pt is the only element that meets all of the criteria and

thus forms a substitutional solid solution having complete

solubility. At elevated temperatures Co and Fe experience

allotropic transformations to the FCC crystal structure, and

thus display complete solid solubility at these

temperatures.

b) Ag, Al, Co, Cr, Fe, and Zn form substitutional solid

solutions of incomplete solubility. All these metals have

either BCC or HCP crystal structures, and/or the difference

between their atomic radii and that for Ni are greater than

15%, and/or have a valence different than 2+.

c) C, H, and O form interstitial solid solutions. These

elements have atomic radii that are significantly smaller

than the atomic radius of Ni.

5.5 For both BCC and FCC crystal structures, there are

two different types of interstitial sites. In each case, one

site is larger that the other, and is normally occupied by

impurity atoms. For FCC, this larger one is located at

center of each edge of the unit cell; it is termed as

octahedral interstitial site. And for BCC structure, the

larger site is found at 0 positions that is lying on

{100} faces, situated midway between two unit cell edges

on those face and one-quarter of the distance between

the other two unit cell edges; it is termed as tetrahedral

interstitial site.

For both FCC and BCC structures, compute the radius r of

an impurity atom that will just fit into one of these sites in

terms of the atomic radius R of the host atom.

FCC structure: (100) plane

From the geometry

a = 2r + 2R

For FCC, a = 2R(2)

1/2

After substitution, r= 0.41 R

BCC structure: (100) plane

From the geometry

(R + r)

2

= (a/2)

2

+ (a/4)

2

For BCC, a = 4R/(3)

1/2

After solving, r = 0.291R

Thus, for a host atom of radius R, the size of an interstitial site for

FCC is approximately 1.4 times that for BCC.

COMPOSITION/CONCENTRATION

Definition: The relative content of a specific element or

constituent in an alloy.

Concentration of weight % of element 1 is

Concentration of atoms (atom %) present in element 1

100

2 1

1

1

+

=

m m

m

C

100

2 1

1

1

+

=

'

m m

m

n n

n

C

where nm1 are number of moles of the element in the alloy.

m

1

-- mass of the element, A

1

atomic weight of element 1

1

1

1

A

m

n

m

=

CONVERSION BETWEEN WT % AND AT %

100

2 2 1 1

1 1

1

'

+

'

'

=

A C A C

A C

C

100

1 2 2 1

2 1

1

+

=

'

A C A C

A C

C

100

2 2 1 1

2 2

2

'

+

'

'

=

A C A C

A C

C

100

1 2 2 1

1 2

2

+

=

'

A C A C

A C

C

Weight % Atoms%

100 ' '

100

2 1

2 1

= +

= +

C C

C C

Since there are only two atoms, we can write as

CONVERSION BETWEEN WT % AND AT% IN AN A-

B ALLOY

Total mass (say in grams)

Since or

From the equation we can write as

since

Substituting we get the

100

2 1

1

1

+

=

'

m m

m

n n

n

C

100

2

'

2

1

'

1

1

'

1

1

+

=

'

A

m

A

m

A

m

C

100

2 1

1

1

+

=

m m

m

C

100

1 1

'

1

M C

m =

' '

2

'

1

M m m = +

100

100 100

100

2

'

2

1

'

1

1

'

1

1

+

=

'

A

M C

A

M C

A

M C

C

100

1 2 2 1

2 1

1

+

=

'

A C A C

A C

C

'

2

'

1

'

m m M + =

1000

2

2

1

1

1

1

X

C C

C

C

|

|

|

|

.

|

\

|

+

=

' '

where C

1

= mass of element 1 per unit volume (kg/m

3

)

C

1

= weight percent of element 1, density in g/cm

3

1000

2

2

1

1

2

2

X

C C

C

C

|

|

|

|

.

|

\

|

+

=

' '

Conversion of concentration from weight % to mass % of

one component per unit volume of material. (from wt% to

kg/m

3

)

Used in diffusion computations.

|

|

|

|

.

