Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Production

Caricato da

tusharprasad24Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Production

Caricato da

tusharprasad24Copyright:

Formati disponibili

1

SUMMER INTERNSHIP PROJECT REPORT HOW TO SMOOTHING THE PROCESS OF PRODUCTION, THROUGH PLANNING AND BETTER SUPERVISION

SUBMITTED IN PARTIAL FULFILLMENT FOR THE AWARD OF POST GRADUATE DIPLOMA IN MANAGEMENT

SUBMITTED BY

ROHIT GUPTA ROLL NO: M2012094

UNDER THE SUPERVISION OF

Dr. POONAM KAIN SUBMITTED TO

APEEJAY INSTITUTE OF TECHNOLOGY SCHOOL OF MANAGEMENT GREATER NOIDA (UP)

(2012-2014)

DECLARATION

I hereby declare that the project entitled HOW TO SMOOTHING THE PROCESS OF PRODUCTION, THROUGH PLANNING AND BETTER SUPERVISION submitted for the Post Graduate Diploma in Management degree is my original work and the project has not formed the basis for the award of any degree, associate ship, fellowship or any other similar titles.

ROHIT GUPTA (Signature of the Student)

CERTIFICATE

This is to certify that the project "HOW TO SMOOTHING THE PROCESS OF PRODUCTION, THROUGH PLANNING AND BETTER SUPERVISION" is the bonafide project work done by Rohit Gupta student of APEEJAY INSTITUTE OF TECHNOLOGY SCHOOL OF MANAGEMENT,GREATER NOIDA, during the 1ST MAY to 30TH JUNE, in partial fulfillment of the requirements for the award of the Degree of POST GRADUATE DIPLOMA IN MANAGEMENT and that the project has not formed the basis for the award previously of any degree, diploma, associate-ship, fellowship or any similar title. To the best of my knowledge and belief the project represents independent and original work on the part of candidate under my guidance.

Dr. Poonam Kain

Name and Signature of Mentor

Prof. D.N. Bajpai Name and Signature of Director

ACKNOWLEDGEMENTS

I would like to take this opportunity to thank Dr. POONAM KAIN for giving me the liberty to work on project of my interest and for letting me work in a location convenient. Last but not the least I would also like to thank all of the helping me in every possible way and giving their valuable time for interviews and filling up of questionnaires without which this project could not have been completed.

ROHIT GUPTA (Signature of the Student)

CONTENTS

Topic

1. Title Summary 2. Introduction 3. Company Profile 4. Objectives of the Study 5. Production Function 6. Steps in PPC 7. Problems with Traditional Production Planning and Control 10. Production Planning and Control at R.L. MASAALA 11. Research Methodology 12. Interpretation of Data 13. Findings 14. Conclusion 15. Recommendation 16. Bibliography 17. Annexure

page no.

6 7 8 - 21 22 23-24 25-30 31-32 33-46 47 48-57 58 59 60 61 62-63

Project Title

HOW TO SMOOTHING THE PROCESS OF PRODUCTION, THROUGH PLANNING AND BETTER SUPERVISION

Title Summary

The project has been developed to identify the need and

importance of PPC i.e. Production Planning and Control in manufacturing industry. Production planning is done with the objective of coordination of materials with suppliers, efficient utilization of people and machines, efficient flow of materials, and communication with customers.

Various activities are supported by Production Planning and Control like- Materials Planning, Purchasing, Raw Material, Inventory Control, Capacity Planning, Scheduling Machine and People, WIP Inventory Control, Coordinate Customer Orders, Finished Goods Inventory Control.

Production planning and control facilitates in various ways like- optimum utilization of capacity, inventory control, ensures quality, and economy in production time.

Production Planning is accompanied with Control Mechanism to ensure desired results. Results are compared with plans, if any deviation is found revision of plan is done. Hence, Production Control is an adjusting process, providing corrective measures for planned development.

INTRODUCTION

India is known as The home of spices. No Indian meal is considered complete without the tangy and delectable flavor of Indian spices, locally known as Masala. Indian spices are famous all over the world for their gastronic value and them known to possess high medicinal values. There is no other country in the world that produces as many kinds of spices as India. Some of the most widely consumed spices in the country inter alia include: chilli, cinnamon, cumin, curry leaf, fennel, asafetida, basil, bay leaves, cardamom-small, cardamom-large, ginger, mustard, bishops, weed, cassia, celery, clove, coriander, fenugreek, garlic, mint, onion, parsley, pomegranate, turmeric, tamarind, pepper, poppy, rosemary and vanilla. The climate of the country is found suitable for growing almost all spices. India produces 25 lakhs tone to 30 lakhs tonne of spices annually. India produces spices of different categories worth around Rs.14, 000 crore. In terms of volume India accounted for 46 percent and 23 percent in value of global spice trade. India accounts for 25-30 percent of worlds pepper production, 35 percent of ginger and about 90 percent of turmeric production.

There are few things that permeate Indian life so completely as spices. The aroma, colour, taste and texture of the astonishing varieties of spices in India nourish a rich variety of cuisines and cultures.

There are few things that permeate Indian life so completely as spices. The aroma, colour, taste and texture of the astonishing varieties of spices in India nourish a rich variety of cuisines and cultures.

Earlier, spices were chosen, measured, pounded and mixed, all in the kitchen. It took hours to prepare these spice recipes passed down by generations. Today, millions of homes enjoy the same authentic taste and aroma of traditional delicacies, with Everest's perfect blend of pure spices. These blends even bring the regions closer by providing the authentic taste of other regional cuisines, in the convenience of a pack, at home.

COMPANY PROFILE

R.L. MASAALA is a brand of a company named KUMAR AUDYOGIK VIKAS PRIVATE LIMITED. Here R.L. stands for Raghunath (grandfathers name) Laxminarayan (name of Goddess Laxmi). Factory was located in Chandauli district (ram nagar) near Varanasi with a land occupying 2 lakh 35000 sq ft. R.L. MASAALA began its business operations on August 8, 2008. Today R.L. MASAALA is a significant player in the Indian spices industry with a gross sales turnover of over Rs. 98.36 crore in the year 2012-13. R.L. MASAALA has been awarded ISO-9001. R.L. MASAALA is wholly owned by Maheshwari Group and the family members are the shareholders.

