Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Rates Tunnel Works 2

Caricato da

vpmohammedCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Rates Tunnel Works 2

Caricato da

vpmohammedCopyright:

Formati disponibili

TUNNEL AND ALLIED WORKS

Sundries ( explosive van / magazine )

LS

8.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

30.00 Total Rs: Rs: Rs: Rs: Rs:

240.00 25225.00 252.25 1045.55 1261.25 27784.05

Description

Unit Hour Hour Hour Hour Hour Hour Hour Day Day Day Day Day Day Day Day Day Day Day

Quantity 11.00 7.50 30.00 6.00 12.00 7.50 2.00 1.00 1.00 2.00 1.00 2.00 2.00 3.00 4.00 8.00 4.00 2.00

17

Crew for Drilling jumbo Crew for Air compressor Crew for Jack hammer Crew for Convey mucker Crew for Dumper Crew for Pump Crew for ventilation fans Surveyor Foreman Fitter / Mechanic Blaster ( Licensed ) Helper blasting Hammerman Maistry 1 in each shift Khalasi for mucking shift 4 Nos Heavy mazdoor for mucking shift 8 Nos for other 2 shifts 2 No each shift Light mazdoor for cleaning & miscellaneous Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Rate in Rs. 60.50 60.10 111.90 60.10 72.60 26.90 9.30 154.50 177.00 157.50 147.00 141.50 146.00 141.50 145.50 132.00 132.00 130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 665.50 450.75 3357.00 360.60 871.20 201.75 18.60 154.50 177.00 315.00 147.00 283.00 292.00 424.50 582.00 1056.00 528.00 261.00 10145.40 101.45 1014.54 1521.81 1014.54 507.27 14305.01

1% 10% 15% 10% 5% Total cost of Labour :

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL Add for Air and Water line @ Add for Ventilation @ Add for Lighting @ Add for Ele sub-station / Demand charges @ Add for other Enabling works @ Total cost for 0.50% 6.10% 1.90% 4.20% 1.70% 49.00 cum

Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs:

13642.33 27784.05 14305.01 55731.39 278.66 3399.61 1058.90 2340.72 947.43 63756.71

20

TUNNEL AND ALLIED WORKS

Rate per cum Rate approved per cum SECTION: TUNNEL AND ALLIED WORKS. YEAR: 2010-11

Rs: Rs:

1301.00 1301.00 ITEM No: 4

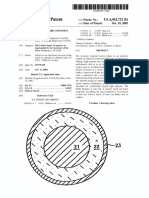

ITEM: Excavation for tunnel by tunnelling methods including excavation for supports in all types of soil / rock strata requiring supports ( excluding cost of providing supports ) including cost of all other materials, machinery, labour, scaling excavated surface, ventilation, lighting, drainage, removing and hauling the excavated muck outside tunnel upto specified dump area and all other ancillary operations etc., complete with initial lead upto 1 km and all lifts. DATA: Size of tunnel assumed ( finished section ) : 4.50 m dia Shape of tunnel assumed for excavation : D - shape Height of tunnel assumed ( finished section ) : 4.50 m Length of tunnel assumed : 1000 m Thickness of CC lining : 0.30 m Extra excavation for supports : 0.25 m Pay-line margin assumed : 0.20 m Diameter of tunnel upto pay line for excavation : 6.00 m Distance of dump yard from face including approach / adit length : Average 1 km Haulage of excavated muck : By dumpers 1. Checking alignment and marking hole locations : Use drilling jumbo for 1 hour for marking hole locations. 2. Drilling holes : Area of tunnel upto pay-line (0.5x0.7857x6x6) + (6x2.75) : 30.64 sqm The number of holes for tunnel excavation will be generally in the range of 2.5 to 3.0 per sqm of cross sectional area upto pay line for tunnel upto 45 sqm and in the range of 2.0 to 2.5 per sqn of cross sectional area upto pay line for tunnel exceeding 45 sqm. For rate analysis 2.5 holes per sqm of cross sectional area considered. Number of holes for full face excavation ( 30.64 x 2.5 ) : 77 Nos Assuming spacing of supports at 0.75 m the depth of pull is considered at 1.5 m. Depth of holes for 1.5 m pull : 1.7 m Extra drilling considered at 10 percent for inclination of holes and for removal of any under cuts and for secondary blasting of large fragments during mucking. Depth of drilling for 77 holes ( 77 x 1.7 x 1.10 ) : 144 m Average rate of drilling per hour per jack hammer : 5m Time for 4 jack hammers with pusher leg for drilling. : 7 hours Time for 1 air compressor 15 cmm for air supply to 4 jack hammers : : 7 hours

Time for drilling jumbo for drilling Time for 10 hp pump for pumping water to storage tank. 3. Loading explosive and blasting : Depth of pull per blast for 1.7 m deep holes Quantity of in-situ excavation per blast ( 30.64 x 1.50 ) Quantity of explosive small dia per blast @ 0.8 kg per cum Quantity of explosive for secondary blasting @ 10 % Quantity of delay detonators per blast Quantity of electric detonators for secondary blasting ( LS ) Detonating fuse coil Use drilling jumbo for 2 hour for loading explosives. 4. Defuming and scaling loose materials

: 7 hours : 7 hours : : : : : : : 1.50 m 46 cum 37 kg 4 kg 77 Nos. 10 Nos. 175 Rm

21

TUNNEL AND ALLIED WORKS

No machinery other than ventilation fans required. For defuming tunnel ventilation fans are installed in duct system at about 300 m interval and are run for about 1 hour after each blast. For 1 km length of tunnel ventilation fans are required at 4 places at 300 m interval. As the fans are installed progressively, for rate analysis consider average 2 fans for 1 hour. 5. Mucking excavated rock : Quantity of muck per blast considering 40 % bulkage ( 46 x 1.4 ) : 65 cum Capacity of dumper per load : 5 cum Quantity of muck per load considered under tunnel working conditions : 4.5 cum Loading cycle time: Moving from pocket position and spotting : 1 minutes Loading muck by convey mucker and work force : 20 minutes Time for loaded dumper to pass waiting point say : 1 minutes Cycle time of loading dumper per load of 4.5 cum : 22 minutes Haulage cycle time: Running time from loading point to dump yard at av. 10 km / hr : : 6 minutes Turning and unloading : 2 minutes Return trip to waiting point @ av. 15 km / hr : 4 minutes Waiting time before spotting : 9 minutes Cycle time for haulage per load of 4.5 cum Total : 21 minutes Round trip cycle time of dumper say : 45 minutes Quantity of muck disposal per hour / dumper : 6 cum Time for 2 dumpers for conveying muck @ 12 cum per hour say : 6 hours Time for convey mucker and labour force for loading say : 6 hours 6. Overall cycle time : Checking alignment and marking hole locations : 2.00 hours Drilling holes : 7.00 hours Loading explosive and blasting : 2.00 hours Defuming and scaling loose rock fragments : 2.00 hours Mucking excavated rock : 6.00 hours Bed cleaning, Jumbo movements, rock bolting, lighting etc say : 4.00 hours Erection of temperary / permanent supports : 9.00 hours Total cycle of excavation & supporting / blast of 1.5 m length : 32.00 hours 7. Requirement of materials : Explosive small dia ( 37 + 4 ) : 41 kg Electric short delay detonators ( 77 x 1 ) : 77 Nos Electric detonators for secondary blasting (1x5) : 10 Nos Fuse coil : 175 Rm

8. Requirement of machinery : Deploy drilling jumbo for various operations ( marking holes 1 hr + drilling 7 hrs + loading explosives 2 hr + misc 1 hr ) Deploy air compressor 15 cmm for air supply to 4 jack hammers Deploy 4 jack hammers with pusher leg for drilling. Deploy 10 hp pump for water supply to drilling work. Deploy 20 hp ventilation fan for defuming (2x1) Deploy convey mucker for loading excavated rock Deploy 2 dumper for conveying muck 9. Requirement of workforce ( other than machinery crew ) : Surveyor for checking alignment and marking hole locations for drilling Foreman for supervising drilling of holes and other operations

11 hours : : : : : : 7 hours 7 hours 7 hours 1 hour 6 hours 6 hours

: 1 No. : 1 No.

