Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")

Caricato da

thomasoburDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Type A Pressure Relief Valve: Standard Features Parts List (Sizes 1/2" - 2")

Caricato da

thomasoburCopyright:

Formati disponibili

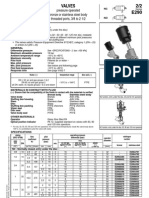

Type A Pressure Relief Valve

Standard Features

Most extensive size range in the industry U-cup seals protect spring chamber while maintaining sensitive operation Designed for fewer flow restrictions and excellent flow capacity Repaired in line, easy maintenance Stainless Steel adjustment feature provides convenient relief pressure setting in the field (Factory set at no additional charge)

Specifications Sizes: 1/2" 2" Materials: PVC and PP Models: 1) Threaded PVC 1/2" 2" PP 1/2" 1" 2) Flanged PVC 1/2" 2" PP 1/2" 2" Seals: EPDM, FKM Max.Line Pres: PVC 110 psi PP 85 psi Setting Range: PVC 5 - 100 psi PP 5 - 75 psi

Parts List (Sizes 1/2" 2")

PARTS NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 DESCRIPTION B o dy Bonnet Se a t Orifice Seal Piston Guide Bushing Bonnet Spacer Upper Spring Keeper Lower Spring Keeper Adjustment Screw Guide Spring 5/8 Washer Adjustment Screw Seal Kit 5/8 Hex Nut 1/4 Hex Screw 5/16 Hex Screw Seat Spacer Ca p Spring Housing MATERIALS PVC, PP PVC, PP PVC, PP EPDM, FKM PVC, PP PVC, PP PVC, PP PVC, PP PVC, PP 300 SS 17-7 SS Stainless Steel 316 SS EPDM, FKM 316 SS 316 SS 316 SS 316 SS PVC, PP PVC, PP

Sample Specification

All Pressure Relief Valves shall be of Thermoplastic construction, (PVC or PP) and have no metal part that comes in contact with media. PVC shall conform to ASTM D1784 Cell Classification 12454-A and PP conforming to ASTM D4101 Cell Classification PP0210B67272. PVC valves shall be rated to 110 psi sizes 1/2" thru 2" and 75 psi sizes 2-1/2" thru 4", PP rated to 75 psi sizes 1/2" thru 4" at 70 degrees F, as manufactured by Asahi/America, Inc.

Troubleshooting

What if valve does not open fully? 1. Not enough overpressure is being applied to valve. Reset. What if valve does not seat fully? 1. Foreign particles may be caught between the seat and plug. Clean seat and plug area. 2. Plug and seat may be damaged or worn. Replace plug and seat. 3. Line pressure is not below set pressure. Check line pressure and reset.

Caution

The valves are not safety devices and must not be substituted for code approved safety relief valves or rupture discs. Never remove valve from pipeline under pressure. Always wear protective gloves and goggles.

Type A Pressure Relief Valves

19

15 12 13 10 8 11 16 9 20 14 2 6 5 4 3 1

20

15 12

19

13 10 8 11 16 9

2 6 5

4 3 1

H

14

L

L

Dimensions (Thr'd 1/2" 2")

NOMINAL SIZE

INCHES

Dimensions (Flange 1/2" 2")

NOMINAL SIZE

INCHES

Ordering Information

Step 1. Determine Set Pressure (110 psi: Max. pres. rating for PVC valve) (85 psi: Max. pres. rating for PP valve) 1. Max. allowable working pressure (MAWP1) for system ______ psi: 2. Overpressure2 ______ psi: 3. Set pressure (normally 15 psi over operating pressure) ______ psi: 4. Normal operating pressure ______ psi:

1 2

L

3.36

3.74

4.33

5.51

7.09

H

9.30 9.40

9.40 12.70

13.00

L 3.36 3.74 4.33 7.48 7.87

H 9.30 9.40 9.40 12.70 13.00

mm

mm

1/2

3/4

15

20

25

40

50

1/2 3/4

15 20 25 40 50

1

1 1/2

2

1 1 1/2 2

Pressure vs. Temperature (PSI)

NOMINAL SIZE

INCHES mm

PVC

PP

30 F 71 F 106 F -5 F 71 F 141 F 70 F 105 F 120 F 70 F 140 F 175 F 110 110 75 75 75 65 85 85 65 50 45 30

MAWP: Max. safe system pressure Overpressure: Amount of additional pressure required for disc to attain full lift, and therefore, full flow capacity. The Asahi/America design attains full lift at 25% overpressure.

