Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

394

Caricato da

Venkateswarlu AlaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

394

Caricato da

Venkateswarlu AlaCopyright:

Formati disponibili

High Pressure Turbine Bypass Valve HBSE

HBSE from Sulzer Valves delivers pressure reduction, temperature control and fast response in a compact, high pressure steam conditioning valve.

The Rugged, Compact Steam Conditioning Solution The HBSE Turbine Bypass Valve by CCI is the standard turbine bypass valve for high pressure bypass systems of combined cycle power plants. With a compact, robust design that easily fits into most existing piping arrangements, it can be installed in any orientation. All components, including the flow diffuser, are removable through the top of the valve making maintenance and inspection quick and easy. The spherical body shape has been designed to avoid material concentrations and abrupt changes of wall thickness, minimizing thermal stress in the valve. In addition, the HBSE is available as a combined control and safe shutoff valve according to TRD 421.

Water-injection nozzle provides smallest water droplet size possible

Spring-Loaded Nozzle Desuperheating HBSE desuperheating features integral spring-loaded water-injection nozzles that optimize water-injection over a wide range of flow rates at low pressures. With a rangeability of up to 50:1, the spring-loaded water-injection nozzles vary the water flow area as required to achieve the fine water droplet size needed for atomization. The spring-loaded water-injection nozzle design provides the smallest water droplet size possible without steam assist. Small-Drilled-Hole Cage Technology The HBSE Turbine Bypass Valve uses Small-Drilled-Hole Cage (SDHC) technology to provide system noise attenuation through frequency shifting. Frequency shifting is a proven method of noise attenuation recognized by ISA in Technical Standard SP75.07 and by the IEC in Technical Standard 5348-3.

Good atomization at wide range of flow rates

In frequency shifting, the main flow stream is separated into hundreds of tiny jets. The size of the jets, which are primarily based on hole size, determines the resulting noise frequency the smaller the size of the jet or drilled hole, the higher the frequency which in turn produces a lower dBA level. SmallDrilled-Hole Cage technology is well suited for high pressure combined cycle and drum boiler turbine bypass applications requiring moderate noise performance. Unlike traditional drilled hole cages, the SDHC trim uses over one thousand small drilled holes spaced apart in a special pattern designed to ensure full jet separation, structural integrity, and noise attenuation. All drilled hole technology is not the same large drilled holes do not shift the frequency high enough, and improper spacing between drilled holes allows the jets to rejoin and form larger jets after exiting the cage. The conical flow diffuser shape limits vibration by increasing the structural strength when compared to cylindrical cage designs.

CCI HBSE Turbine Bypass Valve

Small-Drilled-Hole Cage technology uses frequency shifting to maximize noise attenuation

Highly reliable, fast, accurate pneumatic and hydraulic actuators provide superior system control.

Accurate Control and Available TRD 421 Safety Function CCIs long history of developing advanced technology valves and actuation systems for severe service and safety-related applications has led to the development of the most reliable actuation systems available today. CCI has supplied pneumatic and hydraulic actuation systems for over 30 years and has an extensive installed global base. In addition, if equipped with the necessary safety control devices in combination with the CCI hydraulic actuation system, the HBSE can be used as a combined control and safe shutoff valve according to TRD 421. The selection of pneumatic or hydraulic actuation is primarily a function of valve design for the particular application as well as customer preference. A comparison of the factors influencing actuator selection is given in Table 1. Improve Plant Efficiency Eliminate Lost Steam During normal operation, any leakage past a turbine bypass valve means lost revenue.

g

Steam that does not go through the turbine does not generate electricity or revenue for the plant. Money spent generating the steam is lost. Steam leaking past a valve seat could erode the seat and cause an increase in the leakage rate and maintenance downtime. Steam leaking past a valve to condenser could reduce the efficiency of the condenser by deteriorating the vacuum and raising the condenser temperature.

g g

The CCI HBSE Turbine Bypass Valve comes standard with DIN 3230, Rate 3 or ANSI/FCI 70-2 Class V Shutoff, providing dependable, repeatable, shutoff for long periods of time with high pressure differentials. DIN 3230, Rate 1 or MSS-SP-61 Shutoff is standard with hydraulic actuation.

