Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Id 800026 Ultramar Inc Engr Eval

Caricato da

api-242947664Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Id 800026 Ultramar Inc Engr Eval

Caricato da

api-242947664Copyright:

Formati disponibili

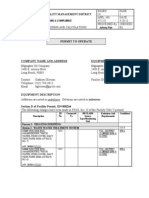

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Johnny PanYee

PAGE 1 DATE October 15, 2009 CHECKED BY:

PERMIT TO OPERATE (CHANGE OF CONDITION) COMPANY NAME, LOCATION ADDRESS Ultramar Inc. Facility ID. 800026 2402 E. Anaheim Street Wilmington CA 90744-4081 EQUIPMENT DESCRIPTION Section D of the Ultramars Facility Permit: Deletions to equipment description and conditions are shown with strikeouts. equipment description and conditions are underlined.

Equipment ID No. Connected To

RECLAIM Source Type/ Monitoring Unit

Additions or changes to

Emissions and Requirements

Conditions

Process 4: HYDROTREATING System 8: NAPHTHA HYDROTREATER/SPLITTER UNIT HEATERS HEATER, HOT OIL, 56-H-2, D430 C431 NOX: MAJOR REFINERY GAS, 200 (SCR) SOURCE; SOX: MAJOR MMBTU/HR WITH SOURCE A/N: 277667 447455 CO: 2000 PPMV (5)[RULE 407]; PM: 0.1 GRAINS/SCF (5) [RULE 409] PM: (9)[RULE 404]

P13.1 S2.1 B61.1, B61.2, D90.3, H23.5

BURNER, 15 BURNERS, REFINERY GAS, CALLIDUS, MODEL LECSGW #5, LOW NOX BURNER, 200 MMBTU/HR

B539

CONDITIONS: PROCESS CONDITIONS P13.1 All devices under this process are subject to the applicable requirements of the following rules or regulations: Contaminant Benzene 40CFR 61 Subpart FF Rule 40CFR61 Rule/Subpart SUBPART FF

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 2 DATE October 15, 2009 CHECKED BY:

SYSTEM CONDITIONS: S2.1 The operator shall limit emissions from this system as follows CONTAMINANT ROG CO PM EMISSIONS LIMIT Less than or equal to Less than or equal to Less than or equal to

34 26 76 101

LBS IN ANY ONE DAY LBS IN ANY ONE DAY LBS IN ANY ONE DAY

For the purposes of this condition, the emission limit(s) are the combined emissions from Heaters 56-H-1 and 56-H-2 measured at the outlet of the common stack when both equipment are in operation. The operator shall calculate the emission limit(s) using monthly fuel use data, and the following emission factors for Heater 56-H-1: ROG: 7.0 lbs/mmscf; CO: 17.5 lbs/mmscf; and PM: 21 lbs/mmscf. The operator shall calculate the emission limit(s) using monthly fuel use data, and the following emission factors for Heater 56-H-2: ROG: 7.0 lbs/mmscf; CO: 4.1 lbs/mmscf; and PM: 21 lbs/mmscf. In lieu of using the default emission factors whenever source test are required by this facility permit, the operator shall calculate the emissions using fuel usage during the calendar month as determined by a RECLAIM certified fuel meter and source test emission data. The source test emissions data will be converted to lb/mmcf, multiplied by the actual calendar month fuel usage, and divided by 30 to determine the daily mass emissions. RULE 1303(b)(2)-Offset, 5-10-1996 Note: The emission limits are the combined emissions from Heaters 56-H-1 and 56-H-2 since the share a common stack. Of the 26 lbs/day limit for CO, Heater 56-H-1 accounted for 11 lbs/day, while the remaining 15 lbs was attributed to Heater 56-H-2. With the new 76 lbs/day CO limit, Heater 56-H-1 accounts for 11 lbs/day, while the remaining 65 lbs is attributed to Heater 56-H-2. The 11 lbs/day CO emission limit for Heater 56-H-1 already accounts for the CO emission factor change which was permitted back in 2007 under A/N 447454.

DEVICE CONDITIONS: B. Material/Fuel Type Limits

B61.1 The operator shall only use fuel gas containing the following specified compounds: Compound Sulfur ppm by volume less than 100

RULE 1303(a)(1)-BACT, 5-10-1996

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 3 DATE October 15, 2009 CHECKED BY:

B61.2 The operator shall not use fuel gas containing the following specified compounds: Compound H2S ppm by volume greater than

160

40CFR 60 Subpart J, 10-4-1991 D. Monitoring and Testing Requirements

D90.3 The operator shall continuously monitor the H2S concentration in the fuel gas before being burned in this device according to the following specifications: The operator shall use an NSPS Subpart J approved instrument meeting the requirements of 40CFR60 Subpart J to monitor the parameter. The operator shall also install and maintain a device to continuously record the parameter being monitored. The operator may monitor the H2S concentration at a single location for fuel combustion devices, if monitoring at this location accurately represents the concentration of H2S in the fuel gas being burned in this device. [40CFR 60 Subpart J, 6-24-2008] H. Applicable Rules

