Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boone S.J., Westland J. - Estimating Displacements Associated With Deep Excavations

Caricato da

dddiego949Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Boone S.J., Westland J. - Estimating Displacements Associated With Deep Excavations

Caricato da

dddiego949Copyright:

Formati disponibili

Estimating Displacements Associated with Deep Excavations

S.J. Boone

Golder Associates, Ltd., Mississauga, Ontario, Canada

J. Westland

Golder Associates, Ltd., Mississauga, Ontario, Canada

ABSTRACT: Methods for estimating excavation-induced displacements generally fall into three categories: empirical envelopes of measurements, structural analyses, and numerical modeling. A few methods combine structural and geotechnical engineering principles but these largely focus on estimating the performance of deep excavations in soft clay. This paper summarizes available design tools, problems in their application, and proposes a new semi-empirical method for this soil structure interaction problem. The proposed method clarifies the distinction between performance of braced and tied-back excavations, isolates several construction variables, and allows estimation of the magnitude and shape of the displacement patterns.

1 INTRODUCTION Over the last 40 years, methods for estimating displacements of deep excavations have received considerable attention. Available methods generally fall into three categories. Empirical envelopes of measured ground displacements, often segregated by soil or wall type, are frequently used but these are somewhat crude. Structural analysis methods are sometimes used for estimating displacements but these suffer from reliance on assumptions of earth pressures that are often greatly simplified and do not address the displacements of the surrounding ground. Numerical modeling is a tool for predicting the performance of excavation support systems, but this comes at the price of increased complexity, cost, and potential for errors or misleading results. A few methods combine structural and geotechnical principles but these focus largely on excavations made in soft clay. This paper summarizes available tools for estimating excavation performance, problems in their application, and proposes a new semi-empirical method for estimating displacement. 2 HISTORICAL BACKGROUND To compare bending of a model sheet-pile wall with full-scale prototypes, Rowe (1952) used the differential equations for deflection of a simple beam with small angles of rotation at the supports:

d / dz = Mz/EI; d 2 / dz 2 = M/EI d 3 / dz 3 = V/EI; d 4 / dz 4 = q/EI

(1)

where q = distributed load; = displacement; z = distance in the vertical plane; M = bending moment; E = modulus of elasticity; and I = internal moment of inertia per unit wall length. He then compared the two systems using:

( d / d z ) model = ( d / d z ) prototype (Mz/EI)

model

= (Mz/EI) prototype

(2)

normalized the differential distance, z, by the total height of the wall (including penetration depth), H, for both model and prototype:

(z/H) model = (z/H) prototype = (3)

and considered that, for given distributed load, relative positions of the top anchor level and penetration depth, the bending moment is proportional to H3 and thus: (M/H 3 ) model = (M/H 3 ) prototype = (4)

Assuming that bending moment is proportional to H3 is contingent upon the load, P, depending upon H (e.g. P = 1/2KaH2 for a simple beam subject to a triangular pressure load). By substitution then:

[H 3H / (EI)]model = [H 3H / (EI)]prototype = H 4 /EI = constant

(5)

though the parameter is dimensionally clumsy. Caspe (1966) estimated surface settlement based on knowing lateral wall displacements. In this approach, the distance limit of the vertical displacements (zone of influence), D, was defined based on the height of the excavation as follows: D = (H + H d )tan(45 ' /2) (6)

composed of discrete structural elements, such as soldier piles, the moment of inertia must be divided by the horizontal distance between such components. Clough et al. (1989) expanded upon this work to produce a chart relating maximum lateral displacement to the base stability factor of safety and relative wall stiffness (see Figure 1, top left) when all factors in Equation (8) equal 1.0. Bowles (1988) assumed that the maximum ground surface settlement, vmax, would occur next to the wall and that this settlement could be approximated as:

where H = total excavation depth; and Hd = width of the excavation, B, for cohesive soils, or 0.5Btan(45 /2) for granular soils. He and Kane (1966) related the total cross section area of the horizontal displacement profile, Ah, to the total area of the vertical displacement profile, Av, through use of Poissons ratio, , to compare vertical and horizontal volumetric strains, vert and horiz, respectively, whereby:

vmax = 4VS /D

(9)

where Vs is the cross section area (or unit volume) of the surface settlement trough. This method assumed that the surface settlement, v, at any point at a distance d from the wall can then be determined by the parabolic equation:

v = vmax[(D d)/D]2

(10)

vert = /(1 )horiz

(7)