CCI HBSE Turbine Bypass Valve

Table 1: Factors Influencing Actuator Selection Performance Attribute Stroke Speed Resolution Thrust Reliability Procurement Cost Installation Cost Maintenance Components CCI Pneumatic Actuator Fast, Less Than 1 Second (optional) Good, Less Than 1% Meets Thrust Requirements for Balanced or Pressurized Seat Valves Very Reliable and Robust Inexpensive Inexpensive Easy, With Medium Skills Low Pressure, Reliable Accessories CCI Hydraulic Actuator Very Fast, Less Than 0.5 Seconds Very Good, Less Than 0.1% Meets Thrust Requirements for Unbalanced Valves Very Reliable and Robust Higher Cost Higher Cost Requires Higher Skills for Maintenance High Pressure, Proven Accessories

Optimized Body Shape For Minimal Thermal Stress Designed for cyclic operation and frequent start-ups.

Top Entry Design Minimizes service time. No Trim Parts are Welded or Screwed Into the Valve Body

Small-Drilled-Hole Cage Technology Ensures low noise levels.

Spring-Loaded Spraywater Nozzle Desuperheaters Provides superior atomization. Mounted directly to outlet eliminating need for additional piping sections. Spraywater Manifold System Multiple attemperation injection points with single water supply source connection.

CCI HBSE Turbine Bypass Valve

Valve Performance Characteristics (% Cv vs. % Stroke)

Valves can be characterized to accommodate a wide range of variables.

Linear

Modified Linear

Modified Equal Percentage

Use this checklist to evaluate the benefits of the HBSE design.

CCI HBSE Turbine Bypass Valve

1. Special needs can be accommodated. Please consult with the factory. 2. Flexible tubing is standard for the spraywater manifold system. Rigid piping manifold option is available. 3. Dump tubes available if required.

Table 2: Dimensional Information

CCI HBSE Turbine Bypass Valve

Valve Size 100 150 200 250 300 350 1. 2. 3. 4. 5.

Inlet Pipe Size (inch) 4"-6" 4"-6" 8"-12" 8"-12" 8"-12" 10"-14" 12" - 16"

Outlet Pipe Size (inch) 6" - 10" 6" - 10" 12" - 16" 12" - 16" 14" - 18" 18" - 22" 20"-24"

C*

5.9 (150) 5.9 (150) 9.8 (250) 9.8 (250) 11.8 (300) 13.8 (350) 15.7 (400)

14.2 (360) 14.2 (360) 15.7 (400) 15.7 (400) 21.1 (535) 25.6 (650) 29.9 (760)

52 (1330) 52 (1330) 54 (1365) 54 (1365) 55 (1390) 56 (1425) 58 (1460)

43 (1080) 43 (1080) 44 (1115) 44 (1115) 45 (1140) 46 (1175) 54 (1360)

All dimensions are in inches except () are in millimeters. Dimension C* is for a hydraulic actuator. Buttweld per ANSI B16.25 and mating pipe schedule. Valve may be installed in any orientation. The upper structure does not require additional support. Flexible tubing to a single connection manifold is supplied as standard.

Technical specifications and materials.

Table 3: Capacity and Performance Data

2 1 5

7 4 8

Table 4: Materials 1. 2. 3. Rangeability may vary with process conditions. Consult with factory. For exact pressure/temperature rating, consult factory. Electro mechanical actuation available on request.

Table 5: Recommended Desuperheating Lengths Using Spring-Loaded

CCI HBSE Turbine Bypass Valve

1. 2.

Alternate materials available per customers specific design requirements. For hydraulic actuator, plug/stem material is X19CrMoVNbN111.