H23.5 This equipment is subject to the applicable requirements of the following rules or regulations: Contaminant H2S Rule 40CFR60, SUBPART Rule/Subpart J

40CFR 60 Subpart J, 10-4-1991

COMPLIANCE RECORD REVIEW A check of the AQMD Compliance Database shows that this facility was issued 18 notices of violation (NOVs) and no Notices to Comply (NCs) since January 1, 2007. No NOVs have been issued to this heater in the past two years.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 4 DATE October 15, 2009 CHECKED BY:

BACKGROUND Ultramar (Wilmington) Refinery operates several process heaters. On August 5, 2005, the refinery submitted the following application listed in Table 1 to modify the CO emission limit and emission factor currently in a permit condition S2.1 for heater 56-H-2. Table 1: AQMD Applications Submitted A/N

447455 Date Submitted 08/05/2005

Equipment

Heater, 56-H-2 (D430)

Type

60

Status

21

Previous A/N

277667/ F62074 n/a

494183

12/17/2008

RECLAIM/Title V Permit Revision

86

21

Note: Ultramar submitted 4 applications (A/Ns 447453-447456) for 4 different heaters to change the CO emission limit and emission factor. The Permits to Operate for A/N 447453, 447454, and 447456 were issued in 2007.

FEE SUMMARY Table 2 : Fee Summary A/N

447455 494183

Equipment

Heater, 56-H-2 (D430) RECLAIM/Title V Permit Revision

Type

60 86

Schedule

Fee Required, $

$3,518.07 $1,687.63

Fee Submitted, $

$3,518.07 $1,687.63

C C

HISTORY Heater 56-H-2 (Device D430) is rated at 200 mmBtu/hr and burns refinery gas. This heater heats hot oil for the Naphtha Hydrotreater/Splitter Unit 56 and Debutanizer Unit 63 reboilers . The NOx emissions from this heater are controlled by low NOx burners and a Selective Catalytic Reduction (SCR) unit (common to Heater 56-H-1, D429). It is a Major Source RECLAIM NOx and SOx source. The maximum operating schedule is 24 hours per day, 7 days per week, and 52 weeks per year. This heater was originally constructed under A/N 277667 due to the Reformulated Fuels Project mandated by EPAs 1990 Clean Air Act Amendments and CARBs California Clean Air Act (a.k.a., Clean Fuels Project) in the early 1990s. The Permit to Operate was issued to Heater 56-H-2 in 2003 under permit # F62074. Heater 56-H-2 was constructed in conjunction with the new Naphtha Hydrotreater (NHT)/Splitter Unit 56 and new Naphtha Hydrotreater Heater 56-H-1 (A/N 447454,

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 5 DATE October 15, 2009 CHECKED BY:

Permit # F93443). The Naphtha Hydrotreater/Splitter Unit pretreats the straight run and purchased naphtha to remove sulfur and nitrogen impurities. The hydrotreated stream will then be routed through the Splitter column. The light ends, which contain the benzene precursors, will be taken off the top of column and used as a gasoline blending component. The heavy ends will be fed to the Reformer. Heater 56-H-1 provides preheat to the naphtha charge and is rated at 30 mmBtu/hr. Heater 56-H-2 is rated at 200 mmBtu and heats hot oil for use as transfer fluid in the Naphtha Hydrotreater/Splitter unit reboilers, stripper, and rerun and Debutanizer reboilers. The two units vent to a common SCR (A/N 281826) providing NOx control for the combined exhaust. During the Permit to Construct phase (A/N 277667) of Heater 56-H-2, Ultramar noted that approximately 86% of the heat provided by Heater 56-H-2 would be used in the Naphtha Hydrotreater/Splitter unit. The remaining 14% would be used for the Debutanizer reboilers, which is not part of the Clean Fuels Project. In July 2003, Ultramar submitted A/N 419147 proposing to modify Heater 56-H-2 by increasing the rating from 200 mmBtu/hr to 260 mmBtu/hr. A/N 419147 was submitted as part of the Alkylation Improvement Project (a.k.a., Reduced Volatility Alkylation Process, ReVAP). The Permit to Construct to A/N 419147 was issued on December 16, 2004. However, during construction of the ReVAP project, Ultramar realized they would not be modifying Heater 56-H-2 and had no plans to upgrade the heater. As a result, A/N 419147 was subsequently cancelled. Permit # F62074 (A/N 277667) remains the latest active permit for Heater 56-H-2.

