Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

How A Power Supply Works

Caricato da

perkinsc305Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

How A Power Supply Works

Caricato da

perkinsc305Copyright:

Formati disponibili

Understanding Electronics

www.kitronik.co.uk

Power Supplies

Kitronik Ltd How a Power Supply Works External power supplies used with electronic products

Battery eliminators

A battery eliminator or adjustable power supply is a device that can be used in place of batteries. It takes mains AC power and converts it to 3v, 4.5v, 6v, 9v or 12v DC allowing an equivalent voltage to be supplied for various different numbers of batteries. The selection of the voltage is normally done by turning a small control on the case of the power supply. Adjustable power supplies are usually sold with a range of adapters allowing them to connect to most electronic equipment (provided they have a power in connection).

External power supplies

When an electronic product is sold with a power supply, this supply will be fixed to one voltage and one connector. This will make it a little cheaper than the adjustable alternative.

Labelling

When you look at a power supply it will tell you what the input voltage and current are as well as the output voltage and current, it may also indicate which pin on the output connector is ground and power. You will also see some symbols; the meaning of these symbols is described below: The CE mark is present on all electronics equipment (sold in Europe) not just power supplies. It indicates that the manufacturer has tested the equipment and it is safe, doesnt interfere with other electronic devices and that its not affected by interference from other electronic devices. The UL mark is usually found on industrial power supplies. It is a US mark similar to the CE mark to indicate it has been tested, however it holds no legal status. This symbol indicates that the electronic equipment should not be disposed of in the normal waste. Instead it should be recycled in accordance with the waste electronic & electrical equipment (WEEE) directive. The directive (in force this year) means shops have to take old equipment (when a similar item is purchased) and recycled it at no extra cost. This symbol is normally found on plastic enclosures and indicates that the mains electricity is double insulated.

This symbol indicates that the product is designed for indoor use only.

The fuse symbol shows that the power supply is protected by a fuse.

www.kitronik.co.uk

Page 1 of 3

Understanding Electronics

www.kitronik.co.uk

Power Supplies

How power supplies work

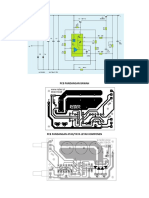

A power supply is used to reduce the mains electricity at 240 volts AC down to some thing more useable, say 12 volts DC. There are two types of power supply, linear and switch mode. A linear power supply uses a transformer to reduce the voltage. The ratio of primary windings (connected to the mains) to the number of secondary windings (connected to the output) would give the ratio of how much the voltage reduced by, in this case a ratio of 20:1 reduces the 240 volts AC input in to 12 volts AC on the secondary windings.

On time Off time

A switch mode supply works by turning the mains electricity on and off very quickly to reduce the voltage. In this case the reduction in voltage depends upon the ratio of the on time and off time. Switching takes place very fast, at 10,000 times a second or quicker. Using this technique the bulky transformer found in a linear supply can be replaced with a smaller one. Below is a block diagram of a switch mode power supply. The AC signal is rectified and regulated to produce a high DC voltage. This is then switched on and off rapidly by a FET. Then the switched signal goes through a transformer, although this can reduce the voltage it isolates the output from the mains electricity (for safety reasons). Feedback of the output is then used to control the mark space ratio of the switching so that the output stays at the required voltage. The transformer used in a switch mode supply is much smaller and cheaper than the type used in linear supply, but must be able to handle the higher switching frequencies.

www.kitronik.co.uk

Page 2 of 3

Understanding Electronics

www.kitronik.co.uk

Power Supplies Linear vs switch mode

Transformers

We have already mentioned that there are two types of transformer, those used at low frequencies (50Hz) in a linear power supply and the high speed (>10KHz) version used in switch mode supplies. The linear power supply transformer typically uses a steel core. Because eddy currents would occur in a solid steel core and reduce the efficiency the core is made from insulated steel plates stacked next to each other with the windings wrapped around them.

Because a large transformer is not needed in a switch mode supply it is smaller, lighter and cheaper. The switch mode supply is more efficient than a linear supply so generates less heat. Switch mode supplies can be designed to run off different input voltages (240v or 115v) so they can be used worldwide. All of the above reasons mean that the switch mode supply far more common than linear supplies Unfortunately the very fast switching of a switch mode supply puts electrical noise or voltage spikes on to the supply each time it switches. If a clean supply is needed it will have to be a linear supply.

Ferrite toroid (donut shaped) cores work much better with higher frequencies and are used in switch mode supplies.