Observed magnitudes and patterns of settlements adjacent to excavations supported by soldier-piles and lagging or sheet-piles were illustrated by Peck (1969) in which measurements were generalized by envelopes of maximum displacement for different ground types. Goldberg et al. (1976) separated deformation behavior by both soil and wall types. They related deformation to the inverse of the flexibility number using EI/h4, where h is the average vertical distance between support levels. Using parametric finite element studies and published measurements, Mana and Clough (1981) evaluated factors influencing the maximum lateral and vertical movements for excavations in soft to medium-stiff clays. The parameters they investigated were: w, wall stiffness; S, strut stiffness and spacing; D, depth to an underlying firm layer; B, excavation width; P, strut preload; and M, elastic modulus of the retained earth. They suggested that an initial estimate of the maximum horizontal wall movements, *hmax, could be modified depending on these factors (see Figure 1):

Clough and ORourke (1990) summarized methods to estimate maximum ground surface deformations associated with construction of excavations and provided another series of charts illustrating envelopes of ground displacement for different soil types (soft clay, stiff clay, and sand) as well as noting wall types where possible. Addenbrooke (1994) integrated the simple beam equation to find the displacement, y, over the span distance, h, and defined a displacement flexibility number, , for use in estimating displacements: = h 5 / (EI) (11)

hmax = * hmax W S D B P M

(8)

Importantly, they introduced the concept of nondimensional relative stiffness, given the term Sr in this paper. Non-dimensional stiffness is defined as EI/(h4), where I is defined as the internal moment of inertia per unit length of the wall. For walls

If earth loads are proportional to H and the loading or bending moment equation is integrated to derive deflection, then deflection will indeed be related to h5. However, when normalizing the complete deflection equation by H (or h) to relate deformation to the height of the wall (or span between supports), the resulting variables should be h/H versus some form of H4 (or h4) as utilized by Mana and Clough (1981). The parameter (per unit length) is also a somewhat counter-intuitive dimensional value with units of length2/force and there is little intrinsic theoretical or practical benefit to the use of . Hsieh and Ou (1998) identified two displacement patterns that constitute vertical settlement profiles: spandrel-shaped deformation, As, from cantilever bending; and inward bulging or convex bending, Ac. Their method based surface settlement on lateral displacements estimated

1.5 Stability Factor of Safety (FS)

4 1.

1.0 0.8

cs

0.6 0.4 0.2 0.0 0 100 Eur (MPa) 200

hmax (%H)

1.0

100

10 5

1.0

300

0.5

2

hmax = (8.5Sr

0.0 1

-1/2

+ 0.4)FS

-1.7

1.0

H 0.5

10

100

1000

Sr (EI)/(h4)

0.0 1.0 1.5 2.0 2.5 Depth to Firm Layer, D/H 1.4

1.0 0.8

Sr

10

1.2

S = 0.3(e

-S/1000

+e

-S/200

)+0.7

PL

0.4 0.2 0.0 0 25 50

20

0.6

30

1.0 0.8 0.6

hmax (wall) vmax (surface)

PL = e

-(PL/(60 + 4Sr)) 75 100 150

0.4 100

1000 Strut Stiffness S/(h)

10000

Preload (% total net load)

Unload-Reload Modulus, Eur (MPa) 2.5 2.0

vmax (surface)

10

100

1.0 0.5 0.0 0 1

hmax (wall)

1.5

FS = 1.0

M = 6.67Eur-2/3

FS > 1.5

M = 0.75 + H/(4B) 0.1 2 3 4 100

1000 Modulus Multiplier, M (E = MSu)

Excavation Width, B/H

Figure 1. Maximum lateral displacements of excavation support systems and modification factors to account for the influence of support system stiffness and factor of safety, construction stage (removal of supports), depth to a firm layer, degree of preloading, strut stiffness, excavation width, and soil stiffness (after Mana and Clough 1981, Boone et al. 1999, Boone 2003).

using finite element or beam on elastic foundation methods. They also stated that ...the deflection of a supported wall during excavation can usually be predicted using the finite element method with good accuracy. However, prediction of the ground surface settlement induced by excavation is not as good as wall deflection. This begs the question: why can lateral displacement results from finite element analyses be believed if the vertical displacements are unbelievable?

