Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WET GAS COMpressor Start Up

Caricato da

mujeeb84Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WET GAS COMpressor Start Up

Caricato da

mujeeb84Copyright:

Formati disponibili

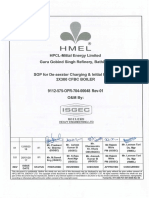

WET GAS COMPRESSOR START UP

No. 1 2 3 4 5 6 7 8 9 10 11 Action Ensure Mechanical, Electrical & Instrumentation Dpt. Clearance. Ensure L.O. quality & adequate level in Lube Oil tank (LT 1804/LG-1801). Lube oil temperature in the reservoir maintained at 40oC (TI1822) Maintain reservoir pressure at 50-100mmWC (PG-1844) through nitrogen PCV-1803. Check that the isolating valves of the oil pumps are open. Ensure that by-pass valve (LO-14) is closed for the pressure control valve PCV-1801 and (LO-09 and LO-11) are open. Ensure that bypass valve LO-26 for PCV-1802 is closed and isolation valve LO-24 & LO-28 is open. Check that all drain valves of coolers, filters, level indicators and pipes are closed (Lube oil coolers). Check that the water inlet and outlet valves of oil cooler are closed (Lube oil coolers). Check all instrument are in line. Start permissive (IZ-34, 35 for lube oil pump) are taken from PT1884 Ensure that nitrogen supply to separation (barrier) seal is on before lube oil pump. Start the main lube oil pump according to vendor instruction. Open the bypass valves of oil cooler and filters. Open the vent valves of oil cooler and filters in service .bleed off the air and close the valves again. Cracks open the vents valves of oil cooler and oil filters not in service and close it again as soon as they are full. Check the oil pressure to the various points as follows:a. Lube Oil Header: 2.0 to 2.5 Kg/cm2 b. Lube Oil pressure to thrust bearings: 0.3 to 1.3 Kg/cm2 c. Lube Oil pressure to radial bearings: 0.9 to 1.3 Kg/cm2 Check the normal flow of oil coming out from radial and thrust bearing by the flow sight glasses devices. Check the L.O pressure drop across the filters. Keep the stand-by oil pump driver ready to start on auto. Stop the main pump driver and check the stand-by pump automatic start-up. Then stop manually the stand-by pump and check the pressure point at which the trip switch (PALL 1835 with a 2-out-of-3 voting) installed in the lube oil header operates.

Action By FE FO/PE FO/PE FO FO FO/PE FO FO FO FO FO

Notes

12 13 14 15 16

FO FO FO FO FO/PE

17 18 19 20

FO FO FO

Ensure C.W. circulation and check healthiness of C.W. header

FO

pressure. 6 4 5 Start L.O. auxiliary pump in manual mode and check healthiness of L.O. header pressure (PT 1834). If the compressor is handed over by the M/M after doing M/M job, then do purging of compressor by N2, 2-3 times. Ensure no leakage with N2 at pressure 4.5-5.0 kg/cm2 and then isolate N2 line. Ensure N2 supply to seal gas system. Do compressor barring to ensure shaft freeness and after that barring device must be disengaged from the compressor shaft. Ensure first stage antis urge and 2nd stage anti surge valves full open. Open fist stage and 2nd stage suction valves and discharge valve full open. Drain suction KOD. Ensure CBD isolation. Ensure Instrument air supply to antis urge, Level & control valves. Open stuffing box to vent to flare. Compressor ready to start from motor purge control unit and VFD available. Check all the other permissive before start the compressor. Take clearance from panel officer/Shift in charge. Press the trip reset from field (trip reset HS 1885) is available in both LCP and HWC). Push the compressor motor start button. Ensure no abnormality (vibration, sound, and leaks). Stop L.O. auxiliary pump after ensuring main oil pump pressure & keep LOP in auto mode. FO FO

6 7 8 9 10 11 12 13

FO FO FO/PE FO FO FO FO FO

14 15 16 17 18

FO/PE FO FO FO FO

Potrebbero piacerti anche

- Electric Shock Safety BasicsDocumento58 pagineElectric Shock Safety Basicsmujeebtalib100% (5)

- Oil SPill ManagementDocumento39 pagineOil SPill Managementmujeebtalib100% (4)

- Typical P&ID for Centrifugal Compressor SystemsDocumento7 pagineTypical P&ID for Centrifugal Compressor SystemsmsaroladanNessuna valutazione finora

- Generator Operation and ProtectionDocumento52 pagineGenerator Operation and Protectionmujeebtalib100% (4)

- Generator Operation and ProtectionDocumento52 pagineGenerator Operation and Protectionmujeebtalib100% (4)

- Catalyst Loading Work InstructionDocumento4 pagineCatalyst Loading Work Instructionvishal bailurNessuna valutazione finora

- Tank OperationDocumento18 pagineTank Operationmujeebtalib100% (1)

- Frame 9e Gas Turbine Presentation OverviewDocumento98 pagineFrame 9e Gas Turbine Presentation Overviewmujeebtalib100% (5)

- Saleh Muhammad Durrani CVDocumento4 pagineSaleh Muhammad Durrani CVJamshaid SultanNessuna valutazione finora

- Field InstrumentationDocumento89 pagineField Instrumentationmujeebtalib100% (6)

- FSSSDocumento45 pagineFSSSlp mishra100% (2)

- Pump BasicsDocumento54 paginePump BasicsmujeebtalibNessuna valutazione finora

- Fire TriangleDocumento50 pagineFire TrianglemujeebtalibNessuna valutazione finora

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocumento7 pagineAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNessuna valutazione finora

- Theory of CompressorsDocumento43 pagineTheory of Compressorsmujeebtalib100% (3)

- Aum Shree Sainathaya NamahDocumento52 pagineAum Shree Sainathaya NamahmujeebtalibNessuna valutazione finora

- Compressors OperationDocumento35 pagineCompressors OperationSalim Chohan100% (1)

- Ammonia Unloading Sop ZaclDocumento2 pagineAmmonia Unloading Sop ZaclHARRY SINGHNessuna valutazione finora

- Delayed Coker Unit OverviewDocumento42 pagineDelayed Coker Unit OverviewmujeebtalibNessuna valutazione finora

- Skimming Job GeneralDocumento5 pagineSkimming Job Generalvishal bailurNessuna valutazione finora

- Hazards in A RefineryDocumento25 pagineHazards in A Refinerymujeebtalib100% (1)

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocumento79 pagineParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib50% (2)

- Mechanical Datasheet - Wellhead Compressor PackageDocumento12 pagineMechanical Datasheet - Wellhead Compressor PackageRokan Pipeline100% (1)

- DH3-31MA-T-SCT-0018 Commissioning Procedure of Varying Load of Turbine-Generator REV.0ADocumento6 pagineDH3-31MA-T-SCT-0018 Commissioning Procedure of Varying Load of Turbine-Generator REV.0AhungNessuna valutazione finora

- 330 Booster CompressorDocumento11 pagine330 Booster Compressornailulfalah17Nessuna valutazione finora

- A 01 Pumps, Valves & CoolersDocumento24 pagineA 01 Pumps, Valves & CoolersСергей КороткийNessuna valutazione finora

- Accurately Calculate Nitrogen RequirementDocumento6 pagineAccurately Calculate Nitrogen RequirementRachel BaileyNessuna valutazione finora

- Use of Personal Protective Equipments: Manoj Kr. Ray SM (F&S)Documento33 pagineUse of Personal Protective Equipments: Manoj Kr. Ray SM (F&S)mujeebtalibNessuna valutazione finora

- Handling of Hazardous Chemicals: Haldia RefineryDocumento34 pagineHandling of Hazardous Chemicals: Haldia RefinerymujeebtalibNessuna valutazione finora

- Request for Inspection & TestDocumento3 pagineRequest for Inspection & TestYusufNessuna valutazione finora

- Introduction To Heat ExchangersDocumento44 pagineIntroduction To Heat ExchangersmujeebtalibNessuna valutazione finora

- Disaster ManagementDocumento39 pagineDisaster ManagementmujeebtalibNessuna valutazione finora

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocumento35 pagineParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib80% (5)

- Hydrotest Procedure for WHR CPP BoilersDocumento12 pagineHydrotest Procedure for WHR CPP BoilersJOHnNessuna valutazione finora

- Boiler Start UpDocumento15 pagineBoiler Start UpMt. Sasongko100% (1)

- Fundamentals of DistillationDocumento51 pagineFundamentals of DistillationmujeebtalibNessuna valutazione finora

- Norsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Documento3 pagineNorsok Electric Process Heater EDS-013 E-001 Data Sheet: Page 1 of 3Anonymous v4akjrQxKNessuna valutazione finora

- Introduction To Storage Tanks & Tank InternalsDocumento40 pagineIntroduction To Storage Tanks & Tank Internalsmujeebtalib80% (5)

- Startup Depropanizer ColumnDocumento3 pagineStartup Depropanizer Columnjayprakash100% (1)

- Furnace Start-Up and ShutdownDocumento47 pagineFurnace Start-Up and Shutdownmujeebtalib100% (3)

- Start Up Slug Catcher and Train 1Documento43 pagineStart Up Slug Catcher and Train 1Larbi HammounNessuna valutazione finora

- AVU Critical EquipmentsDocumento55 pagineAVU Critical EquipmentsmujeebtalibNessuna valutazione finora

- Fundamentals of Refining Products and PropertiesDocumento46 pagineFundamentals of Refining Products and Propertiesmujeebtalib100% (1)

- Amine Recovery Unit (ARU) : E. BayanjargalDocumento12 pagineAmine Recovery Unit (ARU) : E. BayanjargalBayanjargal ErdeneeNessuna valutazione finora

- Integrated Amine Degreasing Schedule 30mar2018Documento1 paginaIntegrated Amine Degreasing Schedule 30mar2018KhairulNessuna valutazione finora

- Offsite FacilitiesDocumento44 pagineOffsite FacilitiesmujeebtalibNessuna valutazione finora

- Physical Properties:: Haldia RefineryDocumento43 paginePhysical Properties:: Haldia Refinerymujeebtalib100% (3)

- Wet Gas Compressor Guide - Essential Questions AnsweredDocumento2 pagineWet Gas Compressor Guide - Essential Questions AnsweredcharzreeNessuna valutazione finora

- Production Engineer Interview Questions Part 2Documento5 pagineProduction Engineer Interview Questions Part 2Rizwan FaridNessuna valutazione finora

- Little Roses School End of Term Exam ResultsDocumento19 pagineLittle Roses School End of Term Exam ResultsNasiru IddrisuNessuna valutazione finora

- Resume: Post For Applied: Production / Commissioning/Field OperatorDocumento5 pagineResume: Post For Applied: Production / Commissioning/Field OperatorRebel Add100% (1)

- Enmas India Private Limited: (SMC Power Generation LTD Unit 2)Documento3 pagineEnmas India Private Limited: (SMC Power Generation LTD Unit 2)Sachin nandgayeNessuna valutazione finora

- Rotating Equipment Engineer ResumeDocumento3 pagineRotating Equipment Engineer Resumesuba ananth100% (1)

- Air, Steam Vent Silencer - Enquiry Data SheetDocumento1 paginaAir, Steam Vent Silencer - Enquiry Data Sheetkishore1214Nessuna valutazione finora

- U#2 Oh Report 2003Documento45 pagineU#2 Oh Report 2003Sony RamaNessuna valutazione finora

- Natural Gas Physical PropertiesDocumento20 pagineNatural Gas Physical PropertiesMarco Antonio Pomahuali BravoNessuna valutazione finora

- Workboat International Dmcco: Appendix 1.0A Drill/Training Form Drill/Training Records FormDocumento1 paginaWorkboat International Dmcco: Appendix 1.0A Drill/Training Form Drill/Training Records FormJeet SinghNessuna valutazione finora

- The Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChlorideDocumento2 pagineThe Acid Function of Platforming Catalyst Is Provided by Support Promoted With ChloriderawadNessuna valutazione finora

- Notes - PSV by MukharjeeDocumento3 pagineNotes - PSV by MukharjeeWade ColemanNessuna valutazione finora

- Andrew Pravin - Field OperatorDocumento6 pagineAndrew Pravin - Field OperatorVenkatesh VaradarajanNessuna valutazione finora

- SOP HP HeatersDocumento1 paginaSOP HP HeatersShailenderNessuna valutazione finora

- Lampiran PerhitunganDocumento8 pagineLampiran PerhitunganVerdi AnggriawanNessuna valutazione finora

- SRU UnitDocumento33 pagineSRU UnitCenk Yağız ÖzçelikNessuna valutazione finora

- C2R Compressor & Turbine ShutdownDocumento10 pagineC2R Compressor & Turbine ShutdownfvaefaNessuna valutazione finora

- 14 Commissioning ProcedureDocumento2 pagine14 Commissioning ProcedureIonut StavaracheNessuna valutazione finora

- SMR Hydrogen Generators-Technologies and Producers 2009Documento28 pagineSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNessuna valutazione finora

- Nitrogen Handling PurgingDocumento9 pagineNitrogen Handling PurgingJeet Singh100% (1)

- Solubility of Calcium Carbonate in WaterDocumento2 pagineSolubility of Calcium Carbonate in WaterKEHALI AbdelheqNessuna valutazione finora

- Valve CV Flow Rate FormlaeDocumento1 paginaValve CV Flow Rate Formlaelatasharma79Nessuna valutazione finora

- Crude OilDocumento19 pagineCrude Oilsupriya guptaNessuna valutazione finora

- Field Operator: Diploma in Mechanical EngineeringDocumento5 pagineField Operator: Diploma in Mechanical Engineeringjohn MNessuna valutazione finora

- Utilities - Equipment ListDocumento1 paginaUtilities - Equipment ListsutanuprojectsNessuna valutazione finora

- SPE 152975 Using Dynamic Simulations To Optimize The Start-Up Procedure of A Lazy Horizontal Oil WellDocumento11 pagineSPE 152975 Using Dynamic Simulations To Optimize The Start-Up Procedure of A Lazy Horizontal Oil Wellmatheus_moreira0990Nessuna valutazione finora

- SOP For BFPDocumento2 pagineSOP For BFPsambhuNessuna valutazione finora

- NGL SeparationDocumento6 pagineNGL SeparationhoustonmathNessuna valutazione finora

- Experiment Determines Boiler EfficiencyDocumento9 pagineExperiment Determines Boiler EfficiencyAniket SinghNessuna valutazione finora

- US9260541 Methods of Catalyst ActivationDocumento22 pagineUS9260541 Methods of Catalyst ActivationyamakunNessuna valutazione finora

- Removal and Disposal of BTEX Components From Amine Plant Acid Gas StreamsDocumento5 pagineRemoval and Disposal of BTEX Components From Amine Plant Acid Gas StreamsMamank Ira SudrajatNessuna valutazione finora

- Question PaperDocumento1 paginaQuestion PaperSouvik PaulNessuna valutazione finora

- Valve CV Sizing Liquids GasesDocumento22 pagineValve CV Sizing Liquids GasesSamuel OnyewuenyiNessuna valutazione finora

- 9112 575 Opr 704 00048 - 01Documento12 pagine9112 575 Opr 704 00048 - 01Anonymous qT80dF24dNessuna valutazione finora

- Generon CatalogDocumento11 pagineGeneron CatalogDonovan BonnerNessuna valutazione finora

- Commissioning checklist for HP bypass systemDocumento8 pagineCommissioning checklist for HP bypass systemGansehNessuna valutazione finora

- PSV Load Calculation For Gas Expantion Fire Case PDFDocumento2 paginePSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaNessuna valutazione finora

- Eo 2.4 Start Stop PurifierDocumento1 paginaEo 2.4 Start Stop PurifierApolLLloNNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Primitive Checkpoints Before Login Into E-Tendering Portal: TroubleshootingDocumento5 paginePrimitive Checkpoints Before Login Into E-Tendering Portal: TroubleshootingmujeebtalibNessuna valutazione finora

- Pump Regular ChecksDocumento3 paginePump Regular ChecksmujeebtalibNessuna valutazione finora

- Velan's Global Leadership in Industrial Valve ManufacturingDocumento8 pagineVelan's Global Leadership in Industrial Valve ManufacturingmujeebtalibNessuna valutazione finora

- Captive Power Plant - Encon Measures: A Sunrise Project For A Sunshine FutureDocumento20 pagineCaptive Power Plant - Encon Measures: A Sunrise Project For A Sunshine Futuremujeebtalib100% (1)