1/2 -1 1/2 15-40

50

Step 2. Service Conditions 1. Media: _________ % Concentration: ______ Temp: ____(F or C) 2. Ambient Temperature: ___________(F or C) 3. Pipe Size: _______Material: ________________ 4. Body Material: PVC ____ Polypropylene ____ 5. End Connections: NPT Threaded ______ 150# ANSI Flat Faced Flanges ______ 6. Downstream Pressure: __________ psig 7. Flow Rate (gpm): Normal ____________or Cv Required ______ Max _______ Mini ______

Authorized Distributor:

Aetna Plastics Corp. 1702 St. Clair Ave. Cleveland, Ohio 44114 Tel: 800-634-3074 216-781-4421 Fax: 216-781-4474 sales@aetnaplastics.com www.aetnaplastics.com

Potrebbero piacerti anche

- Gate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")Documento3 pagineGate Valve: Standard Features Type P Parts (Sizes 1-1/2" - 6")MOHAMMAD ASIFNessuna valutazione finora

- VALVULA DE SOLENOIDE HS7 BulletinDocumento4 pagineVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNessuna valutazione finora

- SRC Alpha Version1 PDFDocumento26 pagineSRC Alpha Version1 PDFRajat JainNessuna valutazione finora

- Diaphragm Valve, Metal: ConstructionDocumento4 pagineDiaphragm Valve, Metal: ConstructionDenial BasanovicNessuna valutazione finora

- Gate Valves ManualDocumento3 pagineGate Valves ManualMOHAMMAD ASIFNessuna valutazione finora

- Ratio Pressure Reducing ValvesDocumento4 pagineRatio Pressure Reducing Valveskanem1Nessuna valutazione finora

- Series 825Y Specification SheetDocumento2 pagineSeries 825Y Specification SheetFEBCONessuna valutazione finora

- Hose Technic DataDocumento28 pagineHose Technic Dataerol_ay98Nessuna valutazione finora

- Sample Engineering Specification: Customer ServiceDocumento2 pagineSample Engineering Specification: Customer ServicePooniam KanjanapatNessuna valutazione finora

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDocumento6 pagineAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNessuna valutazione finora

- Ue 24013Documento8 pagineUe 24013Johnny CormanNessuna valutazione finora

- Unique Single Seat Valve-Simply UniqueDocumento8 pagineUnique Single Seat Valve-Simply UniquelggomezupbNessuna valutazione finora

- Mangas PDFDocumento14 pagineMangas PDFluisfer811Nessuna valutazione finora

- BPS09 P PDFDocumento4 pagineBPS09 P PDFengp3077Nessuna valutazione finora

- Reg RedQ Specialy Regulators PDFDocumento20 pagineReg RedQ Specialy Regulators PDFDavid SaldarriagaNessuna valutazione finora

- Gate Valve SpecificationDocumento1 paginaGate Valve SpecificationMarkhey Alberca GarciaNessuna valutazione finora

- PVC-PP-PVDF Swing Check Valve SpecificationsDocumento4 paginePVC-PP-PVDF Swing Check Valve SpecificationsthangNessuna valutazione finora

- Albion Butterfly ValveDocumento28 pagineAlbion Butterfly ValveZein MubarakNessuna valutazione finora

- Unique SSV - Tank OutletDocumento6 pagineUnique SSV - Tank OutletlggomezupbNessuna valutazione finora

- Atomic Aquatics Ti2Documento20 pagineAtomic Aquatics Ti2aki009Nessuna valutazione finora

- 0996 en 0209Documento8 pagine0996 en 0209fagnermacedosaNessuna valutazione finora

- PW Series Wafer Check ValvesDocumento2 paginePW Series Wafer Check ValvesroadiewebNessuna valutazione finora