|

\

|

+

=

2

2

1

1

100

C C

ave

|

|

|

|

.

|

\

|

'

+

'

'

+

'

=

2

2 2

1

1 1

2 2 1 1

A C A C

A C A C

ave

|

|

|

|

.

|

\

|

+

=

2

2

1

1

100

A

C

A

C

A

ave

100

2 2 1 1

A C A C

A

ave

'

+

'

=

Approximate relations (alloy density & atomic weight)

5.8 What is the composition, in weight % of an alloy that

consists of 5 at% of Cu and 95 at% of Pt? (At wt Cu= 63.55

g/mol, at wt Pt= 195.08 g/mol.)

5.17 Calculate the unit cell edge length for a 80 wt% Ag-

20wt% Pd alloy. All of the Palladium is in solid solution, the

crystal structure for this alloy is FCC. The At wt -Ag and Pd

are 107.9 and 106.4 g/mol, whereas the densities for the Ag

and Pd are 10.49 g/cm

3

and 12.02 g/cm

3

Sol: Average density relation as =

or

Since the crystal structure is

FCC, the value of n= 4.

a can be estimated to be 4.050 x 10

-8

cm

|

|

|

|

.

|

\

|

+

=

2

2

1

1

100

C C

ave

|

|

|

|

.

|

\

|

+

=

2

2

1

1

100

A

C

A

C

A

ave

5.19. For a solid solution consisting of two elements,

sometimes it is desirable to determine the no of atoms per

cubic centimeter of one element in a solid solution, N1,

given the concentration of that element specified in wt %,

C1. Derive the above equation the following expression:

1

=

1

+

2

(100

1

)

Solution: Let the concen., of component 1 in atom %

1

is

just 100*

1

where

1

is the atom fraction of component 1.

Furthermore, it is defined as = N

1

/N where N

1

and N are,

respectively, the number of atoms of component 1 and total

number of atoms per cubic cm.

The above expression can be written as

Substituting in the equation (N is the no of atoms present per

cubic cm or m) =

we get

From relation between C1 and C1 and the relation of

averages, we get,

5.20 Molybdenum forms a substitutional solid solution with

Tn. Compute the no of Mo atoms per cubic cm for a Mo-Tn

alloy that contains 16.4 wt% of Mo. The densities of Mo and

Tnare 10.22 and 19.30 gm/cubic cm.

DEFECTS IN CERAMIC STRUCTURES

Electro neutrality: Equal number of + and - ve charged ions.

Stoichiometry: Defined as a state of ionic compounds where

there is exact number of cations to anions ratio.

Schematic

representation of

cation and anion

vacancies and a

cation interstitial.

Frenkel Defect -- a paired set of cation vacancy and a

cation interstitial is out of place.

Schottky Defect -- a paired set of cation vacancy and

anion vacancy is out of place.

Schottky

Defect:

Frenkel

Defect

Is charge neutrality

maintained in either

of the cases?

Non- stoichiometry occurs for ceramic materials in

which two valence (or ionic) states exist for one of the

ion types. Eg: Fe

2+

and Fe

3+

.

What happens if one Fe

2+

is converted to Fe

3+

?

One Fe

2+

vacancy formed for every two Fe

3+

formed.

Hence chemical formula is Fe

1-x

O.

The equilibrium number of both the defects increase

with and depend on Temperature in a manner similar to

the number of vacancies in metals.

The factor 2 represents two defects (a missing cation

and an interstitial cation) are associated with each

Frankel defect. Similarly with Schottky defect.

= exp (

2

)

= exp (

2

)

N= NA /(At1+At2)

Where N is the number of lattice sites per cubic meter.

