Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Despiece Motor y Conjunto PDF

Caricato da

Borralla CinzaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Despiece Motor y Conjunto PDF

Caricato da

Borralla CinzaCopyright:

Formati disponibili

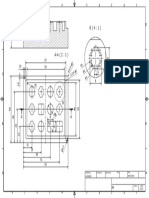

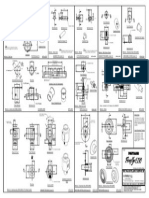

Exploded View of Engine & Remote Needle Assembly

ITEM DESCRIPTION QUANTITY

1 CRANKCASE 1 OFF

2 CRANKCASE BEARING 1 OFF

3 BARREL 1 OFF

4 CYLINDER HEAD 1 OFF

5 BACKPLATE 1 OFF

6 CRANKSHAFT 1 OFF

7 CONROD 1 OFF

8 PISTON 1 OFF

9 GUDGEON PIN 1 OFF

10 PIN END BUTTON 1 OFF

11 LINER 1 OFF

12 CARBURETTOR BODY 1 OFF

13 CARBURETTOR ROTOR 1 OFF

14 BARREL SPACER 1 OFF

15 NIPPLE 1 OFF

16 NEEDLE VALVE BODY 1 OFF

DRG No.

WF46-0003

WF46-0004

WF46-0005

WF46-0006

WF46-0007

WF46-0008

WF46-0009

WF46-0010

WF46-0011

WF46-0013

WF46-0012

WF46-0014

WF46-0015

WF46-0016

WF46-0017

WF46-0018

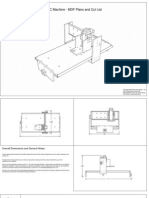

Project

R22.5

1

0

0

76

25

7

2

SIDE ELEVATION

3

8

2

8

PLAN VIEW

5

7

FRONT ELEVATION

Engine Specification

Bore - 21mm

Stroke - 18.4mm

RPM - 2,000-10,000

Prop - 11" x 6", 11" x 7"

4mm Mounting HoIes

Remote Needle Valve Assembly

with In-Flight Mixture Control ITEM DESCRIPTION

28

NEEDLE VALVE (O.S. OR CLONE PART)

19 3,Z COPPER PIPE X 30mm LONS 2 OFF

20 1 OFF

21 1 OFF

22 M3 X 12 LONG SOCKET CAP HEAD SCREW 4 OFF

23 5 OFF

24 4 OFF

25

26

27

THRUST WASHER (O.S. OR CLONE PART) 1 OFF

PART No.

O.S. No. 24081970

O.S. No. 22020001

3,Z COPPER PIPE X Zmm LONS

3,Z COPPER PIPE X Z0mm LONS

M3 X 20 LONG SOCKET CAP HEAD SCREW

M3 X 10 LONG C/SK SOCKET HEAD SCREW

DRIVE WASHER (O.S. OR CLONE PART) 1 OFF O.S. No. 24008000

2 OFF M3 NYLOC NUT

18 18 SWG X 15mm LONG PIANO WIRE PIN 2 OFF

1 OFF

29

30

1 OFF M2.5 X 5 LONG PAN HEAD SCREW (ST.STL)

2 OFF M3 X 16 LONG SOCKET SET SCREW

SERVO HORN (MODIFIED FUTABA) Fut No. FUTM2030 1 OFF 31

ENGINE DIMENSIONS

QUANTITY

17 IN-FLIGHT MIXTURE CONTROL DISC 1 OFF WF46-0019

ASSEMBLED ENGINE

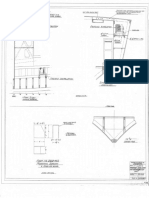

View of Completed Crankcase

WF46-0003 CRANKCASE

37.5

3

7

.5

1

8

.7

5

61.95

19.35

6.15

6.15

3

0

.0

30.0

15

10.0

1

6

.6

0

32

34.00

25.00

Z

0

"

23.45

I

3

"

25

20.00

2

8

.0

0

4

.7

5

1

8

.7

5

15

6

.7

5

R

6

6

.1

5

8

8

Section on A-A Front Elevation

4.35

4 - Holes M3 x 8mm Deep

4 - Holes M3 x 7 Deep

28.2

Rear Elevation

5

Plan View

Material - Aluminium Alloy HE30 (6082)

View of Alternative Crankcase

(Without chamfering)

Chamfers Optional Chamfer Optional

1

2

.2

5

o.I

HoIe 3.Z

A A

29.95

42.60

8.0

44.3

18.75 18.75

Project

RCM&E PLANS SERVICE

A .46cu. in. two-stroke glow engine. DESIGNED BY Alex Whittaker

PLAN No: RC2095 No. of Sheets:

First published in

RCM&E March. 2012

20.0

Section on A-A Front Elevation

A

WF46-0004 CRANKCASE BEARING (Scale 2:1)

16.60

32

30.095

I0.0

A

7

0

"

Notes

1. 10mm intake hole to be bored with

the bearing pressed into crankcase

to ensure correct alignment.

2. This diameter to be a light press

fit inside crankcase.

Material - Bronze PB1

See Note 2.