Regulated supplies

In the block diagram of the switch mode power supply, the final stage was to smooth out the pulses by adding a large capacitor. Depending upon how accurate the supply needs to be this solution may be adequate. In this design the output will have some ripple; it will vary from the required voltage by a small amount, maybe a few percent. A regulated supply uses an IC, where the IC monitors the output voltage relative to a reference voltage and adjusts the output accordingly. Regulators have a much lower ripple and often include over current and over temperature protection, whereby they automatically shut down making them and the rest of the supply indestructible. The part shown right is a 7805, a common 5 volt regulator.

Case types

The most common case type is the plastic case. This is because it can be easily made using an injection moulding process and features such as PCB mounting holes or clips, holes for cable entry exit etc can be included in the design at virtually no extra parts cost. The more expensive alternative is a metal enclosure; however these must be grounded for safety reasons.

www.kitronik.co.uk

Page 3 of 3

Potrebbero piacerti anche

- Star Trek DiscoveryDocumento100 pagineStar Trek Discoveryperkinsc305100% (2)

- Freepowersupplyreport PDFDocumento8 pagineFreepowersupplyreport PDFHumberto MarquesNessuna valutazione finora

- 13.8 V - 15 A From A PC Power Supply PDFDocumento7 pagine13.8 V - 15 A From A PC Power Supply PDFcolorado wildernessNessuna valutazione finora

- Electronic Circuits, Transformerless Power Supply, LED Drivers, Battery Chargers, Solar Circuits - Automatic Simple 12V 100ma NiCd Battery Charger Circuit PDFDocumento2 pagineElectronic Circuits, Transformerless Power Supply, LED Drivers, Battery Chargers, Solar Circuits - Automatic Simple 12V 100ma NiCd Battery Charger Circuit PDFdewasuryanto100% (1)

- Report On Power SupplyDocumento14 pagineReport On Power SupplyBhavesh MaheshwariNessuna valutazione finora

- Catu Daya 723Documento6 pagineCatu Daya 723Audi MirantiNessuna valutazione finora

- APC UPS RepairedDocumento6 pagineAPC UPS Repairedcarlos16702014Nessuna valutazione finora

- 2007 Sharp Aquos TV Service UpdateDocumento72 pagine2007 Sharp Aquos TV Service Updateptvideo9628Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Resonance Mode Converters PDFDocumento105 pagineResonance Mode Converters PDFprakashbuddha99Nessuna valutazione finora

- Optocoupler Solutions Guide PDFDocumento24 pagineOptocoupler Solutions Guide PDFBen Salah IssamNessuna valutazione finora

- How To Troubleshoot and Repair DVD With The SymptomDocumento6 pagineHow To Troubleshoot and Repair DVD With The SymptomJojit AquinoNessuna valutazione finora

- SmpsDocumento21 pagineSmpsilayaNessuna valutazione finora

- Discover The Small Switch Mode Power Supplies Modification SecretsDocumento10 pagineDiscover The Small Switch Mode Power Supplies Modification Secretscarlos1670201480% (5)

- TV Troubleshoot ManualDocumento9 pagineTV Troubleshoot Manualthes0uljahgirlNessuna valutazione finora

- Power Transformer DesignDocumento4 paginePower Transformer DesignMetalloyNessuna valutazione finora

- Power SupplyDocumento9 paginePower SupplyMuhammed HuzaifaNessuna valutazione finora

- How An SMPS WorksDocumento7 pagineHow An SMPS WorksĐorđe PopovićNessuna valutazione finora

- Regulated Power Supply1Documento4 pagineRegulated Power Supply1hamed razaNessuna valutazione finora

- Power Electronics - Kits PDFDocumento31 paginePower Electronics - Kits PDFGaganVishwakarmaNessuna valutazione finora

- Emergency Lighting Fluorescent Lamp: AbstractDocumento20 pagineEmergency Lighting Fluorescent Lamp: AbstractAakash SheelvantNessuna valutazione finora

- Digital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofDocumento53 pagineDigital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofdondbNessuna valutazione finora

- A Power Supply UnitDocumento11 pagineA Power Supply UnitShin Jae JiNessuna valutazione finora

- 02A Lesson Proper For Week 7Documento9 pagine02A Lesson Proper For Week 7Maxela CastroNessuna valutazione finora

- Smps Transformer, Toroidal Winding Core (DC DC)Documento12 pagineSmps Transformer, Toroidal Winding Core (DC DC)Bảo BìnhNessuna valutazione finora

- SM M127 TroubleshootingDocumento37 pagineSM M127 TroubleshootingYsrael Agurto Sejuro100% (2)

- Switch Mode Power Supply Basics TutorialDocumento16 pagineSwitch Mode Power Supply Basics TutorialDavidNessuna valutazione finora