CONTACT

Company Name Telephone : Kumar Audyogik Vikas Pvt. Ltd. : +(91)-(542)-3269111 +(91)-(542)-2440151 Address : K47/2, Visheshshwar Ganj, Varanasi, Varanasi - 221 001, Uttar Pradesh, India

FACT SHEET

Legal status of the firm Private limited company Nature of the business Manufacturer, exporter, wholesaler, trader

HIGHLIGHTS

THE PROMOTOR OF THE COMPANY: - MAHESHWARI GROUP

MANAGING DIRECTOR OF THE COMPANY: - OMKAR NATH MAHESHWARI

PRODUCTION MANAGER: - MAYANK MAHESHWARI

PRODUCTS: - 198 ITEMS RANGE

MARKET STRENGH: 125 MARKETING EMPLOYEES

PRODCUTION WORKER: 350 TOTAL 135 SKILLED AND REST ARE UNSKILLED

METHOD OF PRODUCTION: FIFO

THE GROUP IS NEARLY 45 YEARS OLD

THE PROMOTER OF THE COMPANY ARE VERY WELL VERSED WITH COMMODITY MARKET AS THEY ARE BIG NAME IN THE SPICES COOMDITY TRADING.

THEY BUY GOODS FROM FARMERS DIRECTLY.

THEY HAVE IN THE SPICES TRADING FROM LAST 45 YEARS.

10 It is a semi scaled industry (small and medium scale). There are 657 employees working in this company. Company uses its own vehicles for transportation. They have 35 big and small vehicles which are owned by company itself. They deal in 9 different states:UTTAR PRADESH BIHAR JHARKHAND KARNATAKA MAHARASHTRA UTTARAKHAND ASSAM MADHYA PRADESH WEST BENGAL

In every state they have warehouses which are available at the central location. They have different offices in different cities:-

VARANASI (HEAD OFFICE) KOLKATA HALDWANI SILIGURI PATNA JABALPUR SATNA SANGLI NAGPUR BELGAUM GORAKHPUR KANPUR RANCHI

11

PRODUCTS

MUTTON MASALA

INGREDIENTS - Black paper, cumin seed, cinnamon, Turmeric, Coriander, Nutmeg,

Bay-leaf, ginger Garlic, Clove, chillies, onion, salt, and mace etc.

A Pepper-coriander chili based blend that imparts a dark tan and a hot taste to non-veg dishes. Especially meat, since Indians love their meat really spiced up, a fair amount of flavoring spices lend this blend an aromatic chours. In all meat preparation required dark gravy.

CHICKEN MASALA

INGREDIENTS

Coriander, Chili, Onion, Bay-leaf, Black Pepper, Cumin seed, Salt,

Cinnamon, Garlic, Ginger, Nut weg, cloves, Mace etc. Iodized Common salt is not more than 5% by weight on dry basis. Mixed Masala Powder (Not curry Powder)

12

CHHOLA CHANA MASALA

INGREDIENTS

Coriander, Cumin seed, Pomegranate Seed, Dry Mango, Black

Pepper, Dry Ginger, Cardamom, Nutmeg, Mace, Chili, fenugreek Leaves, Onion, Salt.

SAMBAR MASALA INGREDIENTS

Coriander, Fenugreek leaves, Chili, Pulses, Turmeric, and Curry

leaves, Asafetida, Edible iodized Salt.

KITCHEN KING MASALA

INGREDIENTS

Mace etc.

Coriander, Cumin ,Black Pepper, Dry Clove Turmeric ,Black

Peeper ,Common Salt, Cardamom , Chili, Onion cinnamon, Dry Ginger, Nutmeg, Bay-leaf

13

PAV BHAJI MASALA INGREDIENTS

Coriander, Cumin, Black Peeper, Dry Mango, cassia, clove,

Turmeric, Dry Ginger, Anistar, Fennel seed, Black Cardamom, chili, Cassia Leaf and Iodized Salt.

KASOORI METHI

INGREDIENTS

- Dried Fenugreek Leaves

JAL JEERA MASALA

INGREDIENTS - Cumin, Dry Mango, Chili, Black Peeper, big cardamom, Mint Leaves,

Critic, Dry Ginger, Asafetida, cloves, Aniseeds, Tartaric, Caraway seeds, Myrobalan, edible iodized salt not more than 55 % by weight.

14

CHAT MASALA

INGREDIENTS

- Pomegranate seeds, cardamom, coriander, ginger, Carom White Salt,

Dry Mango, Black Peeper, Black Salt, Mint leaves, Kachari, Cumin seeds, Chilies, seeds, Nutmeg, cloves, Asafetida. (Edible iodized salt not more 50%)

GARAM MASALA

INGREDIENTS

Big Cardamom, Black Pepper, cumin seed, Dry Ginger, cinnamon,

Bay Leaf, Nutmeg, clove, salt, Mace etc.

BUNA JEERA MASALA INGREDIENTS

Roasted cumin Powder, Best quality cumin powder scientifically

graded. Hygienically packed ground and NO artificial colour used.

15

SAHI PANEER MASALA INGREDIENTS

- Coriander, Cumin, Black Peeper, Dry Clove, Turmeric, Black Peeper,

Common Salt Cardamom, chili, Onion, Cinnamon, Dry Ginger, Nutmeg ,Bay leaf ,Mace etc.

KANDA LAHSUN MASALA

INGREDIENTS

Red Chili powder, Iodized Salt, Onion, Garlic, Ground spices,

coriander, Cumin, Black Paper, cloves, Refined Edible oil.

SABJI MASALA INGREDIENTS

- Big Cardamoms, cumin, Bay-leaf, Black Pepper, coriander, Turmeric,

Chilies, salt, Dry mango, Dry Ginger, Nutmeg, Cloves, Edible, Common salt not more than 5% by weight on dry basis.

16

KASHMIRI MIRCH POWDER

INGREDIENTS

- Specialty best quality Karnataka chilies are hygienically powdered to

give a grand red colour to all vegetarian and non vegetarian preparations.

KALI MIRCH POWDER

INGREDIENTS - Black Pepper Powder scientifically graded, hygienically ground and

packed. NO artificial.

DRY GINGER POWDER (SUNTH POWDER)

INGREDIENTS - Dry Ginger powder, Best quality ginger. Scientifically graded

hygienically packed ground and packed. No artificial colour used.