22

TUNNEL AND ALLIED WORKS

Fitter / Mechanic for extending air / water lines Blaster ( Licensed ) Helper blasting Hammerman for scaling Maistry 1 in each shift Khalasi for mucking shift Heavy mazdoor for mucking shift for other 2 shifts 1 No each shift Light mazdoor for cleaning & miscellaneous 10. Use rate of materials: Cost of drill rod 2.5 m long @ Rs: Life of drill rod with reconditioning Use rate of drill rod per Rm drilling Length of air and water hose assumed Cost of 25 mm dia air hose 25 m @ Rs: Life of air hose Use rate of air hose per hour Cost of water hose 25 m each @ Rs: Life of water hose Use rate of water hose per hour RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 4 5 6 Perticulars

: : : : : :

2 Nos. 1 No. 2 Nos. 2 Nos. 3 Nos. 4 Nos.

: 8 Nos. : 4 Nos. : 3 Nos. 5660.00 / No. ( cost / life ) 150.00 / Rm ( cost / life ) 128.00 / Rm ( cost / life ) UNIT : Unit kg Nos Nos Rm Rm Hour Quantity 41.00 77.00 10.00 175.00 144.00 28.00 Rs: : Rs: : Rs: : Rs: Rs: : Rs: 5660.00 150 m 37.73 25 m each 3750.00 800 hours 4.69 3200.00 800 hours 4.00

46.00 cum Rate in Rs. 45.00 18.00 10.00 8.00 37.73 4.69 Contd Amount in Rs. 1845.00 1386.00 100.00 1400.00 5433.60 543.36 131.25

Small dia explosive Delay detonators Electric detonators Detonating fuse coil Use rate of drill rod 2.5 m long Reconditioning charges @ 10% Use rate of air hose

A. MATERIALS ( Contd ) : Sl No Perticulars

Unit

Quantity

7 8

Use rate of water hose Sundries( paint / template etc ) Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

Hour LS

28.00 15.00

1% 10% 5% Total cost of Materials :

Rate in Rs. Contd 4.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 112.00 450.00 11401.21 114.01 1140.12 570.06 13225.40

B. MACHINERY: Sl No

Description

Unit

Quantity

Rate

Amount

23

TUNNEL AND ALLIED WORKS

1 2 3 4 5 6 7 8 9

Drilling jumbo Fuel / Energy charges Air compressor 15 cmm ( ele ) Fuel / Energy charges Jack hammer ( 4 x 7 hrs ) Fuel / Energy charges Pusher leg Fuel / Energy charges Convey mucker Fuel / Energy charges Dumper ( 2 x 6 hrs ) Fuel / Energy charges Pump 10 hp ( ele ) Fuel / Energy charges Ventilation fans 20 hp ( 2 x 1 hr ) Fuel / Energy charges Sundries(explosive van / magazine )

Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour LS

11.00 11.00 7.00 7.00 28.00 28.00 28.00 28.00 6.00 6.00 12.00 12.00 7.00 7.00 2.00 2.00 15.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8

in Rs. 322.00 30.00 108.00 627.00 14.00 5.00 8.00 3.00 658.00 174.00 480.00 277.00 5.00 50.00 6.00 100.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

in Rs. 3542.00 330.00 756.00 4389.00 392.00 140.00 224.00 84.00 3948.00 1044.00 5760.00 3324.00 35.00 350.00 12.00 200.00 450.00 24980.00 249.80 1031.10 1249.00 27509.90

Description

Unit Hour Hour Hour Hour Hour Hour Hour Day

Quantity 11.00 7.00 28.00 6.00 12.00 7.00 2.00 1.00

Crew for Drilling jumbo Crew for Air compressor Crew for Jack hammer Crew for Convey mucker Crew for Dumper Crew for Pump Crew for ventilation fans Surveyor

Rate in Rs. 60.50 60.10 111.90 60.10 72.60 26.90 9.30 154.50 Contd

Amount in Rs. 665.50 420.70 3133.20 360.60 871.20 188.30 18.60 154.50

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

9 10 11 12 13 14 15 16

Foreman Fitter / Mechanic Blaster ( Licensed ) Helper blasting Hammerman 2 Nos Maistry 1 in each shift Khalasi for mucking shift 4 Nos Heavy mazdoor for mucking shift 8 Nos for other 2 shifts 2 No each shift

Day Day Day Day Day Day Day Day Day

1.00 2.00 1.00 2.00 2.00 3.00 4.00 8.00 4.00

Rate in Rs. Contd 177.00 157.50 147.00 141.50 146.00 141.50 145.50 132.00 132.00

Amount in Rs. 177.00 315.00 147.00 283.00 292.00 424.50 582.00 1056.00 528.00

24

TUNNEL AND ALLIED WORKS

17

Light mazdoor for cleaning & miscellaneous Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Day

3.00

1% 10% 15% 10% 5% Total cost of Labour :

130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

391.50 10008.60 100.09 1000.86 1501.29 1000.86 500.43 14112.13

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for Air and Water line @ 0.50% Add for Ventilation @ 6.10% Add for Lighting @ 1.90% Add for Ele sub-station / Demand charges @ 4.20% Add for other Enabling works @ 1.70% Total cost for 46.00 cum Rate per cum Rate approved per cum SECTION: TUNNEL AND ALLIED WORKS. YEAR: 2010-11

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs:

13225.40 27509.90 14112.13 54847.43 274.24 3345.69 1042.10 2303.59 932.41 62745.46 1364.00 1364.00 ITEM No: 5

ITEM: Excavation for tunnel by heading and benching tunnelling methods including excavation for supports in all types of soil / rock strata requiring supports ( excluding cost of providing supports ) for roof before benching including cost of all other materials, machinery, labour, scaling excavated surface, ventilation, lighting, drainage removing and hauling excavated muck outside tunnel upto specified dump area and all other ancillary operations etc., complete with initial lead upto 1 km and all lifts. DATA: Size of tunnel assumed ( finished section ) Shape of tunnel assumed for excavation : 4.50 m dia : D - shape

Height of tunnel assumed ( finished section ) Length of tunnel assumed Thickness of CC lining Extra excavation for supports Pay-line margin assumed Diameter of tunnel upto pay line for excavation Distance of dump yard from face including approach / adit length Haulage of excavated muck 1. Checking alignment and marking hole locations : Use drilling jumbo for 1 hour for marking hole locations. 2. Drilling holes : Pay line