Impurities must also satisfy charge balance (Electroneutrality)

Ex: NaCl

Impurities in Ceramics

Na

+

Cl

-

initial geometry Ca

2+

impurity resulting geometry

Ca

2+

Na

+

Na

+

Ca

2+

cation

vacancy

Substitutional anion impurity

initial geometry O

2-

impurity

O

2-

Cl

-

an ion vacancy

Cl

-

resulting geometry

Calculate the number of Schottky defects per cubic meter

in potassium chloride at 500

o

C. The energy required to

form each Schokkty defect is 2.6 eV, while the density of

KCL (at 500

o

C) is 1.95 g/cm

3

. AK=39.10, ACl=35.54 g/mol

Solution:

Number of lattice sites per cubic meter is

N= NA /(AK+ACl)

From the formula we have

= exp (

2

)

LINES DEFECTS

Dislocations:

are line defects,

cause slip between crystal planes when they

move

produce permanent (plastic) deformation.

are of two types

Edge dislocation

Screw dislocation

1. EDGE DISLOCATION

Extra half plane of atoms

Dislocation line Burgers vector

http://www.youtube.com/wa

tch?v=iKKxTP6xp74

2. SCREW DISLOCATION : DISLOCATION LINE ||

BURGERS VECTOR

Figure showing Burger Vector in both the imperfections

3. MIXED DISLOCATION

Edge

Screw

Dislocations were postulated to explain the discrepancy

between the experimental and the theoretical values of the

elastic limit for (single) crystalline solids.

Experimental value of elastic limit ~ 10

6

N/m

2

Theoretically calculated value ~ 10

10

N/m

2

(assuming

relative motion of entire planes)

If dislocations are present, plastic deformation involves only

the motion of the dislocation, which requires lesser applied

stress.

Analogy: Moving a kink across a carpet is easier than

dragging the entire carpet across a room.

INTERFACIAL DEFECTS

Dislocations (unlike vacancies) are non-equilibrium

defects. However they help in the growth of crystals and

hence are normally present in crystals.

Density of dislocations cannot be predicted and can

increase with applied stress!

Without screw dislocations

crystal growth will be a very

slow process.

Screw dislocation and

growth of crystals

INTERFACIAL DEFECTS

Defined as boundaries that have 2d imperfections in

crystalline solids, have different crystal structures and/or

crystallographic orientations on either side of them.

Distortions lie about a surface having thickness of a few

atomic diameters.

Ex: External surfaces, grain boundaries, twin boundaries,

stacking faults, and phase boundaries.

Not thermodynamically stable, rather they are meta-stable

imperfections.

Arise from the clustering of line defects into a plane.

EXTERNAL SURFACES

The environment of an atom at a surface differs from that

of an atom in the bulk.

The number of neighbors (coordination #) at surface is

less. Thus the unsaturated bonds of surface atoms give

rise to a surface energy.

This results in relaxation (the lattice spacing is decreased)

or reconstruction (the crystal structure changes).

To reduce the energy, materials tend to minimize, if

possible, the total surface area.

This is similar to a liquid drop changing its shape to

spherical.

GRAIN BOUNDARIES

Boundaries separated by two small grains or crystals

having different crystallographic orientation in

polycrystalline materials.

There is mismatch in transition from crystalline orientation

of one grain to that of an adjacent one.

When this misalignment is slight, on the order of few

degrees (< 10), it is called low angle grain boundary.

Low grain boundary formed by edge dislocations is called

tilt boundary; where as twist boundary if formed of screw

dislocations.

Atoms are bonded less regularly along the boundaries; thus

having GB energy, function of degree of mis orientation.

Schematic diagram of grain

boundaries.

A tilt boundary having an

angle of mis-orientation

results from an alignment of

edge dislocation

5.36 For a given material, would you expect the surface

energy to be >/ </ = that of grain boundary energy. Why?

Why GBE for small GBAngle < that of for larger GBAngle?

More atoms

bond across

the

boundary

for the

small-angle,

thus, there

are fewer

unsatisfied

bonds

Tilt and twist boundaries are planar surface imperfections in

contrast to high angle grain boundaries.

Less irregularity in bond formation along the grain boundary that

results in interfacial or grain boundary energy.

Grain boundaries are chemically more reactive because of grain

boundary energy. Impurities segregate along these areas.

