Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Power Application - 002 Physical Properties of Hydraulic Fluids

Caricato da

Hakimi BobCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluid Power Application - 002 Physical Properties of Hydraulic Fluids

Caricato da

Hakimi BobCopyright:

Formati disponibili

UNiSEL (KMD 2223)

Fluid Power Application

(Physical Properties of Hydraulic Fluids)

Hydraulics & Pneumatics KMD 3133

By,

Mohd Darnalis A.Rahman

dARNALis

Learning Objectives

Upon completing this chapter, students should be able to:

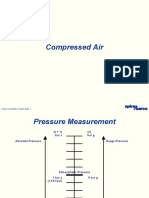

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Explain the primary function of hydraulic fluid. Define the term fluid. Distinguish between a liquid and a gas. Appreciate the properties desired of a hydraulic fluid. Define the terms weight, density and specific gravity. Understand the terms pressure, head, and force. Differentiate between gage pressure & absolute pressures. Calculate the force created by a pressure. Apply Pascal Pascals law to a hydraulic system. Understand the terms kinematic viscosity and absolute viscosity. viscosity. 11. Convert viscosity from one set of units to another set of units. 12. Explain the difference between viscosity and viscosity index.

dARNALis 2

Hydraulics Fluid - Introduction

Understanding hydraulic fluid characteristics have a crucial effect on equipment application, performance and life. � Important to use clean, clean, highhigh-quality fluid in order to achieve efficient hydraulic system operation. � Modern Hydraulic Fluids are complex compounds that have been carefully prepared. � In addition to having a base fluid, special additives helps to provide desired characteristics.

�

dARNALis 3

darnalis '10

UNiSEL (KMD 2223)

Hydraulics Fluid - Introduction

�

Essentially, hydraulic fluid has (4)four primary functions:

1. Transmitting power. 2. Lubricating moving parts. 3. Seal clearances between mating parts. 4. Dissipating heat.

dARNALis

Hydraulics Fluid - Introduction

�

Justifying the primary functions and make it practical from a safety & cost point of view, a hydraulic fluid should have the following properties:

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Good Lubricity Ideal viscosity Chemical & environmental stability Compatibility with system materials High degree of incompressibility Fire resistance Good heatheat-transfer capability Low density Foam resistance NonNon-toxicity Low volatility Inexpensive Ready available

dARNALis 5

Hydraulics Fluid - Introduction

� � �

In reality - no single hydraulic fluid possesses all of the mentioned desirable characteristics. Fluid power designers must select fluid that comes the closest to being ideal overall for a particular application. Must be change periodically

1. 2.

Quality indicator

1. 2. 3. �

Depends on operating conditions. When viscosity & acidity increase due to fluid breakdown or contamination. Viscosity. Water content. Foreign particle contamination level.

This chapter will be examining, The physical properties of fluids dealing with the mechanics of fluid flow.

Density, Pressure, compressibility, viscosity, and viscosity index (VI).

dARNALis 6

darnalis '10

UNiSEL (KMD 2223)

Fluids Liquids

� �

Fluid refers to both gases and liquids Liquids for a given mass, will have a definite volume independent of the shape of the container. container. It will assume the shape of the container. container.

Figure 2-2 Page 36

dARNALis

Fluids Liquids

�

Considered to be incompressible (volume doesn doesnt change with pressure changes) Somehow, the change in volume due to pressure change is so small that it can be ignored for most engineering applications. Assumption of incompressibility will be discussed later.

dARNALis

Fluids Gases

�

Gases fluids that are readily compressible. Volume will vary to fill the vessel containing them.

Figure 2-3 Page 36

dARNALis

darnalis '10

UNiSEL (KMD 2223)

Fluids Gases

�

� � �

Unlike liquids, it have a definite volume for a given mass, the volume of a gas will increase to fill the vessel that contains it. Greatly influenced influenced by pressure which they are subjected. Increase in pressure causes the volume to decrease. Air is the only gas commonly used in fluid power systems due to inexpensive and readily available.

dARNALis 10

Fluids Gases

�

1. 2. 3.

�

Advantages of air as a power fluid;

Fire resistant Not messy Can be exhausted back into the atmosphere.

1.

Disadvantages

2. 3. 4. 5.