: : : : : : : :

4.50 m 1000 m 0.30 m 0.25 m 0.20 m 6.00 m Average 1 km By dumpers

Heading portion

25

TUNNEL AND ALLIED WORKS

Excavated profile Minimum excavation line Drill holes Benching portion

TYPICAL CROSS SECTION OF TUNNEL FOR HEADING & BENCHING In case of tunnel, where the height is more or where the chances of over excavation due to full face blasting is more, the excavation will be generally carried out by heading and benching method. For week strata arch rib supports are also to be erected before benching. Excavation of arch portion is carried out first and the supports are fixed wherever necessary. Depth of hole and explosive charge per cum are also controlled to minimise over excavation. Assuming spacing of arch supports at 0.75 m interval the effective depth of pull per blast is considered at 1.5 m. The depth of hole for 1.5 m pull is considered at 1.7 m. Extra drilling considered at 10 percent for inclination of holes and for removal of any under cuts and for secondary blasting of large fragments during mucking. Heading portion : Area of excavation upto payline : 14.14 sqm Depth of drilling : 1.70 m No. of holes considering 2.5 holes / sqm : 35 Nos. Depth of drilling for 35 holes ( 35 x 1.7 x 1.1 ) : 65.5 m Haunch portion on either side : Area of excavation upto payline : 2.60 sqm Depth of drilling : 1.70 m No. of holes considering 3 holes / sqm : 8 Nos Depth of drilling for 8 holes ( 8 x 1.7 x 1.1 ) : 15 m Benching portion : Area of excavation upto payline ( 6 x 2.75 ) : 16.50 sqm No. of holes considering 2.5 holes / sqm : 41 Nos. Depth of drilling : 1.70 m Depth of drilling for 41 holes ( 41 x 1.7 x 1.1 ) : 76.5 m Total depth of drilling ( 65.5 + 15 + 76.5 ) : 157 m Average rate of drilling per hour per jack hammer : 5m

Time for 4 jack hammers with pusher leg for drilling. : 8 hours Time for 1 air compressor 15 cmm for air supply to 4 jack hammers : : 8 hours Time for drilling jumbo for drilling : 8 hours Time for 10 hp pump for pumping water to storage tank. : 8 hours 3. Loading explosive and blasting : Total area of excavation : 33.24 sqm Depth of pull per blast for 1.7 m deep holes : 1.50 m Quantity of in-situ excavation per blast ( 33.24 x 1.50 ) : 50 cum Quantity of explosive small dia / blast @ 0.8 kg / cum ( 50 x 0.8 ) : 40 kg Quantity of explosive for secondary blasting @ 10 % : 4 kg Quantity of delay detonators per blast ( 35 + 8 + 41 ) : 84 Nos. Quantity of electric detonators for secondary blasting ( LS ) : 10 Nos. Detonating fuse coil : 175 Rm Time for drilling jumbo for loading explosives. ( 1 + 0.5 + 0.5 ) : 2 hours 4. Defuming and scaling loose materials No machinery other than ventilation fans required. For defuming tunnel ventilation fans are installed in duct system at about 300 m interval and are run for about 1 hour after each blast.

26

TUNNEL AND ALLIED WORKS

For 1 km length of tunnel ventilation fans are required at 4 places at 300 m interval. As the fans are installed progressively, for rate analysis consider average 2 fans for 1 hour for 2 blasts. 5. Mucking excavated rock : Quantity of muck per blast considering 40 % bulkage for heading zone : 35 cum Quantity of muck per blast considering 40 % bulkage for benching zone : 35 cum Capacityof dumper per load : 5 cum Quantity of muck per load considered under tunnel working conditions : 4.5 cum Loading cycle time: Moving from pocket position and spotting : 1 minutes Loading muck by convey mucker and work force : 20 minutes Time for loaded dumper to pass waiting point say : 1 minutes Cycle time of loading dumper per load of 4.5 cum : 22 minutes Haulage cycle time: Running time from loading point to dump yard at av. 10 km / hr : : 6 minutes Turning and unloading : 2 minutes Return trip to waiting point @ av. 15 km / hr : 4 minutes Waiting time before spotting : 9 minutes Cycle time for haulage per load of 4.5 cum : 21 minutes Round trip cycle time of dumper say : 45 minutes Quantity of muck disposal per hour / dumper : 6 cum Time for 2 dumpers for conveying muck @ 12 cum per hour say : 6.0 hours As some muck from heading portion needs to be pushed down 1 hour extra time assumed. Time for 2 dumpers for conveying muck @ 12 cum per hour say : 7 hours Time for convey mucker and labour force for loading : 7 hours 6. Overall cycle time : Checking alignment and marking hole locations : 1.00 hours Drilling holes : 8.00 hours Loading explosive : 2.00 hours Blasting / Defuming / Scaling loose rock fragments : 3.00 hours Mucking excavated rock : 7.00 hours Bed cleaning, Jumbo movements, rock bolting, lighting etc say : 5.00 hours Erection of permanent supports : 6.00 hours Total cycle of excavation & supporting / blast of 1.5 m length : 32.00 hours

7. Requirement of materials : Explosive small dia ( 40 + 4 ) Electric short delay detonators ( 35 + 8 + 41 ) Electric detonators for secondary blasting ( 1 x 10 ) Fuse coil 8. Requirement of machinery : Deploy drilling jumbo for various operations of excavation ( marking 1 hr + drilling 8 hrs + loading explosive 2 hrs + misc 1 hr ) Deploy air compressor 15 cmm for air supply to 4 jack hammers Deploy 4 jack hammers with pusher leg for drilling. Deploy 10 hp pump for water supply to drilling work. Deploy 20 hp ventilation fan for defuming Deploy convey mucker for loading excavated rock Deploy 2 dumpers for conveying muck 9. Requirement of workforce ( other than machinery crew ) : Surveyor for checking alignment and marking hole locations for drilling Foreman for supervising drilling of holes and other operations

: : : :

44 kg 84 Nos 10 Nos 175 Rm 12 hours

: : : : : :

8 hours 8 hours 8 hours 2 hour 7 hours 7 hours

: 1 No. : 1 No.

27

TUNNEL AND ALLIED WORKS

Fitter / Mechanic for extending air / water lines Blaster ( Licensed ) Helper blasting Hammerman for scaling Maistry 1 in each shift Khalasi for pushing muck from header portion for mucking shift Heavy mazdoor for mucking shift for other 2 shifts 2 No each shift Light mazdoor for cleaning & miscellaneous 10. Use rate of materials: Cost of drill rod 2.5 m long @ Rs: Life of drill rod with reconditioning Use rate of drill rod per Rm drilling Length of air and water hose assumed Cost of 25 mm dia air hose 25 m @ Rs: Life of air hose Use rate of air hose per hour Cost of water hose 25 m each @ Rs: Life of water hose Use rate of water hose per hour RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars

: : : : :

2 Nos. 2 Nos. 4 Nos. 2 Nos. 3 Nos.

: 4 Nos. : 4 Nos. : 8 Nos. : 4 Nos. : 3 Nos. 5660.00 / No. ( cost / life ) 150.00 / Rm ( cost / life ) 128.00 / Rm ( cost / life ) UNIT : Unit kg Quantity 44.00 Rs: : Rs: : Rs: : Rs: Rs: : Rs: 5660.00 150 m 37.73 25 m each 3750.00 800 hours 4.69 3200.00 800 hours 4.00