- 01PV0C01Documento4 pagine01PV0C01raobabar21Nessuna valutazione finora

- BusDocumento34 pagineBusernesto hidalgoNessuna valutazione finora

- Valve Color CodingDocumento4 pagineValve Color Codingesakkiraj1590Nessuna valutazione finora

- GiacominiDocumento2 pagineGiacominiflorahope4Nessuna valutazione finora

- Rotametro ABBDocumento10 pagineRotametro ABBjoticamario123Nessuna valutazione finora

- Buckling Pin BrochureDocumento12 pagineBuckling Pin Brochureharry_chemNessuna valutazione finora

- Catalogo ASCODocumento4 pagineCatalogo ASCOIkaro MatosNessuna valutazione finora

- Especificaciones Valvulas GEMU E-650-GbDocumento12 pagineEspecificaciones Valvulas GEMU E-650-GbalbetoNessuna valutazione finora

- Fischer Type 99Documento8 pagineFischer Type 99piattaformaNessuna valutazione finora

- Irrigation Solenoid ValveDocumento1 paginaIrrigation Solenoid ValveAtul KalaskarNessuna valutazione finora

- Globe Valve SpecificationDocumento1 paginaGlobe Valve SpecificationJose Alfredo Vasquez GonzalezNessuna valutazione finora

- Fisher - 98HDocumento16 pagineFisher - 98HEduardo RodriguesNessuna valutazione finora

- Pressure Reducing Valves enDocumento41 paginePressure Reducing Valves enkelvinNessuna valutazione finora

- Pressure Relief Devices For Power Transformers (With Electric Contacts)Documento8 paginePressure Relief Devices For Power Transformers (With Electric Contacts)nagpurwale2011Nessuna valutazione finora

- Water Control Valve DV-5Documento8 pagineWater Control Valve DV-5Christian FherNessuna valutazione finora

- C72H NorgrenDocumento4 pagineC72H NorgrenHernando HerreraNessuna valutazione finora

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Documento4 pagineValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNessuna valutazione finora

- A075 Valve Operation Guide PDFDocumento130 pagineA075 Valve Operation Guide PDFedhy_03Nessuna valutazione finora

- Sapag JHP Valves Jun04 enDocumento18 pagineSapag JHP Valves Jun04 enanwar01Nessuna valutazione finora

- 160.75-RP1 (210) - Yk (G)Documento92 pagine160.75-RP1 (210) - Yk (G)JayashtonNessuna valutazione finora

- 14 400E 6DC Final Valvula BermadDocumento4 pagine14 400E 6DC Final Valvula Bermadmax_powerNessuna valutazione finora

- Masoneilan - 78 Series Air Filter Regulators IOMDocumento8 pagineMasoneilan - 78 Series Air Filter Regulators IOMNithyANessuna valutazione finora

- Model PRS09i-P: In-Line Plastic Pressure Regulator (Reducing Valve)Documento5 pagineModel PRS09i-P: In-Line Plastic Pressure Regulator (Reducing Valve)engp3077Nessuna valutazione finora

- Belinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1Documento10 pagineBelinda-MAQ-300-25BA-C Computer Control Safety Valve Test Bench R.1ahsun habibNessuna valutazione finora

- OverpressureDocumento2 pagineOverpressureampowersidNessuna valutazione finora

- Valvulas Plasticas DorotDocumento8 pagineValvulas Plasticas DorotBook menNessuna valutazione finora

- Automatic Valve Gemue DB - 512 - GBDocumento6 pagineAutomatic Valve Gemue DB - 512 - GBTaher Yusuf100% (1)

- FL - Hydronic Piping SpecialtiesDocumento8 pagineFL - Hydronic Piping SpecialtiesAbdul RaheemNessuna valutazione finora

- C16601 Proinert®2 Selector ValveDocumento2 pagineC16601 Proinert®2 Selector Valvevld20082Nessuna valutazione finora

- Air Preparation ProductsDocumento6 pagineAir Preparation ProductssenamotoNessuna valutazione finora