- Elecs 1 - Diode CircuitsDocumento103 pagineElecs 1 - Diode CircuitsAnthony CortezNessuna valutazione finora

- ZVS Full BridgeDocumento20 pagineZVS Full Bridgejameschall1Nessuna valutazione finora

- Texas Instruments. Testing A Form of SMPSDocumento7 pagineTexas Instruments. Testing A Form of SMPSRoger FairchildNessuna valutazione finora

- Electrodes/ADS1298 Interface: ResolvedDocumento10 pagineElectrodes/ADS1298 Interface: ResolvedSummer MamunNessuna valutazione finora

- Resonant Converters: Güç Elektroniğinde Özel KonularDocumento41 pagineResonant Converters: Güç Elektroniğinde Özel Konularkazemy_gNessuna valutazione finora

- What Is A Switched-Mode Power Supply (SMPS) - Definition From Techopedia PDFDocumento1 paginaWhat Is A Switched-Mode Power Supply (SMPS) - Definition From Techopedia PDFBright Tendai ChingwenaNessuna valutazione finora

- HGLRC F4 V5PRO ManualDocumento12 pagineHGLRC F4 V5PRO ManualGobardhan Pudasaini100% (1)

- Inside The Power SupplyDocumento41 pagineInside The Power SupplyBright UzzalNessuna valutazione finora

- The Quad Copter ControllerDocumento11 pagineThe Quad Copter ControllerAdam MahmoodNessuna valutazione finora

- DC Power SupplyDocumento4 pagineDC Power SupplySohaib Ahmed100% (1)

- AN4105 Power Switching ICDocumento23 pagineAN4105 Power Switching ICatomo33100% (1)

- Capacitor Power Supply Design NoteDocumento8 pagineCapacitor Power Supply Design NoteIvez StrausseNessuna valutazione finora

- Oled LCD Led TV Repair (136-181)Documento46 pagineOled LCD Led TV Repair (136-181)darmNessuna valutazione finora

- Crius AIOP V2 0 Guide For MegaPirateNG Ver 1 0Documento43 pagineCrius AIOP V2 0 Guide For MegaPirateNG Ver 1 0FlyeerNessuna valutazione finora

- QuadcopterWithAPM2 8Documento27 pagineQuadcopterWithAPM2 8thanosmit100% (1)

- Vertical Deflection ProblemsDocumento5 pagineVertical Deflection Problemscarlosquebec248100% (1)

- PacDrive Controller C400 C400 A8 Operating ManualDocumento175 paginePacDrive Controller C400 C400 A8 Operating ManualAmine HelailiNessuna valutazione finora

- SMPS Design TutorialDocumento18 pagineSMPS Design TutorialRuve Baba100% (6)

- High Performance Portable BenchSupply, DIYDocumento9 pagineHigh Performance Portable BenchSupply, DIYBryan Fantasía FuryNessuna valutazione finora

- SMPS Test SeduleDocumento6 pagineSMPS Test SeduledeeruNessuna valutazione finora

- JVC Lt-22hg45e Led TV PDFDocumento43 pagineJVC Lt-22hg45e Led TV PDFAnonymous PDNToMmNmRNessuna valutazione finora

- CV801LE-A-15: System BlockDocumento18 pagineCV801LE-A-15: System BlockJibon DasNessuna valutazione finora

- Switch-Mode Power Supplies - SPICE Simulations and Practical Designs - EE Times3 PDFDocumento7 pagineSwitch-Mode Power Supplies - SPICE Simulations and Practical Designs - EE Times3 PDFVIJAYPUTRA0% (1)

- Common CRT TV Problems Cause/s Remedy/iesDocumento2 pagineCommon CRT TV Problems Cause/s Remedy/iesJames BrianNessuna valutazione finora

- Daewoo CRT TV Repair 20VSSFG RepairDocumento5 pagineDaewoo CRT TV Repair 20VSSFG RepairJorge G. Manzanero100% (2)

- AC DC ConvertersDocumento11 pagineAC DC ConvertersMoon BorahNessuna valutazione finora

- LC-60-70LE660U (Main Unit Edition)Documento72 pagineLC-60-70LE660U (Main Unit Edition)Alejandro Alcubierre0% (1)

- Understanding The TV Horizontal Output Stage: Key ComponentsDocumento4 pagineUnderstanding The TV Horizontal Output Stage: Key ComponentsakulimeNessuna valutazione finora

- Kitronik - Co.uk-How A Power Supply WorksDocumento6 pagineKitronik - Co.uk-How A Power Supply WorksfabiobonadiaNessuna valutazione finora