50.00 cum Rate in Rs. 45.00 Contd Amount in Rs. 1980.00

Small dia explosive

A. MATERIALS ( Contd ) : Sl No Perticulars

Unit

Quantity

2 3 4 5 6 7 8

Delay detonators Electric detonator Detonating fuse coil Use rate of drill rod 2.5 m long Reconditioning charges @ 10% Use rate of air hose Use rate of water hose Sundries ( paint / template etc ) Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

Nos Nos Rm Rm Hour Hour LS

84.00 10.00 175.00 157.00 32.00 32.00 10.00

Rate in Rs. Contd 18.00 10.00 8.00 37.73 4.69 4.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 1512.00 100.00 1400.00 5924.13 592.41 150.00 128.00 300.00 12086.55 120.87 1208.65 604.33 14020.39

1% 10% 5% Total cost of Materials :

B. MACHINERY:

28

TUNNEL AND ALLIED WORKS

Sl No 1 2 3 4 5 6 7 8 9

Description Drilling jumbo Fuel / Energy charges Air compressor 15 cmm ( ele ) Fuel / Energy charges Jack hammer ( 4 x 8 hrs ) Fuel / Energy charges Pusher leg Fuel / Energy charges Convey mucker Fuel / Energy charges Dumper ( 2 x 6.5 hrs ) Fuel / Energy charges Pump 10 hp ( ele ) Fuel / Energy charges Ventilation fans 20 hp ( 2 x 1 hr x 2 ) Fuel / Energy charges Sundries (explosive van / magazine )

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour LS

Quantity 12.00 12.00 8.00 8.00 32.00 32.00 32.00 32.00 7.00 7.00 14.00 14.00 8.00 8.00 4.00 4.00 10.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2

Rate in Rs. 322.00 30.00 108.00 627.00 14.00 5.00 8.00 3.00 658.00 174.00 480.00 277.00 5.00 50.00 6.00 100.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 3864.00 360.00 864.00 5016.00 448.00 160.00 256.00 96.00 4606.00 1218.00 6720.00 3878.00 40.00 400.00 24.00 400.00 300.00 28650.00 286.50 1182.80 1432.50 31551.80

Description

Unit Hour Hour

Quantity 12.00 8.00

Crew for Drilling jumbo Crew for Air compressor

Rate in Rs. 60.50 60.10 Contd

Amount in Rs. 726.00 480.80

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

3 4 5 6 7 8 9 10 11 12 13 14 15

16

Crew for Jack hammer Crew for Convey mucker Crew for Dumper Crew for Pump Crew for Ventilation fan Surveyor Foreman Fitter / Mechanic Blaster ( Licensed ) Helper blasting Hammerman 2 Nos Maistry 1 in each shift Khalasi for pushing muck in heading portion for mucking shift 4 Nos Heavy mazdoor

Hour Hour Hour Hour Hour Day Day Day Day Day Day Day Day Day

32.00 7.00 14.00 8.00 4.00 1.00 1.00 2.00 2.00 4.00 2.00 3.00 4.00 4.00

Rate in Rs. Contd 111.90 60.10 72.60 26.90 9.30 154.50 177.00 157.50 147.00 141.50 146.00 141.50 145.50 145.50

Amount in Rs. 3580.80 420.70 1016.40 215.20 37.20 154.50 177.00 315.00 294.00 566.00 292.00 424.50 582.00 582.00

29

TUNNEL AND ALLIED WORKS

17

for mucking shift 8 Nos for other 2 shifts 2 No each shift Light mazdoor for cleaning & miscellaneous Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Day Day Day

8.00 4.00 3.00

132.00 132.00 130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

1056.00 528.00 391.50 11839.60 118.40 1183.96 1775.94 1183.96 591.98 16693.84

1% 10% 15% 10% 5% Total cost of Labour :

Rs: Rs: Rs: TOTAL Rs: Add for Air and Water line @ 0.50% Rs: Add for Ventilation @ 6.10% Rs: Add for Lighting @ 1.90% Rs: Add for Ele sub-station / Demand charges @ 4.20% Rs: Add for other Enabling works @ 1.70% Rs: Total cost for 50.00 cum Rs: Rate per cum Rs: Rate approved per cum Rs:

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour

14020.39 31551.80 16693.84 62266.03 311.33 3798.23 1183.05 2615.17 1058.52 71232.34 1425.00 1425.00

NOTE:Where mucking is to be carried out through vertical inclined shaft using winch and mucking tub syatem increase basic rates for items 3, 4 and 5 by 12 percent.

SECTION: TUNNEL AND ALLIED WORKS.

YEAR: 2010-11

ITEM No: 6

ITEM: Removing and hauling muck overfallen due to natural causes such as geological faults etc., out of tunnel including breaking large fragments by blasting if necessary and disposing off the same in specified dump area or as directed including cost of all materials, machinery, labour, ventilation, drainage, lighting and all other ancillary operations etc., complete with initial lead upto 1 km and all lifts. DATA: Length of tunnel assumed Distance of dump yard from face Haulage of excavated muck Consider 100 cum overfallen muck for rate analysis. Quantity of overfallen muck requiring blasting assumed @ 20 % Depth of drilling @ 0.75 m per cum Rate of drilling for shallow holes in overfallen muck Time for 4 jack hammers for drilling 15 m Time for 15 cmm air compressor for supplying air to jack hammers Deploy convey mucker for loading @ 16 cum / hour Deploy 5 cum dumpers 2 Nos @ 8 cum / hour each 1. Requirement of materials : : 1000 m : 1 km : By dumper : : : : : : : 20 cum 15 m 4 m / hour 1 hour 1 hour 6 hours 6 hours

30

TUNNEL AND ALLIED WORKS

Quantity of explosive @ 0.40 kg / cum ( 20 x 0.4 ) Quantity of electric detonators assuming 0.6 m holes ( 20 x 0.6 ) Quantity of detonating fuse coil 2. Requirement of machinery : Deploy air compressor 15 cmm for air supply to 4 jack hammers Deploy 4 jack hammers with pusher leg for drilling. Deploy 10 hp pump for water supply to drilling work. Deploy 20 hp ventilation fan for defuming Deploy convey mucker for loading excavated rock Deploy 2 dumper for conveying muck 3. Requirement of workforce ( other than machinery crew ) : Blaster ( Licensed ) Helper blasting Maistry Heavy mazdoor Light mazdoor 4. Use rate of materials: Cost of drill rod 1.5 m length @ Rs: 3400.00 / No. Life of drill rod with reconditioning Use rate of drill rod per Rm drilling ( cost / life ) Length of air and water hose assumed Cost of 25 mm dia air hose 25 m @ Rs: 150.00 / Rm Life of air hose Use rate of air hose per hour ( cost / life ) Cost of water hose 25 m each @ Rs: 128.00 / Rm Life of water hose Use rate of water hose per hour ( cost / life )

: 8 kg : 12 Nos : 20 Rm : : : : : : : : : : : Rs: : Rs: : Rs: : Rs: Rs: : Rs: 1 hour 1 hour 1 hour 0.5 hour 6 hours 6 hours 0.5 No. 0.5 No. 1 No. 2 Nos. 2 Nos. 3400.00 150 m 22.67 25 m each 3750.00 800 hours 4.69 3200.00 800 hours 4.00

RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 4 5 6 7 Perticulars Unit Rm kg Nos. Rm Hour Hour LS Quantity

UNIT :

100.00 cum Rate in Rs. 22.67 45.00 10.00 8.00 4.69 4.00 30.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 340.00 34.00 360.00 120.00 160.00 18.75 16.00 180.00 1228.75 12.29 122.88 61.44 1425.35

Use rate of drill rod 1.5 m long Reconditioning charges @ 10% Explosive small dia. Detonator ( ele ) Detonating fuse coil Use rate of air hose Use rate of water hose Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

15.00 8.00 12.00 20.00 4.00 4.00 6.00

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No 1

Description

Unit Hour

Quantity 1.00

Air compressor 15 cmm ( ele )

Rate in Rs. 108.00

Amount in Rs. 108.00

31

TUNNEL AND ALLIED WORKS

2 3 4 5 6 7

Fuel / Energy charges Jack hammer Fuel / Energy charges Pump 10 hp ( ele ) Fuel / Energy charges Ventilation fans 20 hp Fuel / Energy charges Convey mucker Fuel / Energy charges Dumper 4.5 cum Fuel / Energy charges Sundries

Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour LS

1.00 4.00 4.00 1.00 1.00 0.50 0.50 6.00 6.00 12.00 12.00 6.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6

627.00 14.00 5.00 5.00 50.00 6.00 100.00 658.00 174.00 480.00 277.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

627.00 56.00 20.00 5.00 50.00 3.00 50.00 3948.00 1044.00 5760.00 3324.00 180.00 15175.00 151.75 524.50 758.75 16610.00

Description

Unit Hour Hour Hour Hour Hour Hour

Quantity 1.00 4.00 1.00 0.50 6.00 12.00

Crew for Air compressor Crew for Jack hammer Crew for Pump Crew for Ventilation fan Crew for Convey mucker Crew for Dumper

Rate in Rs. 60.10 111.90 26.90 9.30 60.10 72.60 Contd

Amount in Rs. 60.10 447.60 26.90 4.65 360.60 871.20

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

7 8 9 10 11

Maistry Blaster ( Licensed ) Helper blasting Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

Day Day Day Day Day

1.00 0.50 0.50 2.00 2.00

1% 10% 15% 10% 5% Total cost of Labour :

Rate in Rs. Contd 141.50 147.00 141.50 132.00 130.50 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 141.50 73.50 70.75 264.00 261.00 2581.80 25.82 258.18 387.27 258.18 129.09 3640.34

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL Add for Air and Water line @ 0.50%

Rs: Rs: Rs: Rs: Rs:

1425.35 16610.00 3640.34 21675.69 108.38

32

TUNNEL AND ALLIED WORKS

Add for Ventilation @ 6.10% Add for Lighting @ 1.90% Add for Ele sub-station / Demand charges @ 4.20% Add for other enabling works @ 1.70% Total cost for 100.00 cum Rate per cum Rate approved per cum SECTION: TUNNEL AND ALLIED WORKS. YEAR: 2010-11

Rs: Rs: Rs: Rs: Rs: Rs: Rs:

1322.22 411.84 910.38 368.49 24796.99 248.00 248.00 ITEM No: 7

ITEM: Dewatering tunnel by pumping out water collected by natural drainage inside tunnel including providing sump wherever necessary, cost of all materials, machinery, labour, drainage, lighting, ventilation and all other ancillary operations etc., complete. DATA: Consider 20 hp electric pump installed near junction of adit / channel with tunnel. Consider 250 m length of adit and 100 m length of approach cut. 100 mm dia B Class G.I. Delivery pipe 400 m length. Daily average 8 hours pumping. Energy consumption per hour running of pump ( 20 x 0.746 ) : 14.92 kwhr Miscellaneous such as indicator lamps etc : 00.08 kwhr Total / hour : 15.00 kwhr 1. Requirement of materials : No materials required. 2. Requirement of machinery : Deploy 20 hp electric dewatering pump for 1 hour. 3. Requirement of workforce ( other than machinery crew ) : Consider 1 pipe fitter for 4 hours daily and 1 heavy mazdoor for 8 hours daily for maintenance of

pumping including cleaning sump etc. Pipe fitter for maintenance for 1 hour use of pump Heavy mazdoor for assisting pipe fitter 4. Use rate of materials : Cost of 100 mm dia pipe 400 m @ Rs: 250.00 / Rm Add for fixtures @ Less salvage value @ Life of G.I. pipe Use rate of delivery pipe per hour: Add for laying / dismantling pipe line @

: 0.062 day : 0.125 day Rs: 100000.00 Rs: 15000.00 Total Rs: 115000.00 Rs: -11500.00 Total Rs: 103500.00 : 20000 hrs Rs: 5.18 Rs: 1.04 Total Rs: 6.21 15.00 Kwhr Rate in Rs. 6.21 30.00 Total Rs: Rs: Rs: Amount in Rs. 6.21 3.11 7.50 16.82 0.17 1.68

15% 10%

( cost / life ) 20%

RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 Perticulars Unit Hour LS Quantity

UNIT :

Use rate of G.I.pipe 100 mm dia Suction pipe / foot valve etc @ 50% Sundries Add for small Tools and Plants @ Add for Contractor's Profit @

1.00 0.25 1% 10%

33

TUNNEL AND ALLIED WORKS

Add for Contractor's Overheads @

5% Total cost of Materials :

Rs: Rs:

0.84 19.51

B. MACHINERY: Sl No 1 2 3

Description

Unit Hour Hour LS

Quantity 1.00 1.00 0.25

Electric pump 20 hp Fuel / Energy charges Sundries ( Starter / Switches ete )

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3

Rate in Rs. 11.00 100.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 11.00 100.00 7.50 118.50 1.19 10.75 5.93 136.36

Description

Unit Hour Day Day

Quantity 1.00 0.062 0.125 1% 10%

Crew charges for Pump Pipe fitter for maintenance Heavy mazdoor for maintenance Add for small Tools and Plants @ Add for Contractor's Profit @

Rate in Rs. 26.90 152.50 132.00 Total Rs: Rs: Rs: Contd

Amount in Rs. 26.90 9.46 16.50 52.86 0.53 5.29

C. LABOUR ( Contd ) : Sl No Description

Unit

Quantity

Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

15% 10% 5% Total cost of Labour :

Rate in Rs. Contd Rs: Rs: Rs: Rs:

Amount in Rs. 7.93 5.29 2.64 74.53

Rs: Rs: Rs: TOTAL Rs: Add for Air and Water line @ 0.50% Rs: Add for Ventilation @ 0.00% Rs: Add for Lighting @ 1.90% Rs: Add for Ele sub-station / Demand charges @ 4.20% Rs: Add for other Enabling works @ 1.70% Rs: Total cost for 15.00 Kwhr Rs: Rate per Kwhr Rs: Rate approved per kwhr Rs: SECTION: TUNNEL AND ALLIED WORKS. YEAR: 2010-11