- Fisher 1190 Low-Pressure Gas Blanketing RegulatorDocumento20 pagineFisher 1190 Low-Pressure Gas Blanketing Regulatorneurolepsia3790Nessuna valutazione finora

- Codeline, 150 PSI, Drawing - 80S15Documento3 pagineCodeline, 150 PSI, Drawing - 80S15RamanNegiNessuna valutazione finora

- MZQ-B300-25-C Computer Control Horizontal Valve Test Bench Rv.3Documento12 pagineMZQ-B300-25-C Computer Control Horizontal Valve Test Bench Rv.3ahsun habibNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Design Calc Saud It SampleDocumento25 pagineDesign Calc Saud It SampleglazetmNessuna valutazione finora

- Steel Onesteel HandbookDocumento34 pagineSteel Onesteel HandbookjlolhnpNessuna valutazione finora

- Military Standard: WL-S 2155 (A@Documento18 pagineMilitary Standard: WL-S 2155 (A@thomasoburNessuna valutazione finora

- FX 3900 PVDocumento194 pagineFX 3900 PVthomasoburNessuna valutazione finora

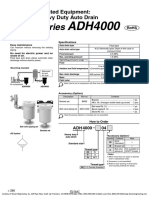

- Auto Drain 70APADH4000Documento3 pagineAuto Drain 70APADH4000thomasoburNessuna valutazione finora

- Bolting Torques - Spiral Wound GasketsDocumento1 paginaBolting Torques - Spiral Wound GasketsthomasoburNessuna valutazione finora

- 3 - SFQ Corrosion Resistant Sump PumpsDocumento1 pagina3 - SFQ Corrosion Resistant Sump PumpsthomasoburNessuna valutazione finora

- Bond Ek Design and Construction Manual June 2012Documento56 pagineBond Ek Design and Construction Manual June 2012rocketNessuna valutazione finora

- Engineering Competency StandardsDocumento11 pagineEngineering Competency StandardsRobbie van LeeuwenNessuna valutazione finora

- Varec 3650B 33-11518Documento15 pagineVarec 3650B 33-11518thomasoburNessuna valutazione finora

- Mack Ball ValvesDocumento10 pagineMack Ball ValvesthomasoburNessuna valutazione finora

- 3% Rule Sizing For PSV-Compressible FlowDocumento1 pagina3% Rule Sizing For PSV-Compressible FlowthomasoburNessuna valutazione finora

- Parker 72 00DDocumento2 pagineParker 72 00DthomasoburNessuna valutazione finora

- Heat Transfer - Transient Hyperbolic Conduction in Hollow CylinderDocumento6 pagineHeat Transfer - Transient Hyperbolic Conduction in Hollow CylinderthomasoburNessuna valutazione finora

- Atlas Metals - Carbon Steel Pipe Pressure Rating ChartDocumento4 pagineAtlas Metals - Carbon Steel Pipe Pressure Rating ChartthomasoburNessuna valutazione finora

- Air Test Gun For Tube BundlesDocumento7 pagineAir Test Gun For Tube BundlesthomasoburNessuna valutazione finora

- Eaton Hydraulic Power PackDocumento6 pagineEaton Hydraulic Power PackthomasoburNessuna valutazione finora

- Metaland KYS CatalogueDocumento96 pagineMetaland KYS CataloguethomasoburNessuna valutazione finora

- DAM DesuperheaterDocumento4 pagineDAM DesuperheaterangeloNessuna valutazione finora

- BPV and TWC - Heshka OilDocumento3 pagineBPV and TWC - Heshka OilMichael PerschkeNessuna valutazione finora

- Operation & Maintenance Manual: Prevacuum Steam Heated Autoclave With One Automatic Hinged Door Model 69150 SP-1ADocumento100 pagineOperation & Maintenance Manual: Prevacuum Steam Heated Autoclave With One Automatic Hinged Door Model 69150 SP-1AEdgarNessuna valutazione finora

- Building The John Smith Organ - Paul Senger, - 24 & 25Documento13 pagineBuilding The John Smith Organ - Paul Senger, - 24 & 25Oscar AtienzaNessuna valutazione finora