17

CHILLI POWDER

INGREDIENTS - Chili Powder

CHILLI PREMIUM POWDER

INGREDIENTS - Chili Powder Premium

HALDI POWDER

INGREDIENTS - Turmeric Powder

18

DHANIYA POWDER

INGREDIENTS - Coriander Powder

CHIVADA MASALA

INGREDIENTS - Dhaniya, cumin, Tamal Patri, Chili Powder, black Pepper powder,

Sounff, Asafoiteda, Salt, turmeric, Sugar, mohari, Badamful, Lavang Pan etc.

CHAKALI MASALA

INGREDIENTS - Cumin, Chili Powder, Salt, Carom seeds, & Black Pepper.

19

GODA MASALA

INGREDIENTS - Coriander, turmeric, Chilies, Onion, Bay leaf, Black Pepper, cumin

seed, Salt, cinnamon, Garlic, Ginger, Nutmeg, clove, MACE Etc.

MISHRAN MASALA

INGREDIENTS - Coriander, Turmeric, Chilies, Onion, Bay-leaf, Black Pepper, cumin

seed, Salt, cinnamon, Garlic, ginger, Nutmeg, clove, mace Etc.

PAV BHAJI MASALA

INGREDIENTS - Coriander, Cumin, Black Peeper, Dry Mango, cassia, clove, Turmeric,

Dry Ginger, Anis tar, Fennel seed, Black Cardamom, chili, Cassia Leaf and Iodized Salt.

KASOORI MASALA

INGREDIENTS - Dried Fenugreek Leaves

20

PICKLES

MANGO PICKLE GREEN CHILI PICKLE RED CHILI PICKLE MIX PICKLE

SWEET GULAB JAMUN

INGREDIENTS - Wheat Flour, Skim milk Powder, Vegetable Oil, Citric acid, sugar, Roller Dried Powder & Backing Powder.

OTHER PRODUCTS SOYABARI

INGREDIENTS Defatted soya flour.

PAPAD MASALA

INGREDIENTS - U dad Dal, Salt, Fulkhar, black Pepper, Compounded Asafetida.

21

MOOG SPECIAL PAPAD

INGREDIENTS - Pluses of Moog & Urad, Salt, Asafetida, Editable veg, oils, Parthan of

wheat, Black Peeper and Gram Flour.

URAD PAPAD

INGREDIENTS - Black Germs pulse flour, Black Pepper, Salt, Papad Khar, Edible oil &

Asafetida (Hing).

TIKALI PAPAD

INGREDIENTS - Pulses of Moog and Urad, Salt, Asafetida, Edible veg, oils, Parthan of

wheat, black Pepper & Gram Flour.

HERBAL GULAL COLORS: RED, YELLOW, GREEN, PINK BANDHANI HING

INGREDIENTS - Edible Starch,, Approximate 50 %, Gum + Asafetida

Health has always been a primary concern with R.L. Masaala; we take extra care on this front In our processing operations.

22

OBJECTIVES OF THE STUDY

Objective of the study is to prove that the production planning and control practices has impact on the efficient utilization of the resources, waste reduction, reduce waiting time and processing, thus contributing to the profitability of the industry. On these premise the study accentuated to address questions in order to achieve the following objectives:

(1)

To know how the production planning contributes to the efficient use of facilities and

equipments.

(2)

To know the effects of Production Planning and Control on Production function.

(3)

To know whether production planning and control practices lead to waste reduction

and increased profit.

(4)

To prove that short term production planning and scheduling techniques employed by

industries, is necessary in minimizing process and customer waiting time.

23

PRODUCTION FUNCTION

After taking decisions about the type of business, its location, layout etc. the entrepreneur steps into the shoe of production manager and attempts to apply managerial principles to the production function in an enterprise. Production is a process whereby raw material is converted into semi finished products and thereby adds to the value of utility of products, which can be measured as the difference between the value of inputs and value of outputs.

A Typical Manufacturing Systems

SUPPLIERS Raw Materials Materials Machines People CUSTOMERS Finished Products

Production function encompasses the activities of procurement, allocation and utilization of resources. The main objective of production function is to produce the goods and services demanded by the customers in the most efficient and economical way. Therefore efficient management of the production function is of utmost importance in order to achieve this objective. Production management involves the managerial decisions regarding design of the product and design of the production system i.e. determination of production processes and production planning and control.

24

PRODUCTION PLANNING AND CONTROL

Once the entrepreneur has taken the decisions regarding the product design and production processes and system, his next task is to take steps for production planning and control, as this function is essentially required for efficient and economical production.

Planned Production is the ability to look ahead, organize and coordinate and having plenty of driving force and capacity to lead and ability to supervise and coordinate work and simulates his associates by means of a program of human relation and organization of employees.

Production Planning and Control involve generally the organization and planning of manufacturing process. Especially it consists of the planning of routing, scheduling, dispatching inspection, and coordination, control of materials, methods machines, tools and operating times. The ultimate objective is the organization of the supply and movement of materials and labour, machines utilization and related activities, in order to bring about the desired manufacturing results in terms of quality, quantity, time and place.

Production planning without production control is like a bank without a bank manager, planning initiates action while control is an adjusting process, providing corrective measures for planned development. Production control regulates and stimulates the orderly how of materials in the manufacturing process from the beginning to the end.

25

STEPS IN PPC (PRODUCTION PLANNING AND CONTROL)

Production Planning and Control (PPC) is a process that comprises the performance of some critical; functions on either side, viz., planning as well as control

Planning

Routing Production Planning Scheduling

Loading Production Planning and control Dispatching

Following up Production Control Inspection

Corrective

26

Production planning

Production planning may be defined as the technique of foreseeing every step in a long series of separate operations, each step to be taken at the right time and in the right place and each operation to be performed in maximum efficiency. It helps entrepreneur to work out the quantity of material manpower, machine and money requires for producing predetermined level of output in given period of time.

Routing

Under this, the operations, their path and sequence are established. To perform these operations the proper class of machines and personnel required are also worked out. The main aim of routing is to determine the best and cheapest sequence of operations and to ensure that this sequence is strictly followed. In small enterprises, this job is usually done by entrepreneur himself in a rather adhoc manner. Routing procedure involves following different activities.

(1) An analysis of the article to determine what to make and what to buy. (2) To determine the quality and type of material (3) Determining the manufacturing operations and their sequence. (4) A determination of lot sizes (5) Determination of scrap factors (6) An analysis of cost of the article (7) Organization of production control forms.