Long (2001), using a large database of published performance results, compared the prediction methods of Clough et al. (1989), Clough and ORourke (1990), and Addenbrook (1994) and concluded that the trends illustrated by Clough et al. (1989) were supported by the data slightly better than others, though no approach was judged superior. Clearly, a systematic and rational approach to analytically estimating displacements of supported excavations is necessary.

3 A NEW APPROACH TO DISPLACEMENT ESTIMATION Parametric non-linear numerical modeling trials were completed by Boone (2003) to examine excavation support behavior for given design conditions. It was considered that the results might discern patterns that could, through curve fitting, produce closed-form equations for this soilstructure interaction problem. A non-linear hyperbolic soil stiffness model with a Mohr-Coulomb failure criterion and linear unloading-reloading response (Duncan and Chang 1970) was used to simulate soil behavior. The majority of trials were completed with the ground mass assumed to consist of granular soils. Trials were also completed assuming cohesive soils similar to those used by Mana and Clough (1981) as a check on the results. One of the more important conclusions was that displacement behavior associated with deep excavations is governed in large measure by the unload-reload stiffness properties of the soil mass, whether or not the soil was predominantly granular or cohesive in nature. Vertical displacements are not often well-represented by finite element models because, when using linear-elastic constitutive models, the ground mass in and beyond the excavation rebounds upward disproportionately in comparison with lateral displacements. By using an unload-reload modulus that is larger than the virgin-loading modulus, vertical rebound is restricted and vertical settlement caused by lateral shoring displacements become evident and more consistent with real observations. The parametric modeling results were combined with those of Mana and Clough (1981), Clough et al. (1989), and Boone et al. (1999). The

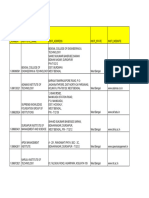

resulting plots of excavation support behavior influence factors are illustrated in Figure 1. Through curve-fitting, a series of equations were developed that could be implemented in spreadsheets without resort to use of charts (see Table 1) for estimating displacements. All parameters are defined in Figure 2. Prior to estimating displacements for an excavation support system, it is necessary to first choose a trial value of relative stiffness. A gauge of an appropriate value can be based on Figure 1. It is then necessary to estimate the excavation factor of safety as an index of the shear strength and deformation modulus mobilized within the retained soil mass. Estimating this factor of safety is best accomplished using limit equilibrium methods (Sabatini et al. 1998, Boone 2003). Based on the relative stiffness and stability factor of safety, the maximum horizontal displacement for the basic conditions (e.g. zero pre-load, removal of supports during backfilling, etc.) may be defined by use of Figure 1 or Table 1. Then, using displacement modification factors provided in Table 1, apply these to estimate the maximum horizontal displacement for the subject analysis conditions. Once the maximum lateral displacement is determined, the equations in Table 1 can be used to define the lateral displacement at the ground surface (at the wall face) and the remaining characteristics of the vertical displacement profiles through superposition of the spandrel and concave profiles as illustrated in Figure 2. 4 DISCUSSION & CONCLUSIONS The method of estimating displacements proposed in this paper provides a logical and step-wise

vcmax dmin i

Dc d hsmax vsmax H

Ds d

Avc H hcmax

Avs

Ahc composite profile

Ahs

Figure 2. Definitions of lateral and vertical displacement parameters: concave on left, spandrel on right (after Boone 2003).

300

Calculated hmax (mm)

250 200 150 100 50 0 0 50 100 150 200

hm

ax

lcu ca

d te la

ed ur s ea m

back excavations, isolates a number of construction variables, and allows direct estimation of both the magnitude and shape of the displacement patterns. REFERENCES