CHANGE OF CONDITION EVALUATION: There will be no changes to the operation or physical design of the heater. Heater 56-H-2 is rated at 200 mmBtu and heats hot oil for use as transfer fluid in the Naphtha Hydrotreater/Splitter unit reboilers, stripper, and rerun and Debutanizer reboilers. The refinery is requesting a change to the CO emission factor and CO mass emission limits listed in the permit condition to better reflect the emissions. Ultramar is requesting that the CO mass emission limit listed on Condition S2.1 to be changed from 26 to 76 lbs in any one day. The new emission limit is based on a 17.5 lbs/mmscf emission factor, which is a change from the 4.1 lbs/mmscf emission factor currently listed on their permit. Note that the emission limit in Condition S2.1 represents the combined emissions from Heaters 56-H-1 and 56H-2.

S2.1 THE OPERATOR SHALL LIMIT EMISSIONS FROM THIS SYSTEM AS FOLLOWS CONTAMINANT ROG CO PM EMISSIONS LIMIT LESS THAN OR EQUAL TO 37 LBS IN ANY ONE DAY LESS THAN OR EQUAL TO 26* 76 LBS IN ANY ONE DAY LESS THAN OR EQUAL TO 113 LBS IN ANY ONE DAY

The operator shall calculate the emission limit(s) using monthly fuel use data, and the following emission factors: ROG: 7.0 lbs/mmscf; CO: 4.1 17.5 lbs/mmscf; and PM: 21 lbs/mmscf.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 6 DATE October 15, 2009 CHECKED BY:

* Of the 26 lbs/day for CO currently listed on Condition S2.1, Heater 56-H-1 accounted for 11 lbs/day, while the remaining 15 lbs was attributed to Heater 56-H-2. This new CO emission limit is derived from a ratio of the previous emission factor used (4.1 lbs/mmscf) with the new emission factor (17.5 lbs/mmscf). This will ensure there is no actual increase of fuel usage with this change of condition. Heater 56-H-2 rating = 200 mmBtu/hr Refinery gas higher heating value = 1,300 Btu/scf Old CO emission factor = 4.1 lbs/mmscf

Previous CO emissions from 56-H-2 =

scf 200 mmBtu 4.1 lbs * * * hr mmscf 1,300 Btu

24 hrs day

= 15.14 lbs/day

New CO emissions from 56-H-2 =

15.14 lbs/day * 4.1 lbs/mmscf

17.5 lbs/mmscf = 64.62 lbs/day

Additional CO emissions = 64.62 lbs/day 15.14 lbs/day = 49.5 lbs/day Revised CO emission limit for Condition S2.1: 26 lbs/day + 49.5 lbs/day = 75.5 lbs/day

The 4.1 lb/mmscf CO emission factor was a default District factor used by Ultramar and many other refineries since the 1980s. However, recent source tests conducted by Ultramar has shown that the CO emission factor are higher than 4.1 lb/mmscf. Therefore, Ultramar would exceed the CO mass emission limit found in conditions S2.1 if emission factor were to remain at 4.1 lb/mmcf. In submitting the change of condition applications, Ultramar has requested that the emission factor be changed to 17.5 lb/mmscf. Ultramar chose the 17.5 lb/mmcf CO emission factor since it is half of the Districts Annual Emissions Reporting (AER) Program CO default emission factor for natural gas (35 lb/mmcf). Ultramar has committed to using this emission factor in calculating the CO emissions for all their process heaters. Beginning in the year 2004-2005 AER Program, they have used the 17.5 lbs/mmscf emission factor for calculating the CO in Form R2 (Permitted Annual Emissions from Fuel Combustion Refinery). In reviewing the most recent CO emission factors for process heater reported on Form R2 of the Annual Emissions Reporting (AER) Program for each refinery, the CO emission factors are as follows:

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 7 DATE October 15, 2009 CHECKED BY:

Table 3. AER CO Emission Factors Reported on Form R2 CO Emission Factor, lb/mmcf

BP/ARCO

ID. 131003 Ultramar ID. 800026 Chevron ID. 800030

ExxonMobil

AER Year

ID. 800089

Paramount ID. 800183

ConocoPhillips

ConocoPhillips

ID. 800362

ID. 800363

Tesoro ID. 800436 Equilon ID. 800370

2003-2004 2004-2005 2005-2006 2006-2007

7/1/200712/31/2007

1.88 3.75 4.32 4.31 7.55 10.31

4.1 17.5 17.5 17.5 17.5 17.5

* 35 35 35 * 35

37.18 34.57 34.57 30.51 28.88 20.46

* * 35 35 85 35

* 84 84 84 35 35

84 84 84 84 35 35

4.1 4.1 4.1 4.1 35 35

2008

* Could not find

As shown in Table 3, Chevron, Paramount, ConocoPhillips (Carson and Wilmington), and Tesoro currently report annual emissions using the Districts AER CO default emission factor for natural gas of 35 lb/mmcf. Both ConocoPhillips refineries used EPAs AP42 CO emission factor for natural gas of 84 lbs/mmcf from 2004-2007. Beginning 7/1/2007-12/31/2007, they used the Districts AER CO default emission factor for natural gas of 35 lb/mmcf. BP ARCO and ExxonMobil use source test data to derive their CO emission factors. Only Tesoro (previously, Equilon) used the 4.1 lb/mmcf emission factor between 2003-2007. Beginning 7/1/2007-12/31/2007, Tesoro used the Districts AER CO default emission factor for natural gas of 35 lb/mmcf.. Ultramar was using the 4.1 lb/mmcf emission factor up until Year 2003-2004. For the year 2004-2005 AER, they have been using the higher 17.5 lbs/mmcf CO emission factor. Recent source tests conducted on various heaters (not necessarily the heater in which a change of CO emission factor is requested) at Ultramar show the CO emissions from as low as 1.87 lbs/mmscf to as high as 21.59 lb/mmscf. Ultramar chose the 17.5 lb/mmcf CO emission factor since it is half of the Districts AER CO default emission factor for natural gas (35 lb/mmcf). Since the AER program allows a facility to use the emission factor which most accurately reflects the emissions from the equipment, it is recommended that Ultramar be allowed to use 17.5 lbs/mmcf as the CO emission factor for their heaters.

EMISSIONS: With the greater CO emission factor of 17.5 lbs/mmcf, the daily emission will undoubtedly increase from what was previously calculated. Table 4 is summary of the emission increase.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 8 DATE October 15, 2009 CHECKED BY:

Table 4. CO Emission Comparison A/N 277667

(previous application)

Heater Rating, mmBtu/hr 200

CO Emission Factor, lb/mmcf 4.1 17.5

CO Emission, lb/day 15.14* 64.62

Increase, lbs/day

447455

+50

* In NSR, the CO emissions are listed as 17 lbs/day. These emissions were based on the lower heating value (LHV) of 1,150 Btu/scf. The higher heating value (HHV) should have been used. Based on the HHV of 1,300 Btu/scf, the CO emissions are 15.14 Btu/scf Table 5. Total Emissions for Heater 56-H-2 Pollutant CO NOx SOx ROG PM10 lbs/hr 2.69 3 2.94 1.22 3.65 lbs/day 64.62 72 70.6 29.3 87.6

The emissions for NOx, SOx, ROG, and PM10 are unchanged.

RULE EVLAUATION: PART 1 SCAQMD REGULATIONS

Rule 212

Standards for Approving Permits

November 14, 1997

In accordance with Rule 219(c), a significant project is a new or modified facility in which: (1) the new or modified permit unit is located within 1000 feet of a school; (2) the new or modified facility has on-site emission increases exceeding the daily maximum specified in subdivision (g); or (3) the new or modified permit unit has an increased cancer risk greater than, or equal to, one in a million (1x 10-6) during a lifetime of 70 years or pose a risk of nuisance. This change of condition is not considered a significant project under this rule since the permit unit is not being modified and is:

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 9 DATE October 15, 2009 CHECKED BY:

Rule 212

Standards for Approving Permits

November 14, 1997

(1) are not located within 1,000 feet of a school; (2) do not exceed the daily maximum specified in subdivision (g); or (3) do not increase the cancer risk greater than, or equal to, one in a million (1x 10-6). Therefore, a public notice is not required.

Rule 401

Visible Emissions

November 9, 2001

Visible emissions are not expected under normal operating conditions.

Rule 402

Nuisance

May 7, 1976

Nuisance complaints associated with the above project are not expected under normal operating conditions.

Rule 404

Particulate Matter-Concentration

February 7, 1986

This rule sets forth particulate mater emission standards based on the gas discharge rate. Normally, equipment which fires on gaseous fuel can be meet these standards. This heater is fired on refinery gas only, therefore compliance is expected.

Rule 409

Liquid and Gaseous Air Contaminants

August 7, 1981

This rule limits CO emissions to 2,000 ppm. A source test performed in June 2005 showed the actual measured CO concentration to be 2.05 ppmv corrected to 3% oxygen, which is well below 2,000 ppm. Therefore, compliance is expected.

Rule 431.1

Sulfur Content Of Gaseous Fuels

June 12, 1998

Ultramar is a SOx RECLAIM facility. In accordance with Rule 2001(j), Rule 431.1 was subsumed by RECLAIM. Therefore, the SOx limits do not apply to this facility.