27

Scheduling

It means working out of time that should be required to perform each operation and also the time necessary to perform the entire series as routed, making allowances for all factors concerned. It mainly concerns with time element and priorities of a job. The pattern of scheduling differs from one job to another which is explained as below:

Production schedule

The main aim is to schedule that amount of work which can easily be handled by plant and equipment without interference. Its not independent decision as it takes into account following factors.

(1) Physical plant facilities of the type required to process the material being scheduled. (2) Personnel who possess the desired skills and experience to operate the equipment and perform the type of work involved. (3) Necessary materials and purchased parts.

Master Schedule

Scheduling usually starts with preparation of master schedule which is weekly or monthly break-down of the production requirement for each product for a definite time period, by having this as a running record of total production requirements the entrepreneur is in better position to shift the production from one product to another as per the changed production requirements. This forms a base for all subsequent scheduling acclivities. A master schedule is followed by operator schedule which fixes total time required to do a piece of work with a given machine or which shows the time required to do each detailed operation of a given job with a given machine or process. Manufacturing schedule: It is prepared on the basis of type of manufacturing process involved. It is very useful where single or few products are manufactured repeatedly at regular intervals. Thus it would show the required quality of each product and sequence in which the same to be operated.

28

Scheduling of Job to order manufacturing

Scheduling acquires greater importance in job to order manufacturing. This will enable the speedy execution of job at each center point. As far as small scale industry is concerned scheduling is of utmost importance as it brings out efficiency in the operations and s reduces cost price. The small entrepreneur should maintain four types of schedules to have a close scrutiny of all stages namely an enquiry schedule, a production schedule, a shop schedule and an arrears schedule out of above four, a shop schedule is the most important most suited to the needs of small scale industry as it enables a foreman to see at a glance.

1. The total load on any section 2. The operational sequence 3. The stage, which any job has reached.

Loading

The next step is the execution of the schedule plan as per the route chalked out it includes the assignment of the work to the operators at their machines or work places. So loading determines who will do the work as routing determines where and scheduling determines when it shall be done. Gantt Charts are most commonly used in small industries in order to determine the existing load and also to foresee how fast a job can be done. The usefulness of their technique lies in the fact that they compare what has been done and what ought to have been done. Most of a small scale enterprise fails due to non-adherence to delivery schedules therefore they can be successful if they have ability to meet delivery order in time which no doubt depends upon production of quality goods in right time. It makes all the more important for entrepreneur to judge ahead of time what should be done, where and when thus to leave nothing to chance once the work has begun.

29

Production control

Production control is the process of planning production in advance of operations, establishing the extract route of each individual item part\ or assembly, setting, starting and finishing for each important item, assembly or the finishing production and releasing the necessary orders as well as initiating the necessary follow-up to have the smooth function of the enterprise. The production control is of complicated nature in small industries. The production planning and control department can function at its best in small scale unit only when the work manager, the purchase manager, the personnel manager and the financial controller assist in planning production activities. The production controller directly reports to the works manager but in small scale unit, all the three functions namely material control, planning and control are often performed by the entrepreneur himself production control starts with dispatching and ends up with corrective actions.

Dispatching

Dispatching involves issue of production orders for starting the operations. Necessary authority and conformation is given for:

1. Movement of materials to different workstations. 2. Movement of tools and fixtures necessary for each operation. 3. Beginning of work on each operation. 4. Recording of time and cost involved in each operation. 5. Movement of work from one operation to another in accordance with the route sheet. 6. Inspecting or supervision of work

Dispatching is an important step as it translates production plans into production.

30

Follow up

Every production program involves determination of the progress of work, removing bottlenecks in the flow of work and ensuring that the productive operations are taking place in accordance with the plans. It spots delays or deviations from the production plans. It helps to reveal detects in routing and scheduling, misunderstanding of orders and instruction, under loading or overloading of work etc. All problems or deviations are investigated and remedial measure are undertaken to ensure the completion of work by the planned date. Inspection: This is mainly to ensure the quality of goods. It can be required as effective agency of production control. Corrective measures: Corrective action may involve any of those activities of adjusting the route, rescheduling of work changing the workloads, repairs and maintenance of machinery or equipment, control over inventories of the cause of deviation is the poor performance of the employees. Certain personnel decisions like training, transfer, demotion etc. may have to be taken. Alternate methods may be suggested to handle peak loads.

Inspection

This is mainly to ensure the quality of goods. It can be required as effective agency of production control.

Corrective measures

Corrective action may involve any of those activities of adjusting the route, rescheduling of work changing the workloads, repairs and maintenance of machinery or equipment, control over inventories of the cause of deviation is the poor performance of the employees. Certain personnel decisions like training, transfer, demotion etc. may have to be taken. Alternate methods may be suggested to handle peak loads.

31

Problems with Traditional Production Planning and Control

There are many problems that occur during the cycle of activities in the traditional approach to production planning and control. Many of these problems result directly from the inability of the traditional approach to deal with the complex and ever-changing nature of manufacturing. The types of problems commonly encountered in the planning and control of production are the following:

1. Plant capacity problems

Production falls behind schedule due to a lack of labor and equipment. This results in excessive overtime, delays in meeting delivery schedules, customer complaints, backordering, and other similar problems.

2. Suboptimal production scheduling

The wrong jobs are scheduled because of a lack of clear order priorities, inefficient scheduling rules, and the ever-changing status of jobs in the shop. As a consequence, production runs are interrupted by jobs whose priorities have suddenly increased, machine setups are increased, and jobs that are on schedule fall behind.

3. Long manufacturing lead times

In an attempt to compensate for problems 1 and 2, production planners allow extra time to produce an order. The shop becomes overloaded, order priorities become confused, and the result is excessively long manufacturing lead times.

4. Inefficient inventory control

At the same time that total inventories are too high for raw materials, work-in-progress, and finished products, there are stock outs that occur on individual items needed for production. High total inventories mean high carrying costs, while raw material stock outs mean delays in meeting production schedules.

32

5. Low work centre utilization

This problem results in part from poor scheduling (excessive product changeovers and job interruptions), and from other factors over which plant management has limited control (e.g., equipment breakdowns, strikes, reduced demand for products).

6. Process planning not followed

This is the situation in which the regular planned routing is superseded by an ad hoc process sequence. It occurs, for instance, because of bottlenecks at work centers in the planned sequence. The consequences are longer setups, improper tooling, and less efficient processes.