With saturated steam, to avoid pipe erosion and liquid drop-out due to droplet impingement, bends should be avoided. ** Saturated steam conditions cannot be controlled through downstream temperature measurement. Feed-forward/enthalpy control recommended. + All dimensions are in feet except () are in meters

Throughout the world, companies rely on CCI to solve their severe service control valve problems. CCI has provided custom solutions for these and other industry applications for more than 40 years.

Sales and service locations worldwide.

CCI World Headquarters California Telephone: (949) 858-1877 Fax: (949) 858-1878 22591 Avenida Empresa Rancho Santa Margarita, California 92688 USA CCI Switzerland formerly Sulzer Thermtec Telephone: 41 52 262 11 66 Fax: 41 52 262 01 65 Hegifeldstrasse 10, P .O. Box 65 CH-8408 Winterthur Switzerland CCI Korea Telephone: 82 31 985 9430 Fax: 82 31 985 0552 26-17, Pungmu-Dong Kimpo City, Kyunggi-Do 415-070 South Korea CCI Japan Telephone: 81 726 41 7197 Fax: 81 726 41 7198 194-2, Shukunosho Ibaraki-City, Osaka 567-0051 Japan CCI Sweden (BTG Valves) Telephone: 46 533 689 600 Fax: 46 533 689 601 Box 603 SE-661 29 Sffle Sweden CCI Austria formerly Spectris Components GmbH Telephone: 43 1 869 27 40 Fax: 43 1 865 36 03 Carlbergergasse 38/Pf.19 1233 Vienna Austria

Contact us at: info@ccivalve.com Visit us online at: www.ccivalve.com

DRAG is a registered trademark of CCI. 2002 CCI 394 3/02 10M

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Motionless Electromagnetic Generator (MEG)Documento3 pagineMotionless Electromagnetic Generator (MEG)dundonaldsNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Atlas Copco - Marine - SolutionsDocumento88 pagineAtlas Copco - Marine - SolutionsCuong TranHung0% (1)

- Sanyo MDF-U4186S Service ManualDocumento30 pagineSanyo MDF-U4186S Service ManualEmRe OflazNessuna valutazione finora

- Protection Application - An Overview: Part 2ADocumento128 pagineProtection Application - An Overview: Part 2AinsanazizNessuna valutazione finora

- Profitable Calcining of Non-Calcinable Pet Coke PDFDocumento4 pagineProfitable Calcining of Non-Calcinable Pet Coke PDFDedik DermadyNessuna valutazione finora

- 82 5KVAto125KVADocumento53 pagine82 5KVAto125KVALU YONessuna valutazione finora

- Super Critical Boiler Technology SKDDocumento35 pagineSuper Critical Boiler Technology SKDSwapnil TingusleNessuna valutazione finora

- New Rolling Method of Reversing Cold Rolling MillDocumento10 pagineNew Rolling Method of Reversing Cold Rolling MillVikas SharmaNessuna valutazione finora

- Marketing Plan RedbullDocumento3 pagineMarketing Plan RedbullabdNessuna valutazione finora

- Studi Kebutuhan Angkutan Umum PenumpangDocumento12 pagineStudi Kebutuhan Angkutan Umum PenumpangWahyu WahyuNessuna valutazione finora

- Clayton Case StudyDocumento3 pagineClayton Case Studyrocker199Nessuna valutazione finora

- Images PDF Files Csp2013Documento93 pagineImages PDF Files Csp2013Amit GuptaNessuna valutazione finora

- UPSC: Engineering Services Examination 2013Documento7 pagineUPSC: Engineering Services Examination 2013TrcStaffNessuna valutazione finora

- SA275Documento8 pagineSA275Venkateswarlu AlaNessuna valutazione finora

- 393Documento8 pagine393Ram MohanNessuna valutazione finora

- Andhra Pradesh Public Service Commission Group 1 Services NotificationsDocumento25 pagineAndhra Pradesh Public Service Commission Group 1 Services NotificationsFreshers Plane IndiaNessuna valutazione finora