Due to compressibility not suitable for accurate positioning & rigid holding application. Due to compressibility tends to be sluggish. sluggish. Air can be corrosive (contains O2 and H20) Lubricant must be added to lubricate valves & actuators Not advisable to use if pressures are greater than 250 psi. psi. (Explosion dangers involved if components such as air tanks should rupture. Air can store large amount of energy as it is compressed)

dARNALis

11

darnalis '10

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Walker, Myles Wilson - How To Indentify High-Profit Elliott Wave Trades in Real Time PDFDocumento203 pagineWalker, Myles Wilson - How To Indentify High-Profit Elliott Wave Trades in Real Time PDFPaul Celen100% (11)

- Supply and DemandDocumento82 pagineSupply and DemandHakimi Bob94% (16)

- Water Management PlanDocumento9 pagineWater Management Plankiller120Nessuna valutazione finora

- CalculationsDocumento3 pagineCalculationsAltif Abood100% (1)

- Vsa Basics PDFDocumento31 pagineVsa Basics PDFdiogonbig100% (1)

- T F T T T: Name: - DateDocumento5 pagineT F T T T: Name: - DateSamantha NortonNessuna valutazione finora

- State of The Art CCS Technologies 2022Documento81 pagineState of The Art CCS Technologies 2022reda100% (1)

- Thales A400M Press Kit 151209Documento4 pagineThales A400M Press Kit 151209Hakimi Bob100% (2)

- Gas AbsorptionDocumento43 pagineGas AbsorptionJoel Ong0% (1)

- Line Sizing Philosophy PDFDocumento21 pagineLine Sizing Philosophy PDFmohammadhadiNessuna valutazione finora

- ISO 9001 CERTIFIED NORMALIZED PUMPS FOR INDUSTRIAL APPLICATIONSDocumento6 pagineISO 9001 CERTIFIED NORMALIZED PUMPS FOR INDUSTRIAL APPLICATIONSBenicio Joaquín Ferrero Brebes100% (1)

- A Detailed Lesson Plan in Science 8Documento11 pagineA Detailed Lesson Plan in Science 8Isabelo De Asis Alferez100% (1)

- Reverse OsmosisDocumento53 pagineReverse Osmosisanabloom100% (2)

- Technical Analysis and Options Strategies Performance BacktestDocumento12 pagineTechnical Analysis and Options Strategies Performance BacktestHakimi Bob100% (1)

- The Dynamics of Financial Markets: Fibonacci Numbers, Elliott Waves, and SolitonsDocumento27 pagineThe Dynamics of Financial Markets: Fibonacci Numbers, Elliott Waves, and SolitonsHakimi BobNessuna valutazione finora

- Currency Pairs and The Best Time To Trade ThemDocumento7 pagineCurrency Pairs and The Best Time To Trade ThemHakimi BobNessuna valutazione finora

- Topic1 Managers in The WorkplaceDocumento36 pagineTopic1 Managers in The WorkplacehunkieNessuna valutazione finora

- DC Motor - AC Motor - Stepper MotorDocumento9 pagineDC Motor - AC Motor - Stepper MotorHakimi BobNessuna valutazione finora

- Chapter 6 - Pneumatic - HydraulicDocumento37 pagineChapter 6 - Pneumatic - HydraulicHakimi BobNessuna valutazione finora

- Lead compensator design reduces settling timeDocumento11 pagineLead compensator design reduces settling timeHakimi BobNessuna valutazione finora

- DC Motor - AC Motor - Stepper MotorDocumento9 pagineDC Motor - AC Motor - Stepper MotorHakimi BobNessuna valutazione finora

- Controle SystemDocumento6 pagineControle SystemSalah UddinNessuna valutazione finora

- Thesis Guideline PDFDocumento85 pagineThesis Guideline PDFHakimi BobNessuna valutazione finora

- EE302 Masons Gain Rule - BlocksDocumento3 pagineEE302 Masons Gain Rule - BlocksanimarumNessuna valutazione finora

- Apa Guide PDFDocumento37 pagineApa Guide PDFLaKiseNessuna valutazione finora

- Technology Profiles-Precise Biometrics-Ensuring Integrity With Fingerprint VerificationDocumento5 pagineTechnology Profiles-Precise Biometrics-Ensuring Integrity With Fingerprint VerificationHakimi BobNessuna valutazione finora

- Root Locus NotesDocumento27 pagineRoot Locus NotesHakimi BobNessuna valutazione finora

- Identifying IVs and DVsDocumento6 pagineIdentifying IVs and DVsHakimi BobNessuna valutazione finora

- CHAPTER 2 A New Product DevelopmentDocumento21 pagineCHAPTER 2 A New Product DevelopmentHakimi BobNessuna valutazione finora

- TABLE 1 Laplace Transform For Both MCS CSDocumento2 pagineTABLE 1 Laplace Transform For Both MCS CSHakimi BobNessuna valutazione finora