7. Errors in engineering and manufacturing records

Bills of materials are not current, route sheets are not up to date with respect to the latest engineering changes, inventory records are inaccurate, and production piece counts are incorrect.

8. Quality problems

Quality defects are encountered in manufactured components and assembled products, resulting in rework or scrapped parts, thus causing delays in the shipping schedule.

33

PRODUCTION PLANNING AND CONTROL AT R.L.MASAALA

Production plan is crucial to the success of any producing unit; it is an activity which is continues in nature and required to be revised time to time as per the requirements. It cant be done in isolation by a particular department; rather it is an integrated activity done by Planning and Control Department in collaboration with Material Department, Production Department, and Quality Control Department. PRODUCTION PROCESS

R.L.MASAALA use HAMMER MILL for Haldi and pulverizer for rest of the spices like garam masala, chicken masala etc. They have 22 product lines and for that they use different machines. Machines which they are using for production are:

HAMMER MILL

Hammer Mill comprises of a heavy duty Mild Steel fabricated body (alternatively stainless steel construction can be provided in hammer mill wherever necessary). The grinding chamber of hammer mill is lined with serrated wear plates, which protects the body from wear and tear. A balanced rotor in hammer mill with a set of Swing Hammers accelerates the grinding process. The screen classifier forms the lower half of the grinding chamber of hammer mill. The blower in hammer mill is driven on a separate shaft with the help of a 'v' belt adjustable driven from the rotor shaft.

34

HAMMER MILL

HAMMER MILL

35

OPERATING PRINCIPLES OF HAMMER MILL

The material to be crushed enters the hammer mill through gravity feed hopper having an adjustable slide to control the feed material. The material is crushed between the hammers and serrated liners. A powerful blower in hammer mill continuously sucks the ground material through a screen classifier and conveyed through the pipe into the cyclone for bagging. The blower maintains constant airflow in the Hammer Mill chamber in order to obtain a cool product and continuously cleans the screens, thus increasing the output. Particle size of the ground material can be varied over a large range by using sieves with the desired openings of hammer mill.

APPLICATIONS OF HAMMER MILL

The D. P. Hammer Mills can be used for a wide range of application e.g. Animal & Poultry Feeds, Food Products, Herbs& Spices, Marine Feeds, Molding Powders, Dry Tea, Coffee, etc.

FEATURES OF HAMMER MILL Improved Grinding Efficiency Accurate and Consistent Product Grinding Low Specific Power Consumption Low Temperature Rise for Heat Sensitive Materials

36

SPICE GRINDING PLANT MACHINE We have three types of pulverizers to offer u for the grinding of spices as under:

1. D. P. Mini pulverizer is a very simple type of pulverizer. The grinding chamber consists of a serrated ratchet liner on top, and screen at the bottom for classification. Feed material is passed into grinding chamber through a hopper manually. The ground power is collected in a through fitted below the screen, depending on the desired fineness, the number of operations could be 2 or 3 in different types of sieves. During the grinding process, a small quantity of air is generated, to remove this air a Polyester dust bag is fixed below the through and the other end of the bag is hung at a height, also acting like a dust collector.

37

Our D.P. Mini Pulverizers are exclusively ideal for the grinding of small quantity of spices, especially for high value condiments like, cinnamon, cloves, cardamom, nutmeg, pulses, and sugar with a capacity from 5 Kgs. To 60 Kgs. Per hour, more ever this machine is also highly capable of grinding wet and pulpy material, like green/red chilli sauce, fresh ginger garlic paste, and other wet and allied food products. The attached illustrated & informative catalogue of D.P. Mini Pulverizer attached over separate following e-mails will give you a thorough idea of the type of equipment manufactured by us. We give here below production figures for the same:H.P. Required Production per Hour Approximately SIZE OF MACHINE

D.P.M. - 6 Mini Pulverizer 2 H.P.

8 - 12 Kgs.

D.P.M. - 7 Mini Pulverizer 3 H.P

15 - 20 Kgs.

D.P.M. - 8 Mini Pulverizer 5 H.P.

20 - 25 Kgs

D.P.M. - 12 Mini Pulverizer 10 H.P.

55 - 60 Kgs.

38 2. Our D.P. Hammer Mill (Screen type Machine) is more efficient than compared to the Mini Pulverizer, with better grinding efficiency. The grinding chamber consists of a serrated liner on top and screen at the bottom, a blower is fitted to suck the ground powder, below the screen driven on the same shaft. At times due to higher oil content in spices, there are chances of the screen getting clogged with spices, thus chocking the grinding chamber. The material passes through the blower and gets discharged through the cyclone through a one way valve. The air generated in the grinding chamber passes out through the cyclone outlet on top. A Polyester dust bag can be fitted above the cyclone working like a dust collector, or we can offer you a totally enclosed dust collector (manually shaken type) or a pulse air type dust collector, the choice we however leave it to your kind decision. The attached illustrated catalogue will also brief you about the type of machine manufactured by us.

Our D.P. Hammer Mills are exclusively meant for the grinding of Chillies, Coriander, Dry ginger, Black Pepper, Turmeric and Curry powders, on a large scale basis. These spices are ground in a two / three stage operation, depending on the fineness desired, i.e. the breaking of the spice in a large whole screen for the first operation, and the subsequent fine grinding done in a fine whole screen for the second and third operation. We give here below production figures for the same.

39

Size of Machine

H. P. Required

Blower H. P

Production Hours Approximately

Per

DPHM -10 Hammer Mill

10 H.P

350 - 400 Kgs

DPHM -20 Hammer Mill

20 H.P

700 - 800 Kgs

DPHM -40 Hammer Mil

40 H.P.

1400 - 1600 Kgs

DPHM -50 Hammer Mill

50 H.P.

7.5

2500 - 2750 Kgs

DPHM -80 Hammer Mill

80 H.P

10

3600 - 4000 Kgs.

40 3. Our D.P. Impact Pulverizer (screen less type) is for the grinding of Turmeric, Pepper in one operation. We give here below the production figures for the same

Size of Machine

H. P. Required

Production Hours Approximately

Per

D.P. - 20 Impact Pulverizer

20 H. P

700 - 800 Kgs

D.P. - 25 Impact Pulverizer

40 H.P

1800 - 2000 Kgs

D.P. - 32 Impact Pulverizer

50 H.P

2800 - 3000 Kgs

D.P. - 42 Impact Pulverizer

100 H.P.

7000 - 7200 Kgs.

