Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ms BA600

Caricato da

Oscar SalazarDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ms BA600

Caricato da

Oscar SalazarCopyright:

Formati disponibili

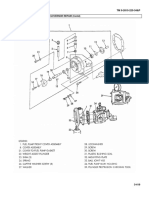

EAGLE Mechanical Seals

BA600

SERIES

EDGE WELDED METAL BELLOWS SEAL

The BA600 Series is a dimensionally interchangeable range

of rotating, edge welded metal bellows seals developed

using the most advanced design and manufacturing

technology available. A wide variety of material options are

available making these seals applicable to general purpose

process pumps in oil refining, chemical, petrochemical, steel

mills, pulp and paper, indeed anywhere there is a need for

secure, economical sealing.

Face Material

BAXX0: CARBON

BAXX1: SiC

Metal Components

BA620: INCONEL 625 Bellows with Alloy 20

BA630: HASTELLOY C

Performance Capabilities

Pressure: Vacuum to 2 MPa (20kgf/cm2G, 285 psi)

Temperature: -75C to 200C(-100F to 400F)

Shaft Speed: to 25 m/s

Viscosity: to 1 Pas(1000cP)

Specific Features of the BA600 Series.

High performance, state of the art edge welded metal

bellows seal. Utilising optimised bellows shape for greatest

flexibility and maximum life.

No dynamic O-rings or other sliding parts to "hang-up" or

damage the shaft or sleeve. No seal "hang-up".

No friction between flexible element and shaft provides

excellent face tracking and low leakage characteristics.

Pressure balanced for low power consumption and low

face wear.

Narrow face design reduces seal interface temperatures

through more efficient cooling.

Ability to handle abrasive media without separators or

clean flushes.

Self-cleaning, non-clogging construction.

Wide application range makes the BA600 series a natural

choice for plant standardisation programmes, allows minimal

inventory to be held and eliminates the need for pump

sleeve replacements.

BA600

SERIES

L 0.3

D -0.05

D1

L1

METRIC SIZES

IMPERIAL SIZES

SIZE

D1

L1

SIZE

020

022

024

025

028

030

032

033

035

038

040

042

043

045

048

050

053

055

060

063

065

070

075

080

085

090

095

100

20

22

24

25

28

30

32

33

35

38

40

42

43

45

48

50

53

55

60

63

65

70

75

80

85

90

95

100

33.3

36.5

39

39

42

44

46

47

49.2

52.4

55.6

58.7

58.7

58.7

61.9

65.1

68.3

69.7

74.6

81

84.1

87.3

95.3

98.4

104.8

108

114.3

120.7

27.5

30

30

30

32.5

32.5

32.5

32.5

32.5

34

34

34

34

34

34

34.5

34.5

34.5

39.5

39.5

39.5

45

45

44.5

44.5

49.5

49.5

49.5

3.3

4.5

4.5

4.5

5.6

5.1

5.1

4.5

4.5

5.2

5.2

5.2

5.2

5.2

5.2

5.2

5.2

4.6

6.6

6.6

6.0

8.2

7.8

6.7

6.7

8.9

8.9

9.0

X12

X14

X15

X16

X18

X20

X22

X24

X26

X28

X30

X32

X34

X36

X38

X40

X42

X44

X46

X48

X50

X52

X54

X56

X58

X60

X62

X64

D

INCH

0.750

0.875

0.938

1.000

1.125

1.250

1.375

1.500

1.625

1.750

1.875

2.000

2.125

2.250

2.375

2.500

2.625

2.750

2.875

3.000

3.125

3.250

3.375

3.500

3.625

3.750

3.875

4.000

METRIC

19.05

22.23

23.81

25.4

28.58

31.75

34.93

38.1

41.28

44.45

47.63

50.8

53.98

57.15

60.33

63.5

66.68

69.85

73.03

76.2

79.38

82.55

85.73

88.9

92.08

95.25

98.43

101.6

D1

L1

33.3

36.5

39

39.7

42.9

46

49.2

52.4

55.6

58.7

61.9

65.1

68.3

71.4

74.6

81

84.1

87.3

92.1

95.3

98.4

101.6

104.8

108

111.1

114.3

117.5

120.7

31.8

31.8

31.8

31.8

31.8

33.3

36.5

36.5

36.5

36.5

38.1

38.1

38.1

39.7

39.7

39.7

41.3

41.3

42.8

42.8

44.5

44.5

44.5

47.6

47.6

47.6

47.6

47.6

4.3

4.3

4.3

4.3

4.3

4.3

5.1

5.1

5.1

5.1

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

5.6

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- EKK ProductsDocumento3 pagineEKK ProductsOscar SalazarNessuna valutazione finora