1

2

.0

0

WF46-0005 BARREL

43

21.5

3

0

.0

30.0

15

38.5

17.75

1

8

.7

5

Front Elevation

4 - HoIes 3.b

Plan View

Material - Aluminium Alloy HE30 (6082)

4

.7

5

A A

3

34.00

37.47

5

.4

2

1

.8

1

1

.5

3

5

.3

3

.5

8

.4

4 - Holes M3 x 8 Deep

43

21.5

6.15

6.15

10.5

1

8

.7

5

R

6

t

y

p

6

.1

5

Section on B-B

4

.7

5

17.75 Exhaust Port

6

.1

5

B

3

.5

2 - Holes 3.5 Dia

4.15

3

.7

5

Transfer Ports 6mm Rad typ

40

1.5mm x 6 hole

Panel pin used to locate liner drill

1.5 mm Hole x 6 Deep to suit Liner

36.5

0

.7

5

10

.7

ref

11.25 11.25

1

1

.2

5

1

1

.2

5

3

7

.3

2

o

3

"

36.5

2

.7

5

C/Bore 6.2 Dia

4b" fyp

2

1

.5

2

1

.5

40

Section on A-A

Front Elevation

A

WF46-0006 CYLINDER HEAD

40

A

Material - Aluminium Alloy HE30 (6082)

9

.8

21.00

6.35

Completed

Cylinder Head

Plan View

4

b

"

1

.4

1

.5 1

.5

T

Y

P

4 - HoIes 3.3mm fhrough &

C/bore b.7mm x 3.bmm deep

2

0

.5

3

.6

0

14

2mm Chamfer

1mm Rad Plug thread 1/4" 32

UNEF (O.S. #8 Plug)

22.5

2

2

.5

R10

14

0.6

1.8 Typ u/cut

Section on A-A

WF46-0007 BACKPLATE

A

Notes

1. This diameter is a close fit inside crankcase to avoid air leaks

2. Copper fuel feed pipes to be a press fit into backplate

Material - Aluminium Alloy HE30 (6082)

15.5

1.5mm Chamfer

4 - Holes drill through

3.b ond C/SI o.Z

1

3

.4

9.65

3

b

"

20

57

2

5

5.8

3- HoIes DriII fhro 4

Z- HoIes DriII fhro 3.Z

for copper fuel feed

pipes (See note 2.)

Machined flat for

piston clearance

2

8

1

4

Elevation on Rear of Plate

2.5

R22.5

Section on A-A

WF46-0008 CRANKSHAFT

Material:-

Crankshaft - Carbon Steel EN8M (212M36)

Big end Pin - SilverSteel

Side Elevation

1.5mm Chamfer

Machined flat

for prop driver

End View

74.15

Z

o

.8

4 11

R

e

a

m

t

o

5

.4

7

21

27.8

34

32.15

7.8

8

.5

12 5.6

26

0.5mm Rad

9

.0

0

Thread 1/4" 28 TPI UNF

6

.3

6

R

25

40.15

1.5mm Chamfer

8 A

A

27.75

1

8

.7

5

Completed Crankshaft

9

.2

5

View on Arrow B

1

2

.0

0

0

B

3

.3

0.2

0.2

R

4

4

0

"

14.25

5

.5

0

0

Big End Pin

(Silver steel)

Big End Pin

(see detail)

0.25mm Chamfer

Drill and ream to suit big

end pin detailed below

1

6

.2

Raised Area

Raised Area

Section on A-A

WF46-0009 CONROD (scale 2:1) Material - H15 Duraluminium (2014)

I.bmm HoIe (Typ)

A

4

.4

3

2

.1

5

3

.0

5

=

=6

.0

4

32.80

R

4

.5

8

A

R

4

4.5 4

5.000

8

.1

Completed Conrod

I0

(fyp)

5.500

2

.9

Front Elevation

Big end pin to be an

interference fit

General Notes

This drawing is to be used in conjunction with the RCM&E column

write up for machining methods, dimensional fits and assembly.

Typical Dimensional Tolerance

0 DecimoI PIoces 0.bmm

I DecimoI PIoces 0.Zmm

Z DecimoI PIoces 0.Imm

3 DecimoI PIoces 0.0bmm

AnguIor 0.Z"

Completed Backplate

Completed Bearing

2

8

.1

5

s

e

e

n

o

t

e

1

A

2 of 3

WF46-0010

Project

RCM&E PLANS SERVICE

A .46cu. in. two-stroke glow engine. DESIGNED BY Alex Whittaker

PLAN No: RC2095 No. of Sheets:

First published in

RCM&E March. 2012

General Notes

This drawing is to be used in

conjunction with the RCM&E

column write up for machining

methods, dimensional fits and

assembly.

Typical Dimensional Tolerance

0 DecimoI PIoces 0.bmm

I DecimoI PIoces 0.Zmm

Z DecimoI PIoces 0.Imm

3 DecimoI PIoces 0.0bmm

AnguIor 0.Z"

Section on A-A

PISTON (Scale 2:1) Material - Cast Iron

Underside

A

A

Completed Piston

21.00*

1

8

.5

1

7

19.00

6

5

.0

0

1

8

.5

8

.3

5

12

1

6

.5

*Note

Make Liner prior to making Piston. Outside

Diameter to be lapped to size to match liner

19.5

R

6

1mm Dia Hole for

future Gudgeon

Pin removal

Section on A-A

WF46-0011 GUDGEON PIN (Scale 2:1)

Material - Silver Steel

A

A

Completed Gudgeon Pin

5.000

18.5

End Elevation

2

.5

3

Chamfer 0.25mm

Notes-

1. The Gudgeon pin diameter should be made to

a minimal clearance to match the piston.

Side View

Section on A-A

WF46-0012 LITTLE END PLUG (Scale 4:1)

Material - Bronze

A

A

Completed Plug

End Elevation

Notes-

1. Test fit the plug in the gudgeon pin & piston

to ensure a sliding fit within the liner.