These are the machines which are used for the manufacturing of spices.

41 Filling Machines

Filling machines are those machines which are used to fill the product in the packaging material.

Semi Automatic Powder Filling Machine

Model: PFMV S304 Suitable for packing multiple products in mutable pack size in small batches Best suited when both laminated and non laminated pre-made pouches are used for packing

APPLICATIONS

Fill Non-Free Flowing Powders, SPICES Food & Beverages, etc.

Powder filling with PLC based controller for filling to achieve very high accuracy in filling. It comes with built in pulse. The auger rotation pulse is modified and adjustable by touch screen system for accurate weight compensation. This assures high filling accuracy as desired.

42 POWDER FILLING MACHINE

FEATURES

Vertically mounted Servo Motor for precise stopping of the screw rotating at high speed. Independently driven agitator Capable of storing filling parameter for up to 99 products makes selecting product - fill weight by touch of a button

Electrical panel within built protective circuit. "Self Centering Funnel" - significantly reduces changeover time during Cleaning, provides automatically factory setting for consistent product flow.

43 TECHNICAL SPECIFICATION

MODEL Filling by Filling range Hopper Capacity Filling Accuracy Power requirement Filling Speed Net Weight Dimension LBH(mm) Power Load

PFMV - S304 Volume 100-1000 gms. 25 Lit 1% 440V / 3 optional 220 V / 1 15 to 25 per minute 250 kg 1000 x 700 x 2000 0.75 kv

POWDER PACKAGING MACHINE

AUTOMATIC POWDER PACKAGING MACHINE

SPECIFICATIONS Method of Screw Type Measurement Range of 0-350ml Measurement (0-5ml, 5-20ml, 20-50ml, 30100ml, 80-250ml) Machine matchs one set of screws Packing Speed 20-40 , 30-50 , 40-60 (bag/min) Bag Size Total Power Voltage Machine Weight Machine Size Width 30-150 mm, Length 30170 mm 1600W 380V or 220V or made accordingly 250kg 1010x730x1780mm

44

SPECIFICATIONS Method of Screw Type Measurement Range of 0-350ml Measurement (0-5ml, 5-20ml, 20-50ml, 30100ml, 80-250ml) Machine matchs one set of screws Packing Speed 20-40 , 30-50 , 40-60 (bag/min) Bag Size Width 30-150 mm, Length 30170 mm Total Power 1600W Voltage 380V or 220V or made accordingly Machine Weight 250kg Machine Size 1010x730x1780mm

45 PLANNING PROCESS Marketing Department Monthly details of Market demand

Production planning starts from the market details provided by Marketing Department. Marketing Department provides their monthly requirements like different varieties of spices, different product lines etc. PPC/Store Preliminary Production Plan

PPC/Store receives message of monthly requirements from marketing department. PPC studies the requirements and prepare a Preliminary Production Plan. This plan is sent to the Materials Department.

Material Department Material requirements planning

A copy of preliminary plan is sent to the material department. Material department studies the plan and prepares a report which shows the availability of material, material in transit, plan of receipt of material in chronological form, expected shortage of material, and any other problem related to the material. Materials Requirements Planning (MRP) can be used in more complex systems. MRP determines time-phased requirements (period-by-period) for all purchased and manufactured parts such as raw materials, components, parts, subassemblies, etc. . This report is sent to the PPC Department.

PPCRevision of preliminary Production plan. On the basis of the report sent by material department, the PPC/Store revises the preliminary plan. This revised plan is sent to the marketing department. Marketing department revises the schedule of requirements according to the availability and sequence/schedule of receipt of material.

46 Production Planning and Master Production Scheduling After the consent of marketing department and material department the monthly Production Plan and weekly master production scheduling is done. A copy of main plan and master production schedule is sent to each department.

Daily Production Plan

Every day in morning the production head, quality head, and material head sits together, discuss their problems, and unanimously prepares a daily production plan. This daily production plan is displayed on planning board of every department and at every level of assembly line. This daily production plan shows sequence of operations, sequence and schedule of material movement, post pending material, pre pending material, and shortage of material. This daily plan is automatically get updated with the completion of operations at every level.

CONTROL In results are not according to the Daily Plans, the plan is required to be revised. Daily Production Plan is revised number of times considering the material shortages, problems with assembly line, etc. if material is post pending i.e. on assembly line its operation cant be changed, but, changes can be made in the sequence and scheduling of pre pending material i.e. material in queue. Efforts are made to plan a sequence which minimizes the idle time of assembly line, labour, and other equipments.

47

RESEARCH METHODOLOGY

Research methodology is a science of studying how research is done scientifically. It is a way to systematically solve the research problem by logically adopting various steps. Methodology helps to understand not only the products of scientific inquiry but the process itself. It also aims to describe and analyze methods, throw light on their limitations and resources and clarify the consequences, relating their potentialities to the twilight zone at the frontiers of knowledge. In the making of this project I adopted the following methodology:

PRIMARY DATA Collection of data through questionnaire Collection of data through interview with the employees. Collection of data through factory visit.

SECONDARY DATA Data collection through the industrys website. Data collection through books.

SAMPLING Sample size 15

48 INTERPRETATION OF DATA

Q1. Which is the first step in a manufacturing planning and control system? Production planning Achieving the forecast Maintaining the required inventory level Maintaining the planned block log

Options Response

A 6

B 7

C 1

D 1

Interpretation

On the basis of 15 respondent 46% respondent said that the first step of manufacturing should be forecasting and 40 % of the respondent give their response in favour of production planning.

49 Q2. Do you think production planning and control is central to the success of any Manufacturing unit? Yes No

Options Response

Yes 15

No 0

No 0%

Yes 100%

Interpretation

All the 100% respondents believe that production planning and control is central to the success of any manufacturing unit. Production planning and control gives direction to the best use of capacity with optimum utilization of production line, resources, and other equipments. It helps in waste reduction and leads to increased profitability.