Boone, S.J. 2003. Design of Deep Excavations in Urban Environments. Ph.D. Thesis. Toronto: University of Toronto. Boone, S.J., Bidhendi, H., Westland, J., and Grabinsky, M. 1999. Rationalizing the practice of strut preloading for braced excavations. Geo-Engineering for Underground Facilities: 393 - 404. Washington: ASCE Bowles, J.E. 1996. Foundation Analysis and Design, Fifth Edition, McGraw-Hill, New York. Fourth Edition, 1988. Caspe, M.S. 1966. Surface settlement adjacent to braced open cuts. Journal of the Soil Mechanics and Foundations Division, 92(4): 51 59. Clough, G.W., Smith, E.M., and Sweeney, B.P. 1989. Movement control of excavation support systems by iterative design. Foundation Engineering, Current Practices and Principles, Vol. 2: 869 884. Washington: ASCE Duncan, J.M. and Chang, C-Y. 1970. Non-linear analysis of stress and strain in soils. Journal of the Soil Mechanics and Foundations Division, 96(5). Goldberg, D.T., Jaworski, W.E., and Gordon, M.D. 1976. Lateral Support Systems and Underpinning: Vol. II, Report No. FHWA-RD-75-130. Washington: Federal Highway Administration Mana, A.I. and Clough, G.W. 1981. Prediction of Movements for Braced Cuts in Clay. Jour. of the Geotech. Div., 107(6): 756 - 777. Peck, R. B. 1969. Deep Excavations and Tunnelling in Soft Ground: State of the Art Report. Proc. 7th Int. Conf. on Soil Mech. and Found. Engng, Mexico: 225-290. Rowe, P.W. 1952. Anchored sheet-pile walls. Proc. Institution of Civil Engineers, 1(1): 27 70. Rowe, P.W. and Briggs, A. 1961. Measurements on Model Strutted Sheet Pile Excavations. Proc. 5th Int. Conf. on Soil Mech. and Found. Engng, Vol. 2: 473 - 478. Sabatini, P.J., Pass, D.G., and Bachus, R.C. 1999. Ground Anchors and Anchored Systems, FHWA Report No. FHWA-SA-99-015. Washington: Federal Highway Administration.

vm

ax

250

300

Measured hmax (mm)

Figure 3. Comparison of measured and calculated lateral (solid) and vertical (open) displacements using a limited database (after Boone 2003).

approach to account for a variety of the most important factors that govern the movement of excavation support structures. Results obtained using this method are consistent with both observations and empirical charts, as well as with prior numerical studies (Boone 2003). Comparisons of measured and back-calculated displacements for 69 and 38 cases of lateral and vertical displacements, respectively, are illustrated in Figure 3. This figure demonstrates some reasonable agreement between the estimation method and field performance where regression coefficients for the trend lines were calculated to be about 0.89 and 0.65 for the lateral and vertical displacements, respectively. Figure 3 suggests that the method may under-predict vertical settlements; however, the following issues must be considered: published cases in which all required data were included were limited; published information regarding when the measurements were taken in the construction sequence (e.g., end of excavation, after struts removed, etc.) was sometimes unclear; and other construction factors may have influenced performance. Future comparisons will be made between preconstruction predictions and construction monitoring results, and to a more refined database of case histories in order to gauge the reliability of this approach. The proposed method can serve as either a check on numerical results, or provide a more rigorous design approach than empirical charts and clarifies the distinction between braced and tied-

Table 1. Summary of displacement estimation equations based on curve-fitting of non-linear numerical modeling results.

Characteristic

maximum unfactored displacement, hmax construction Stage, cs lateral

Condition

Equation

Maximum Lateral Displacement support installation and * hmax = (8.5Sr + 0.4)FS-1.7 removal supports removed =1

CS

tiebacks remaining stressed preloading, PL excavation width, B strut stiffness, S soil modulus, M max. lateral displacement, hmax maximum lateral displacement at surface, hsurface percent of preload maintained

CS = 1

(E ur /p a ) 0 .3 3000/S r + (E ur /p a )

PL = e -{PL/(60+4Sr )} B = 0.75 + H/(4B) S = 0.3(eSr / 1000 + eSr / 200 ) + 0.7

M = 6.67E ur 2 / 3

hmax = * hmax M S PL D B CS

Ground Surface Displacements Supports remain in place hsurfacce Supports removed

hmax hsurfacce hmax

(E ur /p a ) 0.2 500 + (E ur /p a )Sr (E /p ) = ur a 1.0 700

lateral displacement areas Area of lateral spandrel displacement, Ahs Ratio of spandrel displacement to total displacement area, Ahs/Aht

A hs = hsurfacce (H + H p )/2

End of excavation stage After support removal

Area of convex displacement, Ahc Ratio of vertical and horizontal displacement areas