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour

19.51 136.36 74.53 230.39 1.15 0.00 4.38 9.68 3.92 249.51 16.50 16.50 ITEM No: 8

34

TUNNEL AND ALLIED WORKS

ITEM: Providing 25 mm thick guniting to sides and arch of tunnel in cement mortar 1 : 3 proportion by weight including cost of all materials, machinery, labour, ventilation, lighting, drainage and all other ancillary operations etc., complete with lead upto 1 km and all lifts. DATA: Thickness of guniting : 25 mm Mortar mix proportion by weight : 1:3 Water to cement ratio by weight : 0.35 Unit weight of mortar 1 : 3 proportion by weight in kg / cum : 2300 Cement per cum of mortar : 530 kg Sand per cum of mortar : 0.96 cum During guniting a portion of the mortar mix is wasted due to rebounding of mainly sand particles. The extend of rebound varies from 20 to 25 percent. In view of very rich mix the extent of rebound is considered at 20 percent for analysis. For 25 mm thick guniting the rate of progress will be 4 to 5 sqm per hour. For analysis rate of progress is considered at 4.5 sqm per hour. For shift of 8 hours the progress will be 36 sqm. Quantity of mortar for 36 sqm with 20 % rebound ( 36x1.2x0.025 ) : 1.08 cum Add for filling crevices / joints in exposed rock etc @ 5% : 0.05 cum Total quantity of mortar for 36 sqm : 1.13 cum Consider 36 sqm guniting for rate analysis. 1. Requirement of materials : Cement with 1 % wastage for 36 sqm ( 1.13 x 530 x 1.01) : 605 kg Sand with 2 % wastage for 36 sqm ( 1.13 x 0.96 x 1.02 ) : 1.10 cum 2. Requirement of machinery : Deploy Guniting equipment with accessories for 8 hours.

Deploy 8.5 cmm air compressor for 8 hours. Deploy Drilling jumbo for 3.5 hours during guniting of arch portion. Deploy 10 hp pump for 1 hour for pumping water to storage tank for mixing and curing. 3. Requirement of workforce ( other than machinery crew ) : Maistry : 1 No. Mason Cl-I : 1 No. Heavy mazdoor : 3 Nos. Light mazdoor : 2 Nos. 4. Re-handling lead for materials: As cement and sand are stored outside tunnel and are to be conveyed to the guniting location inside tunnel re-handling lead of 1 km is considered for cement and sand required for guniting. 5. Use rate of materials : Cost of grout hose 25 m @ Rs: 150.00 / m Rs: 3750.00 Life of grout hose : 800 hours Use rate of grout hose per hour ( cost / life ) Rs: 4.69 Cost of water hose 25 m @ Rs: 128.00 / m Rs: 3200.00 Life of water hose : 800 hours Use rate of water hose per hour ( cost / life ) Rs: 4.00 Cost of guniting nozzle @ Rs: 312.00 / m Rs: 312.00 Life of guniting nozzle : 200 hours Use rate of guniting nozzle per hour ( cost / life ) Rs: 1.56 RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Quantity UNIT : 36.00 sqm Rate in Rs. Amount in Rs.

35

TUNNEL AND ALLIED WORKS

1 2 3 4 5 6

Cement icluding wastage Sand ( screened ) Use rate of grout hose 20 m Use rate of water hose 20 m Use rate of guniting nozzle Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @ Add for royalty charges on sand @

kg cum Hour Hour Hour LS

605.00 1.10 8.00 8.00 8.00 5.00

1% 10% 5% ( Included in material rate ) Total cost of Materials :

4.00 199.00 4.69 4.00 1.56 30.00 Total Rs: Rs: Rs: Rs: Rs: Rs:

2420.00 218.90 37.50 32.00 12.48 150.00 2870.88 28.71 287.09 143.54 0.00 3330.22

B. MACHINERY: Sl No 1 2 3

Description

Unit Hour Hour Hour Hour Hour Hour

Quantity 8.00 8.00 8.00 8.00 1.00 1.00

Guniting equipment Fuel / Energy charges Air compressor 8.5 cmm ( ele ) Fuel / Energy charges Pump 10 hp ( ele ) Fuel / Energy charges

Rate in Rs. 84.00 9.00 108.00 282.00 5.00 50.00 Contd

Amount in Rs. 672.00 72.00 864.00 2256.00 5.00 50.00

B. MACHINERY ( Contd ) : Sl No Description

Unit

Quantity

4 5

Drilling jumbo Fuel / Energy charges Sundries

Hour Hour LS

3.50 3.50 5.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8

Rate in Rs. Contd 322.00 30.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 1127.00 105.00 150.00 5301.00 53.01 263.30 265.05 5882.36

Description

Unit Hour Hour Hour Hour Day Day Day Day

Quantity 8.00 8.00 1.00 3.50 1.00 1.00 3.00 2.00 1% 10%

Crew for Guniting equipment Crew for Air compressor Crew for pump Crew for Drilling jumbo Maistry Mason Cl I Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @

Rate in Rs. 74.40 56.40 26.90 60.50 141.50 159.00 132.00 130.50 Total Rs: Rs: Rs:

Amount in Rs. 595.20 451.20 26.90 211.75 141.50 159.00 396.00 261.00 2242.55 22.43 224.26

36

TUNNEL AND ALLIED WORKS

Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

15% 10% 5% Total cost of Labour :

Rs: Rs: Rs: Rs:

336.38 224.26 112.13 3162.00

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for Air and Water line @ Add for Ventilation @ Add for Lighting @ Add for Ele sub-station / Demand charges @ Add for other enabling works @ Add for 1 km rehandling lead charges : For cement 605 kg @ Rs: For sand 1.10 cum @ Rs: Total cost for 0.50% 0.00% 1.90% 4.20% 1.70%

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs: Rs: Total Rs: Rs: Rs: Rs: Rs: Rs:

3330.22 5882.36 3162.00 12374.58 61.87 0.00 235.12 519.73 210.37 13401.67 78.11 93.39 13573.16 377.00 377.00

129.10 / tonne 84.90 / cum 36.00 sqm Rate per sqm Rate approved per sqm

SECTION: TUNNEL AND ALLIED WORKS.

YEAR: 2010-11

ITEM No: 9

ITEM: Providing and fixing 25 mm diameter steel rock bolts with mechanical / wedge type anchorage including drilling 35 mm dia holes, providing 150 mm long 20 mm thick tapered steel wedge, 10 mm thick plate washers and nuts, tightening bolt by torque wrench, cost of all materials, machinery, labour, ventilation, lighting, drainage and all other ancillary operations etc., complete with lead upto 1 km and all lifts. DATA: Diameter of ribbed steel rock bolt Length of rock bolt including threaded portion Plate washers 200 x 200 x 10 mm thick Wedge 25 mm wide 20 mm thick at one end 150 mm long M S Nuts for bolts Diameter of hole for fixing rock bolt Depth of hole for fixing rock bolt Conside 10 bolts for analysis. Length of rock bolt excluding threaded portion for 10 bolts Consider 20 m length of rock bolting for rate analysis. Quantity of drilling for 10 bolts Rate of drilling for rock bolts including shifting Time for drilling 20 m with 4 jack hammers ( 20 / 4 / 4 ) 1. Requirement of materials : Quantity of 25 mm dia bars for 10 bolts with 2.5 % wastage ( 10 x 2.15 x 3.85 x 1.025 ) Quantity of washer for 10 bolts with 2.5 % wastage ( 10 x 2 x 0.2 x 0.2 x 78.5 x 1.025 ) Quantity of steel for wedge for 10 bolts with 2.5 % wastage : : : : : : : 25 mm 2.15 m 2 Nos. 1 No. 2 Nos. 35 mm 2.00 m