- Bohler ManualDocumento519 pagineBohler ManualCosmin OlteanuNessuna valutazione finora

- Et Advt EngDocumento1 paginaEt Advt EngAdi NarayanaNessuna valutazione finora

- E6 QmsDocumento37 pagineE6 QmsVenkateswarlu AlaNessuna valutazione finora

- 001 IntroDocumento48 pagine001 IntroSudipta PalNessuna valutazione finora

- 7QCDocumento13 pagine7QCAniketh ShankarNessuna valutazione finora

- Solar Power Forecast: Weather. Impact On Your BusinessDocumento2 pagineSolar Power Forecast: Weather. Impact On Your BusinessCamilo DiazNessuna valutazione finora

- Corporate GEA KestnerDocumento8 pagineCorporate GEA KestnerlaurentpalierneNessuna valutazione finora

- House Hearing, 112TH Congress - Formulation of The 2012 Farm BillDocumento882 pagineHouse Hearing, 112TH Congress - Formulation of The 2012 Farm BillScribd Government DocsNessuna valutazione finora

- Sdmo Telecoms Generator SolutionsDocumento18 pagineSdmo Telecoms Generator SolutionsHani IssaNessuna valutazione finora

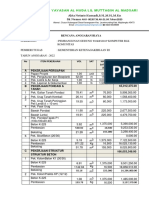

- Yayasan Al Huda Lil Muttaqin Al Madsari: Rencana Anggaran BiayaDocumento6 pagineYayasan Al Huda Lil Muttaqin Al Madsari: Rencana Anggaran BiayaMoja Januba ArifahNessuna valutazione finora

- Problem of Time & CostDocumento14 pagineProblem of Time & CostTamanna Thakur0% (1)

- Fesco Online BillDocumento1 paginaFesco Online BillSaqLain AliNessuna valutazione finora

- Memo - Coal Inspection As of 10-01-2015Documento2 pagineMemo - Coal Inspection As of 10-01-2015Raffy PangilinanNessuna valutazione finora

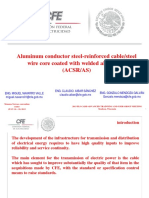

- CFE Regulations For Cables PDFDocumento39 pagineCFE Regulations For Cables PDFEdward FernandezNessuna valutazione finora

- Engg KRADocumento4 pagineEngg KRAMadanKarkiNessuna valutazione finora

- Shell Capital Markets Day 2016 Analyst Webcast Presentation Slides 160607122448Documento80 pagineShell Capital Markets Day 2016 Analyst Webcast Presentation Slides 160607122448kglorstad100% (1)

- Names of Reports Published by OrganisationsDocumento5 pagineNames of Reports Published by OrganisationsAnonymous tLP4Ow6GmNessuna valutazione finora

- Callective Energy Bill ScriptDocumento2 pagineCallective Energy Bill ScriptÓscar Eduardo Acevedo AponteNessuna valutazione finora

- 393Documento1 pagina393ALBERTO ANTONINessuna valutazione finora

- 5.3 Judy-Li Ernst&Young enDocumento11 pagine5.3 Judy-Li Ernst&Young enaasgroupNessuna valutazione finora

- 201.28-Eg1 PDFDocumento52 pagine201.28-Eg1 PDFMr.K chNessuna valutazione finora

- Current Transformer: Profile No.: 273 NIC Code: 27102Documento14 pagineCurrent Transformer: Profile No.: 273 NIC Code: 27102Rama SubrahmanyamNessuna valutazione finora

- SEI School Sustainability Policy GuideDocumento39 pagineSEI School Sustainability Policy GuideMarce VeraNessuna valutazione finora

- Coupon 10% P.A. - 6 Months - Low Strike at 75% - USDDocumento1 paginaCoupon 10% P.A. - 6 Months - Low Strike at 75% - USDapi-25889552Nessuna valutazione finora