A hs (E ur /p a ) = A ht 1,600 + (E ur /p a )S r 0.35 A hs (E ur /p a ) = A ht 300 + (E ur /p a ) A hc = 1 A hs /A ht

ratios of vertical and lateral displacement areas Cantilever walls A /A = A /A

vs hs vc

Supports remain in place Supports removed

= A vt /A ht = 1 A vs /A hs = A vc /A hc = A vt /A ht = 0.85 A vs /A hs = A vc /A hc = A v /A h = 1.1 (no dilation)

hc

spandrel portion of settlement trough Maximum settlement, vsmax Settlement at any point, vs

vsmax = 3A vs /D s ; D s 1.2H to 1.5H

vs = vsmax 3[(Ds - d)/Ds ]2 ; D s 1.2H to 1.5H

concave settlement portion of settlement trough

Maximum settlement, vcmax Settlement at any point, vc

vcmax =

A vc [1 (0, d min , i)] 2 i

(d d min ) 2 2i 2

vc = e

Dc = twice the distance from the wall top to the position of the load resultant i = inflection point, defined as (Dc-dmin)/constant, where the constant 4 to 5 = area of standard normal distribution function, with random variable = 0 (wall position), mean = dmin, and standard deviation = i complete settlement profile Total settlement at any point

v = vc + vs

Potrebbero piacerti anche

- Understanding the Bouguer Anomaly: A Gravimetry PuzzleDa EverandUnderstanding the Bouguer Anomaly: A Gravimetry PuzzleValutazione: 2 su 5 stelle2/5 (1)

- Pile On SlopeDocumento10 paginePile On SlopeChua Chim HueeNessuna valutazione finora

- Lateral Pile Response PDFDocumento10 pagineLateral Pile Response PDFAhmed RamadanNessuna valutazione finora

- Ground Movements Due To Shallow Tunnels in Soft GRDocumento31 pagineGround Movements Due To Shallow Tunnels in Soft GRGeotech Designers IITMNessuna valutazione finora

- Numerical Study of Behavior of Anchor Plates in Clayey SoilsDocumento13 pagineNumerical Study of Behavior of Anchor Plates in Clayey SoilsBilly ArlimanNessuna valutazione finora

- A Study On Load Capacity of Horizontal and Inclined Plate Anchors in Sandy SoilsDocumento9 pagineA Study On Load Capacity of Horizontal and Inclined Plate Anchors in Sandy SoilscustomerxNessuna valutazione finora

- Lateral Pile ResponseDocumento10 pagineLateral Pile ResponseJudy KamalodeenNessuna valutazione finora

- RaftDocumento8 pagineRaftKamarajanNessuna valutazione finora

- Three-Dimensional Effects For Supported Excavations in ClayDocumento34 pagineThree-Dimensional Effects For Supported Excavations in ClayQassun MohammedNessuna valutazione finora

- Vlachopoulos PDFDocumento16 pagineVlachopoulos PDFSérgio BernardesNessuna valutazione finora

- Velloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceDocumento5 pagineVelloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceMarcelaMarquesNessuna valutazione finora

- (OKAMURA) Displacement of Gravity Retaining Walls Under Seismic LoadingDocumento9 pagine(OKAMURA) Displacement of Gravity Retaining Walls Under Seismic Loadinghal9000_mark1Nessuna valutazione finora

- Evaluation of Vertical and Horizontal Bearing Capacities of Bucket Foundations in ClayDocumento8 pagineEvaluation of Vertical and Horizontal Bearing Capacities of Bucket Foundations in Clayvananhlt18Nessuna valutazione finora

- Settlement Analyses of Underground Circular Tunneling in Soft ClayDocumento6 pagineSettlement Analyses of Underground Circular Tunneling in Soft ClayChin Thau WuiNessuna valutazione finora

- Some Aspects of Pile Response Near An ExcavationDocumento6 pagineSome Aspects of Pile Response Near An ExcavationcolawariNessuna valutazione finora

- 2009 Journal JRM VlachopoulosandDiederichsDocumento17 pagine2009 Journal JRM VlachopoulosandDiederichsfernando CanizaresNessuna valutazione finora

- Kahyaoglu 2012Documento9 pagineKahyaoglu 2012Yasmina M NadyNessuna valutazione finora