Polycrystalline solids are still very strong as cohesive forces

present within and across the boundary.

Twin Boundaries: (A mirror lattice symmetry is found.)

Results from atomic displacements produced from shear forces

also during annealing heat treatments following deformation.

Twinning occurs on a definite crystallographic planes and

on specific directions. These depend on crystal structure.

Annealing twins found in FCC structure.

Mechanical Twins in BCC and HCP structures.

BULK OR VOLUME DEFECTS

Larger in size. Ex pores, cracks, foreign inclusions and

other phases. Occurs during processing and fabrication

steps.

Atomic Vibrations: Atoms vibrate very rapidly about its

lattice positions. At any instant not all atoms vibrate at the

same amplitude and frequency.

At a given Temp, there exists a distribution of energies for

the constituent atom about an average energy.

As temp increases, average energy increases.

Many properties and processes in solids are manifestations

of this vibrational atomic motion.

Melting occurs when vibration are vigorous enough to

rupture large number of atomic bonds.

Miscellaneous defects:

Stacking faults in HCP & FCC crystals

Phase boundaries, pores, cracks

Atomic vibrations

DEFECTS IN POLYMERS

5.29 Using the data given below that relate to the formation

of Schottky defects in some oxide ceramic (chemical

formula MO), determine

a) The energy for defect formation (in eV)

b) The eqvlnt. no., of Schottky defects /cubic m at 1000

o

C

c) The identity of the oxide (identify metal M)

T (

o

C) (g/cm

3

) Ns (m

-3

)

750 3.50 5.7 x 10

9

1000 3.45 ?

1500 3.40 5.8 x 10

17

Solution: From the given data, the Schottky defects at 750

and 1500

o

C are known. For an alloy system, we can write

the relations as

As we do not know the metal oxide, from the two equations,

we can find the relation between the number of defects and

temperature by eliminating the atomic weights

Dividing the two equations we

get:

Taking natural log on both the

sides:

Rearranging for Qs (energy of

defect formation):

b)

From the above equation of

Ns

1

/Ns

2

, we can take Ns

2

and T

2

at 750

o

C and since we know T

1

=

1000

o

C, we can get Ns

1

.

c) Rearranging the first equation

to get N from Ns, we have:

Rearranging the above equation

for AM we get:

SUMMARY

Types of imperfections-

Point: Vacancy, interstitial and substitution

Line defects: Dislocations

Area defects: External surfaces, grain boundaries,,

Volume defects: Cracks, pores

Estimation of no of defects, energy of formation of a defect

Edge dislocation, screw dislocation, Burger vectors

Tilt boundaries, Twin boundaries, other defects

Defects in ceramics and ionic crystals, defects in polymers

Problems of interest: 5.26, 5.28, 5.31, 5.34, 5.38

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- CRISIL Ratings NBFC Compendium Mar11Documento0 pagineCRISIL Ratings NBFC Compendium Mar11Heisnam BidyaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Chinese Economy OverviewDocumento2 pagineChinese Economy Overviewandrewkyler92Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Bussiness Analysis and ValuationDocumento4 pagineBussiness Analysis and Valuationandrewkyler92Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Variation of ParametersDocumento40 pagineVariation of Parametersandrewkyler92Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Stages of GrowthDocumento25 pagineStages of Growthandrewkyler92Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- ComparativeDocumento1 paginaComparativeandrewkyler92Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- GDP and Major Industrial Sectors of Economy DatasetDocumento6 pagineGDP and Major Industrial Sectors of Economy Datasetnerdy1991Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Economic Survey STATISTICAL Appendix 2012-13Documento130 pagineEconomic Survey STATISTICAL Appendix 2012-13pavan6754Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Bit Coin AnalysisDocumento3 pagineBit Coin Analysisandrewkyler92Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Multi Folder New Product Details-2Documento1 paginaMulti Folder New Product Details-2nitika kumariNessuna valutazione finora