- Pressure Reducing Valve GP-2000Documento8 paginePressure Reducing Valve GP-2000Anonymous jEXSJ0ebNessuna valutazione finora

- Pig TrapsDocumento16 paginePig TrapsAntoshal100% (14)

- 15 - Pressure Relay For OLTC - (AKM - 35600 - Qualitrol)Documento5 pagine15 - Pressure Relay For OLTC - (AKM - 35600 - Qualitrol)Trần Minh TríNessuna valutazione finora

- AEGIS 1 - Aegis BrowserDocumento75 pagineAEGIS 1 - Aegis BrowserEduardoNessuna valutazione finora

- Open Center Hydraulic SystemDocumento3 pagineOpen Center Hydraulic SystemOxymoromNessuna valutazione finora

- Sealing Piping Plan (API&ANSI)Documento54 pagineSealing Piping Plan (API&ANSI)Prashanttewari100% (1)

- Norma Nfpa 2010Documento40 pagineNorma Nfpa 2010chebas2005Nessuna valutazione finora

- NGL1 V1 Sec 7Documento203 pagineNGL1 V1 Sec 7varatharajan g rNessuna valutazione finora

- Paratherm Heat TransferDocumento9 pagineParatherm Heat TransferWagus GinanjarNessuna valutazione finora

- Check ValvesDocumento44 pagineCheck ValvesOlawale John AdeotiNessuna valutazione finora

- Replace Valve Cover Gaskets W203Documento8 pagineReplace Valve Cover Gaskets W203M'hamed AbdulNessuna valutazione finora

- MFC 5800s Eng PDFDocumento50 pagineMFC 5800s Eng PDFJair EduardoNessuna valutazione finora

- Compressor Valves: Proven Designs For Highest ReliabilityDocumento11 pagineCompressor Valves: Proven Designs For Highest Reliabilitycontango O&GNessuna valutazione finora

- 11165113Documento117 pagine11165113Anonymous xFV7bg7QNessuna valutazione finora

- Roldan, MC (400 Questions)Documento68 pagineRoldan, MC (400 Questions)Couline Castillo Roldan - DinoyNessuna valutazione finora

- Ventricular Shunting ProceduresDocumento22 pagineVentricular Shunting ProceduresAndika GhifariNessuna valutazione finora

- The Pressure Test of The DBB ValveDocumento3 pagineThe Pressure Test of The DBB ValvevaliullahNessuna valutazione finora

- Manual de Operação PDFDocumento50 pagineManual de Operação PDFRogerio Nunes Marinho100% (2)

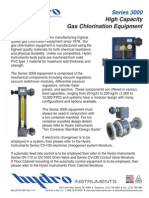

- Gas Chlorination Equipment Series 3000Documento2 pagineGas Chlorination Equipment Series 3000hfguavitaNessuna valutazione finora

- Revision Date: 22 April 2021Documento3 pagineRevision Date: 22 April 2021Reino YuNessuna valutazione finora

- Valve Guide - Inspect: Generator Set C7.1De200E Generator Set Gty C7.1 DE200E0/DE220E0 Generator Set GTY00001-UPDocumento2 pagineValve Guide - Inspect: Generator Set C7.1De200E Generator Set Gty C7.1 DE200E0/DE220E0 Generator Set GTY00001-UPbejoythomasNessuna valutazione finora

- Proportion Air Flow Controller ManualDocumento8 pagineProportion Air Flow Controller ManualRakesh RanjanNessuna valutazione finora

- Zdree 2XDocumento16 pagineZdree 2XTayfun GunalNessuna valutazione finora

- CV For Pressure Up To 50bDocumento4 pagineCV For Pressure Up To 50bmattuiffNessuna valutazione finora

- Ospb, Ospc, Ospd Open Center Steering Units OSPB Closed Center Steering UnitsDocumento28 pagineOspb, Ospc, Ospd Open Center Steering Units OSPB Closed Center Steering UnitsGiang VuNessuna valutazione finora

- Parts Catalog: 0CS10-M48401ENDocumento153 pagineParts Catalog: 0CS10-M48401ENandrelinhares01Nessuna valutazione finora