: 20.00 m : 20 m : 4 m / hr say : 1.5 hour

: 85 kg : 64.5 kg

37

TUNNEL AND ALLIED WORKS

Quantity of nuts for 10 bolts

( 10 x 0.15 x 0.025 x 157 x 1.025 ) ( 10 x 2 x 0.2 )

: 6 kg : 4 kg

2. Requirement of machinery : Deploy 1 Air compressor 15 cmm for 1.5 hours with 50 minutes per hour working. Deploy 4 Jack hammers / Stooper drills for 1.5 hours with 50 minutes per hour working. Deploy Drilling jumbo for 4 hours including fixing bolts. Deploy 10 hp pump for 1.5 hour for pumping water to storage tank. 3. Requirement of workforce ( other than machinery crew ) : Gas cutter for preparing washers and wedges Blacksmith for slitting rods and tapering wedges Turner for threading bolts Hammerman Fitter for fixing bolts Khalasis 2 Nos for 0.5 day Heavy mazdoor for assisting in cutting / fabrication / fixing

: : : : : : :

0.5 No. 0.5 No. 1 No. 0.5 No. 0.5 No. 1 No. 2 Nos.

4. Re-handling lead for materials: As rock bolts are stored outside tunnel and are to be conveyed inside tunnel after fabrication at workshop re-handling lead of 1 km is considered.

5. Use rate of materials : Cost of drill rod 2.5 m long @ Rs: Life of drill rod with reconditioning Use rate of drill rod per m drilling Cost of air hose 25 m / jack hammer @ Rs: Life of air hose Use rate of air hose per hour Cost of water hose 25m/jack hammer Rs: Life of water hose Use rate of water hose per hour RATE ANALYSIS A. MATERIALS: Sl No 1 2 3 4 5 6 7 Perticulars

5660.00 / No. ( cost / life ) 150.00 / Rm ( cost / life ) 128.00 / Rm ( cost / life ) UNIT : Unit kg kg kg kg Rm Hour Hour LS Quantity 85.00 64.50 6.00 4.00 20.00 6.00 6.00 5.00

Rs: 5660.00 : 150 m Rs: 37.73 Rs: 3750.00 : 800 hours Rs: 4.69 Rs: 3200.00 : 800 hours Rs: 4.00 20.00 Rm Rate in Rs. 36.20 40.00 40.00 55.00 37.73 4.69 4.00 30.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 3077.00 2580.00 240.00 220.00 754.67 75.47 28.13 24.00 150.00 7149.26 71.49 714.93 357.46 8293.14

Rein.Steel with 2.5 % wastage Steel plate for washers Steel plate for wedges M S Nuts for bolts Use rate of drill rod Reconditioning charges @ 10% Use rate of air hose 4 Nos Use rate of water hose 4 Nos Sundries ( gas for cutting / heating etc ) Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

38

TUNNEL AND ALLIED WORKS

B. MACHINERY: Sl No 1 2 3 4 5 6

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour LS

Quantity 1.50 1.50 1.50 1.50 6.00 6.00 6.00 6.00 4.00 4.00 7.50

Air compressor 15 cmm ( ele ) Fuel / Energy charges Pump 10 hp ( ele ) Fuel / Energy charges Jack hammer Fuel / Energy charges Pusher leg Fuel / Energy charges Drilling jumbo Fuel / Energy charges Sundries ( lathe, blower etc )

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery :

Rate in Rs. 108.00 627.00 5.00 50.00 14.00 5.00 8.00 3.00 322.00 30.00 30.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 162.00 940.50 7.50 75.00 84.00 30.00 48.00 18.00 1288.00 120.00 225.00 2998.00 29.98 140.85 149.90 3318.73

C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11

Description

Unit Hour Hour Hour Hour Day Day Day Day Day Day Day

Quantity 1.50 1.50 6.00 4.00 0.50 0.50 1.00 0.50 1.00 0.50 2.00

Crew for Air compressor Crew for pump Crew for Jack hammer Crew for Drilling jumbo Fitter Gas cutter Turner Blacksmith Khalasi ( 2 x 0.5 ) Hammerman Heavy mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for additional hidden cost on labour @ Add for Contractor's Overheads @

1% 10% 15% 10% 5% Total cost of Labour :

Rate in Rs. 60.10 26.90 111.90 60.50 157.50 157.50 157.50 141.50 145.50 146.00 132.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 90.15 40.35 671.40 242.00 78.75 78.75 157.50 70.75 145.50 73.00 264.00 1912.15 19.12 191.22 286.82 191.22 95.61 2696.13

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour TOTAL Add for Air and Water line @ Add for Ventilation @ Add for Lighting @ 0.50% 0.00% 1.90%

Rs: Rs: Rs: Rs: Rs: Rs: Rs:

8293.14 3318.73 2696.13 14308.00 71.54 0.00 271.85

39

TUNNEL AND ALLIED WORKS

Add for Ele sub-station / Demand charges @ Add for other enabling works @ Add for 1 km rehandling lead charges : For steel 155 kg @ Rs: Total cost for

4.20% 1.70%

Rs: Rs: Total Rs: Rs: Rs: Rs: Rs:

600.94 243.24 15495.57 20.01 15515.58 776.00 776.00 ITEM No: 10

129.10 / tonne 20.00 Rm Rate per Rm Rate approved per Rm YEAR: 2010-11

SECTION: TUNNEL AND ALLIED WORKS.

ITEM: Providing and fixing 25 mm diameter steel rock bolts with resin bond cement capsule anchorage including drilling 35 mm dia holes, inserting grout capsule, driving bolt,fixing 10 mm thick plate washers and nuts and tightening the same by torque wrench after hardening of cement grout, cost of all materials, machinery, labour, ventilation, lighting, drainage and other ancillary operations etc., complete with lead upto 1 km and all lifts. DATA: Diameter of ribbed steel rock bolt Length of rock bolt including threaded portion Plate washers 200 x 200 x 10 mm thick : 25 mm : 2.15 m : 2 Nos.

1.

2.

3.

4.