- Surveillance of Drinking Water Quality For Safe Water Supply-A Case Study From Shillong, IndiaDocumento22 pagineSurveillance of Drinking Water Quality For Safe Water Supply-A Case Study From Shillong, IndiaHakimi BobNessuna valutazione finora

- Product Use TestingDocumento15 pagineProduct Use TestingHakimi BobNessuna valutazione finora

- SIRIM QAS Intl. Corporate ProfileDocumento32 pagineSIRIM QAS Intl. Corporate ProfileHakimi BobNessuna valutazione finora

- SIRIM QAS Intl. Corporate ProfileDocumento32 pagineSIRIM QAS Intl. Corporate ProfileHakimi BobNessuna valutazione finora

- WHO Declares Ebola Epidemic An International Health Emergency. - by Kate KellandDocumento5 pagineWHO Declares Ebola Epidemic An International Health Emergency. - by Kate KellandHakimi BobNessuna valutazione finora

- AMMONIA & UREA PRODUCTION AND USESDocumento14 pagineAMMONIA & UREA PRODUCTION AND USESHakimi BobNessuna valutazione finora

- New Product DevelopmentDocumento21 pagineNew Product DevelopmentHakimi BobNessuna valutazione finora

- Presentation 1Documento1 paginaPresentation 1Hakimi BobNessuna valutazione finora

- Introduction To Product Testing and SafetyDocumento10 pagineIntroduction To Product Testing and SafetyHakimi BobNessuna valutazione finora

- 2129 Words Essay On Water Crisis in India PDFDocumento6 pagine2129 Words Essay On Water Crisis in India PDFPriyanshu KumarNessuna valutazione finora

- Tutorial 1Documento5 pagineTutorial 1anisNessuna valutazione finora

- 109 Easa Meteorology DemoDocumento6 pagine109 Easa Meteorology DemoRUDRA PRATAP SINGH CHAUHANNessuna valutazione finora

- Compressed Air: Open University' Project Slide 1Documento62 pagineCompressed Air: Open University' Project Slide 1kISHORENessuna valutazione finora

- Purifying Water: Study of MethodsDocumento21 paginePurifying Water: Study of MethodsRohit Thirupasur100% (2)

- Thermosyphon Water PurifierDocumento25 pagineThermosyphon Water PurifierAhmed JishanNessuna valutazione finora

- Subject-Irrigation Engineering: Water-LoggingDocumento22 pagineSubject-Irrigation Engineering: Water-LoggingMorshed Bin Alam FervvezNessuna valutazione finora

- U-Tube ManometerDocumento5 pagineU-Tube ManometerHarold Lee BolingetNessuna valutazione finora

- Wires & Fluxes: W.E.F. 6 APRIL 2022Documento16 pagineWires & Fluxes: W.E.F. 6 APRIL 2022Shivi ChaturvediNessuna valutazione finora

- Pressure in FluidsDocumento23 paginePressure in FluidsANDREW BMGONessuna valutazione finora

- PE326Documento16 paginePE326Ramy MaamounNessuna valutazione finora

- MSFE SOPsDocumento249 pagineMSFE SOPsMohammad Ibnul HossainNessuna valutazione finora

- Hydrology Module 101Documento18 pagineHydrology Module 101juncos0729Nessuna valutazione finora

- Hydrology For DummiesDocumento20 pagineHydrology For DummiesIulian Mihai50% (2)

- Chapter 1. Measures of Atmospheric Composition: 1.1 Mixing RatioDocumento9 pagineChapter 1. Measures of Atmospheric Composition: 1.1 Mixing RatioreneNessuna valutazione finora

- AP Gases WorksheetDocumento4 pagineAP Gases Worksheetburcak gecNessuna valutazione finora

- PART 1 VISCOUS Flow in Pipes 113837Documento23 paginePART 1 VISCOUS Flow in Pipes 113837CedricNessuna valutazione finora

- Fluid Mechanics-II AssignmentDocumento7 pagineFluid Mechanics-II AssignmentMuntaha AnjumNessuna valutazione finora

- What Are Various Environmental Segments?: FourDocumento5 pagineWhat Are Various Environmental Segments?: Fourasim zebNessuna valutazione finora

- What is Percolation and Runoff? Understanding Key Water Cycle ProcessesDocumento43 pagineWhat is Percolation and Runoff? Understanding Key Water Cycle ProcessesglaydelleNessuna valutazione finora

- Zanzibar Oswams WastewaterDocumento31 pagineZanzibar Oswams Wastewatersalum abasiNessuna valutazione finora