Rule 1123

Refinery Process Turnarounds

December 7, 1990

This process unit is subject to the turnaround requirements of this rule. Ultramar currently keeps records of the process unit turnaround and is expected to comply with this rule.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 10 DATE October 15, 2009 CHECKED BY:

Rule 1146

Emissions of Oxides of Nitrogen From Industrial, Institutional, And Commercial Boilers, Steam Generators, And Process Heaters

September 5, 2008

This rule applies to boilers, steam generators, and process heaters of equal to or greater than 5 million Btu per hour rated heat input capacity used in all industrial, institutional, and commercial operations with the exception of: (1) (2) (3) Boilers used by electric utilities to generate electricity; and Boilers and process heaters with a rated heat input capacity greater than 40 million Btu per hour that are used in petroleum refineries; and Sulfur plant reaction boilers.

Heater 56-H-2 is rated at 200 mmBtu/hr and is therefore not subject to this rule. New Source Review December 6, 2002 (Application deem complete date: 2006)

REG XIII

NSR does not apply to this heater for CO. On June 11, 2007, EPA re-designated the South Coast Air Basin (SCAB) as attainment with respect to CO National Ambient Air Quality Standards (NAAQS). Since AQMD was already attainment with State standards and NAAQS for the rest of basin, and CO is not identified as a precursor to any nonattainment pollutants in Regulation XIII, the requirements of Regulation XIII (Rule 1303) do not apply to any new or modified source with a net emission increase in CO. In accordance with Mohsen Nazemis August 14, 2007 memo regarding PSD Delegation, no CO offsets will be required in the form of ERCs and no NSR codes from the Priority Reserve or Rule 1304 exemptions to offset emission increases for CO should be used for all new permits issued for equipment with CO emission increases. Since the NSR system requires any CO emission increases to be offset prior to granting approval to a permit, the exemption code 1301(b)(1)-12/07/95-General [NSR] attainment air contaminant will be used to account for any emission increases of CO. Although the heater is not subject to NSR for CO, below is a summary of the emissions entered in NSR for the previous and current application: Table 6. Heater 56-H-2 NSR CO Emissions A/N Hourly, lbs/hr 0.71 2.71 CO Emissions 30-avg, Exempt, lbs/day lbs/day 17 15 65 65 Non-Exempt, lbs/day 2* ---

277667

(previous application)

447455

* Ultramar provided 2 lbs/day CO ERCs in 1993.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 11 DATE October 15, 2009 CHECKED BY:

Rule 1401

New Source Review of Toxic Air June 5, 2009 Contaminants Application Deem Complete Date: 2006 Rule 1401 should not apply to this change of condition since this rule applies to new, relocated, and modified permit units. Rule 1401(c)(9) defines modification as any physical change in, change in method of operation, or addition to an existing permit unit that requires an application. Therefore, since this change in condition is not a modification according to Rule 1401(c)(9), Rule 1401 does not apply in this case. There is no change in NOx and SOx emissions due to the change of condition. This change of condition is to reflect actual operating conditions. The current CO emission limits are based on an emission factor of 4.1 lb/mmcf, which was found to be extremely low. Source tests have shown that the CO emission factor to be as high as 21.59 lb/mmscf. The 17.5 lb/mmcf emission factor is a better representation of the CO emissions than the 4.1 lb/mmcf factor currently being used. Prevention of Significant Deterioration (PSD) October 7, 1988

REG XVII 1701(b)Applicability

Upon delegation by EPA, this regulation applies to preconstruction review of stationary sources that emit attainment air contaminants. On June 11, 2007, EPA re-designated the South Coast Basin as attainment with respect to CO National Ambient Air Quality Standards (NAAQS). Since the heater emits CO (an attainment air contaminant) and is located in the South Coast Basin, it is subject to PSD review. BACT. As noted in the Emissions section, there is no net emission increase in potential to emit (PTE) emissions. Had the higher CO emission factor been used to calculate the emissions from the previous application, the PTE would remain the same. This change of condition does not result in a change in the method of operation. This change of condition is to update the CO emission factor to better reflect emissions from the heater. The current CO emission limits are based on an emission factor of 4.1 lb/mmcf, which was found to be extremely low. The 17.5 lb/mmcf emission factor is a better representation of the CO emissions than the 4.1 lb/mmcf factor currently being used. Therefore, BACT does not apply to this change of condition since there no increase in PTE emissions. The requirements of this regulation apply to the following stationary sources: (A) Increase in Potential to Emit. The modification proposed at this existing source will not increase the potential to emit greater than 100 tons of CO per year. (B) Significant Emission Increase. Rule 1702(s) defines a significant emission increase of CO as an increase greater than 100 tons per year. Although the potential emissions does not change, the change in emission factor will increase the permitted CO emissions from 2.76 tons per year to 11 tons per year. Therefore, the emission factor change is not

1701(b)(1)

1701(b)(2)

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 12 DATE October 15, 2009 CHECKED BY:

REG XVII

Prevention of Significant Deterioration (PSD) considered a significant increase for CO.