1.1 3

2

.5

1

5

.0

R0.25

R10.5

View of Completed Liner

WF46-0013 CYLINDER LINER

Section on A-A Front Elevation

Plan View

Material - Carbon Steel EN8M (212M36)

A

3

5

.2

5

28.1

0

.7

5

11.0

T

S

F

R

11.0

T

S

F

R

A

21.000

4b"

Sectional Elevation on B-B

4b"

Outside of Liner Port Development

78.54 (25mm Dia)

Circumference

3

4

.5

Underside of Liner Lip

11.39 15.285

Bottom edge of Liner

11.39 13.94 13.94

6.298 6.298

Section on A-A

Front Elevation

A

Material - Mild Steel or Brass

Completed Barrel

10.0

1 - Hole Drill & Tap M3

A

WF46-0015 CARBURETTOR BARREL (Scale 2:1)

I - HoIe 3mm

1

2

.69

.4

5.7

Section on A-A Front Elevation

A

Material - Aluminium alloy HE30 (6082) 3/4" (19mm) Hex Bar

Completed Carburettor

Body

Plan View

2 - Holes Drill & Tap M3

WF46-0014 CARBURETTOR BODY (Scale 2:1)

10

3

0

.7

5

5

.5

1

6

8

1

.2

5

5

1

3

.5

1

7

.2

5

8

8

4

5

.8

5

View on Arrow C

1

2

.8

10.0

5.7

1 - Holes Drill & Tap M6

B B

Section on B-B

6.8

C

A

1- Hole Drill & Tap

M2.5 x 6 Deep

o0"

1.5

Venturi angle cut using a

Countersink Drill

R2

I3

1

8

.7

5

I0.00

Section on A-A

Front Elevation

A

Material - Aluminium Alloy HE30 (6082)

Completed Carb Spacer

A

WF46-0016 CARB BARREL SPACER (Scale 2:1)

I - HoIe 3mm

1

0

.5

1

.2

II.Z

8.Zb

Plan View

Front Elevation

Material - Brass Hex Stock

Completed Nipple

WF46-0017 NIPPLE (Scale 2:1)

I - HoIe Imm fhrough

1

9

4

.2

5

9

.5

A

/

F

M6 Thread

9

.5

5

2

.7

5

3.5

2.35

4.25

2

.2

5

Remove Sharp Corners

10.97

ref

9"

End Elevation

WF46-0018 NEEDLE VALVE BODY (Scale 2:1) Material - Brass

A

A Completed Body

18.0

1

1

.5

2

9

27

7.4 4.5

11 4

6

.8

5

.7

5

8.8

18

23

4

.6

8

1

1

.5

3.2*

1.2

4

.5

Thread M4 x 0.5p

Z HoIes Zmm

^Z-HoIes 3.Zmm fo

be a light press fit for

copper feed pipes

Notes- Suitable for O.S Needle No.24081970

Copper feed pipes to

be a light press fit

1

.2

Section on A-A

WF46-0019 MIXTURE CONTROL DISC (Scale 2:1)

Material - Aluminium Alloy HE30 (6082)

A

Completed Disc

8.5

1.3

1

1

.6

Z4

6

.8

II.o

1 Hole drill to

suit for clevis

Z-HoIes driII I.Zmm fhrough

on on 8.Zmm PCD

R

1

0

A

Section on A-A

8

.2

Section on A-A

WF46-0020 PROP DRIVER (Scale 2:1)

Front Elevation

A

A

Completed Driver

7.54

9

.1

5

2

2

.7

5

3

.3

7

5

5.04 Key depth

1

7

.8

Key

2.94

3b"

Serrated front

face 40 off

0.3mm deep

Rear Elevation

9.15

1

1

.5

R10

6

8

0.5

Material - Aluminium Alloy HE30 (6082)

3 of 3

R

2

2

.5

1

0

0

Title Scale:-

Drawing Number

Drawn

Date Projection

Sheet A3

The Whittaker Firefly .46 Alex Whittaker

First published in RCM&E magazine February / March 2012.

76

25

7

2

SIDE ELEVATION

3

8

2

8

1:1

WF46-0001

Engine General Arrangement

PLAN VIEW

5

7

FRONT ELEVATION

Motor Specification

Bore - 21mm

Stroke - 18.4mm

RPM - 2,000-10,000

Prop - 11" x 6", 11" x 7"

40

4mm Mounting Holes

Remote Needle Valve Assembly

with In-Flight Mixture Contol

Scale:-

Drawing

Number

Drawn

Date

Title

First published in RCM&E magazine February / March 2012.

Third Angle Projection

Project

Sheet Size:- A1 2:1

WF46-0002

Exploded View of

FIREFLY 46 Exploded View of Engine & Remote Needle Assembly

3

4

1

2

11

5

6

7

8

9

10

24

29

22

17

30

23

31

27

13

14

12

15

25

23

22

19

20

21

ITEM DESCRIPTION QUANTITY

1 CRANKCASE 1 OFF

2 CRANKCASE BEARING 1 OFF

3 BARREL 1 OFF

4 CYLINDER HEAD 1 OFF

5 BACKPLATE 1 OFF

6 CRANKSHAFT 1 OFF

7 CONROD 1 OFF

8 PISTON 1 OFF

9 GUDGEON PIN 1 OFF

10 PIN END BUTTON 1 OFF

11 LINER 1 OFF

12 CARBURETTOR BODY 1 OFF

13 CARBURETTOR ROTOR 1 OFF

14 BARREL SPACER 1 OFF

15 NIPPLE 1 OFF

16 NEEDLE VALVE BODY 1 OFF

17 IN-FLIGHT MIXTURE CONTROL DISC 1 OFF

28

NEEDLE VALVE (O.S OR CLONE PART)

19 3.25 COPPER PPE X 30mm LONG 2 OFF

20 1 OFF

21 1 OFF

22 M3 X 12 LONG SOCKET CAP HEAD SCREW 4 OFF

23 5 OFF

24 4 OFF

25

26

27

THRUST WASHER (O.S. OR CLONE PART) 1 OFF

DRG/PART No.