50 Q3. What are the main objectives of Production Planning? a. Optimum utilization of capacity b. Inventory control c. Economy in production time d. Ensure quality e. Waste reduction and increased profit

Options Response

A 4

B 3

c 2

d 1

E 5

5

4 3 2 1 0 a b c d e

Interpretation

All the respondents believe that waste reduction and increased profit is the main objective of production planning, some of them also believe that optimum utilization of capacity is another objective of production planning. The other objective of production planning is inventory control, economy in production time, and quality insurance.

51 Q4. Capacity planning contributes to the efficient use of facilities and equipments? Yes No

Options Response

Yes 12

No 3

Interpretation

Most of the respondents i.e. 80% are in favor of the statement that capacity Planning contributes to the efficient use of facility and equipments. Proper Capacity planning leads to optimum utilization of capacity reduces idle time, under or over utilization of capacity.

52 Q5. Production Planning and Control makes the supervisor ineffective? Yes No

Options Response

Yes 3

No 12

yes 20%

no 80%

Interpretation

80% of respondents are against this statement because supervisor makes the production planning and control effective with the use of various methods of PPC.

53 Q6. The causes of inability to meet delivery date originally promised due to :a) Lack of availability of material in time

b) Lack of availability of supervisor in time c) Lack of staffing shift d) Load balancing not done properly

Options Response

7 6 5 4 3 2 1 0 A

A 6

B 3

C 4

D 2

Interpretation

The causes of inability to meet delivery date originally promised were not fulfilled mainly because lack of availability of materials in time and lack of staffing shift. Load balancing and supervisors not presence also may effect to meet the delivery date.

54

Q7. On what basis do you plan your production? a. Customer needs b. Target of marketing department c. Resources available d. Others

Options Response

A 8

B 3

C 4

D 0

Interpretation

According to the data collected from the respondents the production planning of R.L.MASAALA is based on customer need i.e. dealers demand for particular product. The marketing department reports to the PPC/Store about dealers requirements. PPC/Store communicates with the material department about availability of material. Hence, market demand and availability of resources is considered as base for production plans.

55 Q8. If results are not according to the plans, what control measures are taken? a. Revision of plan b. Any other measures

Options Response

A 13

B 2

Interpretation

If the results are good there is no need to change any plan in their production policy. If revision of the plan takes lot of time then we should go for other measures also. At present people of R.L.MASAALA do not have any other solution except revision of plan to control deviations in plans and results.

56 Q9. Being capable to adjust their production facilities shortly just after change in demand for products and without incurring heavy expenses, greater flexibility in production is provided by:a) Continuous production b) Job and batch production

Options Response

A 4

B 11

No 20%

Yes 80%

Interpretation

Greater flexibility in production is provided by job and batch production because in it the production has been done in lots on the basis of the order taken so the maintenance cost of inventory is very less and it leads to the effective way of production.

57 Q10. Do you feel or experienced hung up and bottlenecks in implementing Production Plans. Yes No

Options Response

Yes 12

No 3

No 20%

Yes 80%

Interpretation

80% of the respondents realize that they feel various difficulties while implementing production plans.

58

FINDINGS

The PPC department of R.L. MASAALA believes in making plans and decisions in cooperation with production department, marketing department, material department, and quality control department. So that a feasible plan can be made, executed properly, and optimum results can be achieved. Hence, production planning and control is an integrated activity and cant be done in isolation by any particular department.

Following are the findings of this project about production planning and control activities of R.L. MASAALA:

1. Production Planning is an integrated activity and cannot be done in isolation by a particular department. 2. PPC helps in scheduling tasks and production runs and ensures production capacity does not remain idle. 3. The work should not be piled up but should be done when it arises. 4. Proper PPC helps to resort to just- in- time systems and thereby reduce the overall inventory. It enables to ensure that the right supplies are available at the right time. 5. PPC helps to reduce the cycle time and increase the turnover via proper scheduling. 6. PPC provide for adherence to the quality standards so that quality of output is ensured.

To sum up we may say that PPC is of immense value to the entrepreneur in capacity utilization and inventory control. More importantly it improves his response time and quality. As such effective PPC contributes to time, quality and cost parameters of entrepreneurial success.

59

CONCLUSION

After doing this project I am in a position to conclude that R.L. MASAALA has well defined and structured production planning system. PPC defines the sequences and schedules of operations; hence production planning contributes to the efficient use of facilities and equipments. Production Planning and Control is done to identify production process which leads to reduced lead time; hence customer waiting time is also reduced. Production Planning and Control ensures optimum utilization of production capacity, material, and other equipments; hence it leads to waste reduction and increased profits. Proper PPC helps to resort to just- in- time systems and thereby reduce the overall inventory. It enables to ensure that the right supplies are available at the right time. Production Planning and Control helps to reduce the cycle time and increase the turnover via proper scheduling. Production Planning and Control provide for adherence to the quality standards so that quality of output is ensured. Sufficient safety stock must be maintained to meet unforeseen hindrances in the production process. The industry should be providing time to time reminders to the farmers and vendors so that they are aware about their responsibilities which would reduce the lead time.The industry could also involve third party logistics for their procurement and distribution processes from farther areas to reduce time gap and cost.

60

RECOMMENDATIONS

The production planning and control of R.L. MASAALA, highly depends on the material availability. In case of shortage of material the overall plan get disturbed. If such problem prevails the optimum results cannot be achieved. To avoid such problem following measures can be taken:

a. Proper Materials Planning should be done. b. R.L. MASAALA purchases materials directly from the farmers, but at the time of an emergency they should be in contact with some vendors. c. Sufficient safety stock must be maintained to meet unforeseen hindrances in the production process. d. The industry should be providing time to time reminders to the farmers and vendors so that they are aware about their responsibilities which would reduce the lead time. e. The industry could also involve third party logistics for their procurement and distribution processes from farther areas to reduce time gap and cost. f. The industry can also involve themselves in expansion process as there is an opportunity for growth in this sector. g. As there is not much awareness about R.L. MASAALA, the company should undertake marketing and promotional programs.