Resin bond cement grout capsule : 1 No. M S Nuts for bolts : 2 Nos. Diameter of hole for fixing rock bolt : 35 mm Depth of hole for fixing rock bolt : 2.00 m Conside 10 bolts for analysis. Length of rock bolt excluding threaded portion for 10 bolts : 20.00 m Consider 20 m length of rock bolting for rate analysis. Quantity of drilling for 10 bolts : 20 m Rate of drilling for rock bolts including shifting : 4 m / hr Time for drilling 20 m with 4 jack hammers ( 20 / 4 / 4 ) say : 1.5 hour Requirement of materials : Quantity of 25 mm dia bars for 10 bolts with 2.5 % wastage ( 10 x 2.15 x 3.85 x 1.025 ) : 85 kg Quantity of washer for 10 bolts with 2.5 % wastage ( 10 x 2 x 0.2 x 0.2 x 78.5 x 1.025 ) : 64.5 kg Quantity of nuts for 10 bolts ( 10 x 2 x 0.2 ) : 4 kg Quantity of grout capsule for 10 bolts ( 10 x 1 ) : 10 Nos Requirement of machinery : Deploy 1 Air compressor 15 cmm for 1.5 hours with 50 minutes per hour working. Deploy 4 Jack hammers / Stooper drills for 1.5 hours with 50 minutes per hour working. Deploy Drilling jumbo for 4 hours including fixing bolts. Deploy 10 hp pump for 1.5 hour for pumping water to storage tank. Requirement of workforce ( other than machinery crew ) : Gas cutter for preparing washers and wedges : 0.5 No. Turner for threading bolts : 1 No. Hammerman : 0.5 No. Fitter for fixing bolts : 0.5 No. Khalasis 2 Nos for 0.5 day : 1 No. Heavy mazdoor for assisting in cutting / fabrication / fixing : 2 Nos. Re-handling lead for materials: As rock bolts are stored outside tunnel and are to be conveyed inside tunnel after fabrication at

40

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Inspection and Maintenance of Steel Girders-9Documento10 pagineInspection and Maintenance of Steel Girders-9vpmohammedNessuna valutazione finora

- Inspection and Maintenance of Steel Girders-12Documento10 pagineInspection and Maintenance of Steel Girders-12vpmohammedNessuna valutazione finora

- Inspection and Maintenance of Steel Girders-5Documento10 pagineInspection and Maintenance of Steel Girders-5vpmohammedNessuna valutazione finora

- Inspection and Maintenance of Steel Girders-2Documento10 pagineInspection and Maintenance of Steel Girders-2vpmohammedNessuna valutazione finora

- Inspection and Maintenance of Steel Girders-3Documento10 pagineInspection and Maintenance of Steel Girders-3vpmohammed100% (1)

- Inspection and Maintenance of Steel Girders-4Documento10 pagineInspection and Maintenance of Steel Girders-4vpmohammedNessuna valutazione finora

- Inspection and Maintenance of Steel Girders-1Documento10 pagineInspection and Maintenance of Steel Girders-1vpmohammedNessuna valutazione finora

- Long Welded Rails-3Documento21 pagineLong Welded Rails-3vpmohammedNessuna valutazione finora

- Railway Curves 3 1Documento10 pagineRailway Curves 3 1vpmohammedNessuna valutazione finora

- Long Welded Rails-3Documento21 pagineLong Welded Rails-3vpmohammedNessuna valutazione finora

- Long Welded Rails-7Documento17 pagineLong Welded Rails-7vpmohammedNessuna valutazione finora

- Fundamentals of Building Orientation 1-1Documento10 pagineFundamentals of Building Orientation 1-1vpmohammedNessuna valutazione finora

- Long Welded Rails-6Documento21 pagineLong Welded Rails-6vpmohammedNessuna valutazione finora

- Long Welded Rails-2Documento21 pagineLong Welded Rails-2vpmohammedNessuna valutazione finora

- Railway Curves 13Documento15 pagineRailway Curves 13vpmohammedNessuna valutazione finora

- Long Welded Rails 1Documento20 pagineLong Welded Rails 1vpmohammed100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- GlycerinDocumento6 pagineGlycerinSusan Carolina Lozano VergaraNessuna valutazione finora

- 2 in GunDocumento68 pagine2 in GunElmehdi HarchecheNessuna valutazione finora

- PDFDocumento359 paginePDFtrexts808Nessuna valutazione finora

- USArmy ExplosivesDocumento398 pagineUSArmy Explosiveswaynefishing100% (1)

- Best Practice Guide On The Destruction of Conventional AmmunitionDocumento22 pagineBest Practice Guide On The Destruction of Conventional AmmunitionSufiyan KhanNessuna valutazione finora

- Chemical Process IndustryDocumento58 pagineChemical Process IndustryJohn Phol Magadia BelenNessuna valutazione finora

- Technical Advisory For Safe Operation of Lifting EquipmentDocumento22 pagineTechnical Advisory For Safe Operation of Lifting EquipmentErlet ShaqeNessuna valutazione finora

- A Model For Injury From Fragments Generated by The Explosion of MunitionsDocumento24 pagineA Model For Injury From Fragments Generated by The Explosion of MunitionsyararaNessuna valutazione finora

- Design Aspects For Safety IN Electrical System: ' OISD-RP-149 Draft-III For Restricted Circulation OnlyDocumento48 pagineDesign Aspects For Safety IN Electrical System: ' OISD-RP-149 Draft-III For Restricted Circulation OnlyArunava Chakraborty100% (5)

- SDS Bentonite EN EUBA 06-12-2010 PDFDocumento17 pagineSDS Bentonite EN EUBA 06-12-2010 PDFadvantage025Nessuna valutazione finora

- Mod6 D InstDocumento41 pagineMod6 D InstClarence PieterszNessuna valutazione finora

- Row08s Eghs enDocumento13 pagineRow08s Eghs enNduong NguyenNessuna valutazione finora

- Bomb Threat AwarenessDocumento35 pagineBomb Threat AwarenessXel Deleon100% (2)

- L P 504eDocumento21 pagineL P 504erobert_in_arNessuna valutazione finora

- Kalmatron KF-B Safety Data Sheet: Section 1: IdentificationDocumento5 pagineKalmatron KF-B Safety Data Sheet: Section 1: IdentificationHelen A. RusinoffNessuna valutazione finora

- 60VUPCH1Documento1 pagina60VUPCH1lucamorlandoNessuna valutazione finora

- User's Manual Eletric InitiationDocumento36 pagineUser's Manual Eletric InitiationMinRicardoNessuna valutazione finora

- Location Risk Assessment Form-Part A: Basic Information &: Hazard ListDocumento4 pagineLocation Risk Assessment Form-Part A: Basic Information &: Hazard Listapi-330575448Nessuna valutazione finora

- BS 5345 P1 PDFDocumento48 pagineBS 5345 P1 PDFAnamulKabir100% (3)

- ECSS-E-33-11A - Explosive Systems and DevicesDocumento64 pagineECSS-E-33-11A - Explosive Systems and DevicessebamonsuNessuna valutazione finora

- Advanced Thermobaric Explosive CompositionsDocumento6 pagineAdvanced Thermobaric Explosive CompositionsjuanNessuna valutazione finora

- Rock ExcavationDocumento14 pagineRock ExcavationRamanarayanSankritiNessuna valutazione finora

- Backdraft VsDocumento4 pagineBackdraft Vsiongeorge90Nessuna valutazione finora

- Alchemist PDFDocumento12 pagineAlchemist PDFCallum CurninNessuna valutazione finora

- Phoenix 9.7 ReferenceDocumento268 paginePhoenix 9.7 ReferenceMarko OreškovičNessuna valutazione finora

- Djordjevic - Two Component of Blast FragmentationDocumento5 pagineDjordjevic - Two Component of Blast FragmentationIbnu Al Farobi100% (1)

- What Size Air/water Deck?Documento12 pagineWhat Size Air/water Deck?Herry Prima SaputraNessuna valutazione finora

- Contaminated Land Investigation Assessment RemediationDocumento74 pagineContaminated Land Investigation Assessment RemediationJames Collins100% (1)

- Criteria of Design Improvement of Shaped ChargesDocumento253 pagineCriteria of Design Improvement of Shaped Chargesyips0001100% (1)