- EAGLE Mechanical Seals: Stationary Mounted, High Temperature, Edge Welded Metal Bellows SealDocumento2 pagineEAGLE Mechanical Seals: Stationary Mounted, High Temperature, Edge Welded Metal Bellows SealOscar SalazarNessuna valutazione finora

- EAGLE Mechanical Seals: Bi-Directional, Single Coil Spring SealDocumento2 pagineEAGLE Mechanical Seals: Bi-Directional, Single Coil Spring SealOscar SalazarNessuna valutazione finora

- Piping Plan & Numbering of Auxiliary Equipment: Drawings of Piping & Seal Chamber Drawings of Piping & Seal ChamberDocumento2 paginePiping Plan & Numbering of Auxiliary Equipment: Drawings of Piping & Seal Chamber Drawings of Piping & Seal ChamberOscar SalazarNessuna valutazione finora

- Ms MA240Documento2 pagineMs MA240Oscar Salazar100% (1)

- API 682 Qualification Mechanical Seal: Type A Seal Type B Seal Type C SealDocumento1 paginaAPI 682 Qualification Mechanical Seal: Type A Seal Type B Seal Type C SealOscar SalazarNessuna valutazione finora

- EAGLE Mechanical Seals: Rotating Outside Mount SealDocumento2 pagineEAGLE Mechanical Seals: Rotating Outside Mount SealOscar SalazarNessuna valutazione finora

- Ms NF992Documento2 pagineMs NF992Oscar SalazarNessuna valutazione finora

- Ms LB500Documento2 pagineMs LB500Oscar SalazarNessuna valutazione finora

- EAGLE Mechanical Seal LA200 Spec SheetDocumento2 pagineEAGLE Mechanical Seal LA200 Spec SheetOscar SalazarNessuna valutazione finora

- EKK ProductsDocumento3 pagineEKK ProductsOscar SalazarNessuna valutazione finora

- EK777 Mechanical Seal High Performance Stationary MountedDocumento2 pagineEK777 Mechanical Seal High Performance Stationary MountedOscar SalazarNessuna valutazione finora

- Engineering Guide For Bearing SelectionDocumento7 pagineEngineering Guide For Bearing Selectionpetar2001Nessuna valutazione finora

- Lubrication SelectionDocumento11 pagineLubrication Selectionjr110livecomNessuna valutazione finora

- Water Pump BearingsDocumento11 pagineWater Pump BearingsOscar SalazarNessuna valutazione finora

- Wastewater BrochureDocumento8 pagineWastewater BrochureOscar SalazarNessuna valutazione finora

- Bullet Point: Nippon Pillow Block Co., LTDDocumento2 pagineBullet Point: Nippon Pillow Block Co., LTDOscar SalazarNessuna valutazione finora

- Why Buy This Bearing For Another 90 Years 4813 EDocumento0 pagineWhy Buy This Bearing For Another 90 Years 4813 EOscar SalazarNessuna valutazione finora

- Extra ToughDocumento2 pagineExtra ToughOscar SalazarNessuna valutazione finora

- CorrosionDocumento16 pagineCorrosionOscar SalazarNessuna valutazione finora

- 266433Documento3 pagine266433Oscar SalazarNessuna valutazione finora

- SKF Roller Bearing CatalogueDocumento452 pagineSKF Roller Bearing CatalogueDarpanrshah67% (3)

- Products Guide: Europe Middle East Africa AmericasDocumento59 pagineProducts Guide: Europe Middle East Africa AmericasOscar SalazarNessuna valutazione finora

- SKF Shaft SealDocumento379 pagineSKF Shaft Sealsatish_trivediNessuna valutazione finora

- 260661Documento90 pagine260661Oscar SalazarNessuna valutazione finora

- SKF 361202 RDocumento1 paginaSKF 361202 ROscar SalazarNessuna valutazione finora

- 32 SHQ ASG 282 Industrial Solutions Selector Guide 200904 85Documento43 pagine32 SHQ ASG 282 Industrial Solutions Selector Guide 200904 85Oscar SalazarNessuna valutazione finora

- Nema Abcde Torque Curves PDFDocumento2 pagineNema Abcde Torque Curves PDFvtadlimbekarNessuna valutazione finora

- Rolamentos EquivalenciasDocumento102 pagineRolamentos EquivalenciasniceajpaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Metallic BellowsDocumento2 pagineMetallic BellowsDinesh SaravanaNessuna valutazione finora