- 3-D Shell Analysis of Cylindrical Underground Structures Under Seismic Shear (S) Wave ActionDocumento13 pagine3-D Shell Analysis of Cylindrical Underground Structures Under Seismic Shear (S) Wave ActionvttrlcNessuna valutazione finora

- Earth Pressures Retaining Walls Rock Faces Numerical SolutionDocumento7 pagineEarth Pressures Retaining Walls Rock Faces Numerical SolutionAnonymous hRWwL7pZnCNessuna valutazione finora

- Manuscript Copyedited: Settlement Calculation of Composite Foundation Reinforced With Stone ColumnsDocumento39 pagineManuscript Copyedited: Settlement Calculation of Composite Foundation Reinforced With Stone ColumnsrkNessuna valutazione finora

- 13 An Experimental Study On Uplift Capacity of Plate AnchorsDocumento35 pagine13 An Experimental Study On Uplift Capacity of Plate AnchorsAna Sofía Arango BermúdezNessuna valutazione finora

- Ground Subsidence Due To Tunneling and Effects On Pile FoundationsDocumento8 pagineGround Subsidence Due To Tunneling and Effects On Pile FoundationsongyinhoeNessuna valutazione finora

- Earthquake Design of Rectangular UndergroundDocumento8 pagineEarthquake Design of Rectangular UndergroundtrabajosicNessuna valutazione finora

- Soil Dynamics and Earthquake Engineering: Ngoc-Anh Do, Daniel Dias, Pierpaolo Oreste, Irini Djeran-MaigreDocumento11 pagineSoil Dynamics and Earthquake Engineering: Ngoc-Anh Do, Daniel Dias, Pierpaolo Oreste, Irini Djeran-MaigrePaloma CortizoNessuna valutazione finora

- Depth of Embedment of Sheet Pile Wall in Cohessiveless SoilDocumento6 pagineDepth of Embedment of Sheet Pile Wall in Cohessiveless Soilmahmoud meslehNessuna valutazione finora

- VLACHOPOULOS, DIEDERICHS - Improved Longitudinal Displacement Profiles For CCM (2009)Documento17 pagineVLACHOPOULOS, DIEDERICHS - Improved Longitudinal Displacement Profiles For CCM (2009)DanielNessuna valutazione finora

- 11SEAGC1993 New Procedure For Predicting Basal Heave StabilityDocumento6 pagine11SEAGC1993 New Procedure For Predicting Basal Heave StabilityfreezefreezeNessuna valutazione finora

- Bearing Capacity of Eccentrically Loaded FootingsDocumento18 pagineBearing Capacity of Eccentrically Loaded FootingsAlaaGaballaNessuna valutazione finora

- Tipical Bearing Capacity of Strip Footings On Eccentric and Inclined LoadsDocumento23 pagineTipical Bearing Capacity of Strip Footings On Eccentric and Inclined LoadsEudkrenutNessuna valutazione finora

- BF03352279Documento6 pagineBF03352279TsaqifNessuna valutazione finora

- 1 s2.0 S0886779818309027 MainDocumento11 pagine1 s2.0 S0886779818309027 MainMert GőkdoğanNessuna valutazione finora

- Keynote Speaker 11Documento9 pagineKeynote Speaker 11Mangisi Haryanto ParapatNessuna valutazione finora

- Improvements in The ConvergenceDocumento8 pagineImprovements in The ConvergencengodangquangNessuna valutazione finora

- Initial Soil Springs Stiffness For Laterally Loaded Piles PDFDocumento7 pagineInitial Soil Springs Stiffness For Laterally Loaded Piles PDFmagdyamdbNessuna valutazione finora

- 2011 Gourvenec & Barnett GeotechniqueDocumento8 pagine2011 Gourvenec & Barnett GeotechniqueArturo MuñozNessuna valutazione finora

- Method To Estimate The System Probability of Failure of Mechanicaly Stabilized Earth WallsDocumento18 pagineMethod To Estimate The System Probability of Failure of Mechanicaly Stabilized Earth WallsCostinel CristescuNessuna valutazione finora

- Effect of Tie Beam Dimensions On Vertica PDFDocumento9 pagineEffect of Tie Beam Dimensions On Vertica PDFAhmed MohammedNessuna valutazione finora