October 7, 1988

(C) Class I Area. The refinery is not located within 10 km of a Class I area. Therefore, the requirements of this regulation do not apply to this heater change of condition. 1701(b)(3) Major Stationary Source. Since the source does not meet any of the conditions of subparagraph (b)(2), it is not considered a major stationary source with a significant increase.

Rule 2005

New Source Review for RECLAIM

April 20, 2001 Application Deem Complete Date: 2006

Since no increase in NOx and SOx emission is expected, these applications are not subject to NSR.

Regulation XXX

Title V

March 16, 2001

Ultramar is a designated as a Title V facility. The facilitys Title V permit has been issued. Therefore, the facility is subject to the requirements of Reg XXX. This application is subject to the requirements of a DeMinimis Significant Revision.

PART 2

STATE REGULATIONS

California Environmental Quality Act (CEQA) According to the Districts CEQA guidelines, the thresholds for significant effect are: NOx ROG PM10 CO SOx 55 pounds per day 55 pounds per day 150 pounds per day 550 pounds per day 150 lbs per day

Based on the emissions shown in Emissions section, this proposed change of condition is not a significant project. Therefore, preparation of a CEQA document is not required.

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 13 DATE October 15, 2009 CHECKED BY:

PART 3

FEDERAL REGULATIONS

Regulation IX: Standards of Performance for New Stationary Sources (NSPS)

Subpart J 60.100

Standards of Performance for Petroleum Refineries Applicability, designation of affected facility, and reconstruction. Since the heater is a fuel combustion device, the heater is subject to this subpart. Standards for sulfur oxides. The operator shall not burn in the heater any fuel gas that contains hydrogen sulfide (H2S) in excess of 230 mg/dscm (0.10 gr/dscf)*. Ultramar operates two H2S CEMS on their fuel gas system. A check of the H2S CEMS data recorded shows the daily average H2S was well below 160 ppm. Therefore, the refinery complies with this subpart. Monitoring of emissions and operations. Ultramar operates two H2S CEMS on their fuel gas system. The 88-AI-942 CEMS analyzes all treated fuel gas that is normally used within the refinery for heater and boiler fuel gas combustion and other process purposes. The 88-AI-945 CEMS analyzes all treated fuel gas that is normally sent directly to the flare for combustion purposes. Each of these analyzers was installed to demonstrate compliance with 40CFR 60.104(a)(1) and 60.105(a)(4)-Monitoring of emissions and operations.

60.104(a)(1)

60.105(a)(4)

*160 ppm Regulation X: National Emission Standards for Hazardous Air Pollutants (NESHAPS)

Subpart DDDDD 63.7485

National Emission Standards for Hazardous Air Pollutants for Industrial, Commercial, and Institutional Boilers and Process Heaters Am I subject to this subpart? A facility is subject to this subpart if it operates an industrial, commercial, or institutional boiler or process heater as defined in 63.7575 that is located at, or is part of, a major source of HAP as defined in 63.2. 63.7575 defines Large gaseous fuel subcategory as any watertube boiler or process heater that burns gaseous fuels not combined with any solid fuels, burns liquid fuel only during periods of gas curtailment or gas supply emergencies, has a rated capacity of greater than 10 MMBtu per hour heat input, and has an annual capacity factor of greater than 10 percent. Therefore, the heater operated at Ultramar is subject to this subpart. What is the affected source of this subpart? The heater is considered an existing source since it is not new or reconstructed. When do I have to comply with this subpart? Existing heater must comply with this subpart no later than September 13, 2007.

63.7490

63.7595(b)

SOUTH COAST AIR QUALITY MANAGEMENT DISTRICT ENGINEERING & COMPLIANCE APPLICATION PROCESSING AND CALCULATIONS

PAGES 14 APPL. NO.

447455

PROCESSED BY: Connie Yee

PAGE 14 DATE October 15, 2009 CHECKED BY:

RECOMMENDATION: Issue a Permit to Operate with the conditions listed in the Conditions Section.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- About The Dyes: Dyes For Cellulose FibersDocumento4 pagineAbout The Dyes: Dyes For Cellulose FibersmanqabatNessuna valutazione finora

- Astm A681 PDFDocumento14 pagineAstm A681 PDFraulNessuna valutazione finora

- Exxonmobil Statement of BasisDocumento49 pagineExxonmobil Statement of Basisapi-242947664Nessuna valutazione finora

- BiochemistryDocumento410 pagineBiochemistryCaptainReeham79% (14)

- The Concrete Producer Article PDF - Comparing The Options For Cooling ConcreteDocumento4 pagineThe Concrete Producer Article PDF - Comparing The Options For Cooling Concretearangar1100% (1)