- Chapter 12Documento101 pagineChapter 12Bruh MomentNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Solid StateDocumento50 pagineSolid StateDina GaranNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- PQT Chapter 3 The Structure of Crystalline SolidsDocumento34 paginePQT Chapter 3 The Structure of Crystalline SolidsDương Hữu PhươngNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Course Objective... : You Will Learn AboutDocumento70 pagineCourse Objective... : You Will Learn AboutThaneswaran BaluNessuna valutazione finora

- Aakash SolutionDocumento34 pagineAakash Solutionrishika ghosh67% (3)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- MSE304 Assignment IDocumento4 pagineMSE304 Assignment IHarshit SachdevNessuna valutazione finora

- Reciprocal LatticeDocumento35 pagineReciprocal LatticeSushil kumarNessuna valutazione finora

- Crystal Structures of Solid StateDocumento26 pagineCrystal Structures of Solid StaternsseturajNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- TCET FE Applied Physics - I (2018-2019)Documento308 pagineTCET FE Applied Physics - I (2018-2019)Kevin100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Material Science and Engineering 9th Solution-7Documento60 pagineMaterial Science and Engineering 9th Solution-7호박Nessuna valutazione finora

- Assignment 1 Marking SchemeDocumento4 pagineAssignment 1 Marking SchemeTamiranashe Tammie NyunguNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Illuminati - 2019: Advanced Chemistry Assignment - 4B - Physical Chemistry Class-XiithDocumento12 pagineIlluminati - 2019: Advanced Chemistry Assignment - 4B - Physical Chemistry Class-XiithBiswajit GhoshNessuna valutazione finora

- Solid State Physics 19UPHE02 ODD SEMDocumento128 pagineSolid State Physics 19UPHE02 ODD SEMLALITHA MNessuna valutazione finora

- FCC, BCC and HCP MetalsDocumento9 pagineFCC, BCC and HCP Metals20ChikaneNessuna valutazione finora

- DPP 01 Solid StateDocumento14 pagineDPP 01 Solid Stateanupamgupta112Nessuna valutazione finora

- (Test 5) Nsec Solved Paper 2011 AnswerkeyDocumento17 pagine(Test 5) Nsec Solved Paper 2011 AnswerkeyDevanshu ShahNessuna valutazione finora

- Chemistry: Solids: Crystals, Alloys, and PolymersDocumento57 pagineChemistry: Solids: Crystals, Alloys, and Polymers張湧浩Nessuna valutazione finora

- Reciprocal LatticeDocumento38 pagineReciprocal LatticeBinoy NambiarNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Crystallography NotesDocumento96 pagineCrystallography NotesNafis AhmedNessuna valutazione finora

- Guangdong Ason Jewelry Co., LTD: Hoop EarringsDocumento18 pagineGuangdong Ason Jewelry Co., LTD: Hoop EarringsRodriguez G YineNessuna valutazione finora

- Trismegistus Official AppendixDocumento5 pagineTrismegistus Official AppendixDaannaahhNessuna valutazione finora

- Forming (NPTEL Web Course)Documento621 pagineForming (NPTEL Web Course)abhisheks5987100% (5)

- Introduction To Solid State Physics - C KittelDocumento692 pagineIntroduction To Solid State Physics - C KittelAlexis Hart100% (4)

- Mse215 Materials Science I Mid Term 2020 2021Documento5 pagineMse215 Materials Science I Mid Term 2020 2021yagmurdeniiizzzNessuna valutazione finora

- Smith CH 03Documento75 pagineSmith CH 03KevinSaldañaNessuna valutazione finora

- About MineralsDocumento32 pagineAbout MineralsDr. Daljeet Singh SidhuNessuna valutazione finora

- Crystal Field TheoryDocumento22 pagineCrystal Field TheoryWasimNessuna valutazione finora

- Solution of Homework # 2: Problem # 1Documento12 pagineSolution of Homework # 2: Problem # 1ct3hNessuna valutazione finora

- BSCPH 203Documento235 pagineBSCPH 203rohitsanju218Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)