- Bellows BrochureDocumento22 pagineBellows BrochureAnthony VargasNessuna valutazione finora

- Metallurgy: Two Chambered Forge BellowsDocumento2 pagineMetallurgy: Two Chambered Forge BellowsFIREREALM66Nessuna valutazione finora

- Iwaki BellowsDocumento2 pagineIwaki BellowsZeljko TomicNessuna valutazione finora

- Oil Drum ForgesDocumento42 pagineOil Drum ForgesMegan AndrewsNessuna valutazione finora

- Forgr Bellows Layout and Construction DetailsDocumento7 pagineForgr Bellows Layout and Construction DetailsartaxerxulNessuna valutazione finora

- Atg IoDocumento4 pagineAtg Ioikehd100% (1)

- Aftermarket Replacement Guide 2010Documento251 pagineAftermarket Replacement Guide 2010AnDy RacerNessuna valutazione finora

- Hand Pumps: PRESSURE (Bar) Type FLOW (CC) Weight (KG)Documento25 pagineHand Pumps: PRESSURE (Bar) Type FLOW (CC) Weight (KG)Carlos Eduardo GalvãoNessuna valutazione finora

- Bellows Systems, Inc.: Leading Manufacturer of Metal Bellows and Expansion JointsDocumento4 pagineBellows Systems, Inc.: Leading Manufacturer of Metal Bellows and Expansion JointsRafik CherniNessuna valutazione finora

- Centrifugal Machine Rubber Seal Kits and Spare Parts ListDocumento16 pagineCentrifugal Machine Rubber Seal Kits and Spare Parts ListAs TNessuna valutazione finora

- Safety Valve SelectionDocumento56 pagineSafety Valve Selectionganesh82Nessuna valutazione finora

- 3-61. Fuel Pump Front Cover and Governor Repair (Contd)Documento54 pagine3-61. Fuel Pump Front Cover and Governor Repair (Contd)Влад БеломестновNessuna valutazione finora

- Safety Valve IntroductionDocumento88 pagineSafety Valve Introductionbhuvi_patu12100% (3)

- Manual de Blacksmith PDFDocumento168 pagineManual de Blacksmith PDFVongandalf100% (1)

- Fisher 480 Series Actuator GuideDocumento12 pagineFisher 480 Series Actuator GuideSergio Figueroa MuñozNessuna valutazione finora

- 4196 Series Temperature Indicating Controllers: Bulletin 34.6:4196Documento12 pagine4196 Series Temperature Indicating Controllers: Bulletin 34.6:4196Datt NguyenNessuna valutazione finora

- 02 Air Spring TypesDocumento5 pagine02 Air Spring TypesRaja Sekaran SajjaNessuna valutazione finora

- DSBC - Iso 15552Documento61 pagineDSBC - Iso 15552NixiusNessuna valutazione finora

- Aft CatDocumento251 pagineAft CatAmit BorseNessuna valutazione finora

- Springride Air Bellows PDFDocumento123 pagineSpringride Air Bellows PDFMichael AkhramovichNessuna valutazione finora

- Dismantling Joint: MOC: Cast Steel or Stainless SteelDocumento2 pagineDismantling Joint: MOC: Cast Steel or Stainless SteelTanmoy DuttaNessuna valutazione finora

- Human Development 3rd Edition Arnett Test BankDocumento25 pagineHuman Development 3rd Edition Arnett Test BankWilliamCartersafg0% (1)

- Product Manual 36606 (Revision B) : PGA Governor 8554-255Documento48 pagineProduct Manual 36606 (Revision B) : PGA Governor 8554-255Mayor Paz GonzálezNessuna valutazione finora

- Air Spring Replacement Guide: Aftcat1109Documento251 pagineAir Spring Replacement Guide: Aftcat1109Sébastien DionNessuna valutazione finora

- Pressure Safety Valve FundamentalsDocumento21 paginePressure Safety Valve Fundamentalsaop10468100% (2)

- Woodward Speed Setting MechDocumento6 pagineWoodward Speed Setting Mechmanuel1122Nessuna valutazione finora

- Spirax PSVDocumento62 pagineSpirax PSVvrushi kadamNessuna valutazione finora

- Governer TroubleshootingDocumento44 pagineGoverner TroubleshootingaliNessuna valutazione finora

- DS AnimalFeedMilling ZA 1214 ENGDocumento2 pagineDS AnimalFeedMilling ZA 1214 ENGThoa Tran VanNessuna valutazione finora