- Parker O-Ring Material Guide-2008Documento72 pagineParker O-Ring Material Guide-2008Ian Pillay50% (2)

- ISO 17746-2016 Steel Wire Rope Net Panels and RollsDocumento24 pagineISO 17746-2016 Steel Wire Rope Net Panels and RollsOctavian Miclescu100% (1)

- 1097 2301 Univar E Detergents Nordic Brochure 4Documento12 pagine1097 2301 Univar E Detergents Nordic Brochure 4troity100% (2)

- HBD - Hearing Board Cases - 5-21-2004 - HB Case 5425-3 Kinder Morgan PetitionDocumento9 pagineHBD - Hearing Board Cases - 5-21-2004 - HB Case 5425-3 Kinder Morgan Petitionapi-242947664Nessuna valutazione finora

- Denatured Ethanol Storage TankDocumento2 pagineDenatured Ethanol Storage Tankapi-242947664Nessuna valutazione finora

- Transmix PermitDocumento3 pagineTransmix Permitapi-242947664Nessuna valutazione finora

- New and Current ResumeDocumento3 pagineNew and Current Resumeapi-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 12-10-2004 - HB Case 5425-3 Kinder Morgan Final DispositionDocumento6 pagineHBD - Hearing Board Cases - 12-10-2004 - HB Case 5425-3 Kinder Morgan Final Dispositionapi-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Map 1Documento2 pagineHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Map 1api-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 7-7-2004 - HB Case 5425-3 Kinder Morgan Tank Inventory-EditedDocumento10 pagineHBD - Hearing Board Cases - 7-7-2004 - HB Case 5425-3 Kinder Morgan Tank Inventory-Editedapi-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 6-16-2004 - HB Case 5425-3 - Fac Id 107042 - Name Kinder Morgan Li-1Documento94 pagineHBD - Hearing Board Cases - 6-16-2004 - HB Case 5425-3 - Fac Id 107042 - Name Kinder Morgan Li-1api-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan NoticeDocumento3 pagineHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Noticeapi-242947664Nessuna valutazione finora

- Edgington Oil Id 800264 An 477953 Eng EvalDocumento7 pagineEdgington Oil Id 800264 An 477953 Eng Evalapi-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Aerial Photo 1Documento1 paginaHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Aerial Photo 1api-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Facility Plot 1Documento1 paginaHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Facility Plot 1api-242947664Nessuna valutazione finora

- HBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan NovDocumento1 paginaHBD - Hearing Board Cases - 5-25-2004 - HB Case 5425-3 Kinder Morgan Novapi-242947664Nessuna valutazione finora

- Id 131003 BP West Coast Products - Carson - Eng Eval An 462618-2Documento10 pagineId 131003 BP West Coast Products - Carson - Eng Eval An 462618-2api-242947664Nessuna valutazione finora

- Id 800026 Ultramar Inc Engr Eval Ans 465213-216Documento22 pagineId 800026 Ultramar Inc Engr Eval Ans 465213-216api-242947664Nessuna valutazione finora

- Id 800183 Paramount Petroleum Corp - Engr Eval Ans 515155 515312Documento20 pagineId 800183 Paramount Petroleum Corp - Engr Eval Ans 515155 515312api-242947664Nessuna valutazione finora

- Id 800264 Edgington Oil - Engr Eval An 471110 471112 ADocumento12 pagineId 800264 Edgington Oil - Engr Eval An 471110 471112 Aapi-242947664Nessuna valutazione finora

- Id 800264 Edgington Oil - Engr Eval An 471105 471107 471109Documento12 pagineId 800264 Edgington Oil - Engr Eval An 471105 471107 471109api-242947664Nessuna valutazione finora

- Id 800183 Paramount Petroleum Corp - Engr Eval An 526347Documento14 pagineId 800183 Paramount Petroleum Corp - Engr Eval An 526347api-242947664Nessuna valutazione finora

- Id 800436 Tesoro Refining and Marketing Co - Engr Eval An 474150 EditedDocumento9 pagineId 800436 Tesoro Refining and Marketing Co - Engr Eval An 474150 Editedapi-242947664Nessuna valutazione finora

- Id 800436 Tesoro Refining Marketing Co-La Refinery - Engr Eval An 470285 470286Documento15 pagineId 800436 Tesoro Refining Marketing Co-La Refinery - Engr Eval An 470285 470286api-242947664Nessuna valutazione finora

- Id 800026 Ultramar Inc - Engr Eval Ans 526586 526261Documento71 pagineId 800026 Ultramar Inc - Engr Eval Ans 526586 526261api-242947664Nessuna valutazione finora

- Edgington Oil Id 800264 An 471225 Eng EvalDocumento14 pagineEdgington Oil Id 800264 An 471225 Eng Evalapi-242947664Nessuna valutazione finora