- Power Supply 1Documento9 paginePower Supply 1mohammed almaswaryNessuna valutazione finora

- Type of Power SupplyDocumento7 pagineType of Power SupplySHah WanHazNessuna valutazione finora

- Has High Efficiency. Fault Current Is Limited by The Inductor Output Short Circuit Current Is Easy To ImplementDocumento6 pagineHas High Efficiency. Fault Current Is Limited by The Inductor Output Short Circuit Current Is Easy To ImplementRajalakshmi ShivakumarNessuna valutazione finora

- Chapter - I 1.1 GeneralDocumento67 pagineChapter - I 1.1 GeneralJilly ArasuNessuna valutazione finora

- Home GRIDDocumento5 pagineHome GRIDramoradoNessuna valutazione finora

- How A Thermistor WorksDocumento1 paginaHow A Thermistor Worksperkinsc305Nessuna valutazione finora

- Metz 76 MZ 5Documento3 pagineMetz 76 MZ 5perkinsc305Nessuna valutazione finora

- Māori Greetings & Signoffs: For Letters and EmailsDocumento1 paginaMāori Greetings & Signoffs: For Letters and Emailsthemu5icroomNessuna valutazione finora

- NetSafe Kit For ECEDocumento42 pagineNetSafe Kit For ECEperkinsc305Nessuna valutazione finora

- Mamiya 645 System: BodysDocumento8 pagineMamiya 645 System: Bodysperkinsc305Nessuna valutazione finora

- How To Use A Thyristor As A LatchDocumento1 paginaHow To Use A Thyristor As A Latchperkinsc305Nessuna valutazione finora

- Understanding Ceramic Disc Capacitor ValuesDocumento1 paginaUnderstanding Ceramic Disc Capacitor ValuesGeoff HampsonNessuna valutazione finora

- How A Darlington Pair Transistor WorksDocumento1 paginaHow A Darlington Pair Transistor Worksperkinsc305Nessuna valutazione finora

- What Is Ohms LawDocumento3 pagineWhat Is Ohms Lawperkinsc305Nessuna valutazione finora

- How A Power Supply WorksDocumento3 pagineHow A Power Supply Worksperkinsc305Nessuna valutazione finora

- How A Thermistor WorksDocumento1 paginaHow A Thermistor Worksperkinsc305Nessuna valutazione finora

- How To Calculate Capacitors in Series and ParallelDocumento6 pagineHow To Calculate Capacitors in Series and ParallelGeoff Hampson100% (1)

- How To Use CapacitorsDocumento3 pagineHow To Use CapacitorsGeoff Hampson100% (1)

- Understanding Ceramic Disc Capacitor ValuesDocumento1 paginaUnderstanding Ceramic Disc Capacitor ValuesGeoff HampsonNessuna valutazione finora

- How A Thermistor WorksDocumento1 paginaHow A Thermistor Worksperkinsc305Nessuna valutazione finora

- How To Use CapacitorsDocumento3 pagineHow To Use CapacitorsGeoff Hampson100% (1)

- How To Calculate Capacitors in Series and ParallelDocumento6 pagineHow To Calculate Capacitors in Series and ParallelGeoff Hampson100% (1)

- How A Power Supply WorksDocumento3 pagineHow A Power Supply Worksperkinsc305Nessuna valutazione finora

- What Is An Integrated CircuitDocumento2 pagineWhat Is An Integrated Circuitperkinsc305Nessuna valutazione finora

- What Is Ohms LawDocumento3 pagineWhat Is Ohms Lawperkinsc305Nessuna valutazione finora

- How A Transistor WorksDocumento1 paginaHow A Transistor Worksperkinsc305Nessuna valutazione finora

- How A Transistor WorksDocumento1 paginaHow A Transistor Worksperkinsc305Nessuna valutazione finora

- Understanding Electronic Component Uses and SymbolsDocumento5 pagineUnderstanding Electronic Component Uses and SymbolsGeoff Hampson100% (2)

- How A Power Supply WorksDocumento3 pagineHow A Power Supply Worksperkinsc305Nessuna valutazione finora

- How A Thermistor WorksDocumento1 paginaHow A Thermistor Worksperkinsc305Nessuna valutazione finora

- How A Transistor WorksDocumento1 paginaHow A Transistor Worksperkinsc305Nessuna valutazione finora

- Canon Professional Brochure SupportDocumento6 pagineCanon Professional Brochure Supportperkinsc305Nessuna valutazione finora

- File 000000Documento228 pagineFile 000000perkinsc305Nessuna valutazione finora