- Soil-Structure Interaction For Landslide Stabilizing Piles: C.-Y. Chen, G.R. MartinDocumento24 pagineSoil-Structure Interaction For Landslide Stabilizing Piles: C.-Y. Chen, G.R. Martinramarathnam1989Nessuna valutazione finora

- 10Documento12 pagine10rowatersNessuna valutazione finora

- Back To Back Retaining WallDocumento6 pagineBack To Back Retaining Walladry_vpNessuna valutazione finora

- Application of Geometric Models To Inverted Listric Fault SystemsDocumento10 pagineApplication of Geometric Models To Inverted Listric Fault SystemsFrancisco AlfaroNessuna valutazione finora

- Masonry Infill Panels - Analytical Modeling and Seismic BehaviorDocumento10 pagineMasonry Infill Panels - Analytical Modeling and Seismic BehaviorIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Braced Excavation - Numerical AnalysisDocumento15 pagineBraced Excavation - Numerical AnalysisnithuNessuna valutazione finora

- An Improved Newmark Method For Predicting The Whole-Life Performance of Pile-Reinforced SlopesDocumento8 pagineAn Improved Newmark Method For Predicting The Whole-Life Performance of Pile-Reinforced SlopesAsad HafudhNessuna valutazione finora

- Divall-Ground Movements Generated by Sequential Twin-Tunnelling in Over-Consolidated ClayDocumento10 pagineDivall-Ground Movements Generated by Sequential Twin-Tunnelling in Over-Consolidated ClayMekonen MagogaNessuna valutazione finora

- Rockfall Travel Distance Analysis by Using Empirical Models (Sol'a D'andorra La Vella, Central Pyrenees)Documento12 pagineRockfall Travel Distance Analysis by Using Empirical Models (Sol'a D'andorra La Vella, Central Pyrenees)asiamonikaNessuna valutazione finora

- Seismic Behavior Retaining WallsDocumento29 pagineSeismic Behavior Retaining WallsSaeedNessuna valutazione finora

- An Analysis For Determination of Foundation Rigidity: December 1998Documento19 pagineAn Analysis For Determination of Foundation Rigidity: December 1998Ihab SorourNessuna valutazione finora

- 10.1016/j.enggeo.2012.11.006: Engineering GeologyDocumento53 pagine10.1016/j.enggeo.2012.11.006: Engineering GeologyNhan DoNessuna valutazione finora

- Asc000080 PDFDocumento8 pagineAsc000080 PDFQassun MohammedNessuna valutazione finora

- Comparison of Different Soil Models For Excavation Using Retaining WallsDocumento6 pagineComparison of Different Soil Models For Excavation Using Retaining WallsnithuNessuna valutazione finora

- Jgeot 15 P 035 PDFDocumento15 pagineJgeot 15 P 035 PDFEvers Quispe CallasacaNessuna valutazione finora

- Numerical Modeling of Laterally Loaded PilesDocumento6 pagineNumerical Modeling of Laterally Loaded PilesMatteo Izzi100% (1)

- Distribucion de Presiones en Estribos Debido Al SismoDocumento12 pagineDistribucion de Presiones en Estribos Debido Al SismoAlexander Abreu DirocieNessuna valutazione finora

- The Evolution of Analysis Methods For Laterally Loaded Piles Through TimeDocumento31 pagineThe Evolution of Analysis Methods For Laterally Loaded Piles Through TimeBabaNessuna valutazione finora

- ASCE Paper Pipeline-LandslideDocumento8 pagineASCE Paper Pipeline-LandslideManuel MoyaNessuna valutazione finora

- Retaining WallDocumento11 pagineRetaining Wallardi rahadianNessuna valutazione finora

- Eccentrically Loaded Strip Foundation On Geogrid-Reinforced SandDocumento19 pagineEccentrically Loaded Strip Foundation On Geogrid-Reinforced SandMohamed MohsenNessuna valutazione finora

- Stability Analysis and Safety Factor Prediction of Excavation Supported by Inclined Piles in ClayDocumento8 pagineStability Analysis and Safety Factor Prediction of Excavation Supported by Inclined Piles in ClayPutik .jajaNessuna valutazione finora