- Reg Review of Eng Eval For Application No 475623 475624 FCC Bypass SCR - Waste Heat Boiler 2f-7Documento11 pagineReg Review of Eng Eval For Application No 475623 475624 FCC Bypass SCR - Waste Heat Boiler 2f-7api-242947664Nessuna valutazione finora

- Edgington Public NoticeDocumento2 pagineEdgington Public Noticeapi-242947664Nessuna valutazione finora

- Id 800264 Edgington Oil Company - Epa Cover Letter An 471226-232Documento2 pagineId 800264 Edgington Oil Company - Epa Cover Letter An 471226-232api-242947664Nessuna valutazione finora

- Exxonmobil 800089 340343 040909 Public Notice EnglishDocumento2 pagineExxonmobil 800089 340343 040909 Public Notice Englishapi-242947664Nessuna valutazione finora

- Id Exxonmobil Oil Corp - Facility Letter - Final Initial Title VDocumento6 pagineId Exxonmobil Oil Corp - Facility Letter - Final Initial Title Vapi-242947664Nessuna valutazione finora

- 008x TF-compressed PDFDocumento66 pagine008x TF-compressed PDFJosé Francisco Blanco VillalbaNessuna valutazione finora

- 10th STD Science Carbon and Its Compounds Lesson Plan Eng Version 2017-18Documento5 pagine10th STD Science Carbon and Its Compounds Lesson Plan Eng Version 2017-18vijos16655Nessuna valutazione finora

- Kolorsafe Liquid Acid Neutralizer - SDS - NA - 012115 - FINALDocumento8 pagineKolorsafe Liquid Acid Neutralizer - SDS - NA - 012115 - FINALJUAN FELIPE ORTIZ PARRANessuna valutazione finora

- 6 9500 F Axera 7 240 PDFDocumento4 pagine6 9500 F Axera 7 240 PDFsegomezpNessuna valutazione finora

- Precipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceDocumento4 paginePrecipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceJose Anisio SilvaNessuna valutazione finora

- Evacuated Tube SystemDocumento2 pagineEvacuated Tube SystemAaron James RuedasNessuna valutazione finora

- Bermad Strainer Model BC-70F-P: Buildings & ConstructionDocumento2 pagineBermad Strainer Model BC-70F-P: Buildings & ConstructionGuillermo GuzmánNessuna valutazione finora

- Lecture - 3 - Heat and The First Law Example ProblemsDocumento22 pagineLecture - 3 - Heat and The First Law Example ProblemsifiokNessuna valutazione finora

- Class 9 Matter in Our Surroundings McqsDocumento3 pagineClass 9 Matter in Our Surroundings McqsHariharan VIIA1Nessuna valutazione finora

- HDA Simulation Laboratory - 054330Documento18 pagineHDA Simulation Laboratory - 054330Fussy Taksn100% (1)

- Chapter 03 AnnotDocumento4 pagineChapter 03 AnnotNur Amira Mardiana ZulkifliNessuna valutazione finora

- Experiment 7Documento4 pagineExperiment 7Edon EduinNessuna valutazione finora

- Basic Mechanical Engineering MCQ PDF Part 3Documento10 pagineBasic Mechanical Engineering MCQ PDF Part 3kibrom atsbhaNessuna valutazione finora

- Molecular Orbital Theory Multiple Choice QuestionsDocumento3 pagineMolecular Orbital Theory Multiple Choice QuestionsRasel Islam100% (3)

- 4) Ultrahib Msds EngDocumento8 pagine4) Ultrahib Msds EngJose AlejandroBlancoNessuna valutazione finora

- Noble Gases 20 Aug 2022Documento2 pagineNoble Gases 20 Aug 2022PLABAN DASNessuna valutazione finora

- SRS 400 A 475 GPMDocumento12 pagineSRS 400 A 475 GPMrhusseinpos4765Nessuna valutazione finora

- TGN-M-04 Weld Procedure Comparison Struc SteelDocumento5 pagineTGN-M-04 Weld Procedure Comparison Struc Steelmanoj983@gmail.comNessuna valutazione finora

- Ladder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DateDocumento2 pagineLadder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DatesantoshjayantiNessuna valutazione finora

- Emerging Pollutants in The EnvironmentDocumento10 pagineEmerging Pollutants in The EnvironmentVita Maryam H.Nessuna valutazione finora

- Chemical CarcinogenesisDocumento24 pagineChemical CarcinogenesisKavitha S DineshNessuna valutazione finora

- MATERIAL TAKE-OFF LIST FOR SAUDI ARABCO GAS PROJECTDocumento12 pagineMATERIAL TAKE-OFF LIST FOR SAUDI ARABCO GAS PROJECTrajum465Nessuna valutazione finora

- ADAGEDocumento32 pagineADAGEDSGNessuna valutazione finora