WF46-0003

WF46-0004

WF46-0005

WF46-0006

WF46-0007

WF46-0008

WF46-0009

WF46-0010

WF46-0011

WF46-0013

WF46-0012

WF46-0014

WF46-0015

WF46-0016

WF46-0017

WF46-0018

WF46-0019

O.S. No. 24081970

O.S No. 22020001

3.25 COPPER PPE X 25mm LONG

3.25 COPPER PPE X 20mm LONG

M3 X 20 LONG SOCKET CAP HEAD SCREW

M3 X 10 LONG C/SK SOCKET HEAD SCREW

DRIVE WASHER (O.S. OR CLONE PART) 1 OFF O.S No. 24008000

2 OFF M3 NYLOC NUT

26

18 18 SWG X 15mm LONG PIANO WIRE PIN 2 OFF

18

28

1 OFF

16

29

30

1 OFF M2.5 X 5 LONG PAN HEAD SCREW (ST.STL)

2 OFF M3 X 16 LONG SOCKET SET SCREW

SERVO HORN (MODIFIED FUTABA) Fut No. FUTM2030 1 OFF 31

View of Completed Crankcase

Title Scale:-

Drawing Number

Drawn

Date Projection

Sheet A3

The Whittaker Firefly .46 Alex Whittaker

First published in RCM&E magazine February / March 2012.

1:1

WF46-0003

Crankcase Details

37.5

3

7

.

5

1

8

.

7

5

61.95

19.35

6.15

6.15

3

0

.

0

30.0

15

10.0

1

6

.

6

0

32

34.00

25.00

2

0

23.45

1

3

25

20.00

2

8

.

0

0

4

.

7

5

1

8

.

7

5

15

6

.

7

5

R

6

6

.

1

5

8

8

Section on A-A Front Elevation

4.35

4 - Holes M3 x 8mm Deep

4 - Holes M3 x 7 Deep

28.2

Rear Elevation

5

Plan View

Material - Aluminium Alloy HE30 (6082)

View of Alternative Crankcase

(Without chamfering)

Chamfers Optional Chamfer Optional

General Tolerance

0 DecimaI PIaces 0.5mm

1 DecimaI PIaces 0.2mm

2 DecimaI PIaces 0.1mm

3 DecimaI PIaces 0.05mm

AnguIar 0.2

1

2

.

2

5

6.1

Hole 3.2

A A

29.95

42.60

8.0

44.3

18.75 18.75

20.0

Section on A-A Front Elevation

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

A

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0004

Crankcase Bearing

16.60

32

30.095

1

0

.0

A

7

0

Notes

1. 10mm intake hole to be bored with

the bearing pressed into crankcase

to ensure correct alignment.

2. This diameter to be a light press fit

inside crankcase.

Material - Bronze PB1

See Note 2.

1

2

.

0

0

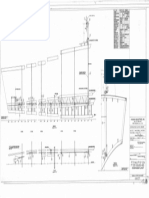

Title Scale:-

Drawing Number

Drawn

Date Projection

Sheet A3

The Whittaker Firefly .46 Alex Whittaker

First published in RCM&E magazine February / March 2012.

1:1

WF46-0005

Barrel Details

43

21.5

3

0

.

0

30.0

15

38.5

17.75

1

8

.

7

5

Front Elevation

4 - Holes 3.5

Plan View

Material - Aluminium Alloy HE30 (6082)

General Tolerance

0 DecimaI PIaces 0.5mm

1 DecimaI PIaces 0.2mm

2 DecimaI PIaces 0.1mm

3 DecimaI PIaces 0.05mm

AnguIar 0.2

4

.

7

5

A A

3

34.00

37.47

5

.

4

2

1

.

8

1

1

.

5

3

5

.

3

3

.

5

8

.

4

4 - Holes M3 x 8 Deep

43

21.5

6.15

6.15

10.5

1

8

.

7

5

R

6

t

y

p

6

.

1

5

Section on B-B

4

.

7

5

17.75

Exhaust Port

6

.

1

5

B

3

.

5

2 - Holes 3.5 Dia

4.15

3

.

7

5

Transfer Ports 6mm Rad typ

40

1.5mm x 6 hole

Panel pin used to locate

liner drill 1.5 mm Hole x 6

Deep to suit Liner

36.5

0

.

7

5

1

0

.7

r

e

f

11.25 11.25

1

1

.

2

5

1

1

.

2

5

3

7

.

3

2

6

3

36.5

2

.

7

5

C/Bore 6.2 Dia

4

5

typ

2

1

.

5

2

1

.

5

40

Section on A-A

Front Elevation

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

A

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

1:1

WF46-0006

Cylinder Head

40

A

Material - Aluminium Alloy HE30 (6082)

9

.

8

21.00

6.35

Completed

Cylinder Head

Plan View

4

5

1

.

4

1

.

5 1

.

5

T

Y

P

4 - Holes 3.3mm through &

C/bore 5.7mm x 3.5mm deep

2

0

.

5

3

.

6

0

14

2mm Chamfer

1mm Rad

Plug thread 1/4"

32 UNEF

(O.S. #8 Plug)

22.5

2

2

.

5

R

1

0

14

0

.

6

1.8 Typ u/cut

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

A

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

1:1

WF46-0007

Motor Backplate

A

Notes

1. This diameter is a close fit inside

crankcase to avoid air leaks

2. Copper fuel feed pipes to be a press

fit into backplate

Material - Aluminium Alloy HE30 (6082)

15.5

Plan View

1.5mm Chamfer

4 - Holes drill through

3.5 and C/SK 6.2

1

3

.

4

9.65

3

5

20

57

2

8

.

1

5

s

e

e

n

o

t

e

1

2

5

5.8

3- Holes Drill thro 4

2- Holes Drill thro 3.2

for copper fuel feed

pipes (See note 2.)

Machined flat for

piston clearance

2

8

1

4

Elevation on Rear of Plate

2.5

R

2

2

.5

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

1:1

WF46-0008

Crankshaft

Material - Carbon Steel EN8M (212M36)

Side Elevation

1.5mm Chamfer

Machined flat for

prop driver

End View

74.15

2

6

.

8

4

11

R

e

a

m

t

o

5

.

4

7

21

27.8

34

32.15

7.8

8

.

5

12 5.6

26

0.5mm Rad

9

.

0

0

Thread 1/4" 28 TPI UNF

6

.

3

6

R

2

5

40.15

1.5mm Chamfer

8

A

A

27.75

1

8

.

7

5

Completed Crankshaft

9

.

2

5

View on Arrow B

1

2

.

0

0

0

B

3

.

3

0.2

0.2

R

4

4

0

14.25

5

.

5

0

0

Big End Pin

(silver steel)

Big End Pin

(see detail)

0.25mm Chamfer

Drill and ream to suit big

end pin detailed below

1

6

.

2

Raised Area

Raised Area

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0009

Conrod

Material - H15 Duraluminium (2014)

1.5mm Hole (Typ)

A

4

.

4

3

2

.

1

5

3

.

0

5

=

=

6

.

0

4

32.80

R

4

.

5

8

A

R

4

4.5 4

5.000

8

.

1

Completed Conrod

5

.

0

(

t

y

p

)

5.500

2

.

9

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0010

Piston

Material - Cast Iron

Underside

A

A

Completed Piston

21.00*

1

8

.

5

1

7

19.00

6

5

.

0

0

1

8

.

5

8

.

3

5

12

1

6

.

5

*Note

Make Liner prior to making Piston. Outside

Diameter to be lapped to size to match liner

19.5

R

6

1mm Dia Hole for

future Gudgeon

Pin removal

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0011

Gudgeon Pin

Material - Silver Steel

A

A

Completed Gudgeon Pin

5.000 18.5

End Elevation

2

.

5

3

Chamfer 0.25mm

Notes-

1. The Gudgeon pin diameter should be made to a minimal

clearance to match the piston.

A 5mm Diameter Engineering Dowel pin may be

substituted for this item just cut/ grind length to suit.

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

4:1

WF46-0012

Little End Plug

Material - Bronze

A

A

Completed Plug End Elevation

Notes-

1. Test fit the plug in the gudgeon pin &

piston to ensure a sliding fit within the liner.

1.1 3

2

.

5

1

5

.

0

R

0

.

2

5

R10.5

View of Completed Liner

Title Scale:-

Drawing Number

Drawn

Date Projection

Sheet A3

The Whittaker Firefly .46 Alex Whittaker

First published in RCM&E magazine February / March 2012.

1:1

WF46-0013

Cylinder Liner

Section on A-A Front Elevation

Plan View

Material - Carbon Steel EN8M (212M36)

General Tolerance

0 DecimaI PIaces 0.5mm

1 DecimaI PIaces 0.2mm

2 DecimaI PIaces 0.1mm

3 DecimaI PIaces 0.05mm

AnguIar 0.2

A

3

5

.

2

5

28.1

0

.

7

5

1

1

.0

T

S

F

R

1

1

.0

T

S

F

R

A

21.000

45

Sectional Elevation on B-B

45

Outside Line Port Development

78.54 (25mm Dia)

Circumference

3

4

.

5

Underside of Liner Lip

11.39 15.285

Bottom edge

11.39 13.94 13.94

6.298 6.298

Section on A-A Front Elevation

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

A

Material - Aluminium alloy HE30 (6082) 3/4" (19mm) Hex Bar

Completed Carburettor Body

Plan View

2 - Holes Drill & Tap M3

Title Scale:-

Drawing Number

Drawn

Date Projection

Sheet A3

The Whittaker Firefly .46 Alex Whittaker

First published in RCM&E magazine February / March 2012.

2:1

WF46-0014

Carburettor Body

10

3

0

.

7

5

5

.

5

1

6

8

1

.

2

5

5

1

3

.

5

1

7

.

2

5

8

8

4

5

.

8

5

View on Arrow C

1

2

.

8

10.0

5.7

1 - Holes Drill & Tap M6

B B

Section on B-B

6.8

C

A

1- Hole Drill & Tap

M2.5 x 6 Deep

60

1

.5

Venturi angle cut using a

Countersink Drill

R

2

13

1

8

.

7

5

10.00

Section on A-A

Front Elevation

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

A

Material - Mild Steel or Brass

Completed Carburettor

Barrel

10.0

1 - Hole Drill & Tap M3

A

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0015

Carburettor Barrel

1 - Hole 3mm

1

2

.

6

9

.

4

5.7

Section on A-A

Front Elevation

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

A

Material - Aluminium Alloy HE30 (6082)

Completed Carb Spacer

A

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0016

Carb Barrel Spacer

1 - Hole 3mm

1

0

.

5

1

.

2

11.2

8.25

Spacer Arrangement

Futaba Servo Arm

Spacer

Plan View

Front Elevation

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Material - Brass Hex Stock

Completed Nipple

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0017

Nipple

1 - Hole 1mm through

1

9

4

.

2

5

9

.

5

A

/

F

M6 Thread

9

.

5

5

2

.

7

5

3.5

2.35

4.25

2

.

2

5

Remove Sharp Corners

10.97

ref

9

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0018

Needle Valve Body

Material - Brass

A

A

Completed Body

18.0

1

1

.

5

2

9

27

7.4 4.5

11 4

6

.

8

5

.

7

5

8.8

18

23

4

.

6

8

1

1

.

5

3.2*

1.2

4

.

5

Thread M4 x 0.5p

2 Holes 2mm

*2-Holes 3.2mm to

be a light press fit for

copper feed pipes

Notes- To be suitable for O.S Needle No.24081970

Copper feed pipes to

be a light press fit

1

.

2

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0019

Mixture Control Disc

Material - Aluminium Alloy HE30 (6082)

A

Completed Disc

8.5

1.3

1

1

.

6

24

6

.

8

11.6

1 Hole drill to

suit for clevis

2-Holes drill 1.2mm through

on an 8.2mm PCD

R

1

0

A

Section on A-A

8

.

2

Section on A-A

General Tolerance

0 Decimal Places 0.5mm

1 Decimal Places 0.2mm

2 Decimal Places 0.1mm

3 Decimal Places 0.05mm

Angular 0.2

Scale:-

Drawing Number

Drawn

Date

Title

Projection

Sheet A4

First published in RCM&E magazine February / March 2012.

The Whittaker Firefly .46 Alex Whittaker

2:1

WF46-0020

Prop Driver

Material - Aluminium

Front Elevation

A

A

Completed Driver

7.54

9

.

1

5

2

2

.

7

5

3

.

3

7

5

5.04 Key depth

1

7

.

8

Key

2.94

3

5

Serrated front face

40 off 0.3mm deep

Rear Elevation

9.15

1

1

.

5

R

1

0

6

8

0.5

Potrebbero piacerti anche

- Powerflex CatalogueDocumento75 paginePowerflex CatalogueLEDOMNessuna valutazione finora

- Workbench Multisystem 2011 (WB-MS11) ManualDocumento12 pagineWorkbench Multisystem 2011 (WB-MS11) Manualsuasponte2Nessuna valutazione finora

- Ford Old TimersDocumento25 pagineFord Old TimersJan-Erik Kaald HusbyNessuna valutazione finora

- Tapping MachineDocumento17 pagineTapping MachineALPHA INTERNET CAFE0% (1)

- E5cs R1KJX 520Documento12 pagineE5cs R1KJX 520nelsongil211Nessuna valutazione finora

- Catalog Strunguri Pentru Lemn - August 2013Documento11 pagineCatalog Strunguri Pentru Lemn - August 2013Expert Masini UnelteNessuna valutazione finora

- Manual Avance AutomaticoDocumento20 pagineManual Avance AutomaticopesyrNessuna valutazione finora

- Bombas EngrenagensDocumento76 pagineBombas EngrenagensjairmorettoNessuna valutazione finora

- Icb GBDocumento8 pagineIcb GBMoises Castillo Guerrero100% (1)

- TaigDocumento1 paginaTaigPeanut d. DestroyerNessuna valutazione finora

- Presentasi AotaiiiDocumento37 paginePresentasi Aotaiiiindo jasunNessuna valutazione finora

- Basic EFIDocumento36 pagineBasic EFIQuangvu Hoang100% (1)

- Plantas CNC de Madeira Kit 1-1 PDFDocumento15 paginePlantas CNC de Madeira Kit 1-1 PDFalexandrearume5392Nessuna valutazione finora

- Suzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveDocumento1 paginaSuzuki Samourai Repair Guides - Electronic Engine Controls - Idle Speed Control Solenoid (Iscs) ValveAymzNessuna valutazione finora

- Documentatie EMCO Compact 5 CNCDocumento3 pagineDocumentatie EMCO Compact 5 CNCFaur DanielNessuna valutazione finora

- Manual FW230 PDFDocumento16 pagineManual FW230 PDFaze20100% (1)

- Designed by Checked by Approved by Date DateDocumento1 paginaDesigned by Checked by Approved by Date DatevivianeNessuna valutazione finora

- Best IEX42Documento2 pagineBest IEX42PurcellMurrayNessuna valutazione finora

- Gamma DGT SW EngDocumento61 pagineGamma DGT SW Engt0d1sNessuna valutazione finora

- Emco Retrofit With UCN5804BDocumento12 pagineEmco Retrofit With UCN5804B63ragtopNessuna valutazione finora

- Manual TornoDocumento60 pagineManual Tornojulie2420140% (1)

- QcadCAM Tutorial enDocumento12 pagineQcadCAM Tutorial enartisanicviewNessuna valutazione finora

- Service Station Manual: SMT RCRDocumento118 pagineService Station Manual: SMT RCRRudolf PaalNessuna valutazione finora

- Unimat3 Compact5Documento1 paginaUnimat3 Compact5Peanut d. DestroyerNessuna valutazione finora

- Designed by Checked by Approved by Date DateDocumento1 paginaDesigned by Checked by Approved by Date DatevivianeNessuna valutazione finora

- Caixa Jogocilada PDFDocumento1 paginaCaixa Jogocilada PDFvivianeNessuna valutazione finora

- 02 Installation and Operating Manual 100825Documento41 pagine02 Installation and Operating Manual 100825hectorNessuna valutazione finora

- Caixa PDFDocumento1 paginaCaixa PDFvivianeNessuna valutazione finora

- Metric Tap and Drill Chart PDFDocumento1 paginaMetric Tap and Drill Chart PDFelmfp7774676Nessuna valutazione finora

- En At125 01Documento14 pagineEn At125 01Pablo SalinasNessuna valutazione finora

- Cemont 2011 Chapter 3 Mig Mag Welding239619Documento21 pagineCemont 2011 Chapter 3 Mig Mag Welding239619josechr6100% (1)

- Deckel GK Universal Engraving and Copy Milling Machines BrochureDocumento22 pagineDeckel GK Universal Engraving and Copy Milling Machines BrochureRyan Fitriawan100% (1)

- Unit 4 MTDocumento18 pagineUnit 4 MTMuthuvel M100% (1)

- Key Features: 4-Axis TB6600 CNC Driver Board Users ManualDocumento12 pagineKey Features: 4-Axis TB6600 CNC Driver Board Users ManualSalva Mancera100% (1)

- Mitsubishi Service ManualDocumento220 pagineMitsubishi Service ManualGingubaNessuna valutazione finora

- HL-Series Service Manual 96-8710 English June 1998Documento234 pagineHL-Series Service Manual 96-8710 English June 1998kumbrov100% (1)

- Ebook Tapping Away Guide To Tapping and Threading Xometry SuppliesDocumento19 pagineEbook Tapping Away Guide To Tapping and Threading Xometry SuppliesAli KhubbakhtNessuna valutazione finora

- Pivot Replacement: ChecklistDocumento7 paginePivot Replacement: Checklistottershaw57Nessuna valutazione finora

- 5-Axis CNC Machining Center With Moving Portal, Especially Designed For MillingDocumento2 pagine5-Axis CNC Machining Center With Moving Portal, Especially Designed For MillingElaine JohnsonNessuna valutazione finora

- Planos para Rack Portabotellas de VinoDocumento12 paginePlanos para Rack Portabotellas de Vinokevineli100% (1)

- 2014 Miteebite Catalog WebDocumento40 pagine2014 Miteebite Catalog WebDonald NeislerNessuna valutazione finora

- Docsity Uzam PLC Ew 22 ArticlesDocumento94 pagineDocsity Uzam PLC Ew 22 ArticlesRecep Ivedik100% (1)

- Ycl-1340 - 1440 Operation and Parts ManualDocumento42 pagineYcl-1340 - 1440 Operation and Parts ManualJacques Van NiekerkNessuna valutazione finora

- Fresadora #12Documento15 pagineFresadora #12jmtortu100% (1)

- Din 1615Documento5 pagineDin 1615David FonsecaNessuna valutazione finora

- Cambio Shimano Ultegra Di2 ManualDocumento24 pagineCambio Shimano Ultegra Di2 ManualktmairohNessuna valutazione finora

- Access Handrail StanchionsDocumento14 pagineAccess Handrail StanchionsMatthew JohnstonNessuna valutazione finora

- 90-1 Rotary Table GuideDocumento5 pagine90-1 Rotary Table GuidehdquanNessuna valutazione finora

- ACU-802 DatasheetDocumento2 pagineACU-802 DatasheetloadrpkNessuna valutazione finora

- Real Racing 3 Car Livery EditingDocumento11 pagineReal Racing 3 Car Livery Editinglh3b100% (5)

- Anyang Power HammerDocumento7 pagineAnyang Power HammeraguswNessuna valutazione finora

- Emco Compact 5Documento140 pagineEmco Compact 5Peterson Stamping100% (1)

- 2013032121504538Documento24 pagine2013032121504538zanella88Nessuna valutazione finora

- Manual em Ingles e Bem Explicado Tig 200 AcdcDocumento16 pagineManual em Ingles e Bem Explicado Tig 200 AcdcMarcelo CarnicelliNessuna valutazione finora

- Sprite Electronic TachDocumento12 pagineSprite Electronic TachshahbunafNessuna valutazione finora

- Manual Capota Golf MK1Documento20 pagineManual Capota Golf MK1Antonio_L_pez__7295Nessuna valutazione finora

- RC2095 3 1Documento1 paginaRC2095 3 1montyviaderoNessuna valutazione finora

- 06 639Documento15 pagine06 639Fernando Sabino100% (1)

- Side Elevation End View: Title Projection Sheet A4 First Published in RCM&E Magazine February / March 2012. 1:1Documento1 paginaSide Elevation End View: Title Projection Sheet A4 First Published in RCM&E Magazine February / March 2012. 1:1montyviaderoNessuna valutazione finora

- ISO Sovereign Parts ListDocumento17 pagineISO Sovereign Parts ListTiago PortanskyNessuna valutazione finora

- Propeller PullerDocumento1 paginaPropeller PullerBorralla CinzaNessuna valutazione finora

- Rudders, Stocks & Rudder PortsDocumento1 paginaRudders, Stocks & Rudder PortsBorralla CinzaNessuna valutazione finora

- Proposed Installation For Refrigeration UnitDocumento1 paginaProposed Installation For Refrigeration UnitBorralla CinzaNessuna valutazione finora

- Rudder Angle IndicatorDocumento1 paginaRudder Angle IndicatorBorralla CinzaNessuna valutazione finora

- Propeller Shaft & Hub Interchangeability DetailsDocumento1 paginaPropeller Shaft & Hub Interchangeability DetailsBorralla CinzaNessuna valutazione finora

- Rudder Carrier and ReinforcementDocumento1 paginaRudder Carrier and ReinforcementBorralla CinzaNessuna valutazione finora

- Exhaust Muffler DetailsDocumento1 paginaExhaust Muffler DetailsBorralla CinzaNessuna valutazione finora

- Location of Holes To Be Drilled in General Light FixturesDocumento1 paginaLocation of Holes To Be Drilled in General Light FixturesBorralla CinzaNessuna valutazione finora

- Navigation LightsDocumento1 paginaNavigation LightsBorralla CinzaNessuna valutazione finora

- Lines & Offsets 78ftDocumento1 paginaLines & Offsets 78ftBorralla CinzaNessuna valutazione finora

- Lines & OffsetsDocumento1 paginaLines & OffsetsBorralla CinzaNessuna valutazione finora

- Steering Gear Assembly & Details (625-660)Documento1 paginaSteering Gear Assembly & Details (625-660)Borralla CinzaNessuna valutazione finora

- Main & Intermediate StrutsDocumento1 paginaMain & Intermediate StrutsBorralla CinzaNessuna valutazione finora

- Exhaust Pipe LayoutDocumento1 paginaExhaust Pipe LayoutBorralla CinzaNessuna valutazione finora

- Alterations To Existing Type Steering WheelDocumento1 paginaAlterations To Existing Type Steering WheelBorralla CinzaNessuna valutazione finora

- Exhaust Jacket ElbowDocumento1 paginaExhaust Jacket ElbowBorralla CinzaNessuna valutazione finora

- Exhaust Muffler and FittingsDocumento1 paginaExhaust Muffler and FittingsBorralla CinzaNessuna valutazione finora

- Center Strut & Keel Bearing Wing Shaft LogDocumento1 paginaCenter Strut & Keel Bearing Wing Shaft LogBorralla CinzaNessuna valutazione finora

- Cradle Assembly & DetailsDocumento1 paginaCradle Assembly & DetailsBorralla CinzaNessuna valutazione finora

- Details of Shaft Logs, Packing Glands, Propeller Shafts & Water Tight Bulkhead SealDocumento1 paginaDetails of Shaft Logs, Packing Glands, Propeller Shafts & Water Tight Bulkhead SealBorralla CinzaNessuna valutazione finora

- 3" Seawater ScoopDocumento1 pagina3" Seawater ScoopBorralla CinzaNessuna valutazione finora

- Steering Gear LayoutDocumento1 paginaSteering Gear LayoutBorralla CinzaNessuna valutazione finora

- Steering Gear Box Variable Splined (625-660)Documento1 paginaSteering Gear Box Variable Splined (625-660)Borralla CinzaNessuna valutazione finora

- Exhaust Flapper ValvesDocumento1 paginaExhaust Flapper ValvesBorralla CinzaNessuna valutazione finora

- Battery BoxDocumento1 paginaBattery BoxBorralla CinzaNessuna valutazione finora

- Variable Steering TransmissionDocumento1 paginaVariable Steering TransmissionBorralla CinzaNessuna valutazione finora

- Rudder & Rudder Port Details (625-660)Documento1 paginaRudder & Rudder Port Details (625-660)Borralla CinzaNessuna valutazione finora

- Steering Gear Details & FittingsDocumento1 paginaSteering Gear Details & FittingsBorralla CinzaNessuna valutazione finora

- Variable Splined Gear BoxDocumento1 paginaVariable Splined Gear BoxBorralla CinzaNessuna valutazione finora

- Steering Gear LayoutDocumento1 paginaSteering Gear LayoutBorralla CinzaNessuna valutazione finora

- JHS Integrated Science Preamble, Jan 2012 - FinalDocumento15 pagineJHS Integrated Science Preamble, Jan 2012 - Finalfrank adamsNessuna valutazione finora

- Classical School of Thought: Ms. Salma ShaheenDocumento62 pagineClassical School of Thought: Ms. Salma ShaheenQasim Ali100% (1)

- AC MachinesDocumento32 pagineAC Machinesjoeney guardiarioNessuna valutazione finora

- NCP81205Documento1 paginaNCP81205Tom TomNessuna valutazione finora

- Imcp - RocketbookDocumento11 pagineImcp - Rocketbookapi-690398026Nessuna valutazione finora

- Architech 06-2016 Room AssignmentDocumento4 pagineArchitech 06-2016 Room AssignmentPRC Baguio100% (1)

- Data Analyst Chapter 3Documento20 pagineData Analyst Chapter 3Andi Annisa DianputriNessuna valutazione finora

- Project Proposal DraftDocumento1 paginaProject Proposal DraftCarl Axel M. FajardoNessuna valutazione finora

- EPA NCP Technical Notebook PDFDocumento191 pagineEPA NCP Technical Notebook PDFlavrikNessuna valutazione finora

- Lecture 08Documento32 pagineLecture 08SusovanNessuna valutazione finora

- Musk Founded Space Exploration Technologies Corporation, or Spacex, in 2002 With TheDocumento4 pagineMusk Founded Space Exploration Technologies Corporation, or Spacex, in 2002 With TheLauren Harris0% (1)

- Auburn Bsci ThesisDocumento5 pagineAuburn Bsci Thesisafksaplhfowdff100% (1)

- Drill Bit Classifier 2004 PDFDocumento15 pagineDrill Bit Classifier 2004 PDFgustavoemir0% (2)

- Ijrpr2741 Study On Investor Perception Towards Stock Market InvestmentDocumento19 pagineIjrpr2741 Study On Investor Perception Towards Stock Market InvestmentAbhay RanaNessuna valutazione finora

- Shaft DeflectionDocumento15 pagineShaft Deflectionfreek_jamesNessuna valutazione finora

- PROP CASES OUTLINE 7 - Right of Way - Light & ViewDocumento108 paginePROP CASES OUTLINE 7 - Right of Way - Light & ViewKringle Lim - DansalNessuna valutazione finora

- Micro Fibra Sintetica at 06-MapeiDocumento2 pagineMicro Fibra Sintetica at 06-MapeiSergio GonzalezNessuna valutazione finora

- I - Pronunciation Choose The Word Whose Stress Pattern Is Different From The Other Three in The Following QuestionsDocumento6 pagineI - Pronunciation Choose The Word Whose Stress Pattern Is Different From The Other Three in The Following QuestionsHaNessuna valutazione finora

- 95 935 Dowsil Acp 3990 Antifoam CompDocumento2 pagine95 935 Dowsil Acp 3990 Antifoam CompZhan FangNessuna valutazione finora

- Bill of Quantity: Supply of Pipes and FittingsDocumento3 pagineBill of Quantity: Supply of Pipes and FittingssubxaanalahNessuna valutazione finora

- ATA212001Documento3 pagineATA212001Tarek DeghedyNessuna valutazione finora

- Cambridge IGCSE Physics 0625 Complete Notes PDocumento5 pagineCambridge IGCSE Physics 0625 Complete Notes PYamikani ManthandoNessuna valutazione finora

- Paper Format IJRDTDocumento3 paginePaper Format IJRDTrock starNessuna valutazione finora

- Cases To Examine - EuthanasiaDocumento1 paginaCases To Examine - EuthanasiadamianmackytNessuna valutazione finora

- Appendicitis Case StudyDocumento6 pagineAppendicitis Case StudyKimxi Chiu LimNessuna valutazione finora

- Grange Fencing Garden Products Brochure PDFDocumento44 pagineGrange Fencing Garden Products Brochure PDFDan Joleys100% (1)

- Kobelco CK1100G Spec BookDocumento38 pagineKobelco CK1100G Spec BookEjeantengNessuna valutazione finora

- FO - Course Transition Info - Acknowledgement - SIT50422 - Dip Hospitality Management - V1Documento2 pagineFO - Course Transition Info - Acknowledgement - SIT50422 - Dip Hospitality Management - V1nitesh.kc06Nessuna valutazione finora

- Fbla Scavenger Hunt 1Documento3 pagineFbla Scavenger Hunt 1api-472648158Nessuna valutazione finora

- Federal Government Employees Housing FoundationDocumento2 pagineFederal Government Employees Housing FoundationMuhammad Shakil JanNessuna valutazione finora