61

BIBLIOGRAPHY

INTERNET rlmasaala.com http://impcat/hammer-mills.html http://www.proprofs.com/quiz-school/story.php?title=production-planningcontrol_1

BOOKS Stephen N. Chapman The fundamentals of production planning and control (First Edition) Year of Publication 2005, Pearson Education India, pg no. (722), (60-88),(146-170,)(189-216) S. N. CHARY Production and Operations Management (Second Edition) Year of Publication 2000,Tata Mc graw- Hill Publishing Company Limited, page no-(1-8),(136-140),(181-186),( 247-253) S.A. Chunawalla and D.R. PATEL Production and Operation Management (Seventh Edition) Year of Publication 2008, Himalaya Publishing House, pg no. (1-15),(22-34),(125-143),(147-166),(220-337) P. Rama Murthy Production and Operation Management (Second Edition) Year of Publication 2005, New Age International Publishers, pg no. (211),(19-26),(44-70),(97-136),(213-243),(332-366) R. Panneerselvam Production And Operations Management (Third Edition) Year of Publication 2012, PHI Learning Private Limited, pg no. (16-27), (5489), (132-177), (243-267)

62

ANNEXURE

Q1. Which is the first step in a manufacturing planning and control system? a) Production planning b) Achieving the forecast c) Maintaining the required inventory level d) Maintaining the planned block log

Q2. Do you think production planning and control is central to the success of any Manufacturing unit? a) Yes b) No

Q3. What are the main objectives of Production Planning? a) Optimum utilization of capacity b) Inventory control c) Economy in production time d) Ensure quality e) Waste reduction and increased profit

Q4. Capacity planning contributes to the efficient use of facilities and equipments? a) Yes b) No

Q5. Production Planning and Control makes the supervisor ineffective a) Yes b) No

63 Q6. The causes of inability to meet delivery date originally promised due to :-

a) Lack of availability of material in time

b) Lack of availability of supervisor in time c) Lack of staffing shift d) Load balancing not done properly

Q7. On what basis do you plan your production?

a) Customer needs b) Target of marketing department c) Resources available d) Others

Q8. If results are not according to the plans, what control measures are taken?

a) Revision of plan b) Any other measures

Q9. Being capable to adjust their production facilities shortly just after change in demand for products and without incurring heavy expenses, greater flexibility in

production is provided by:-

a) Continuous production b) Job and batch production

Q10. Do you feel or experienced hung up and bottlenecks in implementing Production Plans?

a) Yes b) No

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Primo Premium BrochureDocumento2 paginePrimo Premium BrochureFloorkitNessuna valutazione finora

- (BS 5628-3-2005) - Code of Practice For The Use of Masonry. Materials and Components, Design and WorkmanshipDocumento136 pagine(BS 5628-3-2005) - Code of Practice For The Use of Masonry. Materials and Components, Design and WorkmanshipStacy Wilson100% (1)

- Invicta Metal Stamping CatalogueDocumento12 pagineInvicta Metal Stamping CatalogueVbNessuna valutazione finora

- Toyota Production SystemDocumento6 pagineToyota Production SystemSatish_Kumar_4711Nessuna valutazione finora

- Copper AlloysDocumento1 paginaCopper AlloysuzairmetallurgistNessuna valutazione finora

- Packaging GuidelineDocumento38 paginePackaging GuidelineNazzneen AmeerNessuna valutazione finora

- Habasit Industria TextilDocumento28 pagineHabasit Industria TextilFreddy LópezNessuna valutazione finora

- Con Wps SBR LatexDocumento2 pagineCon Wps SBR Latextejas_tNessuna valutazione finora

- MalaKumarEngineers BrochureDocumento6 pagineMalaKumarEngineers Brochuresuraj pandeyNessuna valutazione finora

- Materials For Ultra-High VacuumDocumento3 pagineMaterials For Ultra-High VacuumTanviSharmaNessuna valutazione finora

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocumento1 paginaThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLNessuna valutazione finora

- A Review On Investigation of Casting Defects With SimulationDocumento5 pagineA Review On Investigation of Casting Defects With SimulationInternational Journal of Innovations in Engineering and ScienceNessuna valutazione finora

- Operations Management: Sustainability and Supply Chain ManagementDocumento47 pagineOperations Management: Sustainability and Supply Chain ManagementSHOBANA96Nessuna valutazione finora

- Mechanism and PLC Design of Twin Spindle Drilling Machine - A Innovative ApproachDocumento7 pagineMechanism and PLC Design of Twin Spindle Drilling Machine - A Innovative ApproachGRENZE Scientific SocietyNessuna valutazione finora

- Types of Methods of Powder Production:: Physico Chemical Processes Are As UnderDocumento11 pagineTypes of Methods of Powder Production:: Physico Chemical Processes Are As UnderDevashish JoshiNessuna valutazione finora

- Production Operations Manager Manufacturing in Marshfield WI Resume Wayne BixbyDocumento2 pagineProduction Operations Manager Manufacturing in Marshfield WI Resume Wayne BixbyWayneBixbyNessuna valutazione finora

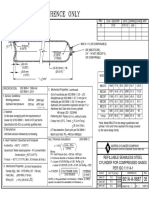

- Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1Documento1 paginaRefillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1bkprodhNessuna valutazione finora

- Samsung WMDocumento7 pagineSamsung WMsarvessaiNessuna valutazione finora

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocumento3 pagineMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNessuna valutazione finora

- Nickel in Ferritic & Martensitic Stainless Steel PDFDocumento23 pagineNickel in Ferritic & Martensitic Stainless Steel PDFhimanshu17121990Nessuna valutazione finora

- Liming Heavy Industry Introduction NewDocumento7 pagineLiming Heavy Industry Introduction NewJohnny DoeNessuna valutazione finora

- PEST Analysis Ceramics Industry in PakistanDocumento2 paginePEST Analysis Ceramics Industry in PakistanabubakarNessuna valutazione finora

- Thesis Pp1 40Documento40 pagineThesis Pp1 4016562306Nessuna valutazione finora

- Refractory and High Temperature Ceramic Coatings and CementsDocumento2 pagineRefractory and High Temperature Ceramic Coatings and CementsAnderman Ceramics LtNessuna valutazione finora

- Iso 9001 Gap AnalysisDocumento3 pagineIso 9001 Gap AnalysisthesancoNessuna valutazione finora

- LNG Infrastructure in IndiaDocumento79 pagineLNG Infrastructure in IndiaXcdxtv100% (1)

- Acs BD Schematic Most CurrentDocumento8 pagineAcs BD Schematic Most CurrentgregfortkampNessuna valutazione finora

- CH 7 MillingDocumento54 pagineCH 7 MillingVirender RawalNessuna valutazione finora

- Manual Gra Vitac Nie NGDocumento38 pagineManual Gra Vitac Nie NGkumbrovNessuna valutazione finora