- An Extension of Analytical Methods For Building Damage Evaluation in Subsidence Regions To Anisotropic BeamsDocumento30 pagineAn Extension of Analytical Methods For Building Damage Evaluation in Subsidence Regions To Anisotropic BeamsThaung Myint OoNessuna valutazione finora

- Pg2022 ResultDocumento86 paginePg2022 ResultkapilNessuna valutazione finora

- Fundamentals of Public Health ManagementDocumento3 pagineFundamentals of Public Health ManagementHPMA globalNessuna valutazione finora

- PDFDocumento10 paginePDFerbariumNessuna valutazione finora

- RFID Seminar AbstractDocumento2 pagineRFID Seminar Abstractanushabhagawath80% (5)

- ChatGpt PDFDocumento19 pagineChatGpt PDFsanx2014100% (1)

- Winter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportDocumento6 pagineWinter CrocFest 2017 at St. Augustine Alligator Farm - Final ReportColette AdamsNessuna valutazione finora

- Sandstorm Absorbent SkyscraperDocumento4 pagineSandstorm Absorbent SkyscraperPardisNessuna valutazione finora

- EqualLogic Release and Support Policy v25Documento7 pagineEqualLogic Release and Support Policy v25du2efsNessuna valutazione finora

- CV Augusto Brasil Ocampo MedinaDocumento4 pagineCV Augusto Brasil Ocampo MedinaAugusto Brasil Ocampo MedinaNessuna valutazione finora

- Cisco UCS Adapter TroubleshootingDocumento90 pagineCisco UCS Adapter TroubleshootingShahulNessuna valutazione finora

- Micro Lab Midterm Study GuideDocumento15 pagineMicro Lab Midterm Study GuideYvette Salomé NievesNessuna valutazione finora

- Jakub - BaZi CalculatorDocumento3 pagineJakub - BaZi Calculatorpedro restinxNessuna valutazione finora

- Introduction To Screenwriting UEADocumento12 pagineIntroduction To Screenwriting UEAMartín SalasNessuna valutazione finora

- Peer PressureDocumento13 paginePeer PressuremightymarcNessuna valutazione finora

- Applications SeawaterDocumento23 pagineApplications SeawaterQatar home RentNessuna valutazione finora

- Phytotherapy On CancerDocumento21 paginePhytotherapy On CancerSiddhendu Bhattacharjee100% (1)

- Module 2 MANA ECON PDFDocumento5 pagineModule 2 MANA ECON PDFMeian De JesusNessuna valutazione finora

- WBDocumento59 pagineWBsahil.singhNessuna valutazione finora

- 2014 - A - Levels Actual Grade A Essay by Harvey LeeDocumento3 pagine2014 - A - Levels Actual Grade A Essay by Harvey Leecherylhzy100% (1)

- Tool Charts PDFDocumento3 pagineTool Charts PDFtebengz100% (2)

- UT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)Documento2 pagineUT Dallas Syllabus For Govt4396.002.08s Taught by Gregory Thielemann (Gregt)UT Dallas Provost's Technology GroupNessuna valutazione finora

- BrochureDocumento3 pagineBrochureapi-400730798Nessuna valutazione finora

- PFEIFER Angled Loops For Hollow Core Slabs: Item-No. 05.023Documento1 paginaPFEIFER Angled Loops For Hollow Core Slabs: Item-No. 05.023adyhugoNessuna valutazione finora

- In Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0Documento21 pagineIn Flight Fuel Management and Declaring MINIMUM MAYDAY FUEL-1.0dahiya1988Nessuna valutazione finora

- Lecture 2 Effects of Operating Conditions in VCCDocumento9 pagineLecture 2 Effects of Operating Conditions in VCCDeniell Joyce MarquezNessuna valutazione finora

- ASHRAE Journal - Absorption RefrigerationDocumento11 pagineASHRAE Journal - Absorption Refrigerationhonisme0% (1)

- Heimbach - Keeping Formingfabrics CleanDocumento4 pagineHeimbach - Keeping Formingfabrics CleanTunç TürkNessuna valutazione finora

- Assistant Cook Learner Manual EnglishDocumento152 pagineAssistant Cook Learner Manual EnglishSang Putu Arsana67% (3)

- Nadee 3Documento1 paginaNadee 3api-595436597Nessuna valutazione finora

- QSP 04bDocumento35 pagineQSP 04bakrastogi94843